Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

JH Step 1 Audit Sheet

Caricato da

Swayambhar MajumderCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

JH Step 1 Audit Sheet

Caricato da

Swayambhar MajumderCopyright:

Formati disponibili

ISPAT INDUSTRIES

DEPT:

S.No

1 2 3

JISHU-HOZEN AUDIT SHEET(1st STEP) M/C:

Audit Levels

L1 - Self Audit L2 - Audit by Sectional Head L3 - Audit by TPM Secretariat

Passing %

90 80 80

L1

Obtained % L2 L3

REMARKS

1

1.1 1.2

Item If the cleaning is through?

Floor below and around the machine. Any other areas.

Marks Allocated Marks Obtained 30

15 15

2 3

3.1 3.2 3.3 3.4 3.5

Any oil / air/ water leakages Are nuts/bolts properly provided?

Missing Loose Without Washer (Where Applicable) Non standard Of more than required length 10 10 10 10 10

50 50

4

4.1 4.2 4.3 4.4 4.5

Wire/cable/electrical

Any loose wires/cables Loose wire/cable more than required length Without glands (Where Applicable) Wires/cables tied without clamps Panels/covers not fully sealed/closed. Any item arround machine without allocated place 10 10 10 10 10

50

5

5.1

Items arround Machine Unsafe conditions

20

20

6

6.1 6.2 6.3 6.4

60

15 15 15 15

Safety gaurds not available Safety guard provided but may cause accident Floor around m/c with pits & projections Sllipery areas around machine

7

7.1 7.2 7.3 7.4

Unaccessible areas identified

Hard to see Hard to perform Hard to clean Hard to lubricate 5 5 5 5

20

8

8.1 8.2 8.3

If the personnel associated with the m/c (claener/operator/ supervisor/manager) clear about TPM.

What is Autonomous Maintenance? What is 1st step of Autonomous Maintenance? What are the defects and type of defects? 20 20 20

60

9

9.1 9.2 9.3 9.4 9.5 9.6 9.7 9.8

If Activity Board provided and process followed?

Team Member. Manager Model Machine marked with yellow line. Pre tentative Standards. Attendance sheet. Individual attendance. Fugai(Defect sheet) Classification defect Gains & 1st step TOTAL Signature: 7 7 7 7 7 7 7 11

60

400

* For every one incidence reduce 25% Marks

TPM Secretariat JH 01/1/NOV02

ISPAT INDUSTRIES

Auditor: Audit Date:

TPM Secretariat JH 01/1/NOV02

Potrebbero piacerti anche

- Toshiba SSA-340A Ultrasound - Diagnostic Function ManualDocumento160 pagineToshiba SSA-340A Ultrasound - Diagnostic Function Manualperla_canto_1100% (4)

- 5 KK PillarDocumento54 pagine5 KK Pillarazadsingh183% (6)

- Jishu Hozen: Presentation By: V.P.SINGHDocumento41 pagineJishu Hozen: Presentation By: V.P.SINGHAbhishek Xc57% (7)

- Slide TPM SHEDocumento14 pagineSlide TPM SHEhdjdjNessuna valutazione finora

- Jishu Hozen - AM PDFDocumento48 pagineJishu Hozen - AM PDFDicky Hartanto100% (1)

- CII JH Step 4Documento4 pagineCII JH Step 4Kumar Swami0% (1)

- Jishu Hozen NotesDocumento13 pagineJishu Hozen NotesPrathmesh AwasthiNessuna valutazione finora

- Autonomous Maintenance Step 1-7Documento18 pagineAutonomous Maintenance Step 1-7riade8883% (6)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDa EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionValutazione: 4.5 su 5 stelle4.5/5 (3)

- SMJ100A Service Manual eDocumento258 pagineSMJ100A Service Manual emarian1_work100% (1)

- Autonomous MaintenanceDocumento38 pagineAutonomous Maintenancechusz100% (1)

- Example One Point LessonsDocumento6 pagineExample One Point Lessonssbtharan100% (1)

- Chapter 5. Jishu Hozen ManualDocumento71 pagineChapter 5. Jishu Hozen ManualVivek Kumar100% (3)

- TPM JH PPT 01 JH AwarenessDocumento28 pagineTPM JH PPT 01 JH AwarenessLakshmanan Venkatesan100% (1)

- TPM Jipm Seiichi Nakajima 2007 KlmanagementDocumento40 pagineTPM Jipm Seiichi Nakajima 2007 KlmanagementDipankar MukherjeeNessuna valutazione finora

- Study of JH Implementation ReadyDocumento27 pagineStudy of JH Implementation ReadyNaveen Jangid100% (1)

- KK Pillar PDFDocumento91 pagineKK Pillar PDFdiwesh26decNessuna valutazione finora

- TPM and The Extended Supply Chain: Tetra Pak Production D.O.O. Gornji Milanovac, Serbia London, Nov 2016Documento36 pagineTPM and The Extended Supply Chain: Tetra Pak Production D.O.O. Gornji Milanovac, Serbia London, Nov 2016Hossam Abdel AzizNessuna valutazione finora

- TPM ChecklistDocumento14 pagineTPM Checklistmuneerpp100% (2)

- JH PillarDocumento39 pagineJH PillarshaktiNessuna valutazione finora

- Autonomous Maintenance Step 3 Audit SheetDocumento6 pagineAutonomous Maintenance Step 3 Audit Sheetrecep1Nessuna valutazione finora

- Autonomous Maintenance Step 1 7Documento18 pagineAutonomous Maintenance Step 1 7Dũng Tây NinhNessuna valutazione finora

- Training ON TPM: Rapl Production SystemDocumento25 pagineTraining ON TPM: Rapl Production Systemabhijit bhattacherjeENessuna valutazione finora

- Apply The E.C.R.S. Technique and Identify Improvement Actions: Mechanise Some MovementsDocumento13 pagineApply The E.C.R.S. Technique and Identify Improvement Actions: Mechanise Some MovementsRahul RawatNessuna valutazione finora

- Master KaizensDocumento52 pagineMaster KaizensNagarajan100% (1)

- TPMDocumento34 pagineTPMJagdeep BajwaNessuna valutazione finora

- E & Tpillar: Education & Training Pillar ActivitiesDocumento21 pagineE & Tpillar: Education & Training Pillar Activitiessamkaria rajeshNessuna valutazione finora

- Chapter 6. Education & Training ManualDocumento23 pagineChapter 6. Education & Training ManualVivek KumarNessuna valutazione finora

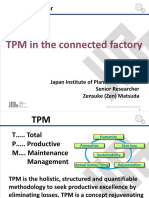

- JIPM MR Matsuda - TPM in The Connected Factory PDFDocumento30 pagineJIPM MR Matsuda - TPM in The Connected Factory PDFSelvaraj Simiyon100% (2)

- JH Step-1 & 2activitiesDocumento34 pagineJH Step-1 & 2activitiesGREENEXE BUSINESS CONSULTANTNessuna valutazione finora

- DOJO CurriculumDocumento47 pagineDOJO CurriculumGulshan SaxenaNessuna valutazione finora

- MT QM PillarDocumento71 pagineMT QM Pillarazadsingh1Nessuna valutazione finora

- OEE PresentationDocumento33 pagineOEE PresentationRoshan YaduwanshiNessuna valutazione finora

- Professional MaintenanceDocumento391 pagineProfessional MaintenanceAimar Vanderlei Ferreira Filho100% (1)

- Step 0 and 1 Management Part 1Documento14 pagineStep 0 and 1 Management Part 1murilocabriniNessuna valutazione finora

- VSM PDFDocumento52 pagineVSM PDFChip ChopNessuna valutazione finora

- TPM Basics and Am Step 1 To 5Documento90 pagineTPM Basics and Am Step 1 To 5Gaurav Mittal100% (5)

- ABC Type DefectsDocumento17 pagineABC Type DefectsMayank Dadhich100% (2)

- Autonomous MaintenanceDocumento32 pagineAutonomous Maintenanceanoopkchand100% (3)

- Jishu Hozen Step 1Documento27 pagineJishu Hozen Step 1Prateep UntimanonNessuna valutazione finora

- Relation Between 7 Major Losses of Equipment and Overall Equipment EfficiencyDocumento2 pagineRelation Between 7 Major Losses of Equipment and Overall Equipment EfficiencySwapnil KhadeNessuna valutazione finora

- 5.6 Office TPM and Concept of PQCDSMDocumento9 pagine5.6 Office TPM and Concept of PQCDSMvenkata_776555228100% (1)

- 16 LossesDocumento27 pagine16 LossesAshrith SNessuna valutazione finora

- TPM Steps 1 JHDocumento10 pagineTPM Steps 1 JHGyanesh_DBNessuna valutazione finora

- TPM Pillar Management Index & Activity IndexDocumento12 pagineTPM Pillar Management Index & Activity Indexrarues9999Nessuna valutazione finora

- Ems KaizenDocumento4 pagineEms KaizenJogender KumarNessuna valutazione finora

- TPM Kick-Off: Newsletter From CII TPM Club IndiaDocumento6 pagineTPM Kick-Off: Newsletter From CII TPM Club IndiaNarendran100% (1)

- TPM AwarenessDocumento51 pagineTPM AwarenessDeepak kumarNessuna valutazione finora

- TPM IntroductionDocumento61 pagineTPM IntroductionDhriti GoswamiNessuna valutazione finora

- Autonomous Maintenance Step 4 Lubrication ModuleDocumento30 pagineAutonomous Maintenance Step 4 Lubrication ModulejesusmemNessuna valutazione finora

- TPM Basic TrainingDocumento38 pagineTPM Basic TrainingRaj Singh80% (5)

- JIPM - Original - QC StoryDocumento18 pagineJIPM - Original - QC StoryVỸ TRẦNNessuna valutazione finora

- Event TPM JipmDocumento29 pagineEvent TPM JipmImamRN100% (3)

- 06 - PMDocumento113 pagine06 - PMMohaiminNessuna valutazione finora

- TPM Equipment ImprovementDocumento22 pagineTPM Equipment Improvementrameshv2801Nessuna valutazione finora

- TPM: Total Productive MaintenanceDocumento88 pagineTPM: Total Productive MaintenanceManu SharmaNessuna valutazione finora

- JH Step 1 Audit SheetDocumento2 pagineJH Step 1 Audit SheetHeena Gulati (Quality)Nessuna valutazione finora

- TCCL IttihadforPrcrCmntsDocumento22 pagineTCCL IttihadforPrcrCmntshisham1958Nessuna valutazione finora

- Blue 7 TPM Part 2 of 2Documento14 pagineBlue 7 TPM Part 2 of 2shamelnaNessuna valutazione finora

- Eliminate All Loss Opportunities: Total Productive MaintenanceDocumento28 pagineEliminate All Loss Opportunities: Total Productive MaintenancePrabhat SharmaNessuna valutazione finora

- Anant SPG MOM 7-08-18Documento4 pagineAnant SPG MOM 7-08-18Abhimanyu Singh ChundawatNessuna valutazione finora

- 3 3bb0aDocumento7 pagine3 3bb0aEleandro JoaquimNessuna valutazione finora

- OSDDocumento1 paginaOSDSwayambhar MajumderNessuna valutazione finora

- Bancil CorporationDocumento1 paginaBancil CorporationSwayambhar MajumderNessuna valutazione finora

- Background Problem: Executive Summary - Western State University CaseDocumento1 paginaBackground Problem: Executive Summary - Western State University CaseSwayambhar MajumderNessuna valutazione finora

- Overview of TPM ImplementationDocumento24 pagineOverview of TPM ImplementationSwayambhar MajumderNessuna valutazione finora

- Gim TM 2013 A4 PDFDocumento11 pagineGim TM 2013 A4 PDFSwayambhar MajumderNessuna valutazione finora

- Gim Elite PDFDocumento10 pagineGim Elite PDFSwayambhar MajumderNessuna valutazione finora

- Indian Media and Entertainment Industry Report 2013Documento202 pagineIndian Media and Entertainment Industry Report 2013Iyer ShankarNessuna valutazione finora

- Sunil Pandey Toyota JIT&KanbanDocumento6 pagineSunil Pandey Toyota JIT&KanbanSunil PandeyNessuna valutazione finora

- MISCases 2012Documento116 pagineMISCases 2012Norsiah ShukeriNessuna valutazione finora

- Sun Vs Zee PDFDocumento31 pagineSun Vs Zee PDFSwayambhar MajumderNessuna valutazione finora

- OP Assignment1 - Learning by SupplyingDocumento40 pagineOP Assignment1 - Learning by SupplyingSwayambhar MajumderNessuna valutazione finora

- Organization & Information Systems: Who Follows Whom?Documento9 pagineOrganization & Information Systems: Who Follows Whom?Swayambhar MajumderNessuna valutazione finora

- MISCases 2012Documento116 pagineMISCases 2012Norsiah ShukeriNessuna valutazione finora

- Clean Edge RazorDocumento4 pagineClean Edge RazorSwayambhar MajumderNessuna valutazione finora

- Case 3-1 - Cathay Pacific - Doing More With LessDocumento26 pagineCase 3-1 - Cathay Pacific - Doing More With LessSwayambhar Majumder100% (1)

- 161012HRM22GWSHOSPITALDocumento5 pagine161012HRM22GWSHOSPITALSwayambhar MajumderNessuna valutazione finora

- Gws Hospital:Manpowr Planning: Human Resource ManagmentDocumento6 pagineGws Hospital:Manpowr Planning: Human Resource ManagmentSwayambhar MajumderNessuna valutazione finora

- Swayambhar MajumderDocumento2 pagineSwayambhar MajumderSwayambhar MajumderNessuna valutazione finora

- Big Data 101 Brief PDFDocumento4 pagineBig Data 101 Brief PDFAruna PattamNessuna valutazione finora

- GA-Z270-Gaming 3: User's ManualDocumento44 pagineGA-Z270-Gaming 3: User's ManualThiago LadeiraNessuna valutazione finora

- Data RepresentationDocumento21 pagineData RepresentationVikas KumarNessuna valutazione finora

- Intel Wireless-Ac-9260 PDFDocumento1 paginaIntel Wireless-Ac-9260 PDFJohn SmithNessuna valutazione finora

- Ve Project DebutDocumento8 pagineVe Project DebutpkmwNessuna valutazione finora

- Advanced Topics&Reference GuideDocumento202 pagineAdvanced Topics&Reference GuideRoberto Hernandez Ameca100% (1)

- DM0100410UAF Model 010041 Users ManualDocumento16 pagineDM0100410UAF Model 010041 Users ManualpozadaomarNessuna valutazione finora

- PV Elite QuickStartDocumento51 paginePV Elite QuickStartYahiaNessuna valutazione finora

- ARM Processors and Architectures - Uni ProgramDocumento81 pagineARM Processors and Architectures - Uni ProgramSaavin AbeygunawardenaNessuna valutazione finora

- Institute of Aeronautical Engineering: P2PMOBILE: A Framework For Remote Execution in Mobile EnvironmentDocumento12 pagineInstitute of Aeronautical Engineering: P2PMOBILE: A Framework For Remote Execution in Mobile EnvironmentGibbs RodrixNessuna valutazione finora

- Emco Concept Turn 450 enDocumento6 pagineEmco Concept Turn 450 enMilea Nicolae-MariusNessuna valutazione finora

- Squid Proxy Configuration GuideDocumento28 pagineSquid Proxy Configuration GuideEdmund OchiengNessuna valutazione finora

- Asrock Thunderbolt 3 AICDocumento3 pagineAsrock Thunderbolt 3 AICed_coNessuna valutazione finora

- Dell Latitude 7212 Rugged Extreme Tablet Bested Apple Ipad Pro in Hands-On Performance and Stress Tests, Principled Technologies Study FindsDocumento2 pagineDell Latitude 7212 Rugged Extreme Tablet Bested Apple Ipad Pro in Hands-On Performance and Stress Tests, Principled Technologies Study FindsPR.comNessuna valutazione finora

- E2 Lab 11 6 3Documento10 pagineE2 Lab 11 6 3Ninja NuggetNessuna valutazione finora

- Your Friendly Neighborhood Quadcopter Platform: A Build TutorialDocumento29 pagineYour Friendly Neighborhood Quadcopter Platform: A Build TutorialriofelizNessuna valutazione finora

- Eee-Vii-Industrial Drives and Applications (10ee74) - NotesDocumento90 pagineEee-Vii-Industrial Drives and Applications (10ee74) - NotesChithra ManivelanNessuna valutazione finora

- Brother ADS-2800 BrochureDocumento2 pagineBrother ADS-2800 BrochureAris Wicaksono NugrohoNessuna valutazione finora

- Manual GT9600Documento28 pagineManual GT9600Viorel Daniel NegrutNessuna valutazione finora

- Use of Pressure Derivative in Well Test InterpretationDocumento10 pagineUse of Pressure Derivative in Well Test InterpretationKarar AL-DahlkiNessuna valutazione finora

- IELTS Listening Practice Test 2 Transcript Paper BasedDocumento10 pagineIELTS Listening Practice Test 2 Transcript Paper BasedPhuong Anh TranNessuna valutazione finora

- Pc-Ee 602Documento19 paginePc-Ee 602Koustav SahaNessuna valutazione finora

- Os Super-Imp-Tie-22 (1) PDFDocumento4 pagineOs Super-Imp-Tie-22 (1) PDFChandana H.RNessuna valutazione finora

- Introduction To NI ELVISDocumento136 pagineIntroduction To NI ELVISchrsolvegNessuna valutazione finora

- Language Laboratory System: Practice, Improve, Excel and Enjoy! Definitely Love Learning!Documento3 pagineLanguage Laboratory System: Practice, Improve, Excel and Enjoy! Definitely Love Learning!Yudhi SetiawanNessuna valutazione finora

- Implementing Failover Services ProxysgDocumento3 pagineImplementing Failover Services ProxysgMohamad MhannaNessuna valutazione finora

- FS16 Saratech 04 PerformanceTuningDocumento38 pagineFS16 Saratech 04 PerformanceTuningStefano MilaniNessuna valutazione finora

- Part Numbers For ISIMDocumento2 paginePart Numbers For ISIMThomas SimmonsNessuna valutazione finora