Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Design Hours: Initial Involvement and Plan of Action

Caricato da

sivavalai0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

7 visualizzazioni1 paginabook

Titolo originale

00067___0eed9aad712efd9be826921db43782fc.pdf

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentobook

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

7 visualizzazioni1 paginaProcess Design Hours: Initial Involvement and Plan of Action

Caricato da

sivavalaibook

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Initial Involvement and Plan of Action

39

Engineering Hours= Equip. Count x Growth Factorx 650

Process Design Hours

The Engineering hours required for process design are not only related to equipment count and type; they are also very sensitive to the type of process and stage of development of the process design. Experience shows that these factors can produce very wide variations inthe hours required. Since the process design hours determine the cost and duration of the initial project activities, it is very important that the initial plan of action be based on realisticestimates.Unfortunately, as mentioned before, the level of information required to prepare accurate estimates is rarely available at this stage of theproject. Nevertheless, this section tries to provide some criteria and guidelines to allow project managers to make thebest out of the scant information available. Analysis of actual cases shows that the hours required to prepare a complete and formally documented process design package (Phase 1) including drafting and all required engineering disciplinesvary widely depending on thetype of project. Low

30 hr/item

Average

High 150 hr/item

75 hr/item

The following factors determine the location within the range: High End

- New technology.

-

Hazardous service. Process complexity. Large equipment. Low equipmentcount.

- Process options. -

Executionby contractor.

Low End

- Simple process.

-

Simple equipment. Repeat project (old Phase 1 manuals).

Potrebbero piacerti anche

- Lean Construction: From Theory To Practice: Antonio Sergio Itri ConteDocumento9 pagineLean Construction: From Theory To Practice: Antonio Sergio Itri ConteRicardo Fernando DenoniNessuna valutazione finora

- Section C - Process Engineers & Design Procedure Rev 2Documento22 pagineSection C - Process Engineers & Design Procedure Rev 2NevlinNessuna valutazione finora

- Plan Contents: Construction HoursDocumento1 paginaPlan Contents: Construction HourssivavalaiNessuna valutazione finora

- What's So Special About Process Control Projects?Documento7 pagineWhat's So Special About Process Control Projects?Pere GilNessuna valutazione finora

- Managing The Rework CycleDocumento11 pagineManaging The Rework CycleDiego VanegasNessuna valutazione finora

- SchedulingDocumento13 pagineSchedulingnsadnanNessuna valutazione finora

- Introduction To Chemical Process Design EngineeringDocumento4 pagineIntroduction To Chemical Process Design Engineeringankur2061100% (1)

- 2 - Drawings.: 3 - SpecificationsDocumento1 pagina2 - Drawings.: 3 - SpecificationssivavalaiNessuna valutazione finora

- ASICDocumento34 pagineASICShaik Khaja SharifNessuna valutazione finora

- Orpert26 30 150112122451 Conversion Gate02Documento14 pagineOrpert26 30 150112122451 Conversion Gate02aayilliyaNessuna valutazione finora

- MCAA Guide ProductivityDocumento11 pagineMCAA Guide ProductivityMike Torbert100% (1)

- SPM Unit 1 NotesDocumento21 pagineSPM Unit 1 NotesPrateek SaxenaNessuna valutazione finora

- 3444S1TKCE70632018 - Perancangan Pabrik Kimia II - Pertemuan 1 - Materi TambahanDocumento24 pagine3444S1TKCE70632018 - Perancangan Pabrik Kimia II - Pertemuan 1 - Materi Tambahanaditya rahmanNessuna valutazione finora

- 12 Phases of A Project ImplementationDocumento7 pagine12 Phases of A Project ImplementationIsd Bamb100% (1)

- Ilovepdf MergedDocumento132 pagineIlovepdf Mergedkalidas BNessuna valutazione finora

- Existing Processes and Business EnvironmentDocumento52 pagineExisting Processes and Business EnvironmentjsaulNessuna valutazione finora

- 6516.chapter2 Evolution of Software EconomicsDocumento23 pagine6516.chapter2 Evolution of Software EconomicsZoyeb ManasiyaNessuna valutazione finora

- Class 12 IP ProjectDocumento26 pagineClass 12 IP ProjectShivendra100% (2)

- IT8075-SPM Unit –I Notes on Project Evaluation and PlanningDocumento35 pagineIT8075-SPM Unit –I Notes on Project Evaluation and PlanningLionel Bharath RazerNessuna valutazione finora

- Production Scheduling Gantt ChartsDocumento16 pagineProduction Scheduling Gantt ChartsSAMRUDA SADANANDNessuna valutazione finora

- Project Management UNIT 1 OkDocumento9 pagineProject Management UNIT 1 OkMohd AqdasNessuna valutazione finora

- Chapter 05 - Software Effort Estimation IVDocumento44 pagineChapter 05 - Software Effort Estimation IVTahir aliNessuna valutazione finora

- Planning & SchedulingDocumento29 paginePlanning & SchedulingBRAYAN DAVID RUIZ VEGANessuna valutazione finora

- Productivity Measurement and Design Efficiency in Product DevelopmentDocumento18 pagineProductivity Measurement and Design Efficiency in Product DevelopmentsouravNessuna valutazione finora

- SPM Unit 1 NotesDocumento21 pagineSPM Unit 1 NotesDr. Sonia Setia (SET Assistant Professor)Nessuna valutazione finora

- 1.0 Construction Operations - A 1.1Documento11 pagine1.0 Construction Operations - A 1.1Anfield FaithfulNessuna valutazione finora

- SPM ImpDocumento13 pagineSPM ImpVishal PalNessuna valutazione finora

- Anatomy Engineering ProjectsDocumento27 pagineAnatomy Engineering Projectsllekhanya-1Nessuna valutazione finora

- 6 SPMDocumento51 pagine6 SPMShubhamNessuna valutazione finora

- 5.CH-2 Project ManagementDocumento9 pagine5.CH-2 Project ManagementKapish SharmaNessuna valutazione finora

- Oil and Gas Process Design FundamentalsDocumento22 pagineOil and Gas Process Design FundamentalsAboyowa Edema100% (1)

- Construction Management: ENCE4331Documento23 pagineConstruction Management: ENCE4331Tania MassadNessuna valutazione finora

- Lecture2930 15483 ProjectplanningandcontrolDocumento54 pagineLecture2930 15483 ProjectplanningandcontrolAshutosh ChauhanNessuna valutazione finora

- 4 Defining The ProjectDocumento31 pagine4 Defining The ProjectPratik TagwaleNessuna valutazione finora

- CHE Article - Best Practices - How To Prepare A Process Design BasisDocumento6 pagineCHE Article - Best Practices - How To Prepare A Process Design BasismatheusdarbiNessuna valutazione finora

- Mirdula Computer Institute Management SystemDocumento33 pagineMirdula Computer Institute Management Systemvnitinkrishna18Nessuna valutazione finora

- 3.2. Technical AnalysisDocumento104 pagine3.2. Technical AnalysisHabtamu AyeleNessuna valutazione finora

- Evolution of Software Economics ParametersDocumento25 pagineEvolution of Software Economics ParametersSami UllahNessuna valutazione finora

- Project Management and EntrepreneurshipDocumento31 pagineProject Management and EntrepreneurshipArsadgamingytNessuna valutazione finora

- Process Design BasisDocumento6 pagineProcess Design BasisMufleh Idris100% (3)

- PLANNING FOR HIGH-RISE CONSTRUCTIONDocumento21 paginePLANNING FOR HIGH-RISE CONSTRUCTIONAnil PatelNessuna valutazione finora

- Job PlanningDocumento11 pagineJob PlanningYasserNessuna valutazione finora

- Sen RequementDocumento14 pagineSen Requementsudarshan sonawaneNessuna valutazione finora

- Week 02 - Project Parameters & CategorizationsDocumento76 pagineWeek 02 - Project Parameters & Categorizationsshan zayNessuna valutazione finora

- Information System: Prepared by SupervisorDocumento33 pagineInformation System: Prepared by SupervisorAli KurdishNessuna valutazione finora

- Organization: Building A High-Performance Facilities EngineeringDocumento6 pagineOrganization: Building A High-Performance Facilities Engineeringlhphong021191Nessuna valutazione finora

- Chapter 23 - Project PlanningDocumento52 pagineChapter 23 - Project PlanningadvifulNessuna valutazione finora

- Construction Project Management: BY Saif Hasan 11510011 M. Arch. 1 YearDocumento35 pagineConstruction Project Management: BY Saif Hasan 11510011 M. Arch. 1 YearKristine Delos ReyesNessuna valutazione finora

- Ashwin Udhe 1 Introduction To Piping Engineering PDFDocumento6 pagineAshwin Udhe 1 Introduction To Piping Engineering PDFPoonam AshwinNessuna valutazione finora

- Exxonmobil Production Company Position DescriptionDocumento2 pagineExxonmobil Production Company Position DescriptionJagan BoseNessuna valutazione finora

- 1-Site Layout 2-Labour Productivity 3-Methods of Labour ProductivityDocumento20 pagine1-Site Layout 2-Labour Productivity 3-Methods of Labour ProductivityAbdul WaliNessuna valutazione finora

- Model Questions & Answers Project MGTDocumento22 pagineModel Questions & Answers Project MGTThe weeb ProdigyNessuna valutazione finora

- Unit VDocumento90 pagineUnit VOnkarNessuna valutazione finora

- Table of Contents (T O C)Documento23 pagineTable of Contents (T O C)adityatiw2111Nessuna valutazione finora

- UtilitiesDocumento2 pagineUtilitiesAfif NugrohoNessuna valutazione finora

- SPM Unit 1 NotesDocumento35 pagineSPM Unit 1 Notes123Nessuna valutazione finora

- IT8075 Software Project Management NotesDocumento132 pagineIT8075 Software Project Management NotesNAGARAJAN.N 011Nessuna valutazione finora

- Making Sense of Your Project Cost EstimateDocumento5 pagineMaking Sense of Your Project Cost Estimategeorge israelNessuna valutazione finora

- Detailed EngineeringDocumento1 paginaDetailed EngineeringsivavalaiNessuna valutazione finora

- Piping Insulation Cost Estimates TableDocumento1 paginaPiping Insulation Cost Estimates TablesivavalaiNessuna valutazione finora

- Detailed Engineering: 11.5 I44 Bldders ofDocumento1 paginaDetailed Engineering: 11.5 I44 Bldders ofsivavalaiNessuna valutazione finora

- Estimating the costs of a construction projectDocumento1 paginaEstimating the costs of a construction projectsivavalaiNessuna valutazione finora

- Master Project Schedule & Execution PlanDocumento1 paginaMaster Project Schedule & Execution PlansivavalaiNessuna valutazione finora

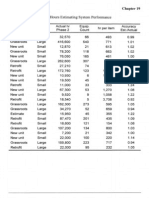

- Hours: Table 19.25 Engineering Estimating System PerformanceDocumento1 paginaHours: Table 19.25 Engineering Estimating System PerformancesivavalaiNessuna valutazione finora

- 00298Documento1 pagina00298sivavalaiNessuna valutazione finora

- 00058Documento1 pagina00058sivavalaiNessuna valutazione finora

- 00055Documento1 pagina00055sivavalaiNessuna valutazione finora

- Guide Plant Startup ProcessDocumento1 paginaGuide Plant Startup ProcesssivavalaiNessuna valutazione finora

- Communications 241: 17.2 Documentation ChecklistDocumento1 paginaCommunications 241: 17.2 Documentation ChecklistsivavalaiNessuna valutazione finora

- This Page Intentionally Left BlankDocumento1 paginaThis Page Intentionally Left BlanksivavalaiNessuna valutazione finora

- Project Control: Plant LayoutDocumento1 paginaProject Control: Plant LayoutsivavalaiNessuna valutazione finora

- Project Control Labor Work Unit ApproachDocumento1 paginaProject Control Labor Work Unit ApproachsivavalaiNessuna valutazione finora

- 14.3 Construction Management ActivitiesDocumento1 pagina14.3 Construction Management ActivitiessivavalaiNessuna valutazione finora

- 19.1 Procedure: GeneralDocumento1 pagina19.1 Procedure: GeneralsivavalaiNessuna valutazione finora

- Construction Site ManagementDocumento1 paginaConstruction Site ManagementsivavalaiNessuna valutazione finora

- PDFDocumento1 paginaPDFsivavalaiNessuna valutazione finora

- PDFDocumento1 paginaPDFsivavalaiNessuna valutazione finora

- Capital CostsDocumento1 paginaCapital CostssivavalaiNessuna valutazione finora

- Process Design Phase 1 SpecsDocumento1 paginaProcess Design Phase 1 SpecssivavalaiNessuna valutazione finora

- 8.3 Risks at The Venture and Project Execution LevelsDocumento1 pagina8.3 Risks at The Venture and Project Execution LevelssivavalaiNessuna valutazione finora

- Project ControlDocumento1 paginaProject ControlsivavalaiNessuna valutazione finora

- AnalysisDocumento1 paginaAnalysissivavalaiNessuna valutazione finora

- Effective Construction Cost ControlDocumento1 paginaEffective Construction Cost ControlsivavalaiNessuna valutazione finora

- Contracted EngineeringDocumento1 paginaContracted EngineeringsivavalaiNessuna valutazione finora

- Project Control Problem Correction: During ConstructionDocumento1 paginaProject Control Problem Correction: During ConstructionsivavalaiNessuna valutazione finora

- 14.3 Construction Management ActivitiesDocumento1 pagina14.3 Construction Management ActivitiessivavalaiNessuna valutazione finora

- Speclfic To Project: 2 - Depth and BreadthDocumento1 paginaSpeclfic To Project: 2 - Depth and BreadthsivavalaiNessuna valutazione finora

- Agreement: ContractingDocumento1 paginaAgreement: ContractingsivavalaiNessuna valutazione finora

- Airbus - Annexes ISI 22.83.00003 (Rev. April 04-2022)Documento28 pagineAirbus - Annexes ISI 22.83.00003 (Rev. April 04-2022)Faiz FahmiNessuna valutazione finora

- Panama CanalDocumento53 paginePanama Canalcjcute91Nessuna valutazione finora

- Spikes-Spider Tire GuideDocumento10 pagineSpikes-Spider Tire GuidePedro LopezNessuna valutazione finora

- GHIALDocumento6 pagineGHIALRandhir ShahNessuna valutazione finora

- Larry Page: Co-Founder and CEO of GoogleDocumento15 pagineLarry Page: Co-Founder and CEO of GoogleOmkar RaneNessuna valutazione finora

- Dics 6100 PDFDocumento97 pagineDics 6100 PDFBf Ipanema100% (1)

- PETRONAS FUTURETECH Demo DayDocumento26 paginePETRONAS FUTURETECH Demo DayNoor FathiahNessuna valutazione finora

- Manual Sugar CRMDocumento6 pagineManual Sugar CRMgovsNessuna valutazione finora

- TELEMEDICINE: A HISTORY AND APPLICATIONSDocumento5 pagineTELEMEDICINE: A HISTORY AND APPLICATIONSRahul AgarwalNessuna valutazione finora

- LITA Lean IT Foundation Glossary - EnGLISHDocumento9 pagineLITA Lean IT Foundation Glossary - EnGLISHSamNessuna valutazione finora

- Titan MicropilesDocumento12 pagineTitan Micropilesmunain_gNessuna valutazione finora

- ITECH 5402 - SampleClassTest2Documento8 pagineITECH 5402 - SampleClassTest2Syed ZubairNessuna valutazione finora

- Built-in Control: How Front-End Loading Maximizes Predictability for Plant ProjectsDocumento4 pagineBuilt-in Control: How Front-End Loading Maximizes Predictability for Plant ProjectsRahul KhandelwalNessuna valutazione finora

- Module 3 AssignmentDocumento21 pagineModule 3 AssignmentTharinduNessuna valutazione finora

- Architectural Reviewers - Air Passenger TerminalsDocumento13 pagineArchitectural Reviewers - Air Passenger TerminalsJenny Jane Sarmiento VeraqueNessuna valutazione finora

- Raising Your Digital QuotientDocumento13 pagineRaising Your Digital QuotientDr Bugs TanNessuna valutazione finora

- Warehousing GuideDocumento26 pagineWarehousing Guidesuresh100% (2)

- Mani VenketDocumento93 pagineMani VenketMahesh majjiNessuna valutazione finora

- Construction of Burj KhalifaDocumento30 pagineConstruction of Burj KhalifaDevendra Sharma100% (4)

- Annotated BibliographyDocumento15 pagineAnnotated Bibliographyapi-190312542Nessuna valutazione finora

- Shanmukhi. SubramaniDocumento2 pagineShanmukhi. SubramaniHarshaNessuna valutazione finora

- Fundamentals of Ship Maintenance and Repair For Future Marine EngineersDocumento11 pagineFundamentals of Ship Maintenance and Repair For Future Marine EngineersantonigorNessuna valutazione finora

- Approach Flow System Study - FlyerDocumento1 paginaApproach Flow System Study - FlyernotengofffNessuna valutazione finora

- Fence ProjectDocumento15 pagineFence ProjectAhmad Ramin Abasy100% (1)

- Workshop BrochureDocumento2 pagineWorkshop BrochureArvind BajpaiNessuna valutazione finora

- AnotacoesDocumento2 pagineAnotacoesicumba6180Nessuna valutazione finora

- Transformer Tender Document31322 08-11-17 25af73Documento68 pagineTransformer Tender Document31322 08-11-17 25af73Rajat NishadNessuna valutazione finora

- Order Picking and Order AccumulationDocumento4 pagineOrder Picking and Order Accumulationschool chelcie100% (1)

- What Vendor Rating Is All About:: 2. The Grading SystemDocumento2 pagineWhat Vendor Rating Is All About:: 2. The Grading SystemengkjNessuna valutazione finora

- South Oil Company (SOC) : SOC Contract No.: CSSP-ITT-04Documento19 pagineSouth Oil Company (SOC) : SOC Contract No.: CSSP-ITT-04Kingsley BaptistaNessuna valutazione finora