Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Maraging Steel Properties PDF

Caricato da

Manideep AnanthulaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Maraging Steel Properties PDF

Caricato da

Manideep AnanthulaCopyright:

Formati disponibili

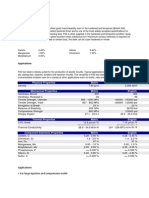

MARAGING STEEL PROPERTIES

INTRODUCTION: Maraging steels are iron-nickel alloys with absence of carbon and have metals such as molybdenum, cobalt, titanium and aluminum. The alloys have ultra-high strength, superior toughness characteristics and weldability. Typically, these alloys are used in aerospace applications, machinery and tooling and ordnance components and fasteners Maraging 300 is also called Vascomax 300 and is a special class of high-strength stainless steel . Maraging 300 is an 18% Nickel and Cobalt strengthened steel. It is a steel alloy with an iron base, where molybdenum, nickel and cobalt make up the the additional alloy components The chemical composition of Maraging 300 steel in wt.% is tabulated below.

Element C Si Mn P S Al Co Ni Mo Ti Cr Cu Fe Min 0.05 8.5 18.00 4.6 0.5 Bal Max 0.03 0.10 0.10 0.010 0.010 0.15 9.5 19.00 5.20 0.8 0.5 0.5

Mechanical Properties

Typical mechanical properties of Maraging 300 steel after heat treatment are given in the table below.

0.2% Proof Stress 1862 MPA Min. Tensile Strength 1930 MPA Min. Elongation 5 % Min. Hardness 52 HRC Min

Maintains high strength and toughness Allows close machining with minimal distortion Has uniform, predictable shrinkage during heat treatment Can be nitrided easily Resists corrosion and crack propagation

Has a high level of cleanliness and excellent polishability Remains readily weldable

Potrebbero piacerti anche

- Grade 309 Stainless Steel Properties and ApplicationsDocumento3 pagineGrade 309 Stainless Steel Properties and ApplicationsGabriel BozzaNessuna valutazione finora

- ASTM A36 and Grade 250 Maraging Steel Are Both Iron AlloysDocumento1 paginaASTM A36 and Grade 250 Maraging Steel Are Both Iron Alloysdesoxiv583Nessuna valutazione finora

- ASTM A36/A36M Standard Specification For Carbon Structural SteelDocumento4 pagineASTM A36/A36M Standard Specification For Carbon Structural SteeliuliamicutNessuna valutazione finora

- Ferrous and Non Ferrous MetalsDocumento31 pagineFerrous and Non Ferrous MetalsadinamdarNessuna valutazione finora

- 2007 Russian Aluminum Alloys For Ultra Deep Water EngDocumento8 pagine2007 Russian Aluminum Alloys For Ultra Deep Water EngHossam Ali RaghebNessuna valutazione finora

- Classification and Properties of Carbon and Low-Alloy SteelsDocumento23 pagineClassification and Properties of Carbon and Low-Alloy SteelsharieduidNessuna valutazione finora

- FC-06-Engineering Material & Metallurgy PDFDocumento431 pagineFC-06-Engineering Material & Metallurgy PDFsomnath ghosh100% (1)

- Ferrous and NonDocumento13 pagineFerrous and NonIrvansyah RazadinNessuna valutazione finora

- Physical Metallurgy: Lecture byDocumento78 paginePhysical Metallurgy: Lecture byqaNessuna valutazione finora

- M 1.2.8 Carbon, Lowalloyed, Fine Grained, and ThermomechanicalyDocumento17 pagineM 1.2.8 Carbon, Lowalloyed, Fine Grained, and Thermomechanicalydokumen qcNessuna valutazione finora

- Application of Steel AloyDocumento2 pagineApplication of Steel AloyTâm QuangNessuna valutazione finora

- Unit - Iii: Ferrous and Non Ferrous MetalsDocumento101 pagineUnit - Iii: Ferrous and Non Ferrous Metalssenthilkumar tsNessuna valutazione finora

- Wrought Iron Properties ApplicationsDocumento2 pagineWrought Iron Properties ApplicationsRaymond LiewNessuna valutazione finora

- Steels For Aerospace Engineering Jan2020.6310.1580092900.0839Documento78 pagineSteels For Aerospace Engineering Jan2020.6310.1580092900.0839EudoNessuna valutazione finora

- Alloying Elements and Their EffectsDocumento5 pagineAlloying Elements and Their EffectsDimas Anugrah100% (2)

- ARMCO Pure Iron Magnetic PropertiesDocumento12 pagineARMCO Pure Iron Magnetic PropertiesprincedrdoNessuna valutazione finora

- Ferrous Alloys GuideDocumento45 pagineFerrous Alloys GuideAthith D100% (1)

- Designation: Magnesium Alloys Are Mixtures ofDocumento4 pagineDesignation: Magnesium Alloys Are Mixtures ofnivdeeNessuna valutazione finora

- Aluminized SteelDocumento6 pagineAluminized SteelMamacintNessuna valutazione finora

- Aluminium Alloys Jan2020.6310.1580092925.3362Documento75 pagineAluminium Alloys Jan2020.6310.1580092925.3362EudoNessuna valutazione finora

- Classification and properties of carbon and low-alloy steelsDocumento15 pagineClassification and properties of carbon and low-alloy steelscal2_uniNessuna valutazione finora

- 3 Steel PDFDocumento16 pagine3 Steel PDFSohanur RahmanNessuna valutazione finora

- Plain Carbon SteelsDocumento47 paginePlain Carbon SteelsRicci Marcelo ÜNessuna valutazione finora

- MEE 511 Course WorkDocumento10 pagineMEE 511 Course WorktornakingstonNessuna valutazione finora

- Isi Lesson 07 MaterialsDocumento8 pagineIsi Lesson 07 MaterialsRizwan NazirNessuna valutazione finora

- Review of SiluminDocumento325 pagineReview of SiluminMukulNessuna valutazione finora

- Alloy Steel (A Textbook of Machine Design)Documento4 pagineAlloy Steel (A Textbook of Machine Design)Muh FarhanNessuna valutazione finora

- Carbon in SteelDocumento8 pagineCarbon in SteelJanice FernandezNessuna valutazione finora

- Interpretation of The Microstructure of SteelsDocumento61 pagineInterpretation of The Microstructure of SteelsCiresica Sanda Cocindau100% (1)

- Steels Used Onboard Ships and How To Perform Maintenance WeldingDocumento35 pagineSteels Used Onboard Ships and How To Perform Maintenance Weldingantonio111aNessuna valutazione finora

- Technical Bulletin: Magnetism and Other Properties of Stainless SteelDocumento2 pagineTechnical Bulletin: Magnetism and Other Properties of Stainless SteelksNessuna valutazione finora

- Aluminum Welding ProceduresDocumento8 pagineAluminum Welding ProceduresManivannanMudhaliar0% (1)

- 10-Low Alloy Steel PDFDocumento32 pagine10-Low Alloy Steel PDFIdes Trian100% (1)

- Assignment Engineering MaterialsDocumento8 pagineAssignment Engineering MaterialsMirza HumzaNessuna valutazione finora

- Selective Hardening MethodsDocumento47 pagineSelective Hardening MethodsvishnuNessuna valutazione finora

- LATEST MATERIALS FOR SHIP CONSTRUCTIONDocumento9 pagineLATEST MATERIALS FOR SHIP CONSTRUCTIONAnonymous e3ceN15Nessuna valutazione finora

- To Extract and Professionally ArranDocumento6 pagineTo Extract and Professionally ArranKareem MohamedNessuna valutazione finora

- Nickel Based Superalloys UsesDocumento6 pagineNickel Based Superalloys UsesHeanjiaAlloysNessuna valutazione finora

- Primary FabricationDocumento86 paginePrimary FabricationDany ChNessuna valutazione finora

- Aluminized Steel Sheet PropertiesDocumento8 pagineAluminized Steel Sheet PropertiesAhmadreza AminianNessuna valutazione finora

- Structure and PropertiedDocumento43 pagineStructure and PropertiedJalaj GaurNessuna valutazione finora

- Metals 2Documento13 pagineMetals 2arooj anjumNessuna valutazione finora

- Debere Berhan University: Collage of EngineeringDocumento15 pagineDebere Berhan University: Collage of EngineeringDagmawi MenweyeletNessuna valutazione finora

- Weldability of High Strength Low Alloy SteelDocumento34 pagineWeldability of High Strength Low Alloy SteelGanesan Veerasamy100% (1)

- Aluminum Alloy Data SheetDocumento1 paginaAluminum Alloy Data SheetAugusto PeinadoNessuna valutazione finora

- Alloy Steel and Cast IronDocumento16 pagineAlloy Steel and Cast IronDennis AlvarezNessuna valutazione finora

- Aircraft Material HardwareDocumento307 pagineAircraft Material HardwareMorrisNessuna valutazione finora

- 06940G Chapter 1Documento7 pagine06940G Chapter 1Tito Winnerson SitanggangNessuna valutazione finora

- AAMRADocumento50 pagineAAMRARona Khairol Pratama100% (1)

- Fabrication of Aluminium 6061-Sic-Al O MMC and HMMC by Strir Casting Technique and Comparing The Mechanical PropertiesDocumento8 pagineFabrication of Aluminium 6061-Sic-Al O MMC and HMMC by Strir Casting Technique and Comparing The Mechanical PropertiesTJPRC PublicationsNessuna valutazione finora

- Armco Pure Iron PDFDocumento12 pagineArmco Pure Iron PDFsmith willNessuna valutazione finora

- Ship Building MaterialsDocumento21 pagineShip Building Materialsimran5705074Nessuna valutazione finora

- Maraging Steel - WikipediaDocumento5 pagineMaraging Steel - WikipediaVysakh VasudevanNessuna valutazione finora

- Steel Material PropertiesDocumento2 pagineSteel Material PropertiescadhoaNessuna valutazione finora

- AISI 4130 Chemistry and Properties ReportDocumento4 pagineAISI 4130 Chemistry and Properties Reportvaibhavporwal1Nessuna valutazione finora

- Oteluri Cai FerateDocumento2 pagineOteluri Cai FerateValentin RadulescuNessuna valutazione finora

- Aluminum in ShipbuildingDocumento5 pagineAluminum in ShipbuildingAnonymous e3ceN15Nessuna valutazione finora

- Types & Properties of Alloy SteelDocumento4 pagineTypes & Properties of Alloy SteelSaadNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Management of Everyday LifeDocumento23 pagineThe Management of Everyday LifeManideep AnanthulaNessuna valutazione finora

- Railway Recruitment Board Examination Question Paper 2006Documento13 pagineRailway Recruitment Board Examination Question Paper 2006Manideep AnanthulaNessuna valutazione finora

- AeenmcalDocumento2 pagineAeenmcalManideep AnanthulaNessuna valutazione finora

- Geography Bit BankDocumento129 pagineGeography Bit Banksuresh0% (1)

- How To Manage Big, Powerful Clients - ProfitablyDocumento50 pagineHow To Manage Big, Powerful Clients - ProfitablyManideep AnanthulaNessuna valutazione finora

- IDPCDocumento68 pagineIDPCRaja SubramanianNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 11apr TW RuralDocumento16 pagine11apr TW RuralManideep AnanthulaNessuna valutazione finora

- Critical Reasoning: Cat 2002/Gmat/Other Mba ExamsDocumento4 pagineCritical Reasoning: Cat 2002/Gmat/Other Mba ExamssrujanbejavadaNessuna valutazione finora

- Fling 9 X 7 W 2Documento1 paginaFling 9 X 7 W 2Manideep AnanthulaNessuna valutazione finora

- SAIL Placement Sample Paper 2Documento6 pagineSAIL Placement Sample Paper 2Janiel JawaharNessuna valutazione finora

- How To Manage Big, Powerful Clients - ProfitablyDocumento50 pagineHow To Manage Big, Powerful Clients - ProfitablyManideep AnanthulaNessuna valutazione finora

- Sail 2010 PaperDocumento3 pagineSail 2010 PaperChristopher WoodNessuna valutazione finora

- Overviews: MillingDocumento12 pagineOverviews: MillingManideep AnanthulaNessuna valutazione finora

- AI SI P20 Steels PDFDocumento2 pagineAI SI P20 Steels PDFManideep AnanthulaNessuna valutazione finora

- Drilling 2Documento12 pagineDrilling 2Manideep AnanthulaNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Argumentation PDFDocumento3 pagineArgumentation PDFManideep AnanthulaNessuna valutazione finora

- Lab Manual PDFDocumento37 pagineLab Manual PDFManideep AnanthulaNessuna valutazione finora

- Mechanics of Chip FormationDocumento10 pagineMechanics of Chip FormationManideep AnanthulaNessuna valutazione finora

- Banking Awareness Quick Reference Guide - Gr8AmbitionZDocumento11 pagineBanking Awareness Quick Reference Guide - Gr8AmbitionZArif SheikhNessuna valutazione finora

- Orthogonal Machining PDFDocumento6 pagineOrthogonal Machining PDFManideep AnanthulaNessuna valutazione finora

- ME364 Cutting MechanicsDocumento4 pagineME364 Cutting Mechanicslamia97Nessuna valutazione finora

- From Organisational Structure To Organisational Behaviour FormalisationDocumento21 pagineFrom Organisational Structure To Organisational Behaviour FormalisationManideep AnanthulaNessuna valutazione finora

- Motivation TheoriesDocumento22 pagineMotivation TheoriesslixsterNessuna valutazione finora

- Cutting Tool PDFDocumento9 pagineCutting Tool PDFManideep AnanthulaNessuna valutazione finora

- Cost Concepts&cost SheetDocumento32 pagineCost Concepts&cost SheetManideep Ananthula0% (1)

- Attribution Theory PDFDocumento12 pagineAttribution Theory PDFManideep AnanthulaNessuna valutazione finora

- Soa 373398 September 2013 PDFDocumento2 pagineSoa 373398 September 2013 PDFManideep AnanthulaNessuna valutazione finora

- PeopleSoft Security TablesDocumento8 paginePeopleSoft Security TablesChhavibhasinNessuna valutazione finora

- Final Year Project (Product Recommendation)Documento33 pagineFinal Year Project (Product Recommendation)Anurag ChakrabortyNessuna valutazione finora

- Dell Compellent Sc4020 Deploy GuideDocumento184 pagineDell Compellent Sc4020 Deploy Guidetar_py100% (1)

- Pemaknaan School Well-Being Pada Siswa SMP: Indigenous ResearchDocumento16 paginePemaknaan School Well-Being Pada Siswa SMP: Indigenous ResearchAri HendriawanNessuna valutazione finora

- Revit 2010 ESPAÑOLDocumento380 pagineRevit 2010 ESPAÑOLEmilio Castañon50% (2)

- The Dominant Regime Method - Hinloopen and Nijkamp PDFDocumento20 pagineThe Dominant Regime Method - Hinloopen and Nijkamp PDFLuiz Felipe GuaycuruNessuna valutazione finora

- JM Guide To ATE Flier (c2020)Documento2 pagineJM Guide To ATE Flier (c2020)Maged HegabNessuna valutazione finora

- MQC Lab Manual 2021-2022-AutonomyDocumento39 pagineMQC Lab Manual 2021-2022-AutonomyAniket YadavNessuna valutazione finora

- Composite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloDocumento15 pagineComposite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloSharan KharthikNessuna valutazione finora

- Precision Machine Components: NSK Linear Guides Ball Screws MonocarriersDocumento564 paginePrecision Machine Components: NSK Linear Guides Ball Screws MonocarriersDorian Cristian VatavuNessuna valutazione finora

- CFO TagsDocumento95 pagineCFO Tagssatyagodfather0% (1)

- Paper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Documento12 paginePaper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Hisham AlEnaiziNessuna valutazione finora

- Public Private HEM Status AsOn2May2019 4 09pmDocumento24 paginePublic Private HEM Status AsOn2May2019 4 09pmVaibhav MahobiyaNessuna valutazione finora

- Revision Worksheet - Matrices and DeterminantsDocumento2 pagineRevision Worksheet - Matrices and DeterminantsAryaNessuna valutazione finora

- Dep 32.32.00.11-Custody Transfer Measurement Systems For LiquidDocumento69 pagineDep 32.32.00.11-Custody Transfer Measurement Systems For LiquidDAYONessuna valutazione finora

- C4 ISRchapterDocumento16 pagineC4 ISRchapterSerkan KalaycıNessuna valutazione finora

- Google Earth Learning Activity Cuban Missile CrisisDocumento2 pagineGoogle Earth Learning Activity Cuban Missile CrisisseankassNessuna valutazione finora

- Mutual Fund PDFDocumento22 pagineMutual Fund PDFRajNessuna valutazione finora

- Iphoneos 31Documento159 pagineIphoneos 31Ivan VeBoNessuna valutazione finora

- Dance Appreciation and CompositionDocumento1 paginaDance Appreciation and CompositionFretz Ael100% (1)

- Chapter 4 DeterminantsDocumento3 pagineChapter 4 Determinantssraj68Nessuna valutazione finora

- Oxgen Sensor Cat WEBDocumento184 pagineOxgen Sensor Cat WEBBuddy Davis100% (2)

- Shopping Mall: Computer Application - IiiDocumento15 pagineShopping Mall: Computer Application - IiiShadowdare VirkNessuna valutazione finora

- Factors of Active Citizenship EducationDocumento2 pagineFactors of Active Citizenship EducationmauïNessuna valutazione finora

- 2010 HD Part Cat. LBBDocumento466 pagine2010 HD Part Cat. LBBBuddy ButlerNessuna valutazione finora

- Three Comparison of Homoeopathic MedicinesDocumento22 pagineThree Comparison of Homoeopathic MedicinesSayeed AhmadNessuna valutazione finora

- Ansible Playbook for BeginnersDocumento101 pagineAnsible Playbook for BeginnersFelix Andres Baquero Cubillos100% (1)

- Srimanta Sankaradeva Universityof Health SciencesDocumento3 pagineSrimanta Sankaradeva Universityof Health SciencesTemple RunNessuna valutazione finora

- CENG 5503 Intro to Steel & Timber StructuresDocumento37 pagineCENG 5503 Intro to Steel & Timber StructuresBern Moses DuachNessuna valutazione finora

- Gabinete STS Activity1Documento2 pagineGabinete STS Activity1Anthony GabineteNessuna valutazione finora