Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

6GR WPS PQR

Caricato da

KiukStaksDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

6GR WPS PQR

Caricato da

KiukStaksCopyright:

Formati disponibili

.

.

WELDING WELDING WELDING

wffiffiw

PROCESS

: SMAW

Ms@ir%.-

IVPS : SMAW-9520-06 REV.O

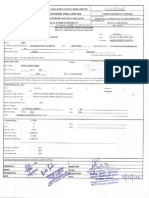

JURONG SHIPYARD PTE LTD Regn No.: 199908265G

WELDING PROCEDURE SPECIFICATION BP ANGOLA PSVM (21-e5201

PQR: 7755-04-04

DATE:31st MARCH 2010

CODE

CLIENT SPEG

AWS D1.1

N/A

MANUAL/AUTO : MANUAL

PROGRESS : ALL POSITIONS POSITION : 6GR

PREPARATION & WELDING SEQUENCE (UNIT IN MM)

"t4=

,rs{}''rr/ t"

METAL SPECIFICATION : : MATERIAL CLASS

BAsE

QUALIFICATION TECHNIQUE

API 5L GR.X 52 N TO API 5L GR.X 52 N AWS GROUP llTO ll

RANGE : 9.1 mm & ABOVE THICKNESS

PIPE DIA LINE-UP CLAMP

CLEANING STRINGER BEAD WEAVE BEAD BACK STRIP BACK GOUGING

HEAT INPUT

: : : : :

GRINDING & BRUSHING YES YES (2Il2 X ELECTRODE DIA)

NO NO

RANGE : MAX 1.9 KJ/mm

: 219 mm : N/A

ELECTRODE NAME

LB-52 U

PASS NO

DIA

CLASS

AWS 5.1

E-7016

GROUP

(mm)

3.2

VOLTS ru)

AMPS (A)

DC/AC

POL

SPEED

(mm/min)

ROOT

20-24 20-24

on-oE

AC

90

120

SIDE A HOT / FILL / CAP LB-52 NS

F4

AWS 5.1

E-701 6G

4.0

120

- 230

100

130

HEAT TREATMENT PRE-HEATING PRE.HEAT ryPE INTER PASS P.W.H.T. HOLDING TIME

TS 65 mm 65'G

T> 65 mm 110'C

HEATING TORCH / HEATING ELEMENTS 250'G MAX N/A N/A

:rr

GAS SHIELDING GAS GAS COMPOSITION FLOW RATE

NA NA NA NA

BACK GAS

u

srG N:

o;\W;ge".,, t$il-ffiFgTlef{,s":!.

,;ffiffi'l: '.

1!:::.:il:z-

6^D

C,lqt<"LJ

DATE:

'N,fwr

hv\atx

r^r-oNk- G-e

03 o6 to

j

r

\)

{t :I::.

II\G

PAGE

SIIIPYARTI LTI)

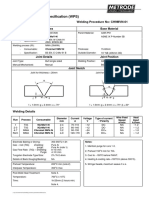

WELDING PROCEDURE SPECIFICATION

SMAW

CODE

1of 24

7755 - 04

WPS

PQR

7755-04-04

2515198

DATE \'/ELDiNG PROCESS MAf {UAI / ALrfO

WELDINGPROGRESS WELDING POSITION

; :

AWS Di.1 - ED. 1998

MANUAL

ALL POSITIONS T-Y-K

CLIENT SPEC

NA

WP6: SHAW.SO81.01

JOII.TT PREPARATION AND WELDING SEQUENCE (LINIT IN \A/T)

PQR:

8MSuRFo2+01

4-8

Note :

Refer to attached sheet 2 of 2 for sample T,Y, K

DIMENSION OF TEST PIECE:

joint details. O.D:219. 1xW.T. : 19.05 mm

API 5L GR.X 52N

AWS GROUP

No. of PASSES

II

TO TO

: :

API 5L GR.X 52N AWS GROUP U GRINDING / BRUSHING

Yes

THICKNESS PIPE DTA LINE-T'P CLAMP

9.5 and

ABOVE /

CLEANING

STRINGERBEAD WEAVE BEAD

219 and

ABOVE

NA

BACK GOUGE BACKING STRIP

Yes ( 2ra No

Electrode dia.)

No

LB.52U

8',l0t6

E 7016G

90-9s 20-24

120

Manual Manual

( KOBELCO ) s - 7016 LS

(

lmNDAr

130

20*24

GAS

PREI]EAT TEMP PREI{EAT TYPE

INTERPASS TEMP

660 C IAWS Table

SHIELD GAS

GAS COMP

Heating Torch / H. Element

2200 Max.

FLOW RATE

PWHT HOLDING TIME

NA NA

BACK GAS

PURGERATE

NA NA NA NA NA

DA'E

, ,AtF*yL:g5MING FY

SECTION

?r" *'n''unJ

l"si'1"i.

li':li4'|'liW0l72{

iiocN cAY

i-u$LNrstvtl

..TU f.'.

.ONG SIIIPYARD LTI)

WELDING PROCEDURE SPECIFICATION

T-Y-K ionqrs ( UNIT rN MM ) AS PERAwS

FIG.B -TESTPOSITION

FLAT

SAINPT,N, JOINT DETAILS FOR

Dl.l

PAGE 2 oI 24 7755 -04 wPS PQR 77ss - 04 - 04 DATE 25lsl98

- ED. 98

FIG. C .TESTPOSITION FLAT (WIDEST ROOT OPENING)

FIG.A -TESTPOSITION

WRTICAL

( GREATEST GROO\rE DEPTH

WrTH

NARROWEST ROOT OPENING )

SMALLEST GROOVEANGLE)

,\ \

ir

650 750

FTG,D -TESTPOSITION OWRHEAD ( NARROWEST ROOT OPENING)

FIG.E -TESTPOSITION

OWRHEAD (WIDEST ROOT OPENING)

BASEMETAL

SPECIFICATION

GR.

LREH 36

MATERIAL CLASS

PASS

AWS GROUP ELECTRODE

il

TO TO

GR.

LREH 36

AWS GROUP II VOLTS

NO

NAME

FIG. A - WRTICA ( KOBELCO ) szu LB s - ?016 LS ( IrY[D{D4J) LB 52U ( KOBELCO ) S - 7016 LS ( HYLTNDAI

AMPS. MMA4IN DC DIA GROU CLASS ( GREATEST GROOW D IPTH / SMALLEST }ROOVE ANGLE ) Manual AC 110 - 120 24-26 2.6 F4 E 7016

F4 130

2.O

AC/

POL.

SPEED

2-

CAP.

E 7016G

- 140 26-28

AC

Manual

FIG.B-FLAT(N

1

870t6

F4

110 130

2 _ CAP.

I

2-CA&.

LB s2U ( KOBELCO ) S - ?016 LS ( HYIINDAI )

F4 E 7016G FIG, C - FLAT ( I4/IDEST ROOT OPENING 12C 1i0 F4 870t6 140 130 3.2 F4 E 7016G

- 120 z4 26 - 140 26-28 24-26 26-28 24-26 26-28

)

AC

AC

Manual Manual

AC AC AC AC AC AC

Marual

Manual Manual Manual Manual

FIC D - OWKHEAD ( NARROWEST P.99!

2.6

110 120

oWNL vG)

F4 8',7016 LB 52U ( KOBELCO ) ?) 120 - 140 F4 2-cAP. s - 7016 LS ( HY{JNDAI ) E 7016G FIG. E. OWRHEAI ( WIDEST ROOT )PBNING) 110 - 120 24-26 3.2 F4 ( 8',70t6 L,B 52U KOBELCO ) 5.2 120 - 140 26-28 F4 2-cAP. s - 7016 LS ( HYUID4J) E 7016G

Manual

QA/QC SECTION

'rl-:_T

N AUTHORITY

,<.j-j:-...., i)3

.:./'. ' ?-r. ! -:__ :

' *Khr DATE ....,u1.ll

n

f,c*

43/l;\r/

ffi

SECTION

t{GNzi

l '^.. :.. ...

t'- .:'

!,

l,

SIGN

SEETOH '

OA/.C

T1\I

:

SJtU&r'

'*[flzY

,

File

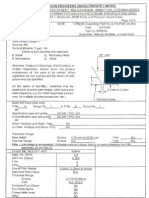

JUBONG SHIPYARD LTD

WELDING PROCEDURE QUALIFICATION RECORI)

SMAW

PAGE PQR WPS DATE : :

:3of 24 : 7755-04-04 i 77ss-04 : 2515198

WELDING PROCESS

CODE

CLIENT SPEC

PQR :

AWS D1.1 - ED. 1998

MANUAL / AUTO

WELDINGPROGRESS

WELDINGPOSITION

MANUAL ALL POSITIONS T.Y-K

NI]\/D

NA

S8i.iSMRP02-081

JOINT PREPARATION AND WELDING SEQUENCE (LIMT IN

WPS: SMAW061-01

o

(-

Note : Refer to attached sheet 2 of 2 for sample T,Y, K joint details' DIMENSION OF TESTPIECE: O.D : 219. I xW.T. : l9,q5 rn4q BASE METAL TO API5L GR.X 52N SPECIFICATION TO AWS GROUP II MATERIAL CLASS

.

No. of PASSES

API5L GR.X 52N

AWS GROUP

II

GRINDING / BRUSHING

Yes Yes (Zrtz ,x Electrode dia.)

OUALIFIED RANGE

THICKNESS

PIPE 9.5 and ABOVE

DIA

219 and ABOVE

LINE-UP CLAMP

PASS

NA

ELECTRODE

CLEANING STRINGERBEAD WEAVE BEAD BACK GOUGE BACKING STRIP DIA

L.O

No

No

NO

NAME LB 52U (KOBELCO )

s - 7016 LS

( }TYUNDAI )

CLASS

GROU

F4

AMPS.

VOLTS

AC/

DC AC AC

POL

SPEED

MMA4IN

Manual Manual

E'7016

E 7016G

90-95 20-24

120

z-5

).2

130

20-24

HEAT TREATMENT

PREHE.AT TEMP

GAS

PREHEATTYPE

INTERPASS TEMP

IAWS Table Heating Torch / H. Element

660

2200 Max.

PWHT HOLDING TIME QA/QC SECTION

NA NA

: GAS COMP : FLOWRATE : BACKGAS :

SHIELD GAS N AUTHORITY

NA NA NA NA PURGERATF: NA

DATE

SIGN

)drh t

tttr...t...'r'tt'"rl

,/@\

srl,l r(ooN cAY

CEM}E

SEETO

QA/ OC SECTION

-P0 1/0

rffi#

I i (ril.+3/SW01724

4l {l

,TUNONG SHIPYARD LTD

WELDING PROCEDURE QUALTFICATION RECORD

PAGE PQR wPS DATE

4 oI

2ar 77Ss - 04 - 04

7155 - 04

2sl5l98

SAMPLE JOINT DE'I'AILS FORT-Y-K JOTNTS ( UNrT rN MM ) AS PER AWS D1.1 - ED. 98 FIG,C -TESTPOSITION FIG.B -TESTPOSITION nrc.j_- rEsT.Posnlau_

VERTICAL

(

FI}IT

( NARROWEST

FUIT

(WIDEST ROOT OPENING)

GREATEST GROOV-E DEPTH WrTH

ROOT OPENING )

SMAILEST GROOVEANGLE)

7x

I

('

FIG.D -TESTPOSITION

(

FIG.E -TESTPOSITION

OWRHEAD (WIDEST ROOT OPENING)

OWRHEAD NARROWEST ROOT OPENING)

BASE METAL SPECIFICATION

GR.

LREH

36

MATERIAL CLASS

PASS

AWS GROUP ELECTRODE

TO TO

AMPS.

GR.

LREH 36

AWS GROTJP II VOLTS

AC/

DC DIA NAME CLASS GROU FIG. A - WRTICAL ( GREATEST GROOW DEPTH / SMALLEST GROOVE ANGLE I 2.6 110- i20 24-26 AC LB 52U ( KOBELCO ) E 7016 F4 2 * CAP. S .7016 LS ( HYLTNDAI ) ).2 F4 130 - 140 26-28 AC E 7016G FIG. B - FLAT ( NARROI4'EST ROOT OPENING ) I 2.6 26 AC F4 110 - 12C 24 LB 52U ( KOBELCO ) 8',7016 ( 2 -CAP. S 7016 LS HYUNDAI ) 3.2 130 - 140 26-28 AC F4 E 7016G FIG. C - FLAT ( WDEST ROOT OPENING ) I r20 24-26 AC )./. t10 LB 52U ( KOBELCO ) 870t6 F4 2 - CAP. S - 7016 LS ( HYIJNDAI ) 3.2 130 - 140 26-28 AC E 7016G F4 FIG. D - OVEREEAD ( NARROWEST ROOT OPEMNG ) ( 2.6 110 - 120 24-26 AC E70T6 F4 LB 52U KOBELCO ) 2 - CAp. S - 7016 LS ( HYUNDAI ) 120 * I40 26-28 AC E'7016G F4 FIG. E- OWRHEAD (WIDEST ROOT OPENING) 1i0 - 120 24-26 AC F4 3.2 LB 52U ( KOBELCO ) E'7016 2-CAP. S - 7Oi6 LS ( HYIINDAI ) 3.2 r20 - t40 26-28 AC E70t6c F4 NO

POL.

SPEED

MM/MIN

)

Manual Manual Manual Manual Manual Manual Manual Manual Manual Manual

OA/QC SECTION

AUTHORITY

DATE

:

:

x4rtqo

,.............v'..'.\1""':f"'::;-""i

SEE.T.OF{

tl"lt-

MING FYE

SECTION

SIGN

QA/OC

File

.

WELDING WELDING WELDING

wffiffiw

PROCESS

: SMAW

Ms@ir%.-

IVPS : SMAW-9520-06 REV.O

JURONG SHIPYARD PTE LTD Regn No.: 199908265G

WELDING PROCEDURE SPECIFICATION BP ANGOLA PSVM (21-e5201

PQR: 7755-04-04

DATE:31st MARCH 2010

CODE

CLIENT SPEG

AWS D1.1

N/A

MANUAL/AUTO : MANUAL

PROGRESS : ALL POSITIONS POSITION : 6GR

PREPARATION & WELDING SEQUENCE (UNIT IN MM)

"t4=

,rs{}''rr/ t"

METAL SPECIFICATION : : MATERIAL CLASS

BAsE

QUALIFICATION TECHNIQUE

API 5L GR.X 52 N TO API 5L GR.X 52 N AWS GROUP llTO ll

RANGE : 9.1 mm & ABOVE THICKNESS

PIPE DIA LINE-UP CLAMP

CLEANING STRINGER BEAD WEAVE BEAD BACK STRIP BACK GOUGING

HEAT INPUT

: : : : :

GRINDING & BRUSHING YES YES (2Il2 X ELECTRODE DIA)

NO NO

RANGE : MAX 1.9 KJ/mm

: 219 mm : N/A

ELECTRODE NAME

LB-52 U

PASS NO

DIA

CLASS

AWS 5.1

E-7016

GROUP

(mm)

3.2

VOLTS ru)

AMPS (A)

DC/AC

POL

SPEED

(mm/min)

ROOT

20-24 20-24

on-oE

AC

90

120

SIDE A HOT / FILL / CAP LB-52 NS

F4

AWS 5.1

E-701 6G

4.0

120

- 230

100

130

HEAT TREATMENT PRE-HEATING PRE.HEAT ryPE INTER PASS P.W.H.T. HOLDING TIME

TS 65 mm 65'G

T> 65 mm 110'C

HEATING TORCH / HEATING ELEMENTS 250'G MAX N/A N/A

:rr

GAS SHIELDING GAS GAS COMPOSITION FLOW RATE

NA NA NA NA

BACK GAS

u

srG N:

o;\W;ge".,, t$il-ffiFgTlef{,s":!.

,;ffiffi'l: '.

1!:::.:il:z-

6^D

C,lqt<"LJ

DATE:

'N,fwr

hv\atx

r^r-oNk- G-e

03 o6 to

j

r

\)

{t :I::.

II\G

PAGE

SIIIPYARTI LTI)

WELDING PROCEDURE SPECIFICATION

SMAW

CODE

1of 24

7755 - 04

WPS

PQR

7755-04-04

2515198

DATE \'/ELDiNG PROCESS MAf {UAI / ALrfO

WELDINGPROGRESS WELDING POSITION

; :

AWS Di.1 - ED. 1998

MANUAL

ALL POSITIONS T-Y-K

CLIENT SPEC

NA

WP6: SHAW.SO81.01

JOII.TT PREPARATION AND WELDING SEQUENCE (LINIT IN \A/T)

PQR:

8MSuRFo2+01

4-8

Note :

Refer to attached sheet 2 of 2 for sample T,Y, K

DIMENSION OF TEST PIECE:

joint details. O.D:219. 1xW.T. : 19.05 mm

API 5L GR.X 52N

AWS GROUP

No. of PASSES

II

TO TO

: :

API 5L GR.X 52N AWS GROUP U GRINDING / BRUSHING

Yes

THICKNESS PIPE DTA LINE-T'P CLAMP

9.5 and

ABOVE /

CLEANING

STRINGERBEAD WEAVE BEAD

219 and

ABOVE

NA

BACK GOUGE BACKING STRIP

Yes ( 2ra No

Electrode dia.)

No

LB.52U

8',l0t6

E 7016G

90-9s 20-24

120

Manual Manual

( KOBELCO ) s - 7016 LS

(

lmNDAr

130

20*24

GAS

PREI]EAT TEMP PREI{EAT TYPE

INTERPASS TEMP

660 C IAWS Table

SHIELD GAS

GAS COMP

Heating Torch / H. Element

2200 Max.

FLOW RATE

PWHT HOLDING TIME

NA NA

BACK GAS

PURGERATE

NA NA NA NA NA

DA'E

, ,AtF*yL:g5MING FY

SECTION

?r" *'n''unJ

l"si'1"i.

li':li4'|'liW0l72{

iiocN cAY

i-u$LNrstvtl

..TU f.'.

.ONG SIIIPYARD LTI)

WELDING PROCEDURE SPECIFICATION

T-Y-K ionqrs ( UNIT rN MM ) AS PERAwS

FIG.B -TESTPOSITION

FLAT

SAINPT,N, JOINT DETAILS FOR

Dl.l

PAGE 2 oI 24 7755 -04 wPS PQR 77ss - 04 - 04 DATE 25lsl98

- ED. 98

FIG. C .TESTPOSITION FLAT (WIDEST ROOT OPENING)

FIG.A -TESTPOSITION

WRTICAL

( GREATEST GROO\rE DEPTH

WrTH

NARROWEST ROOT OPENING )

SMALLEST GROOVEANGLE)

,\ \

ir

650 750

FTG,D -TESTPOSITION OWRHEAD ( NARROWEST ROOT OPENING)

FIG.E -TESTPOSITION

OWRHEAD (WIDEST ROOT OPENING)

BASEMETAL

SPECIFICATION

GR.

LREH 36

MATERIAL CLASS

PASS

AWS GROUP ELECTRODE

il

TO TO

GR.

LREH 36

AWS GROUP II VOLTS

NO

NAME

FIG. A - WRTICA ( KOBELCO ) szu LB s - ?016 LS ( IrY[D{D4J) LB 52U ( KOBELCO ) S - 7016 LS ( HYLTNDAI

AMPS. MMA4IN DC DIA GROU CLASS ( GREATEST GROOW D IPTH / SMALLEST }ROOVE ANGLE ) Manual AC 110 - 120 24-26 2.6 F4 E 7016

F4 130

2.O

AC/

POL.

SPEED

2-

CAP.

E 7016G

- 140 26-28

AC

Manual

FIG.B-FLAT(N

1

870t6

F4

110 130

2 _ CAP.

I

2-CA&.

LB s2U ( KOBELCO ) S - ?016 LS ( HYIINDAI )

F4 E 7016G FIG, C - FLAT ( I4/IDEST ROOT OPENING 12C 1i0 F4 870t6 140 130 3.2 F4 E 7016G

- 120 z4 26 - 140 26-28 24-26 26-28 24-26 26-28

)

AC

AC

Manual Manual

AC AC AC AC AC AC

Marual

Manual Manual Manual Manual

FIC D - OWKHEAD ( NARROWEST P.99!

2.6

110 120

oWNL vG)

F4 8',7016 LB 52U ( KOBELCO ) ?) 120 - 140 F4 2-cAP. s - 7016 LS ( HY{JNDAI ) E 7016G FIG. E. OWRHEAI ( WIDEST ROOT )PBNING) 110 - 120 24-26 3.2 F4 ( 8',70t6 L,B 52U KOBELCO ) 5.2 120 - 140 26-28 F4 2-cAP. s - 7016 LS ( HYUID4J) E 7016G

Manual

QA/QC SECTION

'rl-:_T

N AUTHORITY

,<.j-j:-...., i)3

.:./'. ' ?-r. ! -:__ :

' *Khr DATE ....,u1.ll

n

f,c*

43/l;\r/

ffi

SECTION

t{GNzi

l '^.. :.. ...

t'- .:'

!,

l,

SIGN

SEETOH '

OA/.C

T1\I

:

SJtU&r'

'*[flzY

,

File

JUBONG SHIPYARD LTD

WELDING PROCEDURE QUALIFICATION RECORI)

SMAW

PAGE PQR WPS DATE : :

:3of 24 : 7755-04-04 i 77ss-04 : 2515198

WELDING PROCESS

CODE

CLIENT SPEC

PQR :

AWS D1.1 - ED. 1998

MANUAL / AUTO

WELDINGPROGRESS

WELDINGPOSITION

MANUAL ALL POSITIONS T.Y-K

NI]\/D

NA

S8i.iSMRP02-081

JOINT PREPARATION AND WELDING SEQUENCE (LIMT IN

WPS: SMAW061-01

o

(-

Note : Refer to attached sheet 2 of 2 for sample T,Y, K joint details' DIMENSION OF TESTPIECE: O.D : 219. I xW.T. : l9,q5 rn4q BASE METAL TO API5L GR.X 52N SPECIFICATION TO AWS GROUP II MATERIAL CLASS

.

No. of PASSES

API5L GR.X 52N

AWS GROUP

II

GRINDING / BRUSHING

Yes Yes (Zrtz ,x Electrode dia.)

OUALIFIED RANGE

THICKNESS

PIPE 9.5 and ABOVE

DIA

219 and ABOVE

LINE-UP CLAMP

PASS

NA

ELECTRODE

CLEANING STRINGERBEAD WEAVE BEAD BACK GOUGE BACKING STRIP DIA

L.O

No

No

NO

NAME LB 52U (KOBELCO )

s - 7016 LS

( }TYUNDAI )

CLASS

GROU

F4

AMPS.

VOLTS

AC/

DC AC AC

POL

SPEED

MMA4IN

Manual Manual

E'7016

E 7016G

90-95 20-24

120

z-5

).2

130

20-24

HEAT TREATMENT

PREHE.AT TEMP

GAS

PREHEATTYPE

INTERPASS TEMP

IAWS Table Heating Torch / H. Element

660

2200 Max.

PWHT HOLDING TIME QA/QC SECTION

NA NA

: GAS COMP : FLOWRATE : BACKGAS :

SHIELD GAS N AUTHORITY

NA NA NA NA PURGERATF: NA

DATE

SIGN

)drh t

tttr...t...'r'tt'"rl

,/@\

srl,l r(ooN cAY

CEM}E

SEETO

QA/ OC SECTION

-P0 1/0

rffi#

I i (ril.+3/SW01724

4l {l

,TUNONG SHIPYARD LTD

WELDING PROCEDURE QUALTFICATION RECORD

PAGE PQR wPS DATE

4 oI

2ar 77Ss - 04 - 04

7155 - 04

2sl5l98

SAMPLE JOINT DE'I'AILS FORT-Y-K JOTNTS ( UNrT rN MM ) AS PER AWS D1.1 - ED. 98 FIG,C -TESTPOSITION FIG.B -TESTPOSITION nrc.j_- rEsT.Posnlau_

VERTICAL

(

FI}IT

( NARROWEST

FUIT

(WIDEST ROOT OPENING)

GREATEST GROOV-E DEPTH WrTH

ROOT OPENING )

SMAILEST GROOVEANGLE)

7x

I

('

FIG.D -TESTPOSITION

(

FIG.E -TESTPOSITION

OWRHEAD (WIDEST ROOT OPENING)

OWRHEAD NARROWEST ROOT OPENING)

BASE METAL SPECIFICATION

GR.

LREH

36

MATERIAL CLASS

PASS

AWS GROUP ELECTRODE

TO TO

AMPS.

GR.

LREH 36

AWS GROTJP II VOLTS

AC/

DC DIA NAME CLASS GROU FIG. A - WRTICAL ( GREATEST GROOW DEPTH / SMALLEST GROOVE ANGLE I 2.6 110- i20 24-26 AC LB 52U ( KOBELCO ) E 7016 F4 2 * CAP. S .7016 LS ( HYLTNDAI ) ).2 F4 130 - 140 26-28 AC E 7016G FIG. B - FLAT ( NARROI4'EST ROOT OPENING ) I 2.6 26 AC F4 110 - 12C 24 LB 52U ( KOBELCO ) 8',7016 ( 2 -CAP. S 7016 LS HYUNDAI ) 3.2 130 - 140 26-28 AC F4 E 7016G FIG. C - FLAT ( WDEST ROOT OPENING ) I r20 24-26 AC )./. t10 LB 52U ( KOBELCO ) 870t6 F4 2 - CAP. S - 7016 LS ( HYIJNDAI ) 3.2 130 - 140 26-28 AC E 7016G F4 FIG. D - OVEREEAD ( NARROWEST ROOT OPEMNG ) ( 2.6 110 - 120 24-26 AC E70T6 F4 LB 52U KOBELCO ) 2 - CAp. S - 7016 LS ( HYUNDAI ) 120 * I40 26-28 AC E'7016G F4 FIG. E- OWRHEAD (WIDEST ROOT OPENING) 1i0 - 120 24-26 AC F4 3.2 LB 52U ( KOBELCO ) E'7016 2-CAP. S - 7Oi6 LS ( HYIINDAI ) 3.2 r20 - t40 26-28 AC E70t6c F4 NO

POL.

SPEED

MM/MIN

)

Manual Manual Manual Manual Manual Manual Manual Manual Manual Manual

OA/QC SECTION

AUTHORITY

DATE

:

:

x4rtqo

,.............v'..'.\1""':f"'::;-""i

SEE.T.OF{

tl"lt-

MING FYE

SECTION

SIGN

QA/OC

File

.

WELDING WELDING WELDING

wffiffiw

PROCESS

: SMAW

Ms@ir%.-

IVPS : SMAW-9520-06 REV.O

JURONG SHIPYARD PTE LTD Regn No.: 199908265G

WELDING PROCEDURE SPECIFICATION BP ANGOLA PSVM (21-e5201

PQR: 7755-04-04

DATE:31st MARCH 2010

CODE

CLIENT SPEG

AWS D1.1

N/A

MANUAL/AUTO : MANUAL

PROGRESS : ALL POSITIONS POSITION : 6GR

PREPARATION & WELDING SEQUENCE (UNIT IN MM)

"t4=

,rs{}''rr/ t"

METAL SPECIFICATION : : MATERIAL CLASS

BAsE

QUALIFICATION TECHNIQUE

API 5L GR.X 52 N TO API 5L GR.X 52 N AWS GROUP llTO ll

RANGE : 9.1 mm & ABOVE THICKNESS

PIPE DIA LINE-UP CLAMP

CLEANING STRINGER BEAD WEAVE BEAD BACK STRIP BACK GOUGING

HEAT INPUT

: : : : :

GRINDING & BRUSHING YES YES (2Il2 X ELECTRODE DIA)

NO NO

RANGE : MAX 1.9 KJ/mm

: 219 mm : N/A

ELECTRODE NAME

LB-52 U

PASS NO

DIA

CLASS

AWS 5.1

E-7016

GROUP

(mm)

3.2

VOLTS ru)

AMPS (A)

DC/AC

POL

SPEED

(mm/min)

ROOT

20-24 20-24

on-oE

AC

90

120

SIDE A HOT / FILL / CAP LB-52 NS

F4

AWS 5.1

E-701 6G

4.0

120

- 230

100

130

HEAT TREATMENT PRE-HEATING PRE.HEAT ryPE INTER PASS P.W.H.T. HOLDING TIME

TS 65 mm 65'G

T> 65 mm 110'C

HEATING TORCH / HEATING ELEMENTS 250'G MAX N/A N/A

:rr

GAS SHIELDING GAS GAS COMPOSITION FLOW RATE

NA NA NA NA

BACK GAS

u

srG N:

o;\W;ge".,, t$il-ffiFgTlef{,s":!.

,;ffiffi'l: '.

1!:::.:il:z-

6^D

C,lqt<"LJ

DATE:

'N,fwr

hv\atx

r^r-oNk- G-e

03 o6 to

j

r

\)

{t :I::.

II\G

PAGE

SIIIPYARTI LTI)

WELDING PROCEDURE SPECIFICATION

SMAW

CODE

1of 24

7755 - 04

WPS

PQR

7755-04-04

2515198

DATE \'/ELDiNG PROCESS MAf {UAI / ALrfO

WELDINGPROGRESS WELDING POSITION

; :

AWS Di.1 - ED. 1998

MANUAL

ALL POSITIONS T-Y-K

CLIENT SPEC

NA

WP6: SHAW.SO81.01

JOII.TT PREPARATION AND WELDING SEQUENCE (LINIT IN \A/T)

PQR:

8MSuRFo2+01

4-8

Note :

Refer to attached sheet 2 of 2 for sample T,Y, K

DIMENSION OF TEST PIECE:

joint details. O.D:219. 1xW.T. : 19.05 mm

API 5L GR.X 52N

AWS GROUP

No. of PASSES

II

TO TO

: :

API 5L GR.X 52N AWS GROUP U GRINDING / BRUSHING

Yes

THICKNESS PIPE DTA LINE-T'P CLAMP

9.5 and

ABOVE /

CLEANING

STRINGERBEAD WEAVE BEAD

219 and

ABOVE

NA

BACK GOUGE BACKING STRIP

Yes ( 2ra No

Electrode dia.)

No

LB.52U

8',l0t6

E 7016G

90-9s 20-24

120

Manual Manual

( KOBELCO ) s - 7016 LS

(

lmNDAr

130

20*24

GAS

PREI]EAT TEMP PREI{EAT TYPE

INTERPASS TEMP

660 C IAWS Table

SHIELD GAS

GAS COMP

Heating Torch / H. Element

2200 Max.

FLOW RATE

PWHT HOLDING TIME

NA NA

BACK GAS

PURGERATE

NA NA NA NA NA

DA'E

, ,AtF*yL:g5MING FY

SECTION

?r" *'n''unJ

l"si'1"i.

li':li4'|'liW0l72{

iiocN cAY

i-u$LNrstvtl

..TU f.'.

.ONG SIIIPYARD LTI)

WELDING PROCEDURE SPECIFICATION

T-Y-K ionqrs ( UNIT rN MM ) AS PERAwS

FIG.B -TESTPOSITION

FLAT

SAINPT,N, JOINT DETAILS FOR

Dl.l

PAGE 2 oI 24 7755 -04 wPS PQR 77ss - 04 - 04 DATE 25lsl98

- ED. 98

FIG. C .TESTPOSITION FLAT (WIDEST ROOT OPENING)

FIG.A -TESTPOSITION

WRTICAL

( GREATEST GROO\rE DEPTH

WrTH

NARROWEST ROOT OPENING )

SMALLEST GROOVEANGLE)

,\ \

ir

650 750

FTG,D -TESTPOSITION OWRHEAD ( NARROWEST ROOT OPENING)

FIG.E -TESTPOSITION

OWRHEAD (WIDEST ROOT OPENING)

BASEMETAL

SPECIFICATION

GR.

LREH 36

MATERIAL CLASS

PASS

AWS GROUP ELECTRODE

il

TO TO

GR.

LREH 36

AWS GROUP II VOLTS

NO

NAME

FIG. A - WRTICA ( KOBELCO ) szu LB s - ?016 LS ( IrY[D{D4J) LB 52U ( KOBELCO ) S - 7016 LS ( HYLTNDAI

AMPS. MMA4IN DC DIA GROU CLASS ( GREATEST GROOW D IPTH / SMALLEST }ROOVE ANGLE ) Manual AC 110 - 120 24-26 2.6 F4 E 7016

F4 130

2.O

AC/

POL.

SPEED

2-

CAP.

E 7016G

- 140 26-28

AC

Manual

FIG.B-FLAT(N

1

870t6

F4

110 130

2 _ CAP.

I

2-CA&.

LB s2U ( KOBELCO ) S - ?016 LS ( HYIINDAI )

F4 E 7016G FIG, C - FLAT ( I4/IDEST ROOT OPENING 12C 1i0 F4 870t6 140 130 3.2 F4 E 7016G

- 120 z4 26 - 140 26-28 24-26 26-28 24-26 26-28

)

AC

AC

Manual Manual

AC AC AC AC AC AC

Marual

Manual Manual Manual Manual

FIC D - OWKHEAD ( NARROWEST P.99!

2.6

110 120

oWNL vG)

F4 8',7016 LB 52U ( KOBELCO ) ?) 120 - 140 F4 2-cAP. s - 7016 LS ( HY{JNDAI ) E 7016G FIG. E. OWRHEAI ( WIDEST ROOT )PBNING) 110 - 120 24-26 3.2 F4 ( 8',70t6 L,B 52U KOBELCO ) 5.2 120 - 140 26-28 F4 2-cAP. s - 7016 LS ( HYUID4J) E 7016G

Manual

QA/QC SECTION

'rl-:_T

N AUTHORITY

,<.j-j:-...., i)3

.:./'. ' ?-r. ! -:__ :

' *Khr DATE ....,u1.ll

n

f,c*

43/l;\r/

ffi

SECTION

t{GNzi

l '^.. :.. ...

t'- .:'

!,

l,

SIGN

SEETOH '

OA/.C

T1\I

:

SJtU&r'

'*[flzY

,

File

JUBONG SHIPYARD LTD

WELDING PROCEDURE QUALIFICATION RECORI)

SMAW

PAGE PQR WPS DATE : :

:3of 24 : 7755-04-04 i 77ss-04 : 2515198

WELDING PROCESS

CODE

CLIENT SPEC

PQR :

AWS D1.1 - ED. 1998

MANUAL / AUTO

WELDINGPROGRESS

WELDINGPOSITION

MANUAL ALL POSITIONS T.Y-K

NI]\/D

NA

S8i.iSMRP02-081

JOINT PREPARATION AND WELDING SEQUENCE (LIMT IN

WPS: SMAW061-01

o

(-

Note : Refer to attached sheet 2 of 2 for sample T,Y, K joint details' DIMENSION OF TESTPIECE: O.D : 219. I xW.T. : l9,q5 rn4q BASE METAL TO API5L GR.X 52N SPECIFICATION TO AWS GROUP II MATERIAL CLASS

.

No. of PASSES

API5L GR.X 52N

AWS GROUP

II

GRINDING / BRUSHING

Yes Yes (Zrtz ,x Electrode dia.)

OUALIFIED RANGE

THICKNESS

PIPE 9.5 and ABOVE

DIA

219 and ABOVE

LINE-UP CLAMP

PASS

NA

ELECTRODE

CLEANING STRINGERBEAD WEAVE BEAD BACK GOUGE BACKING STRIP DIA

L.O

No

No

NO

NAME LB 52U (KOBELCO )

s - 7016 LS

( }TYUNDAI )

CLASS

GROU

F4

AMPS.

VOLTS

AC/

DC AC AC

POL

SPEED

MMA4IN

Manual Manual

E'7016

E 7016G

90-95 20-24

120

z-5

).2

130

20-24

HEAT TREATMENT

PREHE.AT TEMP

GAS

PREHEATTYPE

INTERPASS TEMP

IAWS Table Heating Torch / H. Element

660

2200 Max.

PWHT HOLDING TIME QA/QC SECTION

NA NA

: GAS COMP : FLOWRATE : BACKGAS :

SHIELD GAS N AUTHORITY

NA NA NA NA PURGERATF: NA

DATE

SIGN

)drh t

tttr...t...'r'tt'"rl

,/@\

srl,l r(ooN cAY

CEM}E

SEETO

QA/ OC SECTION

-P0 1/0

rffi#

I i (ril.+3/SW01724

4l {l

,TUNONG SHIPYARD LTD

WELDING PROCEDURE QUALTFICATION RECORD

PAGE PQR wPS DATE

4 oI

2ar 77Ss - 04 - 04

7155 - 04

2sl5l98

SAMPLE JOINT DE'I'AILS FORT-Y-K JOTNTS ( UNrT rN MM ) AS PER AWS D1.1 - ED. 98 FIG,C -TESTPOSITION FIG.B -TESTPOSITION nrc.j_- rEsT.Posnlau_

VERTICAL

(

FI}IT

( NARROWEST

FUIT

(WIDEST ROOT OPENING)

GREATEST GROOV-E DEPTH WrTH

ROOT OPENING )

SMAILEST GROOVEANGLE)

7x

I

('

FIG.D -TESTPOSITION

(

FIG.E -TESTPOSITION

OWRHEAD (WIDEST ROOT OPENING)

OWRHEAD NARROWEST ROOT OPENING)

BASE METAL SPECIFICATION

GR.

LREH

36

MATERIAL CLASS

PASS

AWS GROUP ELECTRODE

TO TO

AMPS.

GR.

LREH 36

AWS GROTJP II VOLTS

AC/

DC DIA NAME CLASS GROU FIG. A - WRTICAL ( GREATEST GROOW DEPTH / SMALLEST GROOVE ANGLE I 2.6 110- i20 24-26 AC LB 52U ( KOBELCO ) E 7016 F4 2 * CAP. S .7016 LS ( HYLTNDAI ) ).2 F4 130 - 140 26-28 AC E 7016G FIG. B - FLAT ( NARROI4'EST ROOT OPENING ) I 2.6 26 AC F4 110 - 12C 24 LB 52U ( KOBELCO ) 8',7016 ( 2 -CAP. S 7016 LS HYUNDAI ) 3.2 130 - 140 26-28 AC F4 E 7016G FIG. C - FLAT ( WDEST ROOT OPENING ) I r20 24-26 AC )./. t10 LB 52U ( KOBELCO ) 870t6 F4 2 - CAP. S - 7016 LS ( HYIJNDAI ) 3.2 130 - 140 26-28 AC E 7016G F4 FIG. D - OVEREEAD ( NARROWEST ROOT OPEMNG ) ( 2.6 110 - 120 24-26 AC E70T6 F4 LB 52U KOBELCO ) 2 - CAp. S - 7016 LS ( HYUNDAI ) 120 * I40 26-28 AC E'7016G F4 FIG. E- OWRHEAD (WIDEST ROOT OPENING) 1i0 - 120 24-26 AC F4 3.2 LB 52U ( KOBELCO ) E'7016 2-CAP. S - 7Oi6 LS ( HYIINDAI ) 3.2 r20 - t40 26-28 AC E70t6c F4 NO

POL.

SPEED

MM/MIN

)

Manual Manual Manual Manual Manual Manual Manual Manual Manual Manual

OA/QC SECTION

AUTHORITY

DATE

:

:

x4rtqo

,.............v'..'.\1""':f"'::;-""i

SEE.T.OF{

tl"lt-

MING FYE

SECTION

SIGN

QA/OC

File

Potrebbero piacerti anche

- PQR 014 (Qualified Sa 106 GR BDocumento5 paginePQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Documento6 pagineMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNessuna valutazione finora

- WPS PQR A36.20Documento5 pagineWPS PQR A36.20gchaves504100% (2)

- WPS, PQR, WPQ (Si007)Documento5 pagineWPS, PQR, WPQ (Si007)Suresh RathodNessuna valutazione finora

- WPS & PQRDocumento46 pagineWPS & PQRJohn Candidate CIns88% (8)

- WPSDocumento3 pagineWPSKhurram Burjees100% (1)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Documento20 pagineWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- A 36 WPSDocumento2 pagineA 36 WPSNaqqash Sajid100% (1)

- WPS PQR FormatDocumento1 paginaWPS PQR FormatJatin Kamdar100% (2)

- WPS PQRDocumento23 pagineWPS PQRHashim Khan88% (8)

- WPS PQR-09Documento11 pagineWPS PQR-09Ranjan KumarNessuna valutazione finora

- PQR FormatDocumento2 paginePQR Formatravi0009880% (5)

- Welder Performance Qualification-Interactive Form QW-484ADocumento1 paginaWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WPS (AsmeDocumento8 pagineWPS (AsmeMohammad Elhedaby100% (6)

- According To ASME IX: Welding Procedure Specification (W.P.S)Documento4 pagineAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNessuna valutazione finora

- P91 Profile WpsDocumento6 pagineP91 Profile WpsZead Ali Adal100% (2)

- WPS PQR-03Documento12 pagineWPS PQR-03Ranjan KumarNessuna valutazione finora

- REGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRDocumento2 pagineREGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRAnonymous Xa5rkMZm9ZNessuna valutazione finora

- PQRDocumento2 paginePQRalokbdasNessuna valutazione finora

- Welding Procedure SpecificationDocumento3 pagineWelding Procedure SpecificationAhmed saber100% (1)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 pagineIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Documento48 pagineQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- WPS for 316L Pipe WeldingDocumento3 pagineWPS for 316L Pipe WeldingRichard Periyanayagam100% (3)

- WPS TITLEDocumento2 pagineWPS TITLERichard Periyanayagam86% (14)

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- SS WPSDocumento1 paginaSS WPSMOHAMEDABBASNessuna valutazione finora

- PQRDocumento2 paginePQRHoangNessuna valutazione finora

- Piping WpsDocumento37 paginePiping WpsZulfokar FahdawiNessuna valutazione finora

- Welder Qualification CertificateDocumento2 pagineWelder Qualification CertificateLuttpi100% (1)

- WPS PQR WPQ PeiplDocumento16 pagineWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocumento2 pagineProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNessuna valutazione finora

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- Manual Standard WeldingDocumento192 pagineManual Standard WeldingGEORGE IVAN0% (1)

- WPS-PQR (Er309l Mo)Documento4 pagineWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- QW-483 BlankDocumento2 pagineQW-483 BlankCraftyBob100% (1)

- AWS D1.1 - Example PQR & WPS DocumentsDocumento4 pagineAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- WPS GmawDocumento2 pagineWPS Gmawasikur100% (6)

- Aws d1.1 WPS, PQR & WQTDocumento4 pagineAws d1.1 WPS, PQR & WQTWeld Bro SandeepNessuna valutazione finora

- Asme PQRDocumento4 pagineAsme PQRHong Dae Yoon100% (2)

- WPQR SMAW EN-2 - 30mm (Under Modification)Documento2 pagineWPQR SMAW EN-2 - 30mm (Under Modification)Mohamed Reda HusseinNessuna valutazione finora

- Review WPS/PQR Road Map AcceptanceDocumento1 paginaReview WPS/PQR Road Map AcceptanceBaraa AzebNessuna valutazione finora

- Wps p91 - BhelDocumento2 pagineWps p91 - BhelAshish Gupta100% (4)

- P 91 - Welding WPSDocumento2 pagineP 91 - Welding WPSSuhailshah123475% (4)

- WPQ Sample PrintoutDocumento1 paginaWPQ Sample PrintoutKannan VelNessuna valutazione finora

- Welding Procedure and PQR SSDocumento18 pagineWelding Procedure and PQR SSmonchai_626Nessuna valutazione finora

- WPS Format For ASME IX - PQR-AllDocumento3 pagineWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- 6GR WPS PQRDocumento15 pagine6GR WPS PQRMohammed NazeerNessuna valutazione finora

- SMAW Welding Procedure for 219mm PipeDocumento15 pagineSMAW Welding Procedure for 219mm PipeerwincalvoNessuna valutazione finora

- WPS PQR-02Documento8 pagineWPS PQR-02Ranjan Kumar100% (1)

- KF Trunnion Ball Valve 1-8 900lbsDocumento2 pagineKF Trunnion Ball Valve 1-8 900lbsalefleavNessuna valutazione finora

- Piping Isometrics CPF Area Cpf2 Process Area - Drawing IndexDocumento12 paginePiping Isometrics CPF Area Cpf2 Process Area - Drawing IndexWnava CrisNessuna valutazione finora

- 16 MM Grade 60-70 p1g1 To p2g2Documento8 pagine16 MM Grade 60-70 p1g1 To p2g2John EvansNessuna valutazione finora

- 3119-Gear Box Data Sheet Rev.01Documento4 pagine3119-Gear Box Data Sheet Rev.01SAHTEESHKUMARNessuna valutazione finora

- ISO Pump DataDocumento9 pagineISO Pump DataJanakiraman MalligaNessuna valutazione finora

- wps63 PDFDocumento4 paginewps63 PDFErick HoganNessuna valutazione finora

- WPS PQR-01Documento9 pagineWPS PQR-01Ranjan Kumar0% (1)

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocumento6 pagineSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988Nessuna valutazione finora

- Data Sheet for Power TransformerDocumento3 pagineData Sheet for Power TransformerMuhammad Ibad AlamNessuna valutazione finora

- MTC of Pipe - SSP MakeDocumento4 pagineMTC of Pipe - SSP MakemubeennavazNessuna valutazione finora

- Centrifugal Pump Data Sheet for Yanbu Refinery ProjectDocumento9 pagineCentrifugal Pump Data Sheet for Yanbu Refinery ProjectJanakiraman MalligaNessuna valutazione finora

- AWS Certification for Robotic Arc Welding OperatorsDocumento26 pagineAWS Certification for Robotic Arc Welding OperatorsKiukStaksNessuna valutazione finora

- E8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialDocumento1 paginaE8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialKiukStaksNessuna valutazione finora

- E8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsDocumento1 paginaE8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsKiukStaksNessuna valutazione finora

- E8-E8M-09-Standard Test Methods For Tension Testing of Metallic Materials EspecimenDocumento1 paginaE8-E8M-09-Standard Test Methods For Tension Testing of Metallic Materials EspecimenKiukStaksNessuna valutazione finora

- Actividades SoldaduraDocumento1 paginaActividades SoldaduraKiukStaksNessuna valutazione finora

- Aw StandartsDocumento12 pagineAw StandartsKiukStaksNessuna valutazione finora

- Metric MeditionDocumento4 pagineMetric MeditionKiukStaksNessuna valutazione finora

- E8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsDocumento1 paginaE8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsKiukStaksNessuna valutazione finora

- E8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsDocumento1 paginaE8-E8M-09-Standard Test Methods For Tension Testing of Metallic MaterialsKiukStaksNessuna valutazione finora

- Linde q1 Feb1march31Documento12 pagineLinde q1 Feb1march31KiukStaksNessuna valutazione finora

- Arc Gouging GuideDocumento44 pagineArc Gouging Guidedirtylsu0% (1)

- Arc Gouging GuideDocumento44 pagineArc Gouging Guidedirtylsu0% (1)

- PubCat 2013Documento1 paginaPubCat 2013KiukStaksNessuna valutazione finora

- Cord OnesDocumento2 pagineCord OnesKiukStaksNessuna valutazione finora

- Cord OnesDocumento1 paginaCord OnesKiukStaksNessuna valutazione finora

- Weight of Weld Metal in KG/M of Weld TriangleDocumento5 pagineWeight of Weld Metal in KG/M of Weld TriangleKiukStaksNessuna valutazione finora

- Single V Butt Weld With Both Plates Prepped at Same Angle: Select ProcessDocumento1 paginaSingle V Butt Weld With Both Plates Prepped at Same Angle: Select ProcessKiukStaksNessuna valutazione finora

- SR - No. Name of The Book SpecificationDocumento7 pagineSR - No. Name of The Book SpecificationKiukStaksNessuna valutazione finora

- Enter Data:: Weld Size (Leg) MM Unit Weld Length MDocumento2 pagineEnter Data:: Weld Size (Leg) MM Unit Weld Length MKiukStaksNessuna valutazione finora

- Crane Rails1Documento3 pagineCrane Rails1Cw TanNessuna valutazione finora

- Riel LigeroDocumento6 pagineRiel LigeroHenrry MendozaNessuna valutazione finora

- Weld Metal CalculationDocumento1 paginaWeld Metal CalculationKiukStaksNessuna valutazione finora

- Taking Your Weld's Temperature-1Documento6 pagineTaking Your Weld's Temperature-1KiukStaksNessuna valutazione finora

- Weld Consumable CalculatorDocumento2 pagineWeld Consumable CalculatorKiukStaksNessuna valutazione finora

- Placas SawDocumento1 paginaPlacas SawKiukStaksNessuna valutazione finora

- Heat Input CalculatorDocumento2 pagineHeat Input CalculatorKiukStaksNessuna valutazione finora

- Welding GaugeDocumento11 pagineWelding GaugeDevesh ChauhanNessuna valutazione finora

- Welding GaugeDocumento11 pagineWelding GaugeDevesh ChauhanNessuna valutazione finora

- Catagog 2013Documento48 pagineCatagog 2013KiukStaksNessuna valutazione finora

- Knee Power Generation: An Overview of Hardware and Working PrincipleDocumento93 pagineKnee Power Generation: An Overview of Hardware and Working PrincipleSRL MECHNessuna valutazione finora

- Master Grinding Wheel BrochureDocumento72 pagineMaster Grinding Wheel BrochureSgk Manikandan100% (1)

- 0000 Pi SPC 002Documento24 pagine0000 Pi SPC 002zsmithNessuna valutazione finora

- Material Selection O & GDocumento26 pagineMaterial Selection O & GJay Ganta100% (1)

- Critical Assessment 17 Mechanisms of Hydrogen Induced Cracking in Pipeline SteelsDocumento9 pagineCritical Assessment 17 Mechanisms of Hydrogen Induced Cracking in Pipeline SteelsnankingNessuna valutazione finora

- Steel Tubes and Fittings for ScaffoldingDocumento8 pagineSteel Tubes and Fittings for Scaffoldingthiru_tsn87Nessuna valutazione finora

- Final Me&m PDFDocumento64 pagineFinal Me&m PDFAditi RayNessuna valutazione finora

- Welding Book PipingDocumento184 pagineWelding Book PipingMahaveer Singh100% (2)

- Eifeler Coating Application - ChartDocumento1 paginaEifeler Coating Application - Chartykc38Nessuna valutazione finora

- Ch13 - Steel Fabrication WorkDocumento54 pagineCh13 - Steel Fabrication Workwhyme_bNessuna valutazione finora

- Astm A312Documento3 pagineAstm A312Zeeshan HasanNessuna valutazione finora

- Steel 1Documento25 pagineSteel 1basanthi noorbashaNessuna valutazione finora

- PT Kyung Shin Cipta Engineering Spec SheetDocumento26 paginePT Kyung Shin Cipta Engineering Spec SheetbimaNessuna valutazione finora

- RI 4 Defect CausesDocumento50 pagineRI 4 Defect CausesSathishkumar Srinivasan100% (1)

- CRISIL Rating LIstDocumento1.646 pagineCRISIL Rating LIstSanjeev ChaudharyNessuna valutazione finora

- Syllabus IET - Biotechnology - NewDocumento96 pagineSyllabus IET - Biotechnology - NewRanjeet SinghNessuna valutazione finora

- 428 / Heat Treater's GuideDocumento5 pagine428 / Heat Treater's GuideAntonioNessuna valutazione finora

- Aluminium Welding - 1Documento3 pagineAluminium Welding - 1Sasi Head OfficeNessuna valutazione finora

- SATR-W-2005 Rev 6 PWHT ReportDocumento1 paginaSATR-W-2005 Rev 6 PWHT ReportAWAIS RAJANessuna valutazione finora

- Overlay Products: The Proven Way To Prevent Wear and CorrosionDocumento8 pagineOverlay Products: The Proven Way To Prevent Wear and CorrosionYousab CreatorNessuna valutazione finora

- Ferrous and Non Ferrous MetalsDocumento16 pagineFerrous and Non Ferrous Metalssonu100% (1)

- 5.1 Project Design Basis - NewDocumento22 pagine5.1 Project Design Basis - Newandrieysyah2525Nessuna valutazione finora

- 2016 Front End SampleDocumento12 pagine2016 Front End SampleB GirishNessuna valutazione finora

- Atlas Stainless Steel PDFDocumento56 pagineAtlas Stainless Steel PDFhassanNessuna valutazione finora

- Unbrako CatalogueDocumento92 pagineUnbrako Cataloguerlnjay2003Nessuna valutazione finora

- Society of Automotive EngineersDocumento3 pagineSociety of Automotive EngineersLegend AnbuNessuna valutazione finora

- Ansi-Aws A5.23-A5.23mDocumento44 pagineAnsi-Aws A5.23-A5.23mSugiharnoNessuna valutazione finora

- Learn Welding Fundamentals in 40 HoursDocumento2 pagineLearn Welding Fundamentals in 40 HoursKhalid HafezNessuna valutazione finora

- Stainless Steel Union Din 11851 SmsDocumento8 pagineStainless Steel Union Din 11851 Smsdingobk1Nessuna valutazione finora

- NTU BDC '22 Preliminary Round Case DocumentDocumento11 pagineNTU BDC '22 Preliminary Round Case Documentmyint phyoNessuna valutazione finora