Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Revised Unit-6 TG Repair Works 2009

Caricato da

VIBHAVTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Revised Unit-6 TG Repair Works 2009

Caricato da

VIBHAVCopyright:

Formati disponibili

A PRESENTATION ON HP TURBINE BLADE FAILURE RAMAGUNDAM UNIT-6

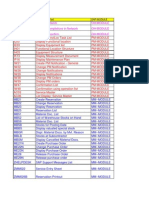

UNIT-6 OVERHAUL HISTORY

Sl NO 1 YEAR 1989 TYPE OF OVERHAUL UNIT FIRST SYNCRONISED LPT HPT & IPT LPT 1R-06 No Root crack IL-03, 2L- 01 & 1R06 No NFT HPT inner casing refinning at RC puram 1R- 06,1L-04 Root crack. IR-02 NFT REMARKS UNIT FIRST SYNCRONISED ON 26.03.1989 2R blads(02 No) replaced

2 3 4

1992 1996 2001

5 6

2004 2006

HPT & IPT LPT

2004 HP/IP OVERHAUL OBSERVATIONS

Sl No

1 2

INSPECTION

HPT INNER CASING REFINNING BLADE LOOSENESS/SHROUD GAP

OBSERVATIONS

PARTIAL REFINNING AT BHEL RC PURAM NIL

3

4

BLADE DEPOSITS

TG BEARING INSPECTION

NORMAL

UT&DPT , OK

LPT OVERHAUL 2006 OBSERVATIONS

Sl No

1 2 3 4

INSPECTION

LPT ROTOR AND BLADES MPI FREE STANDING BLADES NFT BLADE DEPOSITS BEARING INSPECTION

OBSERVATIONS

LP-1R 08 BLADES REPLACED (6 ROOT CRACKS & 2 NFT) LP-IL 04 BLADES REPLACED DUE TO ROOT CRACKS NORMAL UT&DPT , OK

HPT EVACUATION SYSTEM

HPT EVACUATION SYSTEM ORIGINALLY NOT ENVISAGED. INSTALLED AND COMMISSIONED IN 2006. SYSTEM IN SERVICE. LOGIC OF VALVE CLOSING ON TURBINE START UP TO BE REVIEWED.

UNIT-6 TG REPAIR WORKS 2009

ON 10.08.2009 FROM 16:30 HRS, TURBINE SHAFTS & BEARINGS VIBRATIONS STARTED INCREASING & FLUCTUATING. BEARING NO.1 VIBRATION REACHED 45 MICRONS FROM 13 MICRONS AND SHAFT VIBRATION AT BRG No.1 REACHED 125 MICRONS FROM 75 MICRONS. BEARING NO.1 TOP RIGHT SIDE TEMPERATURE INREASED FROM 79 TO 100 DEG. UNIT WAS STOPPED AT 08:03 HRS ON 11.08.2009 FOR INSPECTION AND RECTIFICATION. TG CAME ON BARRING GEAR. CONTROLLED COOLING OF TURBINE CARRIED OUT AS PER LMI. BARRING GEAR STOPPED AT 16:00 HRS ON 14.08.2009. OIL PUMPS STOPPED AT 09:00 HRS ON 15.08.2009.

UNIT-6 TG REPAIR WORKS 2009

AFTER TURBINE COOLING, HAND BARRING WAS NOT FREE AND RUBBING SOUNDS OBSERVED AT HPT REAR SIDE.

AFTER DECOUPLING LPT ROTOR ALSO, HP-IP ROTOR SYSTEM HAND BARRING WAS NOT FREE. AFTER DECOUPLING IP ROTOR FROM HP ROTOR, IP ROTOR WAS FREELY ROTATING, BUT HP ROTOR NOT ROTATING.

UNIT-6 TG REPAIR WORKS 2009

AS HPT ROTOR WAS NOT FREE, HPT EXHAUST (CRH/HRH) CIRCUIT WAS CHECKED FOR ANY BLADE/FIN DEBRIS. METALIC DEBRIS (FIN MATERIAL) FOUND AT HPT EXHAUST WHEN INSPECTED THROUGH EXHAUST PIPE STEAM WASH CONNECTION FLANGE. HRH STEAM CIRCUIT WAS INSPECTED. METALIC DEBRIS FOUND COLLECTED AT HRH STRAINERS,HRH DRAIN POT, HRH HEADER AT BOILER . THE ABOVE OBSERVATIONS INDICATED HPT MOVING/STATIONARY BLADES FAILURE.

PHOTOS

CRH/HRH CIRCUIT INSPECTION

INSPECTION AREA OBSERVATION

HPT EXHAUST

HRH STRAINERS 1,2,3,4 HRH DRAIN POT CRH INLET HEADERS (BOILER) CRHNRVs MS STRAINERS 1-4 CONDENSER HOT WELL

METALLIC DEBRIS FOUND

METALLIC DEBRIS FOUND. DAMAGE TO STRAINERS. METALLIC DEBRIS FOUND METALLIC DEBRIS FOUND NO NO INSPECTED, FLOOD TEST DONE NO

HRH LINE STEAM BLOWING DONE WITH TARGET PLATE

UNIT-6 TG REPAIR WORKS 2009

BASED ON ANALYSIS OF MACHINE VIBRATIONS AND SUBSEQUENT INSPECTION/OBSERVATIONS , PLAN FOR UNIT RESTORATION UNDER BHEL SUPERVISION WAS MADE AS REPLACE HPT MODULE WITH SPARE MODULE WHICH WAS READILY AVAILABLE AT SINGRAULI. INSPECTION OF IPT AND LPT MODULES ALSO, AND CARRY OUT COMPONENTS INSPECTION AND NDT.

1.

2.

3. HRH STEAM BLOWING WHILE UNIT RESTORATION AFTER REPAIR WORKS.

UNIT-6 TG REPAIR WORKS 2009

SPARE HPT MODULE TRANSPORATED FROM SINGRAULI TO RAMAGUNDAM IN 10 DAYS. MODULE REACHED RAMAGUNDAM ON 05.09.2009. IPT BLAST CLEANING IPT CASINGS AND ROTOR MPI DONE, OK. TG BEARINGS DPT & UT ,OK.

UNIT-6 TG REPAIR WORKS 2009

LPT INSPECTION OBSERVATIONS ROTOR BLADE MPI : NORMAL

ROTOR BLADE GROOVE MPI : ONE BLADE ROOT CRACK IN 1R FREE STANDING BLADESNFT: NORMAL

TG BEARINGS INSPECTION

: DPT &UT

UNIT-6 TG REPAIR WORKS 2009

IN MPI OF LP ROTOR, A CRACK WAS DETECTED AT BLADE ATTACHMENT (STEEPLE) AREA AT STAGE 1R OF THE ROTOR. THIS IS FIRST OBSERVATION IN 500 MW LP ROTOR IN NTPC. LPT ROTOR WAS REPLACED WITH POOL SPARE ROTOR (FULLY BLADED ROTOR) WHICH WAS PARKED AT RAMAGUNDAM

UNIT-6 TG REPAIR WORKS 2009

HPT MODULE AND LPT ROTOR REPLACEMENT NECESSITATED REAMING AND HONING OF COUPLING HOLES IN HP-IP,IP-LP & LP-GEN COUPLING.

HRH STEAM LINE STEAM BLOWING SCHEME WAS FINALISED IN CONSULTATION WITH CC/OS . STEAM BLOWING WAS CARRIED OUT AT 25 KSC PRESSURE THROUGH 100NB PIPE WITH MOV AND TARGET PLATE.

UNIT-6 TG REPAIR WORKS 2009

UNIT WAS RESTORED ON 23.09.2009 IN 43.5 DAYS. MACHINE VIBRATIONS AND OTHER PARAMETERS ARE NORMAL

THANK YOU

UNIT-6 HP MODULE BLADE DEBRIS

UNIT-6 HP MODULE BLADE DEBRIS

UNIT-6 HP MODULE BLADE DEBRIS

UNIT-6 HP MODULE BLADE DEBRIS

UNIT-6 HP MODULE BLADE DEBRIS

UNIT-6 HP MODULE BLADE DEBRIS

BACK

LP ROTOR BLADE GROOVE CRACK

LP ROTOR BLADE GROOVE CRACK

LP ROTOR BLADE GROOVE CRACK

LP ROTOR BLADE GROOVE CRACK

BACK

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- List of TCodes in SAPDocumento15 pagineList of TCodes in SAPVIBHAV67% (3)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Y Series Motor BearingDocumento7 pagineY Series Motor Bearingduongthetinhqb50% (2)

- Ogn Ops Mech 031Documento21 pagineOgn Ops Mech 031VIBHAV100% (1)

- Ogn Ops Mech 017Documento4 pagineOgn Ops Mech 017VIBHAVNessuna valutazione finora

- Ogn Ops Perf 002Documento12 pagineOgn Ops Perf 002VIBHAVNessuna valutazione finora

- Report - DF - DT Relay Setting With AnnexDocumento37 pagineReport - DF - DT Relay Setting With AnnexVIBHAVNessuna valutazione finora

- Abb Vs Cost Sheet ExceptionDocumento4 pagineAbb Vs Cost Sheet ExceptionVIBHAVNessuna valutazione finora

- Od Ops Mech 007Documento14 pagineOd Ops Mech 007VIBHAVNessuna valutazione finora

- 1 Outage From Last Overhaul: SL - No. Description Weightag e (A) Marks Obtained (B) CriteriaDocumento3 pagine1 Outage From Last Overhaul: SL - No. Description Weightag e (A) Marks Obtained (B) CriteriaVIBHAVNessuna valutazione finora

- The Maharaja Sayajirao University of Baroda: The Annual Quality Assurance Report of Internal Quality Assurance CellDocumento11 pagineThe Maharaja Sayajirao University of Baroda: The Annual Quality Assurance Report of Internal Quality Assurance CellVIBHAVNessuna valutazione finora

- Overhauling Flash Report: Kawas Overhaul For Fy 2013-14Documento2 pagineOverhauling Flash Report: Kawas Overhaul For Fy 2013-14VIBHAVNessuna valutazione finora

- Performance of Mill Xrp-803Documento4 paginePerformance of Mill Xrp-803VIBHAVNessuna valutazione finora

- UmppDocumento6 pagineUmppVIBHAVNessuna valutazione finora

- Annexure-1 Rihand-Unit # 01 Burner Transition Tubes ObservationsDocumento1 paginaAnnexure-1 Rihand-Unit # 01 Burner Transition Tubes ObservationsVIBHAVNessuna valutazione finora

- Stg2 TG Lub Oil SystemDocumento11 pagineStg2 TG Lub Oil SystemVIBHAVNessuna valutazione finora

- NTPC Talcher-Kaniha WelcomesDocumento16 pagineNTPC Talcher-Kaniha WelcomesVIBHAVNessuna valutazione finora

- Starting Oil Pump in Service Problem at NTPC, Ttps Unit #5, 110 MW UnitDocumento5 pagineStarting Oil Pump in Service Problem at NTPC, Ttps Unit #5, 110 MW UnitVIBHAVNessuna valutazione finora

- Starting Oil Pump in Service Problem at NTPC, Ttps Unit#5, 110 MW UnitDocumento12 pagineStarting Oil Pump in Service Problem at NTPC, Ttps Unit#5, 110 MW UnitVIBHAVNessuna valutazione finora

- Presentation On Simhadri Unit-2 High VibrationDocumento21 paginePresentation On Simhadri Unit-2 High VibrationVIBHAV100% (1)

- A/C Hard Starts: Three (3) Styles To Choose From: ApplicationsDocumento51 pagineA/C Hard Starts: Three (3) Styles To Choose From: Applicationsdavid salazarNessuna valutazione finora

- Difference Between Static Relays and Electromagnetic RelaysDocumento2 pagineDifference Between Static Relays and Electromagnetic Relayskriitka86% (7)

- Multi-Conductor Train Simulations For Electrification SystemDocumento27 pagineMulti-Conductor Train Simulations For Electrification SystemRinu RavikumarNessuna valutazione finora

- OS-Training - Manual - For - 80 - Net - DubaiDocumento55 pagineOS-Training - Manual - For - 80 - Net - DubaiBiju Sasidharan NairNessuna valutazione finora

- Photovoltaic Array / Solar Panel: Design, Analyze & Operate Solar Farms With ETAPDocumento3 paginePhotovoltaic Array / Solar Panel: Design, Analyze & Operate Solar Farms With ETAPamitNessuna valutazione finora

- AND8132/D Performance Improvements To The NCP1012 Evaluation BoardDocumento6 pagineAND8132/D Performance Improvements To The NCP1012 Evaluation BoardStasNessuna valutazione finora

- MTLX 516 CDocumento1 paginaMTLX 516 CAakash PandyaNessuna valutazione finora

- NSW Small Wind Turbine Consumer GuideDocumento78 pagineNSW Small Wind Turbine Consumer Guideanand sahuNessuna valutazione finora

- Uninterruptible Power Systems: Brics Series BR 450E/650E/850EDocumento22 pagineUninterruptible Power Systems: Brics Series BR 450E/650E/850EAbdelwhab ElsaftyNessuna valutazione finora

- Electricity Bill Duplicate Bill: Account No: 6670250000Documento1 paginaElectricity Bill Duplicate Bill: Account No: 6670250000RohitNessuna valutazione finora

- p5. Vacuum Breaker Simulation For Switching OV Study (Modelo Simulink)Documento4 paginep5. Vacuum Breaker Simulation For Switching OV Study (Modelo Simulink)Robinson De La FuenteNessuna valutazione finora

- Using The GrowlerDocumento8 pagineUsing The GrowlerpeterNessuna valutazione finora

- 30-Jan-2020 2 and 4 Quadrant Choppers Chopper Control DrivesDocumento26 pagine30-Jan-2020 2 and 4 Quadrant Choppers Chopper Control DrivesATULYA ALOK 17BEE0065Nessuna valutazione finora

- ER-G12-4 Amendment 1 (2015)Documento40 pagineER-G12-4 Amendment 1 (2015)MenaNessuna valutazione finora

- ASCO-ATS Overview-Catalog-pub2062-R5Documento8 pagineASCO-ATS Overview-Catalog-pub2062-R5j658503Nessuna valutazione finora

- Fuji AF300 G11 Manual PDFDocumento160 pagineFuji AF300 G11 Manual PDFMarceloVictorinoNessuna valutazione finora

- Trouble Shooting For VRFDocumento55 pagineTrouble Shooting For VRFFelixNessuna valutazione finora

- Multilevel InverterDocumento9 pagineMultilevel Invertergaurav rawatNessuna valutazione finora

- CET Power - AGIL+SBP Datasheet v1.0Documento2 pagineCET Power - AGIL+SBP Datasheet v1.0Renzo VelardeNessuna valutazione finora

- CenterPointEnergy ServiceStandards2013RevisionOct2013Documento97 pagineCenterPointEnergy ServiceStandards2013RevisionOct2013Carol HernandezNessuna valutazione finora

- Shakti PumpDocumento5 pagineShakti Pumpbagus saputraNessuna valutazione finora

- Sinamics Common Error CodesDocumento5 pagineSinamics Common Error CodesSuzanne DickersonNessuna valutazione finora

- 1SBE121111R0620 Esb20 20n 06Documento4 pagine1SBE121111R0620 Esb20 20n 06muneeb abdulNessuna valutazione finora

- BL201801052 ZYT02 Timer ManualDocumento2 pagineBL201801052 ZYT02 Timer ManualLu LuNessuna valutazione finora

- (2021) An Efficient Short-Term Energy Management System For A Microgrid With Renewable Power Generation and Electric VehiclesDocumento17 pagine(2021) An Efficient Short-Term Energy Management System For A Microgrid With Renewable Power Generation and Electric VehicleshNessuna valutazione finora

- Observation of Polarity Test of A Single Phase TransformerDocumento3 pagineObservation of Polarity Test of A Single Phase TransformerAbdul Mubin100% (2)

- 15 KW Induction ManualDocumento5 pagine15 KW Induction Manualxreader0Nessuna valutazione finora

- Password Based Circuit Breaker: International Journal For Research in Applied Science & Engineering Technology (IJRASET)Documento5 paginePassword Based Circuit Breaker: International Journal For Research in Applied Science & Engineering Technology (IJRASET)DeyaSuryadirajaNessuna valutazione finora

- Deliverable List Monitoring UpdateDocumento1 paginaDeliverable List Monitoring UpdateJeryco MdcNessuna valutazione finora