Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bulk Deformation Processes Forging

Caricato da

IziCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bulk Deformation Processes Forging

Caricato da

IziCopyright:

Formati disponibili

LECTURE-08

BULK DEFORMATION PROCESSES

-FORGING

Nikhil R. Dhar, Ph.D

Department of Industrial & Production Engineering

BUET

Overview of Metal Forming

Metal forming can be classified as

Bulk deformation processes – generally characterized by significant

deformations and massive shape changes; and the surface area-to- volume of to

work is relatively small.

Forging

Extrusion

Rolling

Wire and bar drawing

Sheet metal forming process

Bending operations

Deep or cup drawing

Shearing processes

Miscellaneous

Lecture-3: Forging 11/2

Forging

Forging is a deformation process in which the work is compressed between two dies, using

either impact or gradual pressure to form the part. Today, forging is an important industrial

process used to make a variety of high-strength components for automotive, aerospace, and

other applications. These components include engine crankshafts and connecting rods, gears,

aircraft structural components, and jet engine turbine parts. In addition, steel and other basic

metals industries use forging to establish the basic forms of large components that are

subsequently machined to final shape and dimensions.

Forging is carried out in many different ways. One way to classify forging is by working

temperature. Most forging operations are performed hot or warm, owing to the significant

deformation demanded by the process and the need to reduce strength and increase ductility of

the work metal. However, cold forging is also very common for certain products. The

advantage of cold forging is the increased strength that results from strain hardening of the

component.

Either impact or gradual pressure is used in forging. The distinction derives more form the

type of equipment used than differences in process technology. A forging machine that applies

an impact load is called a forging hammer, while one that applies gradual pressure is called a

forging press. Another difference among forging operations is the degree to which the flow of

the work metal is constrained by the dies. By this classification there are three types of forging

operations like (i) Open-die forging, (ii) Impression or Close die forging and (iii)

Flashless Forging.

Lecture-3: Forging 11/3

Open-Die Forging

Most forging processes begin with open die forging. Open die forging is hot mechanical forming

between flat or shaped dies in which the metal flow is not completely restricted. The stock is laid on a

flat anvil while the flat face of the forging hammer is struck against the stock. The equipment may

range from the anvil and hammer to giant hydraulic presses.

Open-die hot forging is an important industrial process.

Shapes generated by open-die operations are simple;

examples include shafts, disks, and rings. In some

applications, the work must often be manipulated (for

example, rotating in steps) to effect the desired shape

change. Open-die forging process is shown in the following

Figure.

The skill of the human operator is a factor in the success of

these operations. An example of open-die forging in the steel

industry is the shaping of a large, square cast ingot into a

round cross section. Open-die forging operations produce

rough forms, and subsequent operations are required to

refine the parts to final geometry and dimensions.

Open-Die Forging

• An important contribution of open-die hot forging is that it creates favorable grain low and

metallurgical structure in the metal. Operations classified as open-die forging or related operations

include fullering, edging, and cogging, as shown in the next diagrams.

Lecture-3: Forging 11/4

Fullering is a forging operation performed to reduce the Fullering

cross section and redistribute the metal in a workpart

in preparation for subsequent shape forging.

It is accomplished by dies with convex surfaces.

Fullering die cavities are often used designed into

multicavity impression dies so that the starting bar can

be rough formed before final shaping. Edging

Edging is similar to fullering, except that the dies have

concave surfaces.

Cogging operation consists of a sequence of forging

compressions along the length of a workpiece to reduce

Cogging

cross section and increase length. It is used in the steel

industry to produce blooms and slabs from cast ingots.

It is accomplished using open dies with flat or slightly

contoured surfaces. The term incremental forging is

sometimes used for this process.

Lecture-3: Forging 11/5

Advantages and Limitations

Advantages

Simplest type of forging

Dies are inexpensive

Wide range of part sizes, ranging from 30-1000lbs

Good strength qualities

Generally good for small quantities

Limitations

Simple shapes only

difficult to hold close tolerances

machining necessary

low production rate

poor utilization of material

high skill required

Lecture-3: Forging 11/6

Impression or Close Die Forging

In impression-die forging,

so0metimes called closed die forging,

the die surfaces contain a shape or

impression that is imparted to the

work during compression, thus

constraining metal flow to a

significant degree as shown in

following Figure. In this type of

operation, a portion of the work metal

flows beyond the die impression to

form flash and must be trimmed off

later. The process is shown in the

following Figure as a three step

sequence. The raw workpiece is

shown as a cylindrical part similar to

that used in the previous open-die

operation. Impression die forging

Lecture-3: Forging 11/7

Advantages and Limitations

Advantages

Good utilization of material

Better properties than Open Die Forgings

Dies can be made of several pieces and inserts to create more advanced parts

Presses can go up to 50,000 ton capacities

Good dimensional accuracy

High production rates

Good reproducibility

Limitations

High die cost

Machining is often necessary

Economical for large quantities, but not for small quantities

Lecture-3: Forging 11/8

Flashless Forging

Flashless forging is sometimes called closed-die forging in industry terminology. However, there

is a technical distinction between impression-die forging and true closed-die forging. The

distinction is that in closed-die forging the raw workpiece is completely contained within the die

cavity during compression, and no flash is formed. This process is shown in the following figure.

Flashless forging imposes requirements on process control that are more demanding than

impression-die forging. Most important is that the work volume must equal the space in the die

cavity within a very close tolerance. If the starting blank is too large, excessive pressures may cause

damage to the die or even the press. If the blank is too small, the cavity will not be filled. Because

of the special demands made on flashless forging, the process lends itself best to part geometries

that are usually simple and symmetrical and to work materials such as aluminum and magnesium

and their alloys. Flashless forging is often classified as a precision forging process.

Flashless forging: (1) just before

initial contact with work piece

(2) partial compression and (3)

final punch and die closure.

v=velocity & F=applied force

Lecture-3: Forging 11/9

Advantages and Limitations

Advantages

Close dimensional tolerances

Very thin webs and flanges are possible

Very little or no machining is required

Little or no scrap after part is produced

Cheaper to produce from less finishing operations and faster production

Typical applications are gears, connecting rods, and turbine blades

Common materials used in precision forging are aluminum, magnesium alloys, steel, and

titanium

Limitations

High forging forces

Thus higher capacity equipment is required

Intricate dies leading to increased die cost

Precise control over the Blank’s volume and shape

Accurate positioning of the Blank in the die cavity

Lecture-3: Forging 11/10

Forging Operations

Coining is a special application of flashless forging in which fine details in the die

are impressed into the top and bottom surfaces of the workpart.

Closed-die forging process

Used for minting coins, medallions, & jewelry

Lubricants can not be used in coining

Can be used to improve surface finish

Lecture-3: Forging 14/11

Upsetting: Upsetting is a deformation operation in which a cylindrical workpart is

increased in diameter and reduced in length. However, as an industrial operation, it

can also be performed as closed-die forging, as shown in the following Figure.

Upsetting is widely used in the fastener industry to form the heads of nails, bolts,

and similar hardware products.

Lecture-3: Forging 14/12

Heading: The following Figure illustrates a variety of heading applications,

indicating various possible die configurations. Owing to these types of applications,

more parts are produced by upsetting than any other forging operation. It is

performed as a mass production operation - cold, warm, or hot - on special upset

forging machines, called headers or formers.

Care must be taken so that work piece does not buckle

Can be highly automated

Lecture-3: Forging 14/13

Swaging and Radial Forging: Swaging and radial forging are forging processes

used to educe the diameter of a tube or solid rod. Swaging is often performed on the

end of a workpiece to create a tapered section. The swaging process shown is

accomplished by means of rotating dies that hammer a workpiece radially inward to

taper it as the workpiece is fed into the dies. Radial forging is similar to swaging

in its action against the work and is used to create similar shapes. The difference is

that in radial forging the dies do not rotate around the workpiece; instead , the work

is rotated at it feeds into the hammering dies.

Lecture-3: Forging 14/14

Roll Forging: Roll forging is a deformation process used to reduce the cross

section of a cylindrical (or rectangular) workpiece by passing it through a set of

opposing rolls that have grooves matching the desired shape of the part. The typical

operation is shown in the following Figure. Roll forging is generally classified as a

forging process, even though it utilizes rolls. The rolls do not turn continuously in

roll forging, but rotate through only a portion of one revolution corresponding to the

desired deformation to be accomplished on the part. Roll-forged parts are generally

stronger and possess favorable grain structure compared to competing processes,

such as machining, that might be used to produce the same part geometry.

Lecture-3: Forging 14/15

Forging Machines

Equipment used in forging consists of forging machines, classified as forging

hammers and presses, and forging dies, which are the special tooling used in

these machines. In addition, auxiliary equipment is needed, such as furnaces to

heat the work, mechanical devices to load and unload the work, and trimming

stations to cut away the flash in impression-die forging.

Forging Hammers: Forging hammers operate by applying an impact load against

the work. The term drop hammer is often used for these machines, owing to the

means of delivering impact energy. Drop hammers are most frequently used or

impression-die forging. The upper portion of the forging die is attached to the ram,

and the lower portion to the anvil. In the operation, the work is placed on the lower

die, and the ram is lifted and then dropped. When the upper die strikes the work,

the impact energy causes the part to assume the form of the die cavity.

Lecture-3: Forging 14/16

Drop hammers can be classified as gravity

drop hammers and power drop

hammers.

Gravity drop hammers achieve their

energy by the falling weight of a heavy ram.

The force of the blow is determined by the

height of the drop and the weight of the

ram.

Power drop hammers accelerate the

ram by pressurized air or steam. One

disadvantage of the drop hammers is that a

large amount of the impact energy is

transmitted through the anvil and into the

floor of the building. This results in a great

deal of vibration for the surrounding area.

Lecture-3: Forging 14/17

Forging Presses: Presses apply gradual

pressure, rather than sudden impact, to

accomplish the forging operation. Forging

presses include mechanical presses,

hydraulic presses, and screw presses.

Mechanical presses typically operate by

means of eccentrics, cranks, or knuckle joints,

which convert the rotating motion of a drive

motor into the translational motion of the

ram. These mechanisms are very similar to

Mechanical Press

those used in stamping presses. Mechanical

presses typically achieve very high forces at Hydraulic Press

the bottom of the forging stroke.

Hydraulic presses use a hydraulically

driven piston to actuate the ram.

Screw presses apply force by a screw

mechanism that drives the vertical ram. Both

screw drive and hydraulic drive operate at

relatively low ram speeds and can provide a

constant force throughout the stroke. These

machines are therefore suitable for forging

(and other forming) operations that require a

long stroke.

Screw Press

Lecture-3: Forging 14/18

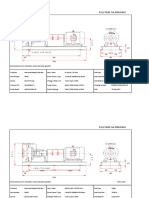

Terminology of Impression Die Forging

Proper die design is important in the success of a forging operation. Parts to be forged

must be designed based on knowledge of the principles and limitations of this process.

The purpose of the next slides is to describe some of the terminology and guidelines

used in the design of forgings and forging dies. Design of open dies is generally

straightforward since the dies are relatively simple in shape. The following details apply

to impression dies and closed dies. The following Figure shows some of the terminology

in an impression die.

Lecture-3: Forging 14/19

Parting line: The parting line is the plane that divides the upper die from the lower die.

Called the flash line in impression-die forging, it is the plane where the two die halves meet. Its

selection by the designer affects grain flow in the part, required load, and flash formation.

Draft: Draft is the amount of taper on the sides of the part required to remove it from the die.

The term also applies to the taper on the sides of the die cavity. Typical drat angles are 3o on

aluminum and magnesium parts and 5o to 7o on steel parts. Draft angles on precision forgings

are near zero.

Webs and ribs: A web is a thin portion of the forging that is parallel to the parting line, while

a rib is a thin portion that is perpendicular to the parting line. These part features cause

difficulty in metal low as they become thinner.

Lecture-3: Forging 14/20

Fillet and corner radii: Fillet and corner radii are shown in the diagram. Small

radii tend to limit metal flow and increase stresses on the die surfaces during

forging.

Flash: Flash formation plays a critical role in impression-die forging by causing

pressure buildup inside the die to promote filling of the cavity. This pressure

buildup is controlled by designing a flash land and gutter into the die as shown. The

land determines the surface area along which lateral flow of metal occurs, thereby

controlling the pressure increase inside the die. The gutter permits excess material

to escape without causing the forging load to reach extreme values

Lecture-3: Forging 14/21

Trimming

Trimming is an operation used to remove flash on the workpart in impression-die

forging. In most cases, trimming is accomplished by shearing, as shown in the next

slide, in which a punch forces the work through a cutting die, the blades for which

have the profile of the desired part.

Trimming is usually done while the work is still hot, which means the that a separate

trimming press is included at each forging hammer or press. In cases where the

work might be damaged by the cutting process, trimming may be done by

alternative methods, such as grinding or sawing.

Trimming operation

(shearing process) to

remove the flash after

impression die forging

Lecture-3: Forging 14/22

Lecture-3: Forging 14/23

Potrebbero piacerti anche

- Bulk Deformation Processes-ForgingDocumento14 pagineBulk Deformation Processes-ForgingIziNessuna valutazione finora

- Hot and Cold WorkingDocumento34 pagineHot and Cold WorkingSam RonnyNessuna valutazione finora

- Extrusion ProcessDocumento24 pagineExtrusion Processchris mushunjeNessuna valutazione finora

- Casting (Metalworking) : Navigation SearchDocumento26 pagineCasting (Metalworking) : Navigation SearchDion Satya GuntaraNessuna valutazione finora

- MD Design ConsiderationDocumento18 pagineMD Design ConsiderationjhpatelNessuna valutazione finora

- ForgingDocumento38 pagineForgingapi-2636010075% (4)

- MP Lecture Unit 3 FormingDocumento21 pagineMP Lecture Unit 3 Formingaakash sharmaNessuna valutazione finora

- Module 2 - Rolling ProcessDocumento51 pagineModule 2 - Rolling Processarun t nNessuna valutazione finora

- Permanent Mold Casting Module - 2BDocumento107 paginePermanent Mold Casting Module - 2BZeeshan RafiqNessuna valutazione finora

- Solidification of MetalsDocumento13 pagineSolidification of MetalsDalitso TemboNessuna valutazione finora

- Powder Metallurgy: Basics & Applications Powder MetallurgyDocumento11 paginePowder Metallurgy: Basics & Applications Powder MetallurgyVivek BajpaiNessuna valutazione finora

- Note CHP 3 Material Science 281 Uitm Em110Documento40 pagineNote CHP 3 Material Science 281 Uitm Em110bino_ryeNessuna valutazione finora

- Metal Casting Guide: Risers, Solidification Times & MoreDocumento8 pagineMetal Casting Guide: Risers, Solidification Times & MoreYash DesaaiNessuna valutazione finora

- Theory of Metal Cutting ExplainedDocumento2 pagineTheory of Metal Cutting ExplainedShivanshu shekhar100% (1)

- Forging: Shaping Materials Through Compressive ForcesDocumento20 pagineForging: Shaping Materials Through Compressive ForcesRam Janm SinghNessuna valutazione finora

- Shaping & Grinding and Realated OperationsDocumento26 pagineShaping & Grinding and Realated OperationsIzi86% (7)

- High Energy Rate Forming ProcessDocumento8 pagineHigh Energy Rate Forming Processjasonmani90Nessuna valutazione finora

- Aluminum Die Casting Process FlowDocumento13 pagineAluminum Die Casting Process FlowPrabish KumarNessuna valutazione finora

- MFG Tooling - 09 Progressive Dies PDFDocumento16 pagineMFG Tooling - 09 Progressive Dies PDFNhan LeNessuna valutazione finora

- Metal Forming Machines: PressesDocumento35 pagineMetal Forming Machines: PressesMohammed Alnashar0% (1)

- MP 1st Module NotesDocumento39 pagineMP 1st Module NotesKailas Sree ChandranNessuna valutazione finora

- Thesis (V Nashine)Documento95 pagineThesis (V Nashine)Salil JainNessuna valutazione finora

- 30 Super Finishing ProcessesDocumento14 pagine30 Super Finishing ProcessesPRASAD326100% (5)

- Metal Casting 3Documento23 pagineMetal Casting 3bhushan wandreNessuna valutazione finora

- Internship Experience at Peenya Fine Comp Pvt LtdDocumento22 pagineInternship Experience at Peenya Fine Comp Pvt LtdMohammed imran100% (1)

- ME 2202 Casting Gating SystemsDocumento67 pagineME 2202 Casting Gating Systemsyash guptaNessuna valutazione finora

- Module 5 Design of Components With Forging ConsiderationDocumento34 pagineModule 5 Design of Components With Forging ConsiderationMaheshNessuna valutazione finora

- Design of 3000 Ton Forge PressDocumento16 pagineDesign of 3000 Ton Forge PressSwaroopReddyNessuna valutazione finora

- MPS PPT Radial ForgingDocumento11 pagineMPS PPT Radial Forgingaashay shewareNessuna valutazione finora

- Foundry Technology GuideDocumento34 pagineFoundry Technology GuidePranav Pandey100% (1)

- Selective Laser SinteringDocumento16 pagineSelective Laser Sinteringnikhil_prasanthNessuna valutazione finora

- Ch21 Fundamentals of Cutting2Documento70 pagineCh21 Fundamentals of Cutting2manojc68Nessuna valutazione finora

- Turning and Drilling PPT MFG Chapter23 FinalDocumento78 pagineTurning and Drilling PPT MFG Chapter23 FinalRavichandran GNessuna valutazione finora

- Presses and Equipment For SheetMetal DiesDocumento153 paginePresses and Equipment For SheetMetal Diessamurai7_77Nessuna valutazione finora

- I Unit - Introduction To Unconventional Machining ProcessesDocumento19 pagineI Unit - Introduction To Unconventional Machining ProcessesRavichandran GNessuna valutazione finora

- SURFACE FINISHING PROCESSDocumento37 pagineSURFACE FINISHING PROCESSramadanNessuna valutazione finora

- Observation of Defects in Cast Iron Castings by Surface AnalysisDocumento19 pagineObservation of Defects in Cast Iron Castings by Surface Analysisgonzalo gimenez100% (1)

- Unit - Iii: Metal Forming ProcessesDocumento63 pagineUnit - Iii: Metal Forming ProcessesRohith RoNessuna valutazione finora

- TRAINING REPORT ON ESCORT INDIA PVT. LTDDocumento34 pagineTRAINING REPORT ON ESCORT INDIA PVT. LTDVarun AggarwalNessuna valutazione finora

- Everything You Need to Know About Rolling of MetalsDocumento28 pagineEverything You Need to Know About Rolling of MetalsSaiful Islam100% (1)

- Forming Processes (MP Module 3)Documento77 pagineForming Processes (MP Module 3)Kailas Sree ChandranNessuna valutazione finora

- Metal Forming Processes GuideDocumento32 pagineMetal Forming Processes GuideWalid DamoniNessuna valutazione finora

- Thin Wall Pressure VesselsDocumento20 pagineThin Wall Pressure VesselsTare Er KshitijNessuna valutazione finora

- Icejet Machining2Documento24 pagineIcejet Machining2Yadu Krishna50% (2)

- Sheet Metal Forming Techniques and DefectsDocumento52 pagineSheet Metal Forming Techniques and Defectsmandakini baskeyNessuna valutazione finora

- How to Make a Slot Using a Shaper MachineDocumento4 pagineHow to Make a Slot Using a Shaper MachineMD Mahmudul Hasan MasudNessuna valutazione finora

- Rolling Mill Guide: Types and Metal Forming ProcessDocumento2 pagineRolling Mill Guide: Types and Metal Forming Processnanda rizkyNessuna valutazione finora

- Plasma Arc MachiningDocumento18 paginePlasma Arc MachiningStephen WeiNessuna valutazione finora

- Chapter 4 Metal CuttingDocumento45 pagineChapter 4 Metal Cuttingamr23Nessuna valutazione finora

- Regulation 2013 Me 6352 Manufacturing Technology Notes - PmsDocumento164 pagineRegulation 2013 Me 6352 Manufacturing Technology Notes - PmsSubramanian PmNessuna valutazione finora

- Ultrasonic Machining SeminarDocumento11 pagineUltrasonic Machining Seminarhyundai31050% (2)

- Total Quality ManagementDocumento36 pagineTotal Quality Managementfonsekapdl100% (1)

- 05 Ch3 ForgingDocumento26 pagine05 Ch3 ForgingKamil BudimanNessuna valutazione finora

- Drop ForgingDocumento5 pagineDrop ForgingVishnu Attitude CountsNessuna valutazione finora

- Metal Forming Processes Guide: Forging, Rolling & MoreDocumento46 pagineMetal Forming Processes Guide: Forging, Rolling & MorearhlboyNessuna valutazione finora

- Proses Tempa (Forging) : Aris Hendaryanto, S.T., M.Eng. Departemen Teknik Mesin SV-UGMDocumento31 pagineProses Tempa (Forging) : Aris Hendaryanto, S.T., M.Eng. Departemen Teknik Mesin SV-UGMHisyam Abdul AzizNessuna valutazione finora

- Study of Forging Process Equipemnts-Practical-3Documento12 pagineStudy of Forging Process Equipemnts-Practical-3prashantNessuna valutazione finora

- LO #2 Metal Froming Processes 201810Documento46 pagineLO #2 Metal Froming Processes 201810Rymshah MoezNessuna valutazione finora

- Manufacturing Engineering II (ch3)Documento111 pagineManufacturing Engineering II (ch3)AlemNessuna valutazione finora

- Classification of Forming & Shaping Processes & EquipmentDocumento51 pagineClassification of Forming & Shaping Processes & EquipmentFarman AliNessuna valutazione finora

- openLCA 1.10.2 User-ManualDocumento127 pagineopenLCA 1.10.2 User-ManualIziNessuna valutazione finora

- World Energy Scenarios - Composing Energy Futures To 2050 - Executive Summary PDFDocumento44 pagineWorld Energy Scenarios - Composing Energy Futures To 2050 - Executive Summary PDFAmir HussainNessuna valutazione finora

- Guide Driving TestDocumento44 pagineGuide Driving TestDennis OngNessuna valutazione finora

- Australian Cotton Industry - CheckedDocumento2 pagineAustralian Cotton Industry - CheckedIziNessuna valutazione finora

- Diesel Fuel InjectionDocumento5 pagineDiesel Fuel InjectionIziNessuna valutazione finora

- Form 1496i Family VisaDocumento2 pagineForm 1496i Family VisaIziNessuna valutazione finora

- 1442 IDocumento6 pagine1442 IIziNessuna valutazione finora

- Australian Wheat Industry - CheckedDocumento2 pagineAustralian Wheat Industry - CheckedIziNessuna valutazione finora

- User ManualDocumento18 pagineUser ManualIziNessuna valutazione finora

- Alzheimer's Disease: Memory Loss and Brain DegenerationDocumento1 paginaAlzheimer's Disease: Memory Loss and Brain DegenerationIziNessuna valutazione finora

- Australian Cotton IndustryDocumento1 paginaAustralian Cotton IndustryIziNessuna valutazione finora

- Vortex 95 MsdsDocumento13 pagineVortex 95 MsdsIziNessuna valutazione finora

- Alzheimer CheckedDocumento2 pagineAlzheimer CheckedIziNessuna valutazione finora

- Australian Wheat IndustryDocumento1 paginaAustralian Wheat IndustryIziNessuna valutazione finora

- Handout15 6333 PDFDocumento17 pagineHandout15 6333 PDFIziNessuna valutazione finora

- Calculating Standard Error Bars For A GraphDocumento6 pagineCalculating Standard Error Bars For A GraphKona MenyongaNessuna valutazione finora

- Hybrid Electric VehicleDocumento33 pagineHybrid Electric VehicleIzi75% (4)

- World Energy Assessment-2000Documento506 pagineWorld Energy Assessment-2000IziNessuna valutazione finora

- Wang 2011 Bio Spary IgnitionDocumento7 pagineWang 2011 Bio Spary IgnitionIziNessuna valutazione finora

- Usb 1616hs BNCDocumento49 pagineUsb 1616hs BNCIziNessuna valutazione finora

- DOP Test ProtocolDocumento10 pagineDOP Test ProtocolIzi100% (2)

- Zakat GuideDocumento15 pagineZakat GuideIziNessuna valutazione finora

- FtirDocumento21 pagineFtirGaurav AcharyaNessuna valutazione finora

- Usb 1616hs BNC SpecDocumento8 pagineUsb 1616hs BNC SpecIziNessuna valutazione finora

- Heat Flux Sensors Measure Fast Surface Temp ChangesDocumento2 pagineHeat Flux Sensors Measure Fast Surface Temp ChangesIziNessuna valutazione finora

- GRE Words ListDocumento2 pagineGRE Words ListIziNessuna valutazione finora

- Unit 7Documento39 pagineUnit 7vijay_oraerp1711Nessuna valutazione finora

- Duct DesignDocumento9 pagineDuct DesignjaswanthNessuna valutazione finora

- Sinus SamuraiDocumento5 pagineSinus SamuraiIziNessuna valutazione finora

- ASTM Biodiesel SpecDocumento1 paginaASTM Biodiesel SpecIziNessuna valutazione finora

- Knuckle Joints DesignDocumento10 pagineKnuckle Joints DesignKvrd Prasad100% (1)

- GA Drawings of Industrial PumpsDocumento9 pagineGA Drawings of Industrial PumpsTheepa SubramaniamNessuna valutazione finora

- To11c5 e 00 PDFDocumento526 pagineTo11c5 e 00 PDFGradimir MilanovicNessuna valutazione finora

- On-Site Operation Training Record Card: Pangkalan Susu Coal Fired Steam Power Plant Project Unit 3&4 2X200MWDocumento3 pagineOn-Site Operation Training Record Card: Pangkalan Susu Coal Fired Steam Power Plant Project Unit 3&4 2X200MWajambookNessuna valutazione finora

- Trane XR202 Programmable Thermostat: TCONT202AS11MA Installation and User GuideDocumento12 pagineTrane XR202 Programmable Thermostat: TCONT202AS11MA Installation and User GuideOsvaldo Milla100% (2)

- Shell Lubricants Albida Alvania Multiservice GreasesDocumento1 paginaShell Lubricants Albida Alvania Multiservice GreasesvinothNessuna valutazione finora

- Performance Requirements: CEN Standard EN 16798-3:2017 On Ventilation For Non-Residential BuildingsDocumento7 paginePerformance Requirements: CEN Standard EN 16798-3:2017 On Ventilation For Non-Residential BuildingsLuca CarusoNessuna valutazione finora

- CAT C13 2007 Service Bulletin (Cooling Sys, DPF, and Diagnostic Trouble Codes)Documento34 pagineCAT C13 2007 Service Bulletin (Cooling Sys, DPF, and Diagnostic Trouble Codes)Jonathan Carlson100% (4)

- EUROPART Inter Catalog Bus Spare Parts 2014-09 EN PDFDocumento778 pagineEUROPART Inter Catalog Bus Spare Parts 2014-09 EN PDFludiloliku67% (3)

- Mechanical Engineer Muhammad Ibtisam's ResumeDocumento1 paginaMechanical Engineer Muhammad Ibtisam's ResumeshoaibNessuna valutazione finora

- TOOLSDocumento5 pagineTOOLSLoraine SenilloNessuna valutazione finora

- Science: Quarter 3 - Module 1: FrictionDocumento29 pagineScience: Quarter 3 - Module 1: FrictionTrisTan Dolojan100% (1)

- Fluids and Buoyancy QuizDocumento2 pagineFluids and Buoyancy QuizWaleed El ShirbeenyNessuna valutazione finora

- Rules for Classification of Ships: Part C Machinery, Systems and Fire ProtectionDocumento485 pagineRules for Classification of Ships: Part C Machinery, Systems and Fire ProtectionTordillo ECV56Nessuna valutazione finora

- Zubair Oil Field Development Project: Eni Iraq B.VDocumento17 pagineZubair Oil Field Development Project: Eni Iraq B.VMohammed HijaziNessuna valutazione finora

- TOX FinePress 45 201201 enDocumento16 pagineTOX FinePress 45 201201 enSirbu SorinNessuna valutazione finora

- The Basics of Shoulder ScrewsDocumento5 pagineThe Basics of Shoulder ScrewsOliver SulibitNessuna valutazione finora

- Chung2006 PDFDocumento9 pagineChung2006 PDFNguyen Tran HieuNessuna valutazione finora

- Kobelco 70SR: The Most Awesome 7-Ton Excavator Under 40 CharactersDocumento16 pagineKobelco 70SR: The Most Awesome 7-Ton Excavator Under 40 Charactershaiccdk6Nessuna valutazione finora

- Structural Steel Design: DR - Mu'taz K.M Ass - Prof. in Civil EngineeringDocumento13 pagineStructural Steel Design: DR - Mu'taz K.M Ass - Prof. in Civil EngineeringZeeshan MunirNessuna valutazione finora

- ISO 9001 Certified U4.70-U4.250 Series Oil-Flooded Vacuum PumpsDocumento4 pagineISO 9001 Certified U4.70-U4.250 Series Oil-Flooded Vacuum PumpsAndy MulyonoNessuna valutazione finora

- Road Crossing Method of StatementDocumento4 pagineRoad Crossing Method of StatementKo Zay100% (1)

- Somar Integra Executive Summary.r2Documento3 pagineSomar Integra Executive Summary.r2vanessa_corneliaNessuna valutazione finora

- Standard Equipment: Hitachi Construction Machinery Co., LTDDocumento15 pagineStandard Equipment: Hitachi Construction Machinery Co., LTDDemo OnlyNessuna valutazione finora

- (PDF) Metal Casting Processes QUALITATIVE PROBLEMS Trien Nguyen - Academia - EduDocumento1 pagina(PDF) Metal Casting Processes QUALITATIVE PROBLEMS Trien Nguyen - Academia - EduAlii AlliNessuna valutazione finora

- SM-McCormick ZTX230 ZTX260 ZTX280 TRACTOR Service Repair ManualDocumento66 pagineSM-McCormick ZTX230 ZTX260 ZTX280 TRACTOR Service Repair ManualRiahi Rezeg20% (5)

- Slip and Crystallographic TexturesDocumento34 pagineSlip and Crystallographic TexturesSunkulp GoelNessuna valutazione finora

- Bottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofDocumento8 pagineBottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofsenaNessuna valutazione finora

- Mcdonnell & Miller Service Parts CatalogDocumento76 pagineMcdonnell & Miller Service Parts Catalogkamran shahNessuna valutazione finora

- Printable Flashcard On API 570 Flashcards - Free Flash CardsDocumento3 paginePrintable Flashcard On API 570 Flashcards - Free Flash Cardstipu321Nessuna valutazione finora