Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

s0!00!06 - Structural Demolition General Notes

Caricato da

huyxpkissCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

s0!00!06 - Structural Demolition General Notes

Caricato da

huyxpkissCopyright:

Formati disponibili

ARCH E 36"x48"

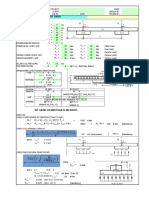

STRUCTURAL CONCRETE PATCHING NOTES

CONCRETE SURFACE PREPARATION AND PATCHING NOTES

STRUCTURAL DEMOLITION NOTES

1. UNLESS NOTED OTHERWISE ALL EXISTING STRUCTURE IS TO REMAIN UNDAMAGED. IF EXISTING STRUCTURE INTENDED TO REMAIN IS DAMAGED OR REMOVED DURING DEMOLITION THAT PORTION OF THE STRUCTURE SHALL BE REPAIRED PER THE NOTES AND TYPICAL DETAILS CONTAINED HEREIN. SEE SDx.xx.xx SERIES SHEETS FOR STRUCTURAL DEMOLITION SCOPE IN EACH PROJECT COMPONENT. CONTRACTOR SHALL NOTE THAT ADDITIONAL STRUCTURAL DEMOLITION MAY BE REQUIRED FOR SCOPE COVERED IN OTHER DESIGN DISCIPLINES SUCH AS CONCRETE SLAB REMOVAL AND REPLACEMENT FOR NEW UNDERGROUND PLUMBING.

A CL EXISTING DECK RIBS AND NEW EXPANSION BOLTS DIMENSION TO BE DETERMINED IN THE FIELD A NEW OPENING

0 0

F

A DECK SPAN

SUMMARY 1. THESE NOTES INCLUDE PROVISIONS FOR ALL LABOR, MATERIALS, SUPERVISION AND INCIDENTALS REQUIRED TO PREPARE AND PATCH CONCRETE SURFACES ASSOCIATED WITH THE STRUCTURAL DEMOLITION. . 2. CONTRACTOR SHALL FULLY ACQUAINT HIMSELF WITH THE EXISTING JOB SITE CONDITIONS AND DISCUSS THE ACCESSIBILITY OF THE WORK AREAS WITH THE OWNER. 3. CONTRACTOR SHALL ENSURE THAT THERE IS ADEQUATE VENTILATION IN AREAS WHERE REPAIR WORK IS BEING PERFORMED AND THAT NO WORK RESULTS IN NAUSEATING, ANNOYING OR TOXIC FUMES AND ODORS FROM ENTERING OCCUPIED AREAS. PROVIDE BARRICADES AROUND THE WORK AREA WITH APPROPRIATE SIGNAGE TO KEEP NONCONSTRUCTION PEOPLE FROM ENTERING WORK AREA 4. REFER TO DEMOLITION NOTES ON S0.00.06 FOR ADDITIONAL INFORMATION.

1" TYPICAL

2.

3.

LEGEND

3" MINIMUM EXISTING LEVEL FINISH FLOOR 3 1/2"

EXISTING FLOOR BEAMS

NEW OPENING

NEW ANGLES

SUBMITTALS 1. ALL SUBMITTALS SHALL BE MADE IN ACCORDANCE WITH DIVISION 01 OF THE SPECIFICATIONS AND THESE NOTES. 2. CONTRACTOR SHALL SUBMIT PROCEDURES TO PROTECT FRESH PATCHES FROM WEATHER AND CONSTRUCTION OR PUBLIC TRAFFIC (IF APPLICABLE). 3. CONTRACTOR SHALL SUBMIT DATA SHEETS FOR ALL SELECTED PRODUCTS REQUIRED TO COMPLETE EACH PATCH. QUALITY ASSURANCE 1. WORK SHALL CONFORM TO REQUIREMENTS OF THE AMERICAN CONCRETE INSTITUTE (ACI) AS APPLICABLE EXCEPT WHERE MORE STRINGENT REQUIREMENTS ARE SHOWN ON DRAWINGS OR SPECIFIED IN THESE NOTES. 2. COMPANIES FURNISHING THE PATCHING MATERIALS SHALL HAVE A PROVEN TRACK RECORD OF AT LEAST FIVE YEARS. FURTHERMORE, THEY SHALL HAVE IN EXISTENCE A PROGRAM OF TRAINING, CERTIFYING, AND SUPPORTING A NATIONALLY ORGANIZED PROGRAM OF APPROVED CONTRACTORS. EVIDENCE OF THIS SHALL BE MADE AVAILABLE TO THE ENGINEER/OWNER UPON REQUEST. 3. CONTRACTOR PERFORMING THE WORK SHALL BE AN APPROVED CONTRACTOR BY THE MANUFACTURER FURNISHING THE REPAIR MATERIALS, AND SHALL HAVE NO LESS THAN FIVE YEARS EXPERIENCE IN THE VARIOUS TYPES OF POLYMER RELATED WORK REQUIRED IN THIS PROJECT. UPON REQUEST BY THE ENGINEER, A NOTARIZED CERTIFICATION FROM THE MANUFACTURER ATTESTING TO THE TRAINING SHALL BE SUBMITTED TO THE ENGINEER/OWNER. PRODUCTS 1. MORTAR USED FOR PATCHING SHALL HAVE THE FOLLOWING PROPERTIES: A. MORTAR SHALL BE NON-SAGGING. B. ACCEPTABLE MATERIALS SHALL HAVE MINIMUM 3-DAY COMPRESSIVE STRENGTH OF 3000 PSI, AND 5000 PSI AS CERTIFIED BY THE MANUFACTURER. C. COEFFICIENT OF THERMAL EXPANSION SHALL BE COMPARABLE WITH THAT OF CONCRETE (5.5 X 10-6 IN.IN/F). D. SAND USED IN PREPARING MORTAR SHALL BE GRADED OVEN DRY QUARTZITE FURNISHED IN BAGS. E. THE MORTAR PATCH MATERIAL SHALL MATCH THE EXISTING TEXTURE AND COLOR OF EXISTING CURED CONCRETE WITHOUT GIVING A BLOTCHY APPEARANCE. A TEST PATCH SHALL BE APPLIED FOR APPROVAL PRIOR TO FINAL ACCEPTANCE OF THE MORTAR. SIZE OF TEST PATCH SHALL BE APPROXIMATELY EQUAL TO THE SIZE OF THE AVERAGE MORTAR PATCH TO BE USED ON THE PROJECT. 2. ACCEPTABLE PRODUCTS AND MANUFACTURERS FOR THE MORTAR PATCHES: A. OVERHEAD/VERTICAL REPAIRS I. GEL PATCH BY BASF II. EMACO 350 CI BY BASF III. VERTICOAT BY EUCLID CHEMICAL COMPANY IV. SIKATOP 123 PLUS BY SIKA B. HORIZONTAL REPAIRS I. EMACO R310 CI BY BASF II. EMACO 300 CI BY BASF III. SIKA 122 PLUS BY SIKA 3. ACCEPTABLE PRODUCTS AND MANUFACTURERS FOR EPOXY FOR BONDING FRESH CONCRETE TO HARDENED CONCRETE (BONDING AGENT): A. CORR-BOND BY EUCLID CHEMICAL COMPANY B. ARMATEC 110 BY SIKA C. EMACO P24 BY BASF 4. ACCEPTABLE PRODUCTS AND MANUFACTURERS FOR THE EPOXY COATING FOR EXISTING EXPOSED NON-PRESTRESSED STEEL REINFORCEMENT: A. ARMATEC 110 BY SIKA B. EMACO P24 BY BASF 5. SUBSTITUTIONS MAY BE CONSIDERED PROVIDED COMPLETE TECHNICAL INFORMATION AND JOB REFERENCES ARE FURNEISHED TO THE OWNER/ENGINEER AND APPROVED PRIOR TO COMMENCEMENT OF THE WORK. 6. CHANGES IN PRODUCTS REQUIRED TO SUIT TEMPERATURE AND ENVIRONMENTAL CONDITIONS AT THE TIME OF THE MATERIAL APPLICATION SHALL BE SPECIFIED AS SEPARATE LINE ITEMS BY THE CONTRACTOR SHOWING CREDIT OR ADDITIONS TO THE PRICE FOR EACH PATCH. 7. IN USING THE ACCEPTABLE PRODUCTS THE CONTRACTOR SHALL STRICTLY FOLLOW THE MANUFACTURERS SPECIFICATIONS AND DIRECTIONS FOR SURFACE PREPARATION, MIXING AND APPLICATION. THE CONTRACTOR SHALL ALSO READ ALL LABEL WARNINGS AND MAKE APPLICATION OF PATCH IN ACCORDANCE WITH APPLICABLE SAFETY LAWS. INSPECTION 1. FOR HORIZONTAL SURFACES CONTRACTOR SHALL SOUND ALL DESIGNATED FLOOR AREAS FOR DELAMINATIONS 2. FOR VERTICAL AND OVERHEAD SURFACES CONTRACTOR SHALL SOUND ONLY DESIGNATED AREAS THAT SHOW EVIDENCE OF CRACKING AND/OR STAINING. CRACKS, USUALLY HORIZONTAL IN ORIENTATION ALONG BEAM FACES, AND VERTICAL IN ORIENTATION NEAR COLUMN CORNERS ARE INDICATORS OF DELAMINATED CONCRETE. 3. ONCE DELAMINATED AREAS ARE LOCATED BY CONTRACTOR, CONTRACTOR SHALL FURTHER SOUND AND MARK THEN TO DEFINE LIMITS 4. CONTRACTOR SHALL LOCATE SPALLS BY VISUAL INSPECTION AND MARK BOUNDARIES. 5. ENGINEER MAY MARK ADDITIONAL UNSOUND CONCRETE FOR REMOVAL. 6. AREAS TO BE REMOVED SHALL BE RECTANGULAR TO PROVIDE ADEQUATE APPEARANCE. 7. CONTRACTOR SHALL LOCATE AND DETERMINE THE DEPTH OF ALL EMBEDDED REINFORCEMENT, ELECTRICAL CONDUIT AND POST-TENSIONED TENDONS IN REPAIR AREA AND MARK LOCATIONS FOR REFERENCE DURING CONCRET REMOVAL. DO NOT CUT ANY EMBEDDED ITEMS UNLESS APPROVED BY THE ENGINEER. LOCATION OF EMBEDDED ITEMS SHALL BE DONE BY VISUAL INSPECTION IF EXPOSED OR BY GROUND PENETRATING RADAR (GPR) OR APPROVED EQUIVALENT NON-DESTRUCTIVE METHOD.

DEMO CONCRETE BUT EXISTING REINFORCING/PT TO REMAIN IN PLACE. DO NOT CUT OR DAMAGE EXISTING REINFORCING/PT.

DEMO CONCRETE AND REINFORCING

4"

EXISTING COMPOSITE FLOOR SLAB NEW L4x3x1/4 WITH 9/16" HOLES NEW 1/2" EXPANSION BOLT (4 REQUIRED FOR EACH ANGLE). FIRST BOLT SHALL BE LOCATED IN NEAREST FULL DECK RIB

EXISTING STRUCTURE TO REMAIN UNDAMAGED

DENOTES AREAS OF EXISTING CONCRETE OR STEEL STRUCTURE TO BE REMOVED. INCLUDES SLAB, JOISTS, BEAMS, WALLS, COLUMNS AND FOUNDATIONS. 4.

PLAN

SECTION A-A

SEE ADx.xx.xx , MDx.xx.xx, EDx.xx.xx AND PDx.xx.xx SERIES SHEETS FOR DEMOLITION ITEMS NOT SHOWN SUCH AS CURBS, HANDRAILS, MASONRY, WINDOWS, MECHANICAL, ELECTRICAL, PLUMBING, ETC. SEE SPECIFICATION 017329 CUTTING AND PATCHING AND SPECIFICATION 024112 FOR BUILDING AND SELECTIVE DEMOTION FOR ADDITIONAL INFORMATION. SEE S0.00.06 AND S0.00.07 FOR STRUCTURAL DEMOLITION TYPICAL DETAILS, SECTIONS AND PARTIAL PLANS. SEE G0.00.04 FOR EXISTING ARENA GRID GEOMETRY PLANS. SEE OTHER ARCHITECTURAL DRAWINGS FOR NEW GRID AND ELEVATION GEOMETRY. FINAL SEQUENCE OF DEMOLITION AND NEW CONSTRUCTION SHALL BE THE RESPONSIBILITY OF THE CONTRACTOR. CONTRACTOR SHALL REVIEW ALL NOTES AND SECTIONS IN EACH COMPONENT FOR CRITICAL SEQUENCE ISSUES RELATED TO DEMOLITION AND NEW CONSTRUCTION OF STRUCTURAL ELEMENTS. MEANS, METHODS, JOB SITE SAFETY, SHORING, TEMPORARY BRACING AND STABILITY IS NOT THE RESPONSIBILITY OF THE OWNER AND THE OWNERS DESIGN TEAM. DIMENSIONS AND ELEVATIONS SHOWN AT EXISTING CONSTRUCTION ARE APPROXIMATE AND SHALL BE FIELD VERIFIED. FIELD VERIFY ALL PERTINENT EXISTING CONDITIONS AND DIMENSIONS PRIOR TO COMMENCEMENT WITH DEMOLITION, FABRICATION OR NEW CONSTRUCTION. NOTIFY ARCHITECT AND ENGINEER IMMEDIATELY IF EXISTING CONDITIONS ARE DIFFERENT THAN INDICATED WITHIN THE CONTRACT DOCUMENTS. CONTRACTOR SHALL FIELD VERIFY ALL EXISTING CONDITIONS AND DIMENSIONS PRIOR TO COMMENCEMENT WITH DEMOLITION. ARCHITECT AND ENGINEER SHALL BE NOTIFIED IMMEDIATELY IF EXISTING CONDITIONS ARE DIFFERENT THAN INDICATED IN THE CONTRACT DOCUMENTS. CONTRACTOR SHALL REVIEW AND DOCUMENT EXISTING STRUCTURAL CONDITIONS PRIOR TO DEMOLITION AND SUBMIT ANY DOCUMENTED DAMAGE OR DISTRESS OF THE EXISTING CONCRETE OR STEEL STRUCTURE TO THE OWNER AND DESIGN TEAM. WHERE REINFORCEMENT EXPOSED DURING DEMOLITION OR SURFACE PREPARATION EXHIBITS SEVERE CORROSION OR HAS LOST MORE THAN 10% OF ITS CROSS SECTIONAL AREA, SUPPLEMENTAL REINFORCEMENT MAY BE REQUIRED. CONTACT ENGINEER FOR REVIEW AND DESIGN OF SUPPLEMENTAL REINFORCEMENT. DEMOLITION METHODS SHALL NOT CAUSE DAMANGE TO ADJACENT BUILDINGS OR PROPERTY. NOTIFY ARCHTECT AND ENGINEER OF ANY CONDITIONS THAT MAY COMPROMISE THE STRENGTH OR STABILITY OF THE EXISTING STRUCTURE. DEMOLITION, CUTTING, CHIPPING, DRILLING, ETC. SHALL BE PERFORMED WITH CARE AND IN A MANNER THAT PERSERVES THE STRUCTURAL INTEGRITY OF THE EXISTING STRUCTURE. DO NOT OVERLOAD EXISTING STRUCTURAL ELEMENTS THAT ARE TO REMAIN. SAFELY SHORE AREAS OF THE ELEVATED STRUCTURE TO BE REMOVED PRIOR TO DEMOLITION. MEANS AND METHODS SHALL BE THE RESPONSIBILTY OF THE CONTRACTOR. SHORING

NOTES: 1. THIS DETAIL APPLIES ONLY WHEN "A" < 2'-0". OMIT NEW ANGLES WHEN "A" IS LESS THAN OR EQUAL TO 10". 2. COORDINATE SIZE AND LOCATION OF NEW OPENINGS WITH ARCHITECTURAL, MECHANICAL, ELECTRICAL, AND PLUMBING DRAWINGS. 3. SAW CUT EXISTING SLAB TO CREATE NEW OPENING. DO NOT CUT SLAB BEYOND CORNERS OF NEW OPENING. 4. INSTALL NEW ANGLES BEFORE CUTTING OPENING. 5. ANGLES SHALL BE FIREPROOFED.

5.

6.

NEW OPENING IN EXISTING COMPOSITE FLOOR SLAB

1" = 1'-0"

05120-FL-OPNG-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2011

7.

8.

9.

10.

11.

12.

CL EXISTING DECK RIBS AND NEW EXPANSION BOLTS

13.

Project Management Initials: Designer: Designer Checked: Checker Approved: Approver

A NEW ANGLES A DECK SPAN A NEW OPENING A

NEW 14 GAGE CLOSURE PLATEFULL SIZE OF OPENING. TACK WELD TO ANGLES

DIMENSION TO BE DETERMINED IN THE FIELD 3" MINIMUM EXISTING OPENING IN FLOOR SLAB "A"

14.

3 1/2"

EXISTING FLOOR BEAMS

EXISTING LEVEL FINISH FLOOR

15. 16.

17.

EXISTING COMPOSITE FLOOR SLAB

4"

18.

NEW L4x3x1/4 WITH 9/16" HOLES NEW 1/2" EXPANSION BOLT (4 REQUIRED FOR EACH ANGLE). FIRST BOLT SHALL BE LOCATED IN NEAREST FULL DECK RIB

19.

AT EDGES OF CONCRETE DEMOLITION ADJACENT TO CONCRETE TO REMAIN, STOP DEMOLITION SHORT SO AS NOT TO DAMAGE, CRACK OR FRACTURE THE CONCRETE TO REMAIN. FOR FINAL MATERIAL REMOVAL USE A METHOD OF REMOVAL THAT LEAVES A SOUND SURFACE. DO NOT CUT, DRILL, CORE OR IN ANY WAY DAMAGE EXISTING REINFORCING STEEL OR POST-TENSIONING TENDONS TO REMAIN. CUT EXISTING REINFORCING STEEL AND POST-TENSIONING TENDONS ONLY WHERE INDICATED.

PLAN NOTES: 1. NUMBER, SIZE AND LOCATION OF EXISTING OPENINGS TO BE DETERMINED BY THE CONTRACTOR IN THE FIELD. 2. WHEN DIMENSION "A" IS EQUAL TO OR LESS THAN 6", USE ONE L4x3 CENTERED UNDER OPENING. 3. USE THIS DETAIL FOR "A" = 2'-0" OR LESS. SEE GENERAL NOTES FOR INFORMATION ABOUT EXISTING CONSTRUCTION. 4. COVER ANGLES WITH A MINIMUM OF 11/2 INCHES OF SPRAYED ON FIREPROOFING.

SECTION A-A

11

CLOSURE OF EXISTING NON-FRAMED FLOOR PENETRATIONS

1" = 1'-0" 10" - 30" WIDE 3" NWC SLAB 2" 20 GAGE COMPOSITE METAL DECK (5" TOTAL THICKNESS)

05120-FL-OPNG-02 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2011

PL 1/4:x6" (GALV.) TYP OR BENT PL 1/4x4x0'-4" (GALV.) EXISTING OPENING IN 5" SLAB B

8" MAX (SQUARE OR ROUND) EXISTING PENETRATION

C

3/8" HILTI KWIK BOLT WITH 1 5/8" EMBED @12" OC AND 2" EACH END, TYP

5/8" PUDDLE WELDS @6" OC TYP EXISTING 3" SLAB

FILL EXISTING PENETRATION WITH HIGH STRENGTH FLOWABLE REPAIR MORTAR PER SPECS. PREPARE SIDE SURFACES AS REQUIRED BY MANUFACTERER

SURFACE PREPARATION 1. CUT IN-PLACE CONSTRUCTION BY SAWING, DRILLING, BREAKING, CHIPPING, GRINDING, AND SIMILAR OPERATIONS USING METHODS LEAST LIKLEY TO DAMAGE ELEMENTS RETAINED OR ADJOINING CONSTRUCTION. 2. IN GENERAL USE HAND OR SMALL POWER TOOLS DESIGNED FOR SAWING AND GRINDING, NOT HAMMERING OR CHOPPING. CUT HOLES AND SLOTS AS SMALL AS POSSIBLE, NEATLY TO SIZE REQUIRED AND WITH MINIMUM DISTURBANCE OF ADJACENT SURFACES. TEMPORARILY COVER OPENINGS WHEN NOT IN USE. 3. DEMOLISHED CONCRETE SURFACES SHALL BE REMOVED PER THESE NOTES A MINIMUM OF 3/4 BEYOND THE DESIRED FINISHED SURFACE, AND ROUGHENED TO AMPLITUDE. ALL DELAMINATED, SPALLED AND UNSOUND CONCRETE SHALL BE REMOVED AS REQUIRED. 4. ALL DELAMINATED, SPALLED AND UNSOUND CONCRETE SHALL BE REMOVED FROM WITHIN THE MARKED BOUNDARY TO A MINIMUM DEPTH OF USING A 15 TO 30 LBS AIR HAMMERS EQUIPPED WITH CHISEL POINT BITS. WHEN DIRECTED BY ENGINEER, CHIPPING HAMMERS LESS THAN 15 LB SHALL BE SUED TO MINIMIZE DAMAGE TO SOUND CONCRETE. 5. LARGE AREAS REQUIRING THE REMOVAL OF A THIN LAYER OF CONCRETE SHALL BE TREATED WITH OTHER METHODS SUCH AS HYDRODEMOLITION. 6. IF DELAMINATED OR UNSOUND CONCRETE EXIST BEYOND THE MINIMUM REMOVAL DEPTH THE ENGINEER SHALL BE NOTIFIED TO REVIEW THE CONDITION. 7. WHERE EMBEDDED REINFORCEMENT OR OTHER STEEL ANCHORAGE IS EXPOSED BY CONCRETE REMOVAL, PROCEED WITH CAUTION TO AVOID DAMAGING IT DURING CONCRETE REMOVAL. IF RUST IS PRESENT ON THE REINFORCEMENT, ADDITIONAL REMOVAL OF CONCRETE ALONG AND BENEATH REINFORCEMENT WILL BE REQUIRED. ADDITIONAL REMOVAL SHALL CONTINUE UNTIL NON-RUSTED REINFORCEMENT IS EXPOSED, OR MAY BE TERMINATED PER ENGINEERS INSTRUCTIONS. 8. EDGES OF PATCH AREAS SHALL BE DRESSED PERPENDICULAR TO MEMBER FACE TO ELIMINATE FEATHER EDGES. ALL EDGES SHALL BE STRAIGHT AND PATCH AREAS SQUARE OR RECTANGULAR SHAPED. 9. ALL EXPOSED REINFORCING STEEL AND STEEL ANCHORAGE SHALL BE CLEANED AND FREE OF RUST AND OTHER CONTAMINANTS. CLEANING SHALL BE ACCOMPLISHED BY ABRASIVE METHODS. CLEANING SHALL BE COMPLETED IMMEDIATELY BEFORE PATCH PLACEMENT TO INSURE THAT BASE METAL IS NOT EXPOSED TO ELEMENTS AND FURTHER RUSTING FOR EXTENDED PERIODS OF TIME. USE POWERED WIRE BRUSHES IN LOCATIONS WHERE REINFORCING STEEL CANNOT BE CLEANED BY ABRASIVE-BLASTING OR WATER-BLASTING. 10. ALL EXPOSED REINFORCING STEEL SHALL BE COATED WITH A CORROSION INHIBITING PRODUCT SPECIFIED IN THE NOTES UNDER PRODUCTS ABOVE. PRIOR TO MORTAR APPLICATION. 11. ALL EMBEDDED REINFORCEMENT EXPOSED DURING SURFACE PREPARATION THAT HAS LOST MORE THAN 10% OF ITS ORIGINAL CROSS-SECTIONAL AREA DUE TO CORROSION SHALL BE CONSIDERED DEFECTIVE. DEFECTIVE REINFORCEMENT SHALL BE SUPPLEMENTED IN ACCORDANCE TO ENGINEERS INSTRUCTIONS AND SHALL BE PAID BY THE OWNER. 12. DAMAGED REINFORCEMENT CAUSED DURING REMOVALS MADE BY CONTRACTOR SHALL BE SUPPLEMENTED IN ACCORDANCE TO ENGINEERS INSTRUCTIONS AND SHALL BE PAID FOR BY CONTRACTOR. 13. MINIMUM OF 1 CONCRETE COVER SHALL BE RPOVIDED OVERA ALL NEW/EXISTING REINFORCMENT EXCEPT WHERE MORE STRINGENT REQUIREMENTS APPLY IN THE DRAWINGS OR DETAILS. 14. FOLLOW ALL OTHER PRODUCT MANUFACTURER INSTRUCTIONS FOR SURFACE PREPARATION INCLUDING, BUT NOT LIMITED TO, SATURATING THE SURFACE WITH MOISTURE TO OBTAIN A SATURATED SURFACE DRY CONDITION IF APPLICABLE. 15. THE SURFACE OF THE PATCH SHALL HAVE A MINIMUM AMBIENT TEMPERATURE OF 45F AND RISING AT THE TIME OF MORTAR APPLICATION. BONDING AGENT APPLICATION 1. APPLY A BONDING AGENT TO ALL CONCRETE SURFACES PREPARED TO RECEIVE AN EPOXY MORTAR PATCH. APPLICATION SHALL BE IN STRICT ACCORDANCE WITH ALL MANUFACTURER INSTRUCTIONS. 2. IF BONDING AGENT DRIES PRIOR TO APPLICATION OF THE MORTAR PATCHING MATERIAL, THE CAVITY SHALL NOT BE PATCHED UNTIL IT HAS BEEN RE-CLEANED AND PREPARED AS INDICATED IN THE SECTION SURFACE PREPARATION ABOVE. BONDING AGENT SHALL NOT BE APPLIED TO MORE PATCH AREAS THAN CAN BE PATCHED WITHIN 15 MINUTES BY AVAILABLE MANPOWER. MORTAR APPLICATION 1. CONDITION POLYMER MORTAR MATERIAL TO 65F-80F UNLESS OTHERWISE RECOMMENDED BY THE MANUFACTURER. MATERIALS BEYOND THIS RANGE OF TEMPERATURE SHALL NOT BE USED. 2. MIX THE TWO COMPONENTS IN A CLEAN CONTAINER FREE OF CONTAMINANTS AS RECOMMENDED BY THE MANUFACTURER. 3. THOROUGHLY BLEND EPOXY COMPONENTS WITH MECHANICAL MIXERS TO A UNIFORM AND HOMOGENOUS MIXTURE. 4. MIXING SHALL BE ACCOMPLISHED WELL WITHIN THE POT LIFE OF THE EPOXY AFTER ALLOWING FOR TIME REQUIRED FOR APPLICATION. 5. APPLY MORTAR BY MEANS SUITABLE FOR THE CONSISTENCY OF THE MORTAR MIX. 6. USE APPROPRIATE FORMS AS REQUIRED FOR RETAINING MORTAR IF MIXED TO A FLOWABLE CONSISTENCY. 7. CONSOLIDATE THE MORTAR THOROUGHLY TO REMOVE ENTRAPPED AIR. 8. FINISH SURFACE OF MORTAR TO MATCH THE TEXTURE AND CONTOURS OF EXISTING CONCRETE. MORTAR PATCH CURING 1. IMMEDIATELY AFTER FINISHING, KEEP PATCH MATERIAL CONTINUALLY MOIST FOR AT LEAST 24 HOURS. CONTINUE CURING FOR FIRST 7 DAYS AFTER PATCH PLACEMENT. DURING INITIAL AND FINAL CURING PERIOEDS MAINTAIN PATCH MATERIAL ABOVE 50F. 2. PREVENT RAPID DRYING AT END OF CURING PERIOD. 3. PROVIDE ADDITIONAL CURING AS REQUIRED BY THE MANUFACTURERS RECOMMENDATIONS. CLEANUP 1. PROTECT SURFACES SURROUNDING THE WORK AREAS AGAINST SPILLAGE. 2. MATERIAL SPIALLAGE SHALL BE CLEANED BEFORE THEY SET AND BECOME DIFFICULT TO REMOVE. 3. CLEANUP ALL PORTIONS OF EXISTING STRUCTURE THAT ARE SOILED OR STAINED IN THE PROCESS OF MORTAR PATCHING WORK. FIELD QUALITY CONTROL 1. THE TESTING AGENCY SHALL BE AN INDEPENDENT TESTING LABORATORY EMPLOYED BY THE OWNER AND ACCEPTABLE TO THE ENGINEER. 2. SAMPLING AND TESTING OF MORTAR SHALL BE PERFORMED BY ACI CERTIFIED CONCRETE FIELD TECHNICIANS GRADE I. CERTIFICATION SHALL BE NO MORE THAN THREE YEARS OLD. 3. TESTING AGENCY IS RESPONSIBLE FOR CONDUCTING, MONITORING, AND REPORTING RESULTS OF ALL TESTS REQUIRED UNDER THIS SECTION. TESTING AGENCY HAS AUTHORITY TO REJECT MORTAR NOT MEETING SPECIFICATIONS. 4. CONCRETE COMPRESSIVE STRENGTH (MOLD TEST CUBES PER ASTM C-109): A. TAKE MINIMUM OF 6 CUBES (2X2) FOR EACH 10 FT3 OR FRACTION OF EACH REPAIR MORTAR PLACED IN ANY ONE DAY. B. ADDITIONAL CUBES SHALL BE TAKEN AS DIRECTED BY ENGINEER, C. COVER AND PROTECT MOLDS FROM CONTACT WITH WATER FOR THE FIRST 24-HRS. AFTER MOLDING. D. FOLLOW ACI SPECIFICATIONS FOR STORAGE AND HANDLING OF SPECIMENS. E. TEST 2 CUBES AT 3 DAYS. F. TEST 2 CUBES AT 7 DAYS. G. TEST 2 CUBES AT 28 DAYS. ACCEPTANCE OF MORTAR PATCHES 1. ACCEPTANCE OF COMPLETED MORTAR PATCHES WILL BE IN ACCORDANCE WITH ACI 301. 2. PATCHED AREAS SHALL BE SOUNDED BY ENGINEER AND CONTRACTOR AFTER CURING FOR 72 HOURS. CONTRACTOR SHALL REPAIR ALL HOLLOWNESS DETECTED BY REMOVING AND REPLACING PATCH OR AFFECTED AREA AT NO COST TO OWNER. 3. IF SHRINKAGE CRACKS APPEAR IN PATCH AREA AFTER THE INITIAL CURING PERIOD IS CONCLUDED, THE PATCH IN QUESTION SHALL BE CONSIDERED UNACCEPTABLE AND IT SHALL BE REMOVED AND REPLACED BY CONTRACTOR AT NO COST TO OWNER. 4. ALL PATCHES THAT DO NOT MEET THE VISUAL AND AESTHETIC REQUIREMENTS SET FORTH FROM THE INITIAL TEST PATCH SHALL BE REMOVED AND REPLACED AT THE DISCRETION OF THE ARCHITECT. COSTS FOR REPLACEMENT OF ALL PATCHES DUE TO UNACCEPTABLE AESTHETICS ARE BY CONTRACTOR AND AT NO COST TO OWNER.

20.

Last Plotted: 5/8/2013 11:02:58 AM

MAX

1'-0"

FINISH LEVEL WITH EXISTING SLAB

PROVIDE PLATE AT SLAB

2"

PROVIDE BENT PLATE AT JOIST OR BEAM

EXISTING OR BEAM JOIST

EXISTING CONC SLAB OR BEAM FORM BOTTOM AS REQUIRED. REMOVE FORMS WHEN MORTAR IS CURED

5" - 19"

SECTION A-A

SECTION B-B

NOTES: 1. FOR EXISTING OPENINGS LARGER THAN SHOWN CONTACT ENGINEER FOR A SPECIAL INFILL DETAIL. 2. FOR EXISTING CONDITIONS OTHER THAN SHOWN CONTACT ARCHITECT AND ENGINEER FOR REVIEW. 3. FOR SLABS REQUIRING A 2 HOUR FIRE RATING THE METAL DECK AND CONNECTIONS SHALL RECEIVE SPRAY-ON FIREPROOFING.

17

B

INFILL OF PENETRATIONS THROUGH EXISTING SLABS AND BEAMS

1" = 1'-0"

Filename: C:\localdata\Kelly-Revit\NOA\NEW ORLEANS ARENA - CENTRAL.rvt

Printed on 30% Post-Consumer Recycled Content Paper

PROJECT

NEW ORLEANS ARENA ENHANCEMENTS 2012 ARENA RENOVATION & EXPANSION LSED # NOA-ENH-2012-AFC35.4M

New Orleans Arena 1501 Girod Street New Orleans, LA 70113

CLIENT

LOUISIANA STADIUM AND EXPOSITION DISTRICT

1500 Girod Street New Orleans, LA 70112

ARCHITECTS

STRUCTURE

AECOM LOUISIANA, A PROFESSIONAL CORPORATION

2380 McGee Suite 200 Kansas City, Missouri 64108 816.561.4443 tel 816.561.2863 fax www.aecom.com

ESKEW+DUMEZ+RIPPLE

365 Canal Street Suite 3150 New Orleans, LA 70130 504.561.8686 tel 504.522.2253 fax www.eskewdumezripple.com

MANNING ARCHITECTS

650 Poydras Street Suite 1250 New Orleans, LA 70130 504.412.2000 tel 504.412.2001 fax www.manningarchitects.com

CONSULTANTS

CIVIL AECOM

232 Third Street, Suite 201 Baton Rogue, LA 70801 225.663.4309 tel www.aecom.com

LANDSCAPE AECOM

1360 Peachtree Street NE Suite 500 Atlanta, GA 30309 404.965.9627 tel www.aecom.com

COST ESTIMATING DAVIS LANGDON An AECOM Company

710 Second Avenue Suite 100 Seattle, WA 98104 206.343.8119 tel 206.343.8541 fax www.davislangdon.com

CODE CONSULTANT FP&C Consultants, Inc.

3770 Broadway Kansas City, MO 64111 816.931.3777 tel 816.931.3378 fax www.fpc-consultants.com

BRANDING/GRAPHICS INFINITE SCALE DESIGN GROUP

16 Exchange Place Salt Lake City, UT 84111 801.363.1881 tel 801.363.1841 fax www.infinitescale.com

FOOD SERVICE CONSULTANT S20 CONSULTANTS, INC.

452 W. James Way Cary, IL 60013 224.717.1999 tel 847.516.5855 fax www.S20Consultants.net

ENGINEERING MAZZETTI NASH LIPSEY BURCH

650 Poydras Street Suite 2242 New Orleans, LA 70130 615.329.4460 tel 615.329.3660 fax www.mazzetti.com

STRUCTURAL WALTER P MOORE

920 Main Street, Tenth Floor Kansas City, MO 64105 816.701.2100 tel 816.701.2200 fax www.walterpmoore.com

SPORTS TECHNOLOGIES WRIGHTSON JOHNSON HADDON & WILLIAMS

4801 Spring Valley Road Suite 113 Dallas, TX 75244 972.934.3700 tel 972.934.3720 fax www.wjhw.com

REGISTRATION

CONFORMED SET

PACKAGE ISSUED DATE: 2013.05.08

ISSUE / REVISION

NO.

DATE

DESCRIPTION

KEY PLAN

PROJECT NORTH

PROJECT NUMBER

60263613

SHEET TITLE

STRUCTURAL DEMOLITION GENERAL NOTES

SHEET NUMBER

S0.00.06

1

Potrebbero piacerti anche

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Pile NotesDocumento16 paginePile NotesSatya kaliprasad vangara100% (1)

- S3-0-0 - Typical Slab On Grade Details PDFDocumento1 paginaS3-0-0 - Typical Slab On Grade Details PDFVictor Miranda AcuñaNessuna valutazione finora

- Blockwork DetailsDocumento5 pagineBlockwork DetailsrthomsanNessuna valutazione finora

- Code Notes FoundationsDocumento8 pagineCode Notes FoundationsleeseeseeNessuna valutazione finora

- Retaining Wall Details Package 11.10Documento9 pagineRetaining Wall Details Package 11.10Mohammed AdelNessuna valutazione finora

- ACI 318-14 RC Shear Wall Design - Short Walls PDFDocumento9 pagineACI 318-14 RC Shear Wall Design - Short Walls PDFHuzil FernandezNessuna valutazione finora

- Steel Connection With Block DetailsDocumento6 pagineSteel Connection With Block DetailsAlaaBadwyNessuna valutazione finora

- Composite Slab DesignDocumento8 pagineComposite Slab DesignOladunni AfolabiNessuna valutazione finora

- Edge Distance - For HolesDocumento2 pagineEdge Distance - For Holessamix999Nessuna valutazione finora

- Concrete Grade Beam Design ExampleDocumento3 pagineConcrete Grade Beam Design ExampleJoe0% (1)

- Case & Uzun: Mount Pisgah Christian School New Upper School BuildingDocumento20 pagineCase & Uzun: Mount Pisgah Christian School New Upper School Buildingervikas34Nessuna valutazione finora

- Apex Masonry Ebook Fence Design Guide CMAA PDFDocumento10 pagineApex Masonry Ebook Fence Design Guide CMAA PDFJohnson SambranoNessuna valutazione finora

- Structural Drawing-Himel Vaiya-01-03-2020Documento11 pagineStructural Drawing-Himel Vaiya-01-03-2020MD Shakil AhmedNessuna valutazione finora

- 2019-08-09 - Structural Design CriteriaDocumento13 pagine2019-08-09 - Structural Design CriteriaGerald Ordoñez Delos ReyesNessuna valutazione finora

- "Roofdeck" - Roof Steel Deck Analysis / Design: Program DescriptionDocumento9 pagine"Roofdeck" - Roof Steel Deck Analysis / Design: Program DescriptionamachmouchiNessuna valutazione finora

- Canam Steel DeckDocumento168 pagineCanam Steel DeckAnonymous 8hx6hKN3Nessuna valutazione finora

- Strap FootingDocumento3 pagineStrap FootingVinayak Potdar100% (1)

- Masonry Retaining WallDocumento3 pagineMasonry Retaining WallreynoldNessuna valutazione finora

- E-2 Sidewalk Ramp With Handrails Section - 201407301802192344Documento1 paginaE-2 Sidewalk Ramp With Handrails Section - 201407301802192344Dhina karan75% (4)

- General NotesDocumento12 pagineGeneral NotesShekh Muhsen Uddin AhmedNessuna valutazione finora

- Slab DesignDocumento96 pagineSlab DesignIMAGENIERIA S.A.C. GUSTAVONessuna valutazione finora

- Define Abbrev: Issue Date: Drawn By: Checked By: Issue Date Author CheckerDocumento2 pagineDefine Abbrev: Issue Date: Drawn By: Checked By: Issue Date Author Checkerdnl_vicarsNessuna valutazione finora

- Open Web Joist SystemDocumento122 pagineOpen Web Joist Systemaminjoles100% (3)

- General Notes 4Documento1 paginaGeneral Notes 4Miljan TrivicNessuna valutazione finora

- Beam DesignDocumento33 pagineBeam DesignstructuresNessuna valutazione finora

- Strap Footing TheoryDocumento4 pagineStrap Footing TheorySwopnilOjhaNessuna valutazione finora

- Snow Drift and Joist DesignDocumento4 pagineSnow Drift and Joist DesigngmkmalNessuna valutazione finora

- Daniel Tian Li: Grade Beam Design Based On ACI 318-02Documento2 pagineDaniel Tian Li: Grade Beam Design Based On ACI 318-02mdalgamouniNessuna valutazione finora

- Cmu Block Wall DetailDocumento2 pagineCmu Block Wall DetailAbdulBari100% (1)

- Residential Site Retaining Walls: Based On The 2006 International Building CodeDocumento5 pagineResidential Site Retaining Walls: Based On The 2006 International Building CodeNeven Ahmed HassanNessuna valutazione finora

- "Anchor Reinforcement (Metric) ." - Anchor Reinforcement AnalysisDocumento8 pagine"Anchor Reinforcement (Metric) ." - Anchor Reinforcement AnalysisazwanNessuna valutazione finora

- 5417.ductile Special Beam Design As Per ACI 318MDocumento4 pagine5417.ductile Special Beam Design As Per ACI 318MNapoleon CarinoNessuna valutazione finora

- Structural General NotesDocumento1 paginaStructural General Notesjuan camiloNessuna valutazione finora

- FewfweefwDocumento1 paginaFewfweefwanthony christian yangNessuna valutazione finora

- Xstructures Xstructures Engineering Engineering Consultants Consultants Engr. Engr. John John Paul Paul Dela Dela Rosa RosaDocumento150 pagineXstructures Xstructures Engineering Engineering Consultants Consultants Engr. Engr. John John Paul Paul Dela Dela Rosa RosaKurtuNessuna valutazione finora

- TG Block Foundation-2Documento26 pagineTG Block Foundation-2Syed Zeeshan HusainNessuna valutazione finora

- Sample Steel Framing ElevationDocumento1 paginaSample Steel Framing ElevationJoseph Cloyd LamberteNessuna valutazione finora

- ACI 318-08 - Slab Punching - Design For Interior ColumnDocumento9 pagineACI 318-08 - Slab Punching - Design For Interior Columnamin alzuraikiNessuna valutazione finora

- Structural Report of Proposed Fencing and ExtensionDocumento21 pagineStructural Report of Proposed Fencing and ExtensionLester LazoNessuna valutazione finora

- Fence Calculation FinalDocumento200 pagineFence Calculation FinalMohamed HassanNessuna valutazione finora

- Cavity WallsDocumento24 pagineCavity WallsRevathi RoopiniNessuna valutazione finora

- 15-320 Struct DWG Full SetDocumento20 pagine15-320 Struct DWG Full SetAnonymous 9MDGo2jNessuna valutazione finora

- Column Design Aci Code PDFDocumento15 pagineColumn Design Aci Code PDFPhil MarceloNessuna valutazione finora

- 5 - Base Connection - Fixed Base Plate ExampleDocumento23 pagine5 - Base Connection - Fixed Base Plate ExampleTuanQuach100% (2)

- Irregular DiaphragmsDocumento8 pagineIrregular DiaphragmsJose L Mexia100% (1)

- Conventional Slab On GradeDocumento14 pagineConventional Slab On Gradejklo12Nessuna valutazione finora

- Choosing Design Methods For Industrial Floor Slabs PDFDocumento4 pagineChoosing Design Methods For Industrial Floor Slabs PDFNatalia Indah Permata Putri100% (1)

- Masonry CMUDocumento23 pagineMasonry CMUManoj JaiswalNessuna valutazione finora

- Slab On Grade Design NotesDocumento54 pagineSlab On Grade Design NotesrealchicNessuna valutazione finora

- Building Rebar InspectionDocumento41 pagineBuilding Rebar Inspectionjackcan501Nessuna valutazione finora

- Twonhouse Cotman Drawings Final 8-20-13recoveryDocumento12 pagineTwonhouse Cotman Drawings Final 8-20-13recoveryapi-241288391Nessuna valutazione finora

- Designing A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Documento15 pagineDesigning A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Jigar100% (1)

- Strutcural Steel General Notes BSDocumento1 paginaStrutcural Steel General Notes BSSumeshNessuna valutazione finora

- POLEDocumento18 paginePOLEJosue HasbunNessuna valutazione finora

- 4 Masonry Retaining Walls PDFDocumento27 pagine4 Masonry Retaining Walls PDFCarlos GilNessuna valutazione finora

- Foundations High MastDocumento6 pagineFoundations High MastPriya Ranjan SinghNessuna valutazione finora

- Engineering 20140829 PDFDocumento41 pagineEngineering 20140829 PDFSarah HillNessuna valutazione finora

- 994 Structural PDF BookletDocumento20 pagine994 Structural PDF BookletRommel Abenoja100% (2)

- BT General NotesDocumento14 pagineBT General NotesRufina Patricia MendozaNessuna valutazione finora

- Tekla - Bridge-Std - Noi Dung Dao TaoDocumento3 pagineTekla - Bridge-Std - Noi Dung Dao TaohuyxpkissNessuna valutazione finora

- BS 8666 - 2005 Rebar - Shape - Code PDFDocumento1 paginaBS 8666 - 2005 Rebar - Shape - Code PDFhuyxpkiss100% (1)

- RevitKeynotes Imperial 2004Documento90 pagineRevitKeynotes Imperial 2004huyxpkiss100% (1)

- Tekla User Assistance - How To Unwrap Pipes Through The Mean-Dimeter - 2016-03-28Documento3 pagineTekla User Assistance - How To Unwrap Pipes Through The Mean-Dimeter - 2016-03-28huyxpkissNessuna valutazione finora

- Tekla User Assistance - Area Selection in Model Is Missing - 2016-03-22Documento2 pagineTekla User Assistance - Area Selection in Model Is Missing - 2016-03-22huyxpkissNessuna valutazione finora

- Tekla Structures 2016 Open API Release NotesDocumento8 pagineTekla Structures 2016 Open API Release NoteshuyxpkissNessuna valutazione finora

- Tekla User Assistance - Adding Images in A Template - 2014-08-26Documento3 pagineTekla User Assistance - Adding Images in A Template - 2014-08-26huyxpkissNessuna valutazione finora

- CaseStudy 3-Bruecken-Projekt US English PrintDocumento2 pagineCaseStudy 3-Bruecken-Projekt US English PrinthuyxpkissNessuna valutazione finora

- Brochure DK 2015 New 1936Documento12 pagineBrochure DK 2015 New 1936huyxpkissNessuna valutazione finora

- Tutorials 3DDocumento162 pagineTutorials 3DhuyxpkissNessuna valutazione finora

- Env 1992-1-5-1996Documento25 pagineEnv 1992-1-5-1996huyxpkissNessuna valutazione finora

- CADWorx PID ProfessionalDocumento2 pagineCADWorx PID ProfessionalhuyxpkissNessuna valutazione finora

- Design Calculation For Prestressed BeamDocumento20 pagineDesign Calculation For Prestressed BeamW SNessuna valutazione finora

- PC Lecture 2 ADVANTAGES LIMITATIONS TYPES OF PRESTRESSINGDocumento15 paginePC Lecture 2 ADVANTAGES LIMITATIONS TYPES OF PRESTRESSINGLenard SantiagoNessuna valutazione finora

- BSD BS 5400Documento51 pagineBSD BS 5400Fredrik AndresenNessuna valutazione finora

- AASHTO M203 1235767gDocumento8 pagineAASHTO M203 1235767gGanesh PersaudNessuna valutazione finora

- Post - Tensioned Concrete SlabsDocumento18 paginePost - Tensioned Concrete SlabsAakash MohanNessuna valutazione finora

- 369 1M-17Documento116 pagine369 1M-17nyssa789050% (4)

- The First Extradosed Bridge in SloveniaDocumento7 pagineThe First Extradosed Bridge in SloveniaZakee MohamedNessuna valutazione finora

- The Filigree Method Chapter 4Documento13 pagineThe Filigree Method Chapter 4lidetechristoszinabuNessuna valutazione finora

- S04 - Basic Parameters and Design of Cast in Situ Box GirderDocumento71 pagineS04 - Basic Parameters and Design of Cast in Situ Box GirderSMR STPNessuna valutazione finora

- PC Spun PilesDocumento2 paginePC Spun PilesBahrul AliemNessuna valutazione finora

- Design of Pedestrian Bridge Ground and Structures Encv4Gs MR .M.JarosDocumento15 pagineDesign of Pedestrian Bridge Ground and Structures Encv4Gs MR .M.JarosnavinNessuna valutazione finora

- PC Strand Certification Manual 2col PDFDocumento27 paginePC Strand Certification Manual 2col PDFsalaverriaNessuna valutazione finora

- Post-Tensioned Box Girder Bridge An Analysis Approach Using EquivDocumento30 paginePost-Tensioned Box Girder Bridge An Analysis Approach Using Equivvrajan1988Nessuna valutazione finora

- Problem of CracksDocumento11 pagineProblem of CracksVipin Kumar ParasharNessuna valutazione finora

- Transverse: Compressive StressesDocumento12 pagineTransverse: Compressive StressesAnnamalai Vaidyanathan100% (1)

- Manual CubusDocumento32 pagineManual Cubusminh thi lương trầnNessuna valutazione finora

- Is 13935 1993Documento26 pagineIs 13935 1993Alam Mohammad Parvez Saifi100% (1)

- Pre-Tensioning or Post-TensioningDocumento5 paginePre-Tensioning or Post-TensioningAnushree guptaNessuna valutazione finora

- Conc Seg Cabstay Euro PDFDocumento107 pagineConc Seg Cabstay Euro PDFNurali MamenNessuna valutazione finora

- Structural Design of Immersed TunnelsDocumento17 pagineStructural Design of Immersed TunnelsTrong TranNessuna valutazione finora

- Freyssinet Prestressing: The System of The Inventor of Prestressed ConcreteDocumento52 pagineFreyssinet Prestressing: The System of The Inventor of Prestressed ConcretemikorizNessuna valutazione finora

- Post Tension Tendon - How To Inspect A Post Tension TendonDocumento4 paginePost Tension Tendon - How To Inspect A Post Tension TendonmoshaNessuna valutazione finora

- Structure SyllabusDocumento25 pagineStructure SyllabuspraveennagarajanNessuna valutazione finora

- Post Details For BridgesDocumento18 paginePost Details For BridgesbiniamNessuna valutazione finora

- Structural Design Sample Exams-95-96-97-98Documento73 pagineStructural Design Sample Exams-95-96-97-98Arnel FreoNessuna valutazione finora

- Sap 2000 BrochureDocumento15 pagineSap 2000 BrochureGörög NorbertNessuna valutazione finora

- A 416 A416-M - 99Documento5 pagineA 416 A416-M - 99Tan Tanju100% (1)

- Analysis and Design of Prestressed Concrete Box Girder BridgeDocumento13 pagineAnalysis and Design of Prestressed Concrete Box Girder BridgeNatarajan Nalanth100% (1)

- Hilti Tech PublicationDocumento178 pagineHilti Tech Publicationmuh2006Nessuna valutazione finora

- Introduction To Prestressing CE 572: Purdue University School of Civil EngineeringDocumento21 pagineIntroduction To Prestressing CE 572: Purdue University School of Civil EngineeringNatarajan SaravananNessuna valutazione finora

- University of Chicago Press Fall 2009 CatalogueDa EverandUniversity of Chicago Press Fall 2009 CatalogueValutazione: 5 su 5 stelle5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDa EverandUniversity of Chicago Press Fall 2009 Distributed TitlesValutazione: 1 su 5 stelle1/5 (1)