Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

11.water Tube Boilers

Caricato da

awsdotcdotaws0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

2K visualizzazioni3 pagineWater TUBE BOILERS are used exclusively, when pressure above 10 bar and capacity in excess of 7000 kg of steam per hour is required. A Babcock and Wilcox water tube boiler with cross draw differs from longitudinal drum boiler in a way that how a drum is placed with reference to the axis of the water tubes of the boiler.

Descrizione originale:

Titolo originale

11.Water Tube Boilers

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoWater TUBE BOILERS are used exclusively, when pressure above 10 bar and capacity in excess of 7000 kg of steam per hour is required. A Babcock and Wilcox water tube boiler with cross draw differs from longitudinal drum boiler in a way that how a drum is placed with reference to the axis of the water tubes of the boiler.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

2K visualizzazioni3 pagine11.water Tube Boilers

Caricato da

awsdotcdotawsWater TUBE BOILERS are used exclusively, when pressure above 10 bar and capacity in excess of 7000 kg of steam per hour is required. A Babcock and Wilcox water tube boiler with cross draw differs from longitudinal drum boiler in a way that how a drum is placed with reference to the axis of the water tubes of the boiler.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

WATER TUBE BOILERS

Babcock and Wilcox Boiler:

The water tube boilers are used exclusively, when pressure above

10 bar and capacity in excess of 7000 kg of steam per hour is

required. Babcock and Wilcox water-tube boiler is an example of

horizontal straight tube boiler and may be designed for stationary

and marine purposes.

The particulars (dimensions, capacity etc.) relating to this boiler

are given below

Diameter of the drum 1.22 to 1.83m

Length 6.096 to 9.144m

Size of the water tube 7.62 to 10.16cm

Size of superheater tubes 3.84 to 5.71 cm

Working pressure 40 bar (max.)

Steaming capacity 40000 kg/hr (max.)

Efficiency 60 to 80 %

Fig. shows a Babcock and Wilcox boiler with longitudinal drum. It

consists of a drum connected to a series of front and end rear end

header by short riser tubes. A feed valve is provided in the header

in front of each tube for cleaning and inspection of tubes. A feed

valve provided to fill the drum and incline tubes with water and

level of which is indicated by the water level indicator. Through

the fire door the fuel is supplied to grate where it is burnt. The hot

gases are forced to move upwards between the tubes by baffle

plates provided. The water from the drum flows through the

inclined tubes via downtake headers and goes back into the shell

in the form of water and steam via uptake header. The steam gets

collector in the steam space of the drum. The steam then enters

through the antipriming pipe and flows in the superheater tubes

where it is further heated and finally taken out through the main

stop valve and supplied to the engine when needed.

At the lowest point of the boiler is provided a mud collector to

remove the mud particles through a blow-down-cock.

The entire boiler except the furnace are hung by means of

metallic slings or straps or wrought iron girders supported on

pillars. This arrangement enables the drum and the tubes to

expand or contract freely. The brick work around the boiler

encloses the furnace and the dot gases.

The various mountings used on the boiler are shown in the fig.

A Babcock and Wilcox water tube boiler with cross draw differs

from longitudinal drum boiler in a way that how a drum is placed

with reference to the axis of the water tubes of the boiler. The

longitudinal drum restricts the number of tubes that can be

connected to one drum circumferentially and limits the capacity

of the boiler. In the cross there is no limitation of the number of

connecting tubes.

The pressure of steam in case of cross drum boiler may be as high

as 100 bar and steaming capacity upto 27,000 kg/hr.

BABCOCK AND WILCOX BOILER

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 101 - 200 KVA » Silent » LOVOL Genset Silent 100 Kva • Penjualan & Service Aneka Generator Set _ Genset - Perkins, Cummins, Deutz, MWM, FG Wilson, MAN, MTU, YANMAR, Mitsubishi, PRAMAC, Stamford, Leroy Somer, LovolDocumento2 pagine101 - 200 KVA » Silent » LOVOL Genset Silent 100 Kva • Penjualan & Service Aneka Generator Set _ Genset - Perkins, Cummins, Deutz, MWM, FG Wilson, MAN, MTU, YANMAR, Mitsubishi, PRAMAC, Stamford, Leroy Somer, LovolGIGsantonNessuna valutazione finora

- Ae2255 Propulsion-1 Question Bank UNIT-1Documento5 pagineAe2255 Propulsion-1 Question Bank UNIT-1kanscse100% (1)

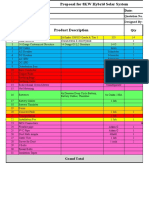

- Off Grid Solar System Installation ProposalDocumento11 pagineOff Grid Solar System Installation ProposalHabtamu GaromaNessuna valutazione finora

- Pipe - 1Documento4 paginePipe - 1Victor John PingkianNessuna valutazione finora

- 10kw Hybrid SystemDocumento6 pagine10kw Hybrid SystemUmar HamidNessuna valutazione finora

- Problems On Thermodynamics Flow ProcessesDocumento2 pagineProblems On Thermodynamics Flow ProcessesRexel ReedusNessuna valutazione finora

- Bomba - Weir - Curvas Bombas Espuma PrincipaisDocumento7 pagineBomba - Weir - Curvas Bombas Espuma PrincipaisWanderson AlcantaraNessuna valutazione finora

- Lab Manual: RGPV University (Bhopal)Documento6 pagineLab Manual: RGPV University (Bhopal)Pushpendra KushwahaNessuna valutazione finora

- Fusion FissionDocumento19 pagineFusion FissionJeevaniNessuna valutazione finora

- C5008098319 PDFDocumento5 pagineC5008098319 PDFRamkishan SahuNessuna valutazione finora

- HMP HT: Technical ManualDocumento32 pagineHMP HT: Technical ManualCRETU NICOLAENessuna valutazione finora

- Datos Oreda Modos de Falla Parte MantenibleDocumento135 pagineDatos Oreda Modos de Falla Parte MantenibleCarlos Jose Sibaja Cardozo100% (1)

- Boilers: - Asit MondalDocumento29 pagineBoilers: - Asit MondalAJITSPATILNessuna valutazione finora

- Government Gazette - 26th FebruaryDocumento156 pagineGovernment Gazette - 26th FebruaryistructeNessuna valutazione finora

- Hydraulic Turbine-1Documento6 pagineHydraulic Turbine-1Suman Kumar DashNessuna valutazione finora

- July RevampYourHome DigitalDocumento8 pagineJuly RevampYourHome DigitalMlungisi SibusisoNessuna valutazione finora

- Steam Injectors ARI CONA 651Documento2 pagineSteam Injectors ARI CONA 651CalinNessuna valutazione finora

- Steam TrapDocumento60 pagineSteam Trap~E~67% (3)

- Gas Turbine TheoryDocumento49 pagineGas Turbine Theorymmbataineh100% (2)

- Jet Aircraft Engine Lubrication Systems: Types of LubricantsDocumento4 pagineJet Aircraft Engine Lubrication Systems: Types of Lubricantsalfredsunny100% (1)

- Pra-Rancangan Pabrik Sabun Cair Dari Crude Palm Oil (Cpo) Dengan Kapasitas 20.000 Ton/TahunDocumento1 paginaPra-Rancangan Pabrik Sabun Cair Dari Crude Palm Oil (Cpo) Dengan Kapasitas 20.000 Ton/TahunNurulhafizNessuna valutazione finora

- ASC Presentation PDFDocumento89 pagineASC Presentation PDFAhmadHussain09Nessuna valutazione finora

- Troubleshooting Air ConditionerDocumento4 pagineTroubleshooting Air ConditionerrpshvjuNessuna valutazione finora

- CHAPTER III IV and VDocumento84 pagineCHAPTER III IV and VJohn Louie Pimentel0% (1)

- API PILOT WorkbookVideoOrderSheetDocumento1 paginaAPI PILOT WorkbookVideoOrderSheetAhmed YehiaNessuna valutazione finora

- Ec460b 09Documento6 pagineEc460b 09Khinmg Aye 554Nessuna valutazione finora

- Unical GCDocumento94 pagineUnical GCHassan ALkhaledyNessuna valutazione finora

- Aseptic Steriliser P&IDDocumento1 paginaAseptic Steriliser P&IDbharat.tumuluru2431Nessuna valutazione finora

- Aeolos Vertical Axis Wind Turbine EXW Price List - 2019Documento5 pagineAeolos Vertical Axis Wind Turbine EXW Price List - 2019Anonymous U7o8tht51KNessuna valutazione finora