Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tables For Pipe Support Spacin1

Caricato da

Sharon LambertTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tables For Pipe Support Spacin1

Caricato da

Sharon LambertCopyright:

Formati disponibili

Tables for pipe support spacing

SourceInternet AuthorUnknow Pubdate2008-04-15

Tankman650 (Structural) 14 Mar 03 16:27 Are there published tables for the maximum unsupported run of pipe per given pipe size??? I can calculate the maximun stress values but was wondering if there are standard tables for support apacing based on stress and deflection.

ChasBean1 (Mechanical) 14 Mar 03 16:58 1996 International Mechanical Code, Table 305.4 - "Piping Support Spacing." Also, "Pipe Hangers and Supports - Selection and Application" by Manufacturers Standardization Society of the Valve and Fittings Industry, Inc., MSS SP-69-2002. Table 3 - "Maximum Horizontal Pipe Hanger and Support Spacing." Neither are available without forking out cash. Since you are a valued guest of this forum, I'd be happy to email you pdf forms of these tables. I can't copy the whole publication for copyright issues, etc., but I don't see a problem with providing just the table info. (hopefully these folks don't either). 1 -CB LSThill (Mechanical) 23 Mar 03 3:54 Hi Tankman650 (Structural), cceballos (Mechanical) ASME B31.1-2001: TABLE 121.5 SUGGESTED PIPE SUPPORT SPACING Page 46. Suggested Manimum Span for Water Services and Steam, GAs or Air Service. Need to read the General Notes on page 46 StressGuy (Mechanical) 27 Mar 03 8:43 You're going to want to be careful with a 30" line, particularly if it is liquid full. Most of these span tables are based on bending stress and deflection. When you gets to pipes that large, local/horn stresses at the support location become a bigger concern that need to be address by the support design (typically a saddle). A common reference in this area is the work of L.P. Zick on the design of support saddles for horizontal vessels. I'm sure others here can suggest more references. 7 I haven't looked at Isthill's reference since I've not really worked with Power Piping, but I would imagine it probably makes some note of these issues. Edward L. Klein Pipe Stress Engineer

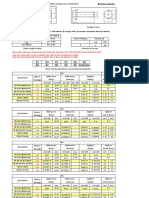

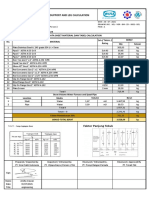

Houston, Texas All opinions expressed here are my own and not my company's. LSThill (Mechanical) 28 Mar 03 2:14 Tankman650 (Structural) The Piping Engineer will have the SUGGESTED PIPE SUPPORT SPACING in the Piping and Piping Stress Specification. With the SUGGESTED PIPE SUPPORT SPACING spread sheet calculation for Wt. dead load. 1969grad (Mechanical) 29 Apr 03 6:03 I have calculated the pipe stresses for the given spans in the MSS publication and found that the stresses are usually less than the allowables found in either B31.3 or B31.8. So the problem then becomes how much deflection is acceptable. I might add that I do not think that the MSS publication includes 30" pipe but I could be wrong as it has been some time since I looked at it. Does anyone have any deflection guidelines for services other than steam? DLANDISSR (Mechanical) 29 Apr 03 8:41 Tankman650: ITT- Grinnell publication "Pipng Design and Engineering" have a table of suggested pipe hanger spacing of Carbon Steel pipe filled with water based on a bending and shear stess not exceeding 1500psi and a deflection between hangers not to exceed .1". as follows: Nom. Size Span 1 7 1.5 9 2 10 2.5 11 7 3 12 3.5 13 4 14 5 16 6 17 8 19 10 22 12 23 14 25 16 27 18 28 20 30 24 32

26, 28 33 30, 32 34 34, 36 35 42 36 I have found this to be a good basic guide. These spans are for straight pipe only. Bends, valves and other added loadas will effect the span. If there is any question as to the span a stress analysis should be done. CaesarII is an excellend stress program which is user friendly and easy to use. A 50 run version can be purchased for about $700. Look on the web.

StressGuy (Mechanical) 29 Apr 03 8:51 Be aware also that the B31.1 table is fairly conservative, particularly for smaller lines. For B31.3 refinery piping, most engineering companies that I know of allow down to 2" diameter piping to span 20ft in standard pipe rack bays. With that table, you need to have a minimum of 10" piping in your pipe racks. 2 Also, typical deflection criteria is 1/2"-5/8" for ISBL lines. This span translates to a minimum natural frequency of 4Hz which is a suggested minimum to keep your pipe spans from galloping like the Tacoma Narrows Bridge. Edward L. Klein Pipe Stress Engineer Houston, Texas All opinions expressed here are my own and not my company's. umreng (Mechanical) 29 Apr 03 9:19 Previous replies and responses to the pipe span question have not considered siesmic forces. If the location of the piping installation is in an area with earthquake history, this may lead the engineer or officials to make certain site-specific recommendations or design requirements. chicopee (Mechanical) 12 May 03 5:59 All horizontal pipe support equations that I have seen are based on the fundamental beam equations found in strength of material. Bending stress and deflection are the two main criteria. ASME piping code for power boilers also requests the additional load of water filling the pipes.

Hookem (Mechanical) 29 Sep 04 22:19 Stress Guy: I have many criteria for supports before, but not the 4 hertz. Please advise on background and basis. Thanks. Hookem aka TomChesney chesney@uei-houston.com bchesnfish@aol.com

StressGuy (Mechanical) 30 Sep 04 8:31 I'll have to do some digging for the documentation. That one comes from my boss, who's been doing pipe stress since before I was born. I'm pretty sure it comes from Kellogg's Design of Piping Systems. Edward L. Klein Pipe Stress Engineer Houston, Texas "All the world is a Spring" All opinions expressed here are my own and not my company's. StressGuy (Mechanical) 5 Oct 04 16:08 I did confirm - the 4Hz criteria comes from the Kellogg Design of Piping Systems. In general, if your piping system sags less than 5/8" between supports, the natural frequency will be above 4Hz. You want it above this to avoid exciting a resonance with the wind blowing across it. (Tacoma Narrows Bridge, anyone?) Edward L. Klein Pipe Stress Engineer Houston, Texas "All the world is a Spring" All opinions expressed here are my own and not my company's. KernOily (Petroleum) 13 Oct 04 18:20 OK Ed what do I have to do to get you to make me a copy of Kellogg's book? How 'bout lunch at Pappadeaux's? Thanks! Pete

StressGuy (Mechanical) 13 Oct 04 18:29 I gladly would if I could, as there is a lot of good information in that book. I've written the publisher to let them know there's interest in a new printing, but they indicate they've no plans to reprint it at this time. They show up on Ebay about once or twice a year and never go for less that $50. For now, I have to rely on the library of my boss, Noble Stewart, who thankfully has managed to amass copies of just about everything in his career.

In fact, I'm currently borrowing a 30 year old catalog for a spring manufacturer that went out of business about 25 years ago to evaluate a piping system with some existing springs. It's amazing how much information is simply dissapearing, save for a few pockets that are keeping it alive.

Edward L. Klein Pipe Stress Engineer Houston, Texas "All the world is a Spring" All opinions expressed here are my own and not my company's. KernOily (Petroleum) 13 Oct 04 18:37 AARGH! Not good news. What about the 25-years-and-the-copyright-expires/public domain thing? The web is a good thing for manufacturer's catalogs in most cases. A major excpetion to this is old equipment (as you related) which lots of owners still have in operation, forcing us to keep paper copies around. Worthington pumps is one good example. Guess I will have to watch ebay... well I'll buy you lunch anyway next time I'm down there, how bout that. Thanks Ed. Thanks! Pete

ctink (Civil/Environme) 5 Jan 05 18:18 Any possibility that I could get a copy of the tables mentioned above? "Pipe Hangers and Supports - Selection and Application" by Manufacturers Standardization Society of the Valve and Fittings Industry, Inc., MSS SP-69-2002. Table 3 - "Maximum Horizontal Pipe Hanger and Support Spacing."

ApC2Kp (Mechanical) 6 Jan 05 14:49 Manufacturers Standardization Society publications are available from website, www.mss-hq.com Along with SP-69 for pipe support selection, also consider the SP-58, and SP-89 publications for the loads on the support components. pipingdesigner (Mechanical) 11 Jan 05 12:09 Hi guys, Interesting discussion ! On my website, www.pipingdesigners.com you will find a file under the "tools" section called pipe and vessel data. 9 It contains a wealth of charts etc on excel, including allowable pipe spans (just tab through the pages).

Just download, unzip and leave on your pc. I use it everyday !! Hope it helps, Kind Regards Anton www.pipingdesigners.com JohnBreen (Mechanical) 11 Jan 05 12:21 Hello All, I am surprised that nobody mentioned that the classic "span length tables" always include warnings (in fine print) that these recommended spans are for simply supported piping (no moment connections) and do not address the presence of concentrated loads (valves, strainers, etc). Also, changes in direction add some complexity to the equation. I wonder if ye olde Grinnell publication on pipe support design is still available through Anvil. EPRI members should look on the EPRI website for a PowerPoint presentation that some olde codger prepared. Regards, John.

DSB123 (Mechanical) 12 Jan 05 7:36 JohnBreen, Good observations and post. Another thing a lot of people forget is that the pipe span tables are created in many instances for "ambient" piping systems and are then applied irrespective of the pipe temperature. Spans should be modified if high temperature lines are to be considered. I know that high temp lines are nearly always stressed out but the designer needs to account for the temperature in assessing spans. As you say a lot of the span tables are based on simple supports but in reality the end conditions are never simple and there is always some rotational restraint. StressEng (Industrial) 12 Jan 05 9:23 Anyone know the formulae to calculate these spans? So we can make a excel table for all diameters, thickness, materials, temperatures, etc.

Thanks to all. JohnBreen (Mechanical) 12 Jan 05 14:41 Hi All, Ed, don't I remember that Pete developed that spread sheet already? How 'bout it Pete, did you ever get around to doing that?

Regards, John. StressGuy (Mechanical) 12 Jan 05 14:49 I have a 500kb PDF file that has six pages scanned from the old Kellogg book on the span calcs. I'll see about finding a place to put it and then I'll post a link to it. Obviously, I can't scan the whole book, but this much ought to at least be able to spread the understanding on this topic. Judging from the interest this thread keeps getting, it is quite obviously needed. Stay tuned. Edward L. Klein Pipe Stress Engineer Houston, Texas "All the world is a Spring" All opinions expressed here are my own and not my company's.

sterl (Mechanical) 12 Jan 05 22:06 Lot of good stuff in this thread... For my own $1./50 : Certain pipe industries utilize normalized tabulations that yield support spacings "closer than" the ANSI B31 or Kellog spans due to the cumulative effects of low points in specific pipes that are deliberately sloped. Normally these slopes are effected to ensure that flow variances do not result in unantipated flow phenomena, for example: Condensate induced shock when re-applying steam to what should be a dry header; pumped recirculaion return lines on many central refrigeration systems, where not only could there be a charge management problem due to sags accumulating liquid but also a temperature induced stress when the pressure is reduced on a pipeline carrying relative warm vapor and pockets of liquid at low points. The practicalities of supporting even that slope over 1000 or so feet of pipe leads the refrigeration industry to use 1/240 as a practical, and manageable, design slope....With the Deflection in a 10foot support span headed for 5/8" per some of the mentioned tabular data, the accumulation problem, with its inclemencies, is not solved by the "field applied" slope.

As well, above and beyond the "stress" considerations: At the lower and lower temperatures that "normal" end-user industries are requiring of large compression systems: the Rigidity and (nil) Ductility Transition Temperatures become a very real concern and the incorporation of conventinal "expansion loops" exacerbates the problem... So investigations of the rupture of a low temperature 2-phase pipe often establish the immediate conditions as: Bottom of pipe broke while the pressure was reducing; the flow was near its lowest; in the midst of a long stright run; halfway between supports; where its most proximate area of support is at the immediate point of contact, a deformable or otherwise, flexible insulation

material. Conclusion: Minimal localized stress at the supports, minimal hoop and axial stress, minimal momentum forces due to changes in flow direction, minmal bending moment, on tensile side of pipe...Pipe still broke.

1974vet (Mechanical) 13 Jan 05 14:11 Here goes my efforts to explain (hope isnt too long)A little more info on the span charts: Looking at Navco, p150, the Navco suggested support spacing is based on 2300 psi bending stress. MSS-SP-69, p8, is based on 1,500 psi, although I cant seem to quickly find it in the text. There are many company standard span charts also. Anyway, most tables have notes and qualifications although Ive seen some company charts copy other sources and leave this critical information out. These notes may include items like the following: *The pipe is assumed to have standard wall thickness with insulation, *No concentrated loads present such as valves, *There are no changes of direction in the spans, *Spans are assumed to run in the horizontal plane, *The maximum deflection of the span under load is limited to 0.1, and *The stress intensification factors of components are not considered. 5 I am almost certain that SP-69 was generated using allowable stress values from the power piping code. The following is an attempt to show how the span tables might have been generated: Select a low allowable stress value, e.g., 1,500 psi (Sall(weight)/i), for the combined bending and shear value, such that a sufficient factor of safety is provided, and allowing the standard span chart to be applied to a wide range of piping systems: Beginning with the generalized primary stress equation, PD/4t + iM/Z <= kSh where iM/Z values are code dependent, and k values are code dependent and occurrence of load (assumed = 1.0 here), and Sh is code dependent Using beam formulas for span: M = 1/2[(wl^2)/8 + (wl^2)/12] is the average of a uniformly loaded simple beam and a uniformly loaded beam fixed at both ends. This reduces to: M = (wl^2)/10 Substituting this expression of M into the generalized stress equation and rearranging results: L<=SQRT[(Sh-PD/4t)(10Z/iw)]

So then, an example of a non-critical type system might look like: Assuming B31.1 and A106 Gr B material P = 150 psig

T = 350F Sh = 15,000 psi Let PD/4t = 3000 psi (approx) This leaves 12,000 psi. A system design of this type will utilize higher SIFs, say in the range of 6-8, so, 12,000/8 = 1,500 psi An example of a critical type system might look like: Assuming B31.1 and A181 material P = 2600 psig T = 1060F Sh = 6,000 psi Let PD/4t = 3000 psi (approx) This leaves 3,000 psi. A system design of this type will utilize lower SIFs, say in the range of 12, so, 3,000/2 = 1,500 psi Note that the wall thicknesses will be greater and the fabrication control improved resulting in the lower SIFs. Ive left out several steps to save some space, because I think that the most important thing to know when using a standard span table is generally how it was constructed, and what simplifying assumptions were made. Also related is a calculation (ref. Hicks) to determine the minimum slope of a pipe to ensure complete draining. On the one hand it is a little conservative since emptying is not considered, but there are other factors that can negate its conservatism. If interest, I can post that relation also. . . 7

StressGuy (Mechanical) 17 Jan 05 21:10 Alright, I found a spot to post the excerpt from the out of print Kellogg book. http://home.houston.rr.com/edwardklein/Support_Spans.PDF Edward L. Klein Pipe Stress Engineer Houston, Texas "All the world is a Spring" All opinions expressed here are my own and not my company's. pipingdesigner (Mechanical) 7 Nov 05 7:03 You can find an excel pipespan chart here: http://www.pipingdesigners.com/downloads/pipe%20span%20chart.xls

pipingdesigner www.pipingdesigners.com

superpiper (Mechanical) 8 Nov 05 4:13 To mr Klein, I learnt more from reading those six pages than from spending 4 years in our stress department.thanks. 2

To 1974vet I am after an equation to calculate pipe spans for sloping lines in the format of span being a function of slope, so that no pockets occur. please post the hicks equation as commented.

UW1981 (Mechanical) 8 Nov 05 17:31 By the way, another good source for span charts is from Chapter B-4, Stress Analysis of Piping Systems, Piping Handbook, 7th edition. This has charts for various sizes of pipe (standard schedules), both empty and water full. It also has a neat deflection chart. As most everybody has observed, these charts are good "estimates" or guidelines - given the assumptions they are based on...... For slope considerations, there is a good article available on the web titled "DETERMINATION OF THE OPTIMAL PIPE SUPPORT SPANS FOR GEOTHERMAL PIPELINES. If you just type in the first four words of the title in Sectin 5.3 talks about sag and drainage.

Good luck!> 1974vet (Mechanical) 21 Nov 05 10:38 (please post the hicks equation as commented) Sorry for delay . . . From Hick's 1. Compute the allowable span between hangers for a pipe filled with water, S = WL^2/8m, where S = bending stress in pipe, lb/in^2; W = weight of pipe and water lb/lin in; L - maximum allowable distance between hangers, in; m = section modulous of pipe, in^3. by using a table of pipe properties, as in Crocker and King-Piping Handbook, L = (8mS/W)^0.5

2. Compute the pipe slope required by the span to prevent pocketing of water of condensate at the low point in the pipe, the pipe must be pitched so that the outlet is lower than the lowest point in the span. when the pipe has no concentrated lods-such as valves, cross connections, or meters-the deflection of the pipe is y in = 22.5wl^4/(EI), wehre w = weight of the pipe and its contents, lb/ft; l = distance between hangers, ft; E = modulous of elasticity of pipe, lb/in^2 = 30 x 10^6 for steel; I = moment of inertia of the pipe, in^4. with the deflection y known, the pipe slope, expressed as 1 in per G ft of pipe length, is 1 in per G ft = l(lower case L)/4y. Thus, a pipe slope of 1 in in 4.53 ft is necessary to prevent pocketing of the water when the hanger span is 47.4 ft. with this slope, the outlet of teh pipe would be 47.4/4.53 = 10.45 in below the outlet. Personally, on the one hand I think this is a bit conservative since the deflection decreases as the pipe empties. However, it may not be so conservative when some construction practices, creep, and so on are considered. Dracula (Mechanical) 22 Nov 05 18:13 First of all, each of the above response above are very accurate and well taught. The best rule of thumb for hanger spacing for pipe is the pipe diameter in feet plus 10. Example: a 3" pipe would require a support every 3'+10" = 13'-0. Use that and you should be fine for small diameter pipes 1/2" - 12".

Potrebbero piacerti anche

- FRP PipeDocumento4 pagineFRP PipealvinchuanNessuna valutazione finora

- 2395 CH 15Documento19 pagine2395 CH 15abdülkadir cebeciNessuna valutazione finora

- Bend Freq Beams Rods PipesDocumento47 pagineBend Freq Beams Rods PipesAsur Cortes GNessuna valutazione finora

- Thrust Block Calculations for PipesDocumento5 pagineThrust Block Calculations for PipesalbertooooooNessuna valutazione finora

- Pipe Support2of 5Documento1 paginaPipe Support2of 5Anonymous fLgaidVBhz100% (1)

- Wiik Catalogue 2007Documento16 pagineWiik Catalogue 2007suosvannakNessuna valutazione finora

- Columns DesignDocumento60 pagineColumns DesignifsrebraNessuna valutazione finora

- Platform - Bracing SupportDocumento12 paginePlatform - Bracing Supportpandiangv100% (1)

- Dead Load Only From The PipeDocumento5 pagineDead Load Only From The PipeНемања Караклајић100% (1)

- Wind Design - ASCE 7-16Documento22 pagineWind Design - ASCE 7-16Nguyen Tan PhatNessuna valutazione finora

- Calculation of RC PAD2Documento1 paginaCalculation of RC PAD2m 418Nessuna valutazione finora

- 134004-SEP-MEC-DAT-0004 Rev.B2 PDFDocumento11 pagine134004-SEP-MEC-DAT-0004 Rev.B2 PDFDhakshina KNessuna valutazione finora

- Questions Related To Stress Analysi1Documento12 pagineQuestions Related To Stress Analysi1Jagadish JasNessuna valutazione finora

- Specialist Services: Heavy Oil Production Facility at Umm Niqa (15049) CONTRACT NO. 15052398Documento1 paginaSpecialist Services: Heavy Oil Production Facility at Umm Niqa (15049) CONTRACT NO. 15052398Naresh KumarNessuna valutazione finora

- Design OfSteel Structures-IDocumento50 pagineDesign OfSteel Structures-IBhagyshri SiddheNessuna valutazione finora

- Simple joint design in steel structuresDocumento8 pagineSimple joint design in steel structuresNikola PejatovicNessuna valutazione finora

- Future Pipe InfoDocumento29 pagineFuture Pipe Infomekag94Nessuna valutazione finora

- CAESAR II Input Echo and OutputDocumento264 pagineCAESAR II Input Echo and OutputSanjayNessuna valutazione finora

- Isolated Footing (ACI)Documento4 pagineIsolated Footing (ACI)engyana engyyyNessuna valutazione finora

- Fluids - IIIDocumento29 pagineFluids - IIINitin GandhareNessuna valutazione finora

- Dynamic Analysis of Slug by Advance Input MethodDocumento53 pagineDynamic Analysis of Slug by Advance Input MethodYogesh PangareNessuna valutazione finora

- Nozzle neck thickness calculation UG-45Documento2 pagineNozzle neck thickness calculation UG-45Lcm TnlNessuna valutazione finora

- Nozzle Load CheckDocumento4 pagineNozzle Load CheckpipestressNessuna valutazione finora

- Restrained JointsDocumento3 pagineRestrained JointsViswanathan NaraNessuna valutazione finora

- Dimensions of Bolts and Nuts BS3692Documento6 pagineDimensions of Bolts and Nuts BS3692azam RazzaqNessuna valutazione finora

- Support and Leg Calculation: Data Sheet Material Dan Tabel CalculationDocumento3 pagineSupport and Leg Calculation: Data Sheet Material Dan Tabel CalculationliusNessuna valutazione finora

- Product Manual PM-1239-pt1-cmd2 PDFDocumento12 pagineProduct Manual PM-1239-pt1-cmd2 PDFMohd Masoom AliNessuna valutazione finora

- Pipe Stress Analysis Training Complete CourseDocumento24 paginePipe Stress Analysis Training Complete CourseFábio GamaNessuna valutazione finora

- Discharge Nozzle Load Analysis for Fire Water Pump P-05ADocumento22 pagineDischarge Nozzle Load Analysis for Fire Water Pump P-05ASeptian FirdausNessuna valutazione finora

- BOSS Flamco Pipe Support SystemDocumento64 pagineBOSS Flamco Pipe Support Systempaulo100% (1)

- Examples On Indian Seismic Code Is 1893 - Part2Documento23 pagineExamples On Indian Seismic Code Is 1893 - Part2Katherine Stuart100% (1)

- Mathcad - Pond Hex - FinalDocumento6 pagineMathcad - Pond Hex - FinalMohammed A IsaNessuna valutazione finora

- Project Fire and Service Water Pump Shelter DesignDocumento8 pagineProject Fire and Service Water Pump Shelter DesignHabibur RahmanNessuna valutazione finora

- Vertical CompressDocumento47 pagineVertical CompressSivi NallamothuNessuna valutazione finora

- Lug CalcionulatDocumento1 paginaLug CalcionulatkurniawanandreasNessuna valutazione finora

- Structural Analysis of Pipe Rack Structures - FinalDocumento205 pagineStructural Analysis of Pipe Rack Structures - FinalJasna Trifković MešićNessuna valutazione finora

- HeatExchanger DrawingDocumento7 pagineHeatExchanger DrawingSivateja NallamothuNessuna valutazione finora

- Correlation table for two-phase flow modelsDocumento4 pagineCorrelation table for two-phase flow modelssouthliNessuna valutazione finora

- Base Plate Design - Rev-0Documento8 pagineBase Plate Design - Rev-0KINGSUK PALNessuna valutazione finora

- Offshore Intake Velocity Cap Structure DesignDocumento1 paginaOffshore Intake Velocity Cap Structure Designpreeti kumariNessuna valutazione finora

- Anchor ForceDocumento14 pagineAnchor ForceAdi Mulyadi100% (1)

- Technical Data: 150x100 FS2KA 5 90Documento5 pagineTechnical Data: 150x100 FS2KA 5 90infonetsmgNessuna valutazione finora

- UB254 To UB457Documento7 pagineUB254 To UB457ihpeterNessuna valutazione finora

- Design of Steel ColumnDocumento7 pagineDesign of Steel ColumnKim Javier EstaNessuna valutazione finora

- Applicability of Caesar II For Stress Analysis of Lines Having DT Ratio More Than 100 PDFDocumento2 pagineApplicability of Caesar II For Stress Analysis of Lines Having DT Ratio More Than 100 PDFBogdan ChivulescuNessuna valutazione finora

- Steel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)Documento22 pagineSteel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)AlphaNessuna valutazione finora

- Storage Tank Design GuidelinesDocumento6 pagineStorage Tank Design GuidelinespaaryNessuna valutazione finora

- Clamp Design-2Documento6 pagineClamp Design-2Harpreet SinghNessuna valutazione finora

- SC348-ME-FDN-006 - RE - Foundation DrawingDocumento6 pagineSC348-ME-FDN-006 - RE - Foundation DrawingsajanNessuna valutazione finora

- CONNECTION: UB305X165X40BS5950 - Base Plate: AdminDocumento3 pagineCONNECTION: UB305X165X40BS5950 - Base Plate: AdminPNessuna valutazione finora

- CALCULO de Pullout de Pernos en ConcretoDocumento10 pagineCALCULO de Pullout de Pernos en ConcretoJuan Carlos VillalbaNessuna valutazione finora

- Trunnion 6 TonDocumento3 pagineTrunnion 6 TonEngr Khurram Jaan RamayNessuna valutazione finora

- 10 Stability of SlopesDocumento18 pagine10 Stability of Slopesامين الزريقيNessuna valutazione finora

- Pipe SupportsDocumento62 paginePipe Supportsmih1Nessuna valutazione finora

- Comp 2Documento9 pagineComp 2YYo YudiNessuna valutazione finora

- Eye Bolt CalculationDocumento4 pagineEye Bolt CalculationAlok KumarNessuna valutazione finora

- Stress analysis of buried cross-country pipingDocumento3 pagineStress analysis of buried cross-country pipingSharon LambertNessuna valutazione finora

- Boiler and Pressure Vessel Engineering - Vessel Nozzle LoadingDocumento7 pagineBoiler and Pressure Vessel Engineering - Vessel Nozzle Loadingvenkatrangan2003Nessuna valutazione finora

- Scholarly Survey of Steel-On-Steel Friction?Documento3 pagineScholarly Survey of Steel-On-Steel Friction?ktsnlNessuna valutazione finora

- Hvac Basics 4Documento74 pagineHvac Basics 4Sharon LambertNessuna valutazione finora

- Hvac BasicsDocumento73 pagineHvac BasicsSharon LambertNessuna valutazione finora

- 20170706140654483Documento66 pagine20170706140654483Sharon LambertNessuna valutazione finora

- JournalofBuildingPhysics 2012 Younes 267 302Documento37 pagineJournalofBuildingPhysics 2012 Younes 267 302Sharon LambertNessuna valutazione finora

- Duct SilencersDocumento125 pagineDuct SilencersesagcojrNessuna valutazione finora

- REQ 15 Sizing of Oil and Grease TrapsDocumento40 pagineREQ 15 Sizing of Oil and Grease TrapsSharon LambertNessuna valutazione finora

- Fundamentals of Water Distribution: TopicsDocumento89 pagineFundamentals of Water Distribution: TopicsRonald Kahora0% (1)

- 20170706140756729Documento36 pagine20170706140756729Sharon LambertNessuna valutazione finora

- HVAC Chilled Water Distribution SchemesDocumento56 pagineHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- Commercial Kitchen Design PDFDocumento21 pagineCommercial Kitchen Design PDFRocky WidjajaNessuna valutazione finora

- Background Noise Rating Calculator: InstructionsDocumento29 pagineBackground Noise Rating Calculator: InstructionsSharon LambertNessuna valutazione finora

- HVAC Duct Sizing GuideDocumento91 pagineHVAC Duct Sizing GuidePrabir Bhowmik100% (1)

- HVAC Expansion Tanks: Plain Steel vs. Bladder-Type: Air Control or Air EliminationDocumento4 pagineHVAC Expansion Tanks: Plain Steel vs. Bladder-Type: Air Control or Air EliminationSharon LambertNessuna valutazione finora

- AHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetDocumento17 pagineAHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetbinishNessuna valutazione finora

- Calculating Sump VolumeDocumento2 pagineCalculating Sump VolumeSharon LambertNessuna valutazione finora

- MD He Tema Asme v0.1Documento31 pagineMD He Tema Asme v0.1Sharon Lambert100% (1)

- Grease Trap Calculator 03Documento2 pagineGrease Trap Calculator 03Sharon LambertNessuna valutazione finora

- Test different beam configurations for bending stressDocumento3 pagineTest different beam configurations for bending stressSharon Lambert100% (1)

- MD He Tema Asme v0.1Documento31 pagineMD He Tema Asme v0.1Sharon Lambert100% (1)

- The Importance of Drying Compressed Air - Paerker BalstonDocumento12 pagineThe Importance of Drying Compressed Air - Paerker Balstonppluis90Nessuna valutazione finora

- Pipe and Fitting Calcs MasterDocumento8 paginePipe and Fitting Calcs MasterSharon LambertNessuna valutazione finora

- Expansion LoopDocumento54 pagineExpansion Loopsteepa22Nessuna valutazione finora

- Piping Pressure Drop Functions by Stephen Hall, PE: Pipe DataDocumento4 paginePiping Pressure Drop Functions by Stephen Hall, PE: Pipe DataSharon LambertNessuna valutazione finora

- Temperature Expansion PipesDocumento2 pagineTemperature Expansion PipesSharon LambertNessuna valutazione finora

- Recommended velocities and pressure drops for common process pipelinesDocumento5 pagineRecommended velocities and pressure drops for common process pipelinesger80Nessuna valutazione finora

- Wap 3 Ventilation WksheetDocumento7 pagineWap 3 Ventilation WksheetSharon LambertNessuna valutazione finora

- Pertes de Charge (Fluide Compressibles) V2Documento20 paginePertes de Charge (Fluide Compressibles) V2Sharon LambertNessuna valutazione finora

- Pressure Drop Calculation Equations For PIPING and PIPELINEDocumento3 paginePressure Drop Calculation Equations For PIPING and PIPELINETiano BaLajadia100% (4)

- AST Emergency Vent Flow Rates ChartDocumento3 pagineAST Emergency Vent Flow Rates ChartSharon LambertNessuna valutazione finora

- Equivalent Length Calculator - RevADocumento10 pagineEquivalent Length Calculator - RevArkrajan1502Nessuna valutazione finora

- CO2 Car Project Workbook 2010 ENGDocumento178 pagineCO2 Car Project Workbook 2010 ENGhamidhard100% (2)

- Determine pKa of Potassium Hydrogen Phthalate via Potentiometric TitrationDocumento5 pagineDetermine pKa of Potassium Hydrogen Phthalate via Potentiometric TitrationSheenly Anne SaavedraNessuna valutazione finora

- Ordinary Level Heat NotesDocumento44 pagineOrdinary Level Heat Notespatrick omonyNessuna valutazione finora

- Design and Optimization of Runner and Gating Systems For Permanent Mould CastingDocumento7 pagineDesign and Optimization of Runner and Gating Systems For Permanent Mould CastingJulie TremblayNessuna valutazione finora

- Homogeneous CoordinatesDocumento27 pagineHomogeneous CoordinatesGogyNessuna valutazione finora

- Contacts Modeling in AnsysDocumento74 pagineContacts Modeling in Ansyssudhirm16100% (2)

- Theory of Time MachineDocumento127 pagineTheory of Time MachineUday HiwaraleNessuna valutazione finora

- Inroduction To AnysisDocumento7 pagineInroduction To Anysissantosh gorliNessuna valutazione finora

- User Manual: Finite Element Model of 2016 Xenith X2E (Safety Equipment Institute Model X2E) Version 1.0 For LS-DYNADocumento41 pagineUser Manual: Finite Element Model of 2016 Xenith X2E (Safety Equipment Institute Model X2E) Version 1.0 For LS-DYNAchoopoNessuna valutazione finora

- ME8501 Metrology and Measurements PDFDocumento93 pagineME8501 Metrology and Measurements PDFpuneetNessuna valutazione finora

- Cross-Validation of Component Models: A Critical Look at Current MethodsDocumento12 pagineCross-Validation of Component Models: A Critical Look at Current MethodsDũng PhạmNessuna valutazione finora

- Design of New Biomedical Titanium Alloy Based On D-Electron Alloy Design Theory and JMatPro SoftwareDocumento6 pagineDesign of New Biomedical Titanium Alloy Based On D-Electron Alloy Design Theory and JMatPro SoftwareAbraão Santos SilvaNessuna valutazione finora

- Price ListDocumento3 paginePrice ListkiaangelieNessuna valutazione finora

- Tensile Testing Apparatus Design with 220000 N Load LimitDocumento5 pagineTensile Testing Apparatus Design with 220000 N Load LimitMunir EffendyNessuna valutazione finora

- Is - 807Documento47 pagineIs - 807Mohit Arora0% (1)

- Matrix Acidizing Course PDFDocumento74 pagineMatrix Acidizing Course PDFBehzad Hosseinzadeh100% (1)

- The Four Ethers: Contributions to Rudolf Steiner's Science of the EthersDocumento33 pagineThe Four Ethers: Contributions to Rudolf Steiner's Science of the EthersSolomanTrismosin100% (2)

- Calibration Report For Eurocode 1 On Wind ActionsDocumento4 pagineCalibration Report For Eurocode 1 On Wind ActionsIssa Kazeem KolawoleNessuna valutazione finora

- Relevance of Research in Social WorkDocumento15 pagineRelevance of Research in Social WorkangelgijoNessuna valutazione finora

- Pile RefereneDocumento24 paginePile RefereneamazonNessuna valutazione finora

- Unit 3 Potentiometry-II (PH Metry)Documento24 pagineUnit 3 Potentiometry-II (PH Metry)Nathanian100% (1)

- Science of Releasing: An Introduction To The 4-Stage Release RundownDocumento46 pagineScience of Releasing: An Introduction To The 4-Stage Release Rundownalkaro288% (8)

- Centurion University of Technology and Management: Recent Developments in Mechanical Engineering (Rdme - 2019)Documento5 pagineCenturion University of Technology and Management: Recent Developments in Mechanical Engineering (Rdme - 2019)Babuli KumarNessuna valutazione finora

- Caldera causa-efecto diagrama mantenimiento fallasDocumento2 pagineCaldera causa-efecto diagrama mantenimiento fallasDaniel Will Morales GuerreroNessuna valutazione finora

- DS-500 Series Weighing ScaleDocumento1 paginaDS-500 Series Weighing ScaleAntmavrNessuna valutazione finora

- FRP Column AbaqusDocumento14 pagineFRP Column AbaqusAlvin PurmawinataNessuna valutazione finora

- Organic Matter's Role in Copper ComplexationDocumento208 pagineOrganic Matter's Role in Copper ComplexationEveltonNessuna valutazione finora

- Closing The Gaps in Inertial Motion Tracking (MUSE - Magnitometer-Cenrtic Sensor Fusion) (Romit Roy Choudhury) (2018) (PPTX)Documento60 pagineClosing The Gaps in Inertial Motion Tracking (MUSE - Magnitometer-Cenrtic Sensor Fusion) (Romit Roy Choudhury) (2018) (PPTX)ip01Nessuna valutazione finora

- Microphone Calibration by Transfer Function Comparison MethodDocumento5 pagineMicrophone Calibration by Transfer Function Comparison MethodJulian A. TinaoNessuna valutazione finora

- Engineering and Chemical Thermodynamics 2e: Chapter 1 SolutionsDocumento41 pagineEngineering and Chemical Thermodynamics 2e: Chapter 1 SolutionsLalo RubioNessuna valutazione finora