Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fiebing's Fantastic Finishes Book

Caricato da

Anonymous KMWzXegkCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fiebing's Fantastic Finishes Book

Caricato da

Anonymous KMWzXegkCopyright:

Formati disponibili

FANTASTIC FINISHES

CoIorin and!inishin|cathcrthc!icbinVa

JOn u uC

TABLE OF CONTENTS

GETTING STARTED e e++ s + e++e ++ + s + e s + e ++ + e e e e e ee+ 1

LEATHER DYES: ALCOHOL, OIL WATER BASED . +++e e e e e e e e s +sZ

BRUSH SELECTION CARE e + e e e + e eeee . . + e e +e e + e ee e ee ++++ ee ^

BACKGROUND DYEING + e+e +emseee +d

COLORING AN OAK LEAF +es+++s e eeee+ + +es se b

COLORING A FLORAL e e + e e + e eeee e e + e e e e + e e e e e e e +e e e ee e e + e++e e e e e e

COLORING A FIGURE PICTORIAL SCENE s e e es+ e s e e + e e e e e e s + s s e +e eeeeeeJ

MORE COLORING TECHNIQUES eee + seeeseee e e e e + +e e + ee o

ACRYLIC COLORS e+ + e . em++ . ++ V

ANTIQUES + + + + ++++ee + e e e e + e e q+ + + s + ++e e + e e ee++qqs + e e + e e e +e + +e qe + + e + + e e + e e e qq e + + e e +e 1

SPECIAL EFFECTS ++ e e e e ++ e e e e + s + e e e & e e e e e e e e e e e s + s s e + 11

TOP FINISHES eee e e e e ee e e e . e e e + e e e e +e e +++ . e e l4

EDGE FINISHING eees s s s +s + + s s e eeeeee + e e +e e e e s e e . e e 1J

LEATHER CARE + ++ + + + + + s + qq e e s e s + +++ ++q e s e e e e e + s +qqe e + + + + e qq++ e + +e e e 1'

COLOR CHARTS ee e eeee ++e + e e e e +++++ ++ s s . e Z

COMPATIBILITY CHARTS ee++++ e e se e + e e ss ee+ e + e e 21

INTRODUCTION

Since IVD, the Fiebing Company has been manufacturing and developing high quality dyes, stains, fnishes and

leather care products in Milwaukee, Wisconsin. cbngv, as it has come to be known, is dedicated to serving the

needs of leather workers, crafts people and hobbyists worldwide. The Fiebing Company continues to combine

classic formulations with moder processes and materials to create products that are trusted by professionals and

hobbyists of all ages. This book illustrates how Fiebing's dyes, stains, antiques and finishes will help your leather

projects come alive and how Fiebing's leather care products will ensure that your work is preserved for all to enjoy.

This book is intended to provide a collection of demonstrations and informative tips and is sure to be a worthy

addition to your leather working library.

Fiebing's Fantastic Finishes

TOOLED BORDER

WITH FIGURE

CARVED CENTER

BORDER CENTER

BACKGROUND DYED

SHERIDAN COLORING

ADDED TO BORDER

GETTING STARTED

SELECTING THE RIGHT DYE, STAIN, ANTIQUE AND FINISH FOR

YOUR PROJECT: After spending hours tooling your leather project, adding color can

often seem like a "leap of faith". To lessen the doubt and increase your confidence, first

consider all of the possibilities illustrated in this book before settling on products to use.

Each has its advantages and can enhance the look and durability of your leather project.

Some will penetrate the leather more than others; some will result in bolder and brighter

colors and others will vary depending on the type of leather used. By the time you fnish

this book and with practice, you should be able to identify which Fiebing's product best

suits your needs.

CHOOSE THE RIGHT COLOR: Experiment with applying diferent colors on samples

of leather that are as close as possible to the leather used for your final piece. No two pieces

of leather are exactly the same; be patient and practice. Expect some variances even when

using the same products and colors.

SET UP A PROPER WORKSPACE: Work in a well lit space. A good mix of natural

and artifcial lighting is always preferable. Make sure your workspace is well ventilated

and free of unnecessary obstacles. Set up your work bench so that everything needed for

coloring your project is within easy reach. Keep lots of rags or paper towels close for clean

up. Choose a chair that puts you in a comfortable position over your project.

PREPARE THE LEATHER FOR DYEING AND FINISHING: Be sure your leather is

as clean as possible. Fie bing's Dye Prep is a formulated cleaner for use on leather that has

not been previously dyed or fnished. Fiebing's Deglazer can be used to clean and prepare

leather that has been previously fnished - it is the more potent of the two prep products.

COMPATIBILITY: Always consider which products work best together before applying

them to your leather project. A Compatibility Chart is found on page Z1.

THE BUCKING SADDLE BRONC COVER was designed, tooled and colored by

Tony Laier. Shown on this page are some of the techniques used to add color to the

original tooled piece. The following pages of this book will explain in more detail these

techniques and offer tips for coloring and finishing your projects.

CENTER COLORED

TOOLED LOGO APPLIED

Copyright ?003Fiebing Company. All rights reserved

LOGO COLORED FOR

FINAL COVER

LEATHER DYES: ALCOHOL, OIL WATER BASED

Choose the best dye or stain for your project, style and comfort level.

See pages 20 & 21 for color swatches.

FIEBING'S LEATHER DYE FIEBING'S PROFESSIONAL OIL DYE

The most recognized and trusted

penetrating alcohol based leather dye

in the world.

FIEBING'S LEATHERCOLORS

Penetrating leather dye that complies

with VOC regulations. Formulated with

a low VOC solvent base resulting in a

uniform fnish.

FIEBING'S LEATHER STAIN

Non-flammable, penetrating dye that

provides long lasting color. Fiebing's

Leather Stain is Linseed Oil based.

An alcohol based, penetrating dye created specifically

for natural strap leather, vegetable tanned leather,

bag and case leather. Vibrant colors and superior \

protection.

FIEBING'S INSTITUTIONAL

LEATHER DYE

Non-fammable, water based, penetrating leather dye

formulated for usc in hospitals, schools. prisons and

other institutions.

FIEBING'S DYE REDUCER

Use with alcohol based Leather Dye, Leather Colors

and Professional Oil Dye to dilute colors.

OVERALL COLORING TECHNIQUES

To do "overall" (large space) dyeing, be sure to have a suffcient quantity of dye on hand to cover the entire area.

Dyes may vary slightly in shade so consider combining more than one bottle to create a large enough batch needed to

complete the job without color variance. As always, make sure your workspace is well ventilated before using any of

these dyes. Here are various application techniques for applying the dye:

USING A DAUBER:

Dip dauber in dye and begin

in upper left corer moving

quickly in a continuous

circular motion, overlapping

the previous stroke. Keep

dauber full of dye, resuming

circular movement over

lapping previous strokes.

When the !st coat is dry, you may see light and dark spots. Go

over the entire project again, in te opposite direction with the

same procedure. If necessary, dye a third time or more until proper

coverage is achieved. When dry, buff to remove any excess dye

off surface and to achieve a sheen.

USING A SPRAYER (Air Brush or Aerosol

Sprayer with Bottle): Be sure you have plenty of

pre-mixed dye before starting. Fill bottle with dye. Attach

sprayer. Place project in a spray booth or spray box made

from cardboard. Position box on a sturdy table covered

with paper in a well ventilated area. Prop up project on

cardboard pieces or sticks to raise it up off paper. Tlus

will prevent dye from pooling along bottom edge.

USING BRUSHES:

When dyeing with a FLAT brush,

use cross and diagonal strokes for

1st, 2nd and 3rd applications for

a more solid, even dye coverage.

When using a ROUND brush, move

quickly in a circular motion so each

stroke slightly overlaps the previous

stroke. When more dye is needed,

dip, then resume circular movement

overlapping previous stroke. When

dry, buff to remove excess dye off

surface and for a sheen.

Begin spraying of the project on one side. Move across project spraying off project on the other side. Continue back and forth until

project is covere. Maintain a uniform distance from the project while spraying. Spray light coats until desired color is achieved. Allow

to dry. Give project a quarter mand re-spray if necessary. Allow to dry and buff with sheep wool or soft cloth to remove excess dye in

preparation for a top fnish and to achieve a sheen.

Fiebing's Fantastic Finishes

#4

ROUND

RED SABLE

BRUSHES

BRUSH SELECTION CARE

Most techniques of coloring can be done with a good quality or h+Round Red Sable brush. The head

should be approximately 1lin diameter by /long with a good snap or spring and a gradual taper to

a fine sharp point. A 1Round Sable is also good to have at hand for very fne detail work. Have separate

brushes for each color category (browns, reds, greens, yellows, blues and black). No matter how well a

brush is cleaned, some dye color will always remain in the brush ferrule. Dye that remains hidden in the

ferrule will eventually migrate down the bristles and mix with whatever color is being used.

GENERAL RULE: "The better the brush, the better the results."

TIP: Mark the end of each brush handle with electrical tape or paint that matches the

color category each brush is to be used for to avoid confusion.

HOW TO USE BRUSHES: Before using new brushes for the frst time, clean them thoroughly as described

below. Familiarize yourself with the brushes on scrap leather. Dip brush tip into dye (only Jl4of the bristle

length) but never up to or over the ferrule. Practice using varied

amounts of dye and pressure. LOADED means the brush is full

of dye. Too much dye is not a good practice. However, an over

loaded brush can be carefully used when fooding a background

surface. The amount of downward pressure on brush tip will

dictate the width of the stroke and the amount of dye

released. Only practice will help you decide when to

_

use more or less pressure.

1

CLEANING AND CARING FOR BRUSHES:

DYE REDUCER OR

WATER

When using ALCOHOL or OIL DYES, clean brushes with Fiebing's DYE REDUCER.

When using WATER BASED DYES, clean with water. TO CLEAN: Pull brush head

across a stack of folded paper towels or tissues while dripping dye reducer or water

directly on the bristles. Move to a clean area of the towel after each wipe. This will

remove most of the dye without harming the bristles. Then gently wash brush head

in warm soapy water (mild hand or dish soap). Pat brush dry on a paper towels and

reform the tip to opoint by rolling the tip in the crease of your palm.

TIP: Apply a drop of hand lotion in crease of your palm

before forming the tip. This will help retain the tip's point and

condition bristles for longer life. When properly cared for, good

quality brushes should last for many years.

REFORM TIP

OF BRUSH

MORE USEFUL ITEMS TO HAVE ON HAND

SCRAP LEATHER

MATCHING PIECE TO

BE COLORED

PAPER TOWELS

REDUCER FOR OIL

& ALCOHOL DYES

WATER FOR

WATER-BASED DYES

PLASTIC MULTI

HOLE PALLET

4

PLASTIC

SQUEEZE

BOTTLES &

EYE DROPPERS

Copyright 200SFiebing Compay. AII rights reserved

EXTRA APPLICATORS

.\\1J|l|

q

RACK FOR BRUSHES

(Brushes rack holes marked w/colors)

BACKGROUND DYEING

By defnition, the background behind a tooled design is dyed

separately from the rest of the piece. Practice using a h+Sable

brush for large areas and tight spaces on a piece of scrap leather

until you can control the movement of the brush. A h1 Sable may

be used in tight spaces if desired.

Always begin dyeing in the center of an open larger space; then

work towards the edges and into tight corners. Never touch

a cut edge or small area. Place brush near the space or edge

and let dye work up into the space. The technique for coloring

silhouetted designs and background coloring are the same.

TIP: After dipping brush in dye, touch tip on paper

Starting in a small space risks

having dye "bleed".

Correctly started in the

center of a space.

or scrap leather to remove excess dye before applying

dye to your project. Too much dye will run and "bleed"

into tool cuts and impressions.

WET BRUSHING is applying full strength or diluted hues of dyes with a heavily

loaded brush to obtain the most even full cover of dye tones.

This technique is most commonly used for background coloring Useen here and in Step I

on the next page. It is also used when base coats are applied to projects in preparation for

other techniques.

SHADING WITH DILUTED HUES is a shading technique using 2 or more

(nmmally 3) progressively darker strengths of one or more dye colors to create shape and

shadow. This type of coloring almost always follows the old water color rule "work light to

dark". Lighter and darker shades of dye are created by diluting dyes with diferent amounts

of the appropriate diluter: thinner or dye reducer for alcohol or oil based dye and water

for water based dves Refer to Monochrome Coloring on \HUf K !nrH diferent

appucauon or tccfiIQUe.

Heavily diluted

Kelly Green

Alcohol Dye

Lightly diluted

Kelly Green

Alcohol Dye

Full strength

Chocolate Brown

& Yellow

Full strength

Kelly Green

Alcohol Dye

DRY BRUSH SHADING is shading with full strength or diluted hues using a brush containing very little dye. To do this technique, dip

the tip of the brush into the dye, then stroke the brush on a paper towel or scrap piece of leather to remove most of the dye while forming

the tip of the brush into a fan shape. The fan shaped tip of the brush is then stroked lightly over the leather allowing only a very small

amount of dye to penetrate into the most raised areas of the leather adding color to those areas.

HIGHLIGHTING or "bringing out" (1) GRASS

and bark pattern detail on pictorial carvings and (2)

HAIR detail on fgure carved pictures are just two

of the many uses for the DRY BRUSH SHADING

coloring technique. This technique defines detail.

(1) GRASS

Fiebing's Fantastic Finishes

(2) HAIR

COLORING AN OAK LEAF

DEMO USING FIEBING'S LEATHERCOLORS

The How-To on this page is done using Fiebing's low VOC LeatherColors. The same steps can be followed using

Fiebing's alcohol or oil based dyes as well. The demonstration below includes 5steps to achieve a finished, colored

piece. However, depending on your choice of colors and hues (diluted colors) you may require more or less steps.

DYES & HUES USED

Yellow

(diluted) (diluted)

(diluted) (diluted)

| dilutedI |u|!utcu) cd

Mix desired color hues in enough quantity

to complete your project and keep count

of how much Fiebing's Reducer full

strength color you use to create the hue.

STEP 3

Diluted & full strength Green

(with Yellow added)

STEP I

Full strength Chocolate & Yellow

STEP 4

Diluted & full strength

Chocolate

Copyright ?008Fiebing Company. All rights reserved

STEP 2

Diluted & full strength

Medium Brown

STEP 5

Diluted & full strength Red

COlORING A FlORAl

DEMO USING FIEBING'S INSTITUTIONAL LEATHER DYES

The How-To on this page is done using Fiebing's water based Institutional Leather Dye. The same steps can be

followed using Fiebing's alcohol or oil based dyes as well. The demonstration below includes 5steps to achieve a

finished, colored piece. However, depending on your choice of colors and hues (diluted colors), you may require

more or less steps.

DYES & HUES USED

Black Yellow

(diluted) (diluted)

Red

Tan

Green

Mix your desired color hues in

enough quantity to complete

your project or keep count of

how much water & f\ll strength

color you use to create the hue.

STEP 3

Diluted & full strength Tan

STEP 1 STEP 2

Full strength Black Full strength Yellow

STEP 4 STEP 5

Diluted & full strength Green Full strength Red

Fiebing's Fantastic Finishes

COLORING A FIGURE PICTORIAL SCENE

DEMO USING FIEBING'S LEATHER DYE

The How-To on this page is done using Fiebing's alcohol based Leather Dye. The same steps can be followed using

Fiebing's water based or oil based dyes as well. The demonstration below includes 5steps to achieve a fnished, colored

piece. However, depending on your choice of colors and hues (diluted colors), you may require more or less steps.

Acrylic Dyes were used to add accent colors to the sky, deer and snow on mountains.

DYES & HUES USED

Chocolate Britsh

1anMx

(diluted)

(diluted) (diluted)

Chocolate

Green

Kelly Green

Chocolate & Black Mix

(diluted) (full 1f C 11g1f1)

Acrylic Dyes:

White Blue

D

STEP 3

--

Diluted full strength Green

--

LIutcd uII strength Kelly Green

STEP 1

Diluted & stronger Chocolate &

British Tan Mix

STEP 4

Diluted & full strength Chocolate &

Black Mix on rocks & mountains

Copyright 208F.cbngCompny.AIItights reserved

STEP 2

Full strength Chocolate

STEP 5

D

White & Mix of Blue

& White Acrylic Colors

MORE COLORING TECHNIQUES

MONOCHROME COLORING

MONOCHROME COLORING is coloring with one color or various shades of that one color. This technique

involves beginning with a light shade of one color and adding darker shades of the same color to create a 3-D effect

of roundness and depth on an object.

Brown is the preferred color. when using this technique on leather because natural vegetable tanned leather is a shade

of brown. However, any color will work. The samples below show how efective the Monochrome Coloring technique

can be using just three shades of one brown color. Drawings on the left show where different shades are used.

2A) Second area to be colored. Use about a half and half

mx of dye and solvent (or water).

3A) Third area to be colored. Use full strength dye.

lB) FIRST COAT: Acts as a base coat, defining

muscle tones, shadow areas and highlights.

2B) SECOND COAT: Used to strengthen and defne

muscle tones, shadow areas and highlights.

3B) THIRD COAT: Used to color eye and apply final

shading and coloring for definition.

Fiebing's Fantastic Finishes

ACRYliC COLORS

FIEBING'S ACRYLIC DYE

Quick drying, long lasting leather paint for color

coating a smooth leather surface. Acrylic dye is fexible

and water resistant. The colors are easily mixed and

can be diluted with water. Acrylic dye also makes for a

great edge finish. Fiebing's offers a convenient Acrylic

Dye Pack that includes ! Acrylic Dye colors, Fiebing's

Resolene top fin ish and 2mtist brushes.

TIP: Normally, Acrylic Dye is applied over

natural or dyed leather using a brush. Many

different textured effects can be achieved

using other applicators, such as sponges

(natural and synthetic), daubers, wool, cloth,

etc. Clean applicators with water.

TIP: To color a sky as shown above, dampen leather frst to extend the time Acrylic Dye can be worked before drying. Begin

at the top using a dark blue-white mix. Blend in more white to lighten the sky as it approaches the mountain tops. Add in

wispy clouds last using straight white thinned with water to form a wash.

STRONG USE: Sample above shows white

acrylic applied in quantity to bring out the

flo

wer petals.

TIP: When adding accent

detail using acrylic dyes on

a fgure or pictorial carved

piece, it is important to have

as much control of the dye

direction as possible. This

control requires a quality

brush. A #1 Round Red Sable

brush works very well for

detail and allows control

of dye placement.

SUBTLE USE: Sample above shows white

acrylic applied paringly with a quality

brush to accent deer features.

Copyright 200SFiebing Company. Arights reserved

FIEBING'S

ANTIQUE

LEATHER STAIN

Antique Leather Stain is

an acrylic, water based

antique fnish. Apply in

a circular motion with

a dauber, wool swatch

or cloth. Wipe off excess with a cloth or

damp sponge leaving antique in the cuts

for contrast.

ANTIQUES

FIEBING'S

ANTIQUE FINISH

Antique Finish is a paste

that offers a soft patina

that emphasizes tooling,

carving and embossing.

Antique Finish is applied boldly in a

circular motion with a dry piece of wool

or cloth. Immediately remove excess of

raised areas leaving desired amount in the

cuts for contrast. Antique Finish can be

thinned with Fiebing's Tan Kote. Use a top

fnish of your choice for desired results.

FIEBING'S

HI-LITER

Hi-Liter is an easy to

use stain that imparts

a light brown color to

natural leather combined

with a dark brown build

up of color in cuts and

impressions for maximum contrast. Apply

with a damp sponge and rub well into cuts

and tooled impressions. Remove excess

with a damp sponge and apply a top finish

of choice as needed.

APPLICATORS FOR ANTIQUES STAINS

CLOTH

Cloth may be used to apply all antiques and stains but is most commonly used to remove excess after the antique or stain has been

applied using other applicators such sheep wool, sponges or daubers. Cloth, especially when wrapped tightly around a small wooden

block ("block dyeing"), will leave more antique down in cuts and impressions than other types of applicators. For a lighter look to an

antiqued project, slightly dampen the cloth with water before use, which will allow more pigment (color) to be lifted and removed. A

clean, soft cloth also works well to buf antiques to a nice sheen in preparation for the application of a fnal top fnish.

SHEEP WOOL

Sheep wool is also a good applicator for all antiques and stains, but is preferred for applying Antique Finish. The texture of wool helps

to push Antique Finish, a thick paste, down into cuts and impressions. Sheep wool also holds a lot of antique and stain allowing for

greater coverage and a longer working time in between trips to the container. No other material works better to remove unwanted excess

antique stain, wax fnishes, soap, etc. from cuts and impressions. In addition, the softness of wool makes it ideal for almost all buffng

and polishing.

SPONGE

A sponge, slightly dampened, is the preferred applicator for applying Antique Leather Stains and Hi-Liter. These liquids tend to dry

quickly during application. A sponge's cell structure allows it to hold a lot of stain and the added water acts as an extender which allows

for a longer time to work the product evenly into the leather. A slightly dampened sponge also works well to remove excess stain and

Hi-Liter before a top fnish is applied.

BRUSHES & DAUBERS

Brushes and daubers are mainly used to apply liquid dyes or edge coatings, but they can also be used in some cases to apply antiques

and stains. These include applying antique and stain on smaller projects or on projects where a lot of control is called for, such as areas

to be left antique or stain fee resisted).

Fiebing's Fantastic Finishes

SPECIAL EFFECTS: BASE COAT ANTIQUING

BASE COAT ANTIQUING TECHNIQUE involves using diferent colors of Fiebing's alcohol, oil or water based

dyes together with different colors of Fie bing's Antique Finish to produce an almost limitless combination of deep,

vibrant colors on vegetable tanned leather. This technique brings out carved, stamped and tooled designs as well as

highlights seams, edges of appliques and overlays.

HOW TO DO BASE COAT ANTIQUING

1) Apply an overall base coating of Fiebing's water, alcohol or oil leather dye using an aerosol sprayer or air

brush . The more even the base coat the better.

2) Optional: Adding shading around figures and edges plus background dyeing some areas a darker color than

the base coat color can emphasize and add depth to the design. (See Bison Head shown below.)

3) Allow dye to dry completely. Then buff with a clean soft cloth or piece of sheep wool to remove any pigment

from the surface.

4) Apply a liberal coat of Fiebing's Antique Finish. (For best results, use a darker color of Antique Finish than

the dye color used for the original base coat.) Be sure antique gets into all impressions and cuts.

5) Before Antique Finish dries, remove excess fnish with a clean piece of sheep wool and buff to a soft luster.

6) Allow to dry completely. Then apply a Fie bing's Top Finish of your choice.

Tooling by Tony Laier /Coloring by Philip Smith (Phoro courtesy of Steel Strike Leather Products, Inc.)

Copyright 2008Fiebiog Compay. AIIrights reserved

SPECIAL EFFECTS: RESISTS (BLOCKING)

Most Fiebing's top finishes, when applied to natural or dyed leather, will resist or block the penetration of antiques

and stains. Some will resist or block more than others depending on what base was used, not only in the top finish,

but also in the antique or stain. For instance, acrylic based Leather Sheen will resist or block more with acrylic based

antiques or stains than resin based Tan-Kote. The various hues possible can be used to create many different effects.

USING RESISTS ON NATURAL (UNDYED) LEATHER:

EXAMPLE Al shows a RESIST OF FIEBING'S LEATHER SHEEN applied with a brush to a design on natural leather. EXAMPLE A2

shows Fiebing's Antique Leather Stain applied over the design, after top fnish dried.

Al A2

EXAMPLE Bl shows the same design RESISTED WITH FlEEING'S TAN-KOTE. EXAMPLE B2 shows application ofFiebing's

Antique Leather Stain. Notice the darker hues created with the lesser resisting or blocking power of the resin based Tan-Kote.

Bl

USING RESISTS ON DYED LEATHER:

A resist of Fiebing's Leather Sheen, Fiebing's Tan-Kote or other top fnish over a design colored with Fiebing's

Leather Dye (alcohol, oil or water based) can be used with great effect to tone down harsh colors and defne cuts

and impressions.

EXAMPLE Cl shows a design colored with alcohol dye, RESISTED WITH LEATHER SHEEN. EXAMPLE C2 shows design coated

with Fiebing's Antique Leather Stain after the Leather Sheen dried.

Fiebing's Fantastic Finishes

SPECIAL EFFECTS: RESISTS (BLOCKING)

EXAMPLE Dl shows the same alcohol dye colored design. RESISTED WITH FlEBfNG'S TA-KOTE.EXAMPLE D2 shows the

design coated with Fiebing's Antique Leather Stain after the TanKote dried.

Dl D2

USING ANTIQUE AND STAINS WITH ACRYLIC DYES:

Antiques and stains may also be applied over a design painted with acrylic dye. The antique or stain will tone down

acyclic dyes' bright colors, at the same time accenting all cuts lines and impressions. Note: it is advisable to seal the

color white with an acrylic top fnish to prevent the antique or stain from turning the white dye yellow. Diferent top

finishes may be applied as resists over all colors of acrylic dye.

EXAMPLE El >hoYs a design colored with Fie bing's Acrylic Dye before a coat of Fiebing's Antique Finish is applied.

EXAMPLE E2 shows the same acrylic colored design after a coat of Fiebing's Dark Brown Antique Finish was applied. A top coat resist

may be applied over leaves and fowers before antiquing if brighter colors are desired.

El E2

BEESWAX AND LEATHERCRAFT CEMENT

FIEBING'S BEESWAX CAKES

Fiebing's Bees Wax is the perfect thread pre-coating for all linen handstitching threads. Strengthens and protects

thread for easier sewing and longer thread life. Pure beeswax cakes are also used by boot makers to fill cracks in the

toes and heels of boots and shoes before final finishing.

TIP: Beeswax can be used as a creative resist. Lightly draw a design onto leather with edge of wax. Gently

brush off excess wax residue. Apply dye. Remove excess dye and lightly buf. Great for kids.

FIEBING'S LEATHERCRAFT CEMENT

High strength bonding leathercraft cement for all leathers. Fiebing's Leathercraft Cement is the perfect adhesive to

use for filigree and applique work. Non-fammable. non-toxic and quick drying.

TIP: May also be used as a resist or block. Use a brush to apply. Thin with water if necessary. Let dry

completely before applying dyes, stains or antiques.

Copyright 200SFiebing Company. AIIrights reserved

TOP FINISHES

BEFORE APPLYING A TOP FINISH TO YOUR PROJECT:

PREPARE YOUR WORKSPACE:

1) Clear away all unnecessary supplies, especially dyes, applicators, cloths, wool pieces that may

contain dye residue that could get onto your fnished project.

2) Use a small dish or extra empty clean bottle for easier access with applicator.

3) Also have a dish of water available for dampening sponges or cloths if necessary.

4) Have all possible applicators handy and ready to use.

5) Have excess amounts of paper towels and a trash can with plastic liner.

APPLYING A TOP FINISH:

NOTE: Practice finishing techniques on scrap leather.

1) Dip end of sponge (or other applicator) into finish and

apply to the leather, beginning at top and working downward.

2) Dip in finish as often as needed.

3) Apply liberally and work into all cuts and depressions.

4) Move quickly and try to spread finish as evenly as possible.

5) Some fnishes should not be rubbed or buffed after they are dry.

Always read directions for use before applying the finish.

TIP: Most Fiebing's top fnishes may be applied with an air brush, aerosol or commercial sprayer. Thicker

top fnishes such as Fiebing's Tan-Kote and Fiebing's Bag Kote should be thinned with water before use.

Always begin and end spraying off of the project to prevent spots of heavy build-up. Spray on light coats

allowing each to dry before applying another.

FIEBING'S INSTITUTIONAL

LEATHER FINIS

H

A water based neutral top finish for use in schools,

hospitals, prisons and other institutions. Although it is

best applied with a spray, it can be applied sparingly

with a soft cloth or brush. Do not let finish run.

FIEBING'S LEATHER BALM

WITH ATOM WAX

A specifically formulated liquid wax fnish that can be

buffed to a rich, soft, velvety luster. Although Leather

Balm with Atom Wa is not a water resistant top fnish,

it is the preferred fnish of many professional belt

makers. It is best applied sparingly with a soft cloth or

wool skin worked evenly into the leather and allowed

to dry.

FIEBING'S CARNAUBA CREAM

This blend of natural waxes, originally developed

for use on smooth leather, also works well on certain

carved and stamped projects. If used on carved or

stamped leather, any residue should be removed from

cuts and impressions as explained in the TIP on this

page. Work evenly into the leather with a soft cloth or

sheep wool. Allow to dry and buff to a mellow glow.

TIP: When a top finish containing wax is used

on a tooled design, care must be taken to prevent

an unsightly build-up of wax residue in cuts and

impressions. Listed below are a few ways to safely

remove the residue if it does occur:

1) Try to remove the residue by rubbing briskly

with sheep wool. This method works best if

the fnish is still wet.

2) If the wool does not remove all of the residue,

scrub affected areas with a soft, fne bristled

tooth brush. Clean up and buff with sheep

wool.

3) If wax residue still remains in cuts and

impressions after trying Steps 1 and 2,try

warming np the wax using a hair dryer set

on low heat. In most cases, this will re-Iiquify

the wax enough allowing Steps 1 and 2to work.

CAUTION: Use a low or no-heat setting only!

A high-heat setting may damage the leather.

Fiebing's Fantastic Finishes

TOP FINISHES

This piece shows a base coat of Fiebing alcohol based

Leather Dye, Fiebing's Antique (paste) and Fiebing:

Leather Sheen top fnish. Tooled by Tony Lier &colored

by Philip Smith. (Photo courtesy of Steel Strike Leather

ProduCls, Inc.)

TIP: Make eyes come alive

by using a high gloss top

finish, such as Leather

Sheen, instead of painting

white spots on the eyes.

FIEBING'S

LEATHER SHEEN

(LIQUID VS.

AEROSOL SPRAY)

Fiebing's Leather Sheen is available in liquid form

and as an aerosol spray and are very different in

application and result. Both are acrylic, wax top

fnishes but that is where the similarity ends. The

aerosol version is best used for providing a quick

and high gloss shine. The liquid version is preferred

if an acrylic seal is desired over the top of your

colored leather project. The liquid version will

provide a more water resistant finish.

FIEBING'S SADDLE LAC

A clear, quick drying lacquer fnish in an

aerosol can. Saddle Lac dries glossy and hard

yet fexes without cracking. Apply to your

project when completely dry by holding the

can o inches fom the surface and spraying

lightly. Saddle Lac may be used as a resist

for Sheridan Style coloring as shown

on page 16.

Designed, tooled and colored by Tony Laier this J dimensional picture

shows the use of Fie bing :Alcohol Based Dyes applied with a red sable

brush. Leather Sheen top finish, both liquid and aerosol, were used for

the final seal on the individual pieces before assembly. Leather Sheen

liquid applied with a brush works best for detail pieces, while spray is

easier to use for an even overall background coverage.

^

FIEBING'S ACRYLIC RESOLENE

A fexible, durable, water resistant acrylic top fnish

for dyed, antiqued or polished leathers. The surface

of your item should be dry and clean before applyig

Resolene. If you are spraying, spray one light coat

and let dry. If using an applicator, use a damp sponge

in long strokes once over to prevent tacky build up.

Resolene may also be used over Fiebing's Edge Dye

for a durable top fnish.

Copyright 2008Fiebing Company. PlIrghts reserved

TOP FINISHES

SHERIDAN STYLE COLORING USING OVERAll TOP FINISH RESIST

) Optional: After all tooling is completed, add a very light coat

of Fiebing's Neatsfoot Oil. This helps replenish oils lost in the

casing and tooling processes.

3) Apply a liberal coat of Fiebing's Sheridan Brown Antique

Finish or other color. Mix colors for different hues. Use a sheep

wool applicator. Work antique down into all cuts and

impressions. Remove excess antique with clean pieces of sheep

wool using long straight strokes (not circular) to keep as much

antique down in cuts and impressions as possible.

2) Apply a coat of Fiebing's Tan Kote, Leather Sheen, Saddle-Lac,

Resolenc or other top fnish to act as a resist. (NOTE: Use Tan

Kate or Bag Kote as a resist on saddles.) Allow to dry completely.

4) After all excess antique has been removed, leaving desired

antique in cuts and impressions, allow project to dry

completely. Then buff with a clean piece of sheep wool.

5) Apply Fiebing's Tan-Kote as a fnal fnish. NOTE: Tan-Kote

will pick up some of the antique, so do not rub too hard while

applying. Buf to a mellow satin glow.

-

8W

M

WMW

.

FIEBING'S TAN-KOTE

Tan-Kote is a resin based, moisture resistant, easy to apply top fnish. It goes on smooth, even and streak free

leaving a soft, mellow satin fnish. Tan-Kote is a preferred finish for saddle makers because it allows the saddle

to be periodically cleaned and oiled. Tan-Kote is often used to thin down Fiebing's Antique Finish. Neutral can

be tinted different colors by mixing in small amounts of water based Fiebing's dye. Tan-Kote also brings out

and enhances carved and stamped designs. Apply an even coat with sheep wool, sponge, brush or sprayer. lf a

sprayer is used, thin with water. Always let dry between coats and always allow to dry completely.

FIEBING'S BAG KOTE

Bag Kote, another top finish preferred by saddle makers, will give a soft, satin fnish no other product can

achieve. Fiebing's Bag Kote was originally developed by John Ficbing over 6U years ago U a treatment for US

Mail Carrier's leather mail bags and remains unchanged to this day. Bag Kote may either be sprayed or applied

with a damp sponge, sheep wool or dauber. Bag Kote may be applied over natural or dyed leather. A thin coat

is all that is necessary. Bag Kote may be applied over natural or dyed leather. lt may be diluted with water up

to 2U%.

Fiebing's Fantastic Finishes

EDG

jNAMI

ACK

(q/, 114^'

EDGE FINISHING

FIEBING'S EDGE ENAMEL

Edge Enamel is a heavy bodied, resin

based edge finish. To use, apply after

smoothing the edges to produce a clean,

smooth and glossy edge. Edge enamel

can be thinned with water.

FIEBING'S EDGE DYE

A penetrating edge fnish that is

durable and long lasting. Edge Dye

will dry to a semi-gloss and needs to

be applied to edges that have been

smoothed down. After it is applied,

Edge Dye can be polished, burnished

or fnished with Resolene.

APPLICATORS

FIEBING'S EDGE KOTE

Edge Kote dries water resistant with a fexible,

deep semi-gloss. Edge Kote is recommended

for use on nah1ral edges and can be thinned with

water. Always stir Edge Kote, never shake. If a

higher gloss is desired, allow to dry completely

and buff gently with a soft cloth.

FIEBING'S EDGE DYE

FINISH & APPLICATOR

A convenient, water resistant acrylic edge finish

that dries in minutes. Provides a quick and easy

professional fnish on the edges of belts, saddles

and other leather goods. lnve11 bottle and apply

evenly with attached sponge applicator.

Many types of applicators will work to apply edge dye or finish including the following: A small ( I long 7 3/4" wide 7 Ii2'

thick) square of thick dense felt or a small square of sponge held by a clothes pin. An applicator preferred by many professionals

is a wool dauber prepared by trimming to desired size. All of these applicators will work well with all edge dyes and fnishes.

APPLICATOR MACHINES

Various companies make different types of machines that apply edge finishes. These machines normally involve a wheel of some

type that rotates through a reservoir containing the edge fnish. Running a project over the wheel causes rotation which picks up

edge fnish from the reservoir and transfers it to the project's edge. All of the above Fiebing's edge finishes will work in most of

these types of machines.

SELECTING THE RIGHT EDGE TREATMENT APPLICATOR:

L

There are many options for Edge Treatment Applicators.

Some can be pmchased ready-made:

Small & large wool daubers

Sponges of all sizes

Sponge brush

Many leather workers prefer to make their own

applicators or modify the store bought variety as needed

for their individual projects.

Felt Daubers

Wool daubers trimmed to desired size

Rectangular felt on end of clothespin

Many options custom to the individual worker

Copyright 200SFiebing Compan). rights reserved

EDGE FINISHING

EDGE PREPARATION:

For more professional looking projects, preparing edges prior to the application of edge dyes or fnishes is essential.

The basic steps used to prepare an edge are:

) Round of square cut edges with an edge beveler

or bissonnette sized for the thickness of the

leather.

2) Use a sponge to lightly dampen the beveled edge

with water or Fiebing's Gum Tragacanth. NOTE:

Gum Tragacanth acts as a light resist or block. For

best results, apply after project has been antiqued

or stained.

3) Rub edge briskly with an edge slicker, bone folder

or piece of natural coarse canvas to compress the

fbers and burish the edges. If some fbers on the

edge refuse to lay down, remove them by

rubbing edge with a piece of very fne grit sand

paper. Then repeat Steps Z and J.

4) Apply your choice of edge dye or fnish using one

of the applicators described in this section.

LEATHER

EDGE BOTH SIDES OF LEATHER

NOTE: Edge dressings should

normally be applied after top fnishes.

Care should be taken to keep fnish

off slicked (burnished) edges of your

projects. If fnish gets on edge, sand

edge with a very fne grit sandpaper.

Then re-slick (burnish) edge and

apply edge dressing.

TIP: Lightly dampen edge with water before rounding

off with an edge beveler or bissonnette. The edger will

cut through the leather much easier and leave a smoother

surface in preparation for next step.

TIP: Dip applicator into edge dye or fnish and touch to a

piece of scrap leather or paper towel to remove excess. Use

quick, long light strokes to apply on edge. For best control

during application, lay project fat on work table with

edge of project overhanging the edge of table, if possible.

EDGE APPLICATOR OPTIONS:

1) DIFFERENT SIZED TRIMMED DAUBERS

2) FELT DAUBERS

J)SPONGE BRUSHES

4)SMALL PIECE OF FELT ON A CLOTHESPIN

CANVAS

TIP: Projects that

have multi-layers of

appliqued leather

will need to have

edges prepped for

dyeing before they are

assembled. A fnal top

finish is applied after all

pieces are assembled.

Fiebing's Fantastic Finisbes

APPLICATOR

(Dauber Shown)

LEATHER CARE

Oi lS: Many leather workers prefer to use oils (natural and compounds) on their leather projects, adding or replacing

oils lost in construction or with time, use and weathering. For best results, apply oils sparingly and allow to set. Then

apply more coats if necessar. The following products work especially well on Leather items that will be subjected to harsh

treatment and outdoor use.

FIEBING'S 100% PURE NEATSFOOT OIL

For smooth or tooled new leather or previously oiled with Fiebing's

Pure Neatsfoot Oil. Apply a light even coat, rubbing briskly with a soft

clean cloth. Allow oil to set and penetrate for 24hours. Apply additional

coats if necessary.

FIEBING'S PRIME NEATSFOOT OIL COMPOUND

A combination of natural and synthetic oils for softening, preserving

and waterproofing smooth leathers. Clean leather and apply oil allowing

to penetrate freely. Rub briskly with soft, dry cloth.

FIEBING'S MINK OIL PASTE

A natural by-product that softens, preserves and waterproofs all smooth

leather or vinyl. Best when used on medium to dark colored a1ticles.

Apply freely, working well into leather and wipe of excess. Helps

prevent salt stains.

FIEBING'S MINK OIL LIQUID

This blend of Mink Oil and !UU%Pure Neatsfoot Oil softens, preserves

and waterproofs smooth leather. Will darken light leather. Apply freely

and work into leather. Allow for absorption and then wipe off excess.

Pbotoo{sooJ|ecourtes,o{RickBeon

C 0 N D IT I 0 N E R S: The following leather conditioners were developed to replenish oils and waxes lost through

use and weathering. One contains a mild soap especially formulated for use on .ne and exotic leathers. The other was

created for leather items that receive hard use and are subject to harsh climates.

I

FIEBING'S 4-WAY CARE LEATHER CONDITIONER

A combination of oil and wax that I ) cleans, 2)conditions, 3) waterproofs and 4)replenishes the tanning oils in leather. 4Way

Care Leather Conditioner can also be used to clean fne leather including exotics because it contains leather soaps that float

out dirt and grime. Especially effective on leather upholstery including leather car seats. Use a clean cloth or sponge to spread

a thin coat on the leather. Allow to penetrate thoroughly, then rub briskly with a soft, dry cloth to clean and polish.

FIEBING'S AUSSIE LEATHER CONDITIONER

This product should be used after frst cleaning the leather article with Fiebing's Saddle Soap. Aussie Leather Conditioner was

developed for Australian horsemen living in harsh climates. It contains natural beeswax and is perfect for use on saddles, tack,

boot, gun cases, and handbags. Apply a light coat with a clean cloth. Allow product to penetrate. Buff of excess.

SOAPS: When leather needs more than just a conditioner, serious cleaners like these should be used. Keeping your

leather articles clean will prolong their life and restore the beaut ofthe leather.

FIEBING'S LIQUID

GLYCERINE SADDLE SOAP

For large, smooth articles that need to be cleaned, using

a spray will be easier than paste. Spray on a generous

amount. Rub thoroughly with sponge or brush until

foam disappears. After leather is dry, buff with cloth to

a rich, satin finish.

FIEBING'S SADDLE SOAP PASTE

This is Fiebing's signature product. It cleans @

leather and lubricates fbers to prevent brittleness,

while maintaining suppleness and strength.

Dampen cloth or sponge and rub lightly over

soap to produce lather. Apply to leather surface.

When dry. polish with soft cloth for light luster.

Copyright 2008Fiebing Comny. .rights reser ved

FIEBING'S

LEATHER

COLORS

See page 2

RED

LIGHT BROWN

FIEBING'S

INSTITUTIONAL

LEATHER DYE

See page 2

FIEBING'S

LEATHER DYE

See page 2

MAHOGANY

UGHT BROWN

LIGHT TAN

LIGHT BLUE

FIEBING'S

PROFESSIONAL

OIL DYE

See page ?

LIGHT BROWN

FIEBING'S

ACRYLIC DYE

See page 9

LlGHTBLUE

LLLLkLNPk1o

MAHOGANY

SADDLE TAN

RED

GREEN

RED

DARK BROWN

BEIGE

YELLOW

NAVY BLU

RED

SADDLE TAN

RED

BLUE

CORDOVAN CHOCOLATE DARK BROWN MEDIUM BROWN

YELLOW GREEN ROYAL BLUE

DARK BROW MEDIUM BROWN TA\

BLUE

OXBLOOD

CORDOVAN

TAN

W ,

KLI^GREEN

PURPLE

MAHOGANY

YELLOW

ORANGE

MEDIUM BROWN

BLACK

DARK R

CHOCOLATE

BRITISH TAN

GREEN

BLACK

CHOCOLATE

GREEN

YELLOW

DARK BROWN

Fiebing's Fantastic Finishes

BURGUNDY

MEDIUM BROWN

BUCKSKIN

AQUA GREEN

GREY

DARK BROWN

ROYAL BLUE

GREEN

BLACK

BLACK

YELLOW

MAROON

RUSSET

ORANGE

TURQUOISE

L

WHITE

WALNUT

BLACK

TURQUOISE

WJ

COMPATIBILITY CHART

Always test the compatibility of products before applying them to your leather piece.

CODES

A = YES - but fnish may pick up some color.

B YES - but be sure to remove excess ANTIQUE from surface before applying a fnish.

Allow antique to dry completely or finish may streak, crack and fake off.

C = NO on items that bend or fex. YES on items that will NOT be bent or fexed. / . '

* D YES - may be applied BEFORE or AFTER finish.

* E NO - may not be applied over fnish.

* NOTE: Edge dressings should normally be applied afer top fnishes. Care should be taken to keep

finish off slicked (burnished) edges. Ufinish gets on edge, sand edge with a very fe grit sandpaper.

Then re-slick (burnish) edge and apply edge dressing.

FIEBING'S DYES, FIEBING'S FINISHES:

STAINS, ANTIQUES: Leather Sheen Institutional Finish Resolene Saddle Lac Leather Balm w/Atom N Tan Kote Bag Kote Carnauba Cream

Leather Dye ^ ^ ^ yes ^ ^ ^ ^

Leather Color yes ^ ^ yes yes yes yes yes

Leather Stain ^ ^ ^ ^ ^ ^ ^ ^

ImI. Oil Dye ^ ^ ^ yes ^ ^ ^ ^

Inst . Dye ^ ^ ^ yes ^ ^ ^ ^

Antique Leather Stain ^ ^ ^ yes ^ ^ ^ ^

Antique Finish ^ ^ ^ ^ ^ ^ !

Hi-Liter ^ ^ ^ yes ^ ^ ^ L

Edge Enamel D D D E E D D E

Edge Kote

D D D D E D D E

Edge Dye

D E E D D D D D

Edge Dye Finish

D D D

w/Applicator

D E D D E

Copyr ight ?008Fiebing Company. Arights reserved

Potrebbero piacerti anche

- 1303CF BasicsOfLeathercrafting PDFDocumento7 pagine1303CF BasicsOfLeathercrafting PDFCristina RăileanuNessuna valutazione finora

- Eco Flo Leathercraft Dyeing Finishing GuideDocumento8 pagineEco Flo Leathercraft Dyeing Finishing GuideCawton Mentor100% (1)

- The Leatherworking Starter Handbook: Beginner Friendly Guide to Leather Crafting Process, Tips and TechniquesDa EverandThe Leatherworking Starter Handbook: Beginner Friendly Guide to Leather Crafting Process, Tips and TechniquesNessuna valutazione finora

- Leatherwork Manual by Al Stohlman AD Patten and JA WilsonDocumento165 pagineLeatherwork Manual by Al Stohlman AD Patten and JA WilsonAndrei Twin93% (54)

- Leather Working - With Numerous Engravings and DiagramsDa EverandLeather Working - With Numerous Engravings and DiagramsValutazione: 5 su 5 stelle5/5 (1)

- An Insiders Guide To LeathercraftingDocumento24 pagineAn Insiders Guide To LeathercraftingNewbearLongfish74% (23)

- Basic Leathercrafting: All the Skills and Tools You Need to Get StartedDa EverandBasic Leathercrafting: All the Skills and Tools You Need to Get StartedValutazione: 4 su 5 stelle4/5 (5)

- Inverted Leather Carving by Al StohlmanDocumento52 pagineInverted Leather Carving by Al Stohlmanrobaczek_wrednej_zolzy100% (17)

- A Guide to Making a Leather Purse - A Collection of Historical Articles on Designs and Methods for Making PursesDa EverandA Guide to Making a Leather Purse - A Collection of Historical Articles on Designs and Methods for Making PursesNessuna valutazione finora

- Al Stohlman - Finesse Figure CarvingDocumento136 pagineAl Stohlman - Finesse Figure CarvingEliana Ferreyra100% (11)

- Complete Guide To Ornamental Leather WorkDocumento104 pagineComplete Guide To Ornamental Leather Workwriath1974100% (9)

- 史东门箱包制作Ⅰ手工皮革艺术leather+caseDocumento118 pagine史东门箱包制作Ⅰ手工皮革艺术leather+caseBonanza Chan100% (18)

- The Leather Crafting, Wood Burning and Whittling Starter Handbook: Beginner Friendly 3 in 1 Guide with Process,Tips and Techniques in Leatherworking and Wood CraftingDa EverandThe Leather Crafting, Wood Burning and Whittling Starter Handbook: Beginner Friendly 3 in 1 Guide with Process,Tips and Techniques in Leatherworking and Wood CraftingNessuna valutazione finora

- Stohlman - The Art of Hand Sewing Leather - 1977 PDFDocumento72 pagineStohlman - The Art of Hand Sewing Leather - 1977 PDFDiego Marzocchi90% (21)

- Al Stohlman - How To Make HolstersDocumento37 pagineAl Stohlman - How To Make Holstersmerregue93% (15)

- Al Stohlman - Belts GaloreDocumento37 pagineAl Stohlman - Belts GaloreLucasKrow100% (6)

- Get Started in Leather Crafting: Step-by-Step Techniques and Tips for Crafting SuccessDa EverandGet Started in Leather Crafting: Step-by-Step Techniques and Tips for Crafting SuccessValutazione: 4.5 su 5 stelle4.5/5 (3)

- Decorative Leather ToolingDocumento7 pagineDecorative Leather ToolingMutually Exclusive, Collectively Exhaustive100% (1)

- A Guide to Making Leather Gloves - A Collection of Historical Articles on the Methods and Materials Used in Glove MakingDa EverandA Guide to Making Leather Gloves - A Collection of Historical Articles on the Methods and Materials Used in Glove MakingNessuna valutazione finora

- Weaver Leather 2013 EditionDocumento294 pagineWeaver Leather 2013 EditionPhuoc Loc Nguyen Pham100% (6)

- The Art of Leather Burning: Step-by-Step Pyrography TechniquesDa EverandThe Art of Leather Burning: Step-by-Step Pyrography TechniquesValutazione: 4 su 5 stelle4/5 (5)

- 6009 00 The Leather Craft Handbook by Tony Laier & Kay LaierDocumento33 pagine6009 00 The Leather Craft Handbook by Tony Laier & Kay Laiersereke7790% (21)

- Making Leather Bags, Wallets, and Cases: 20+ Projects with Contemporary StyleDa EverandMaking Leather Bags, Wallets, and Cases: 20+ Projects with Contemporary StyleValutazione: 5 su 5 stelle5/5 (2)

- Leather CraftingDocumento57 pagineLeather CraftingAna Maria Gruia100% (19)

- A Guide to the Decoration of Leather - A Collection of Historical Articles on Stamping, Burning, Mosaics and Other Aspects of Leather DecorationDa EverandA Guide to the Decoration of Leather - A Collection of Historical Articles on Stamping, Burning, Mosaics and Other Aspects of Leather DecorationNessuna valutazione finora

- 4-Slot Bifold DirectionsDocumento2 pagine4-Slot Bifold DirectionsAmanda Merritt100% (3)

- Artistic Leather Work - A Handbook on the Art of Decorating LeatherDa EverandArtistic Leather Work - A Handbook on the Art of Decorating LeatherNessuna valutazione finora

- Tooling Leather (E-How)Documento9 pagineTooling Leather (E-How)blackriptonite100% (1)

- Learning How to Work with Leather: Includes DIY ProjectsDa EverandLearning How to Work with Leather: Includes DIY ProjectsNessuna valutazione finora

- Leather CraftingDocumento9 pagineLeather CraftingChristopher Hufanda Lensig0% (2)

- Sew Luxe Leather: Over 20 Stylish Leather Craft AccessoriesDa EverandSew Luxe Leather: Over 20 Stylish Leather Craft AccessoriesNessuna valutazione finora

- Leather BriefcaseDocumento34 pagineLeather Briefcasesteeluis100% (3)

- Woven Leather Bags: How to Craft and Weave Purses, Pouches, Wallets and MoreDa EverandWoven Leather Bags: How to Craft and Weave Purses, Pouches, Wallets and MoreValutazione: 5 su 5 stelle5/5 (1)

- Manual of Leather GoodsDocumento153 pagineManual of Leather Goodssnatesan96% (56)

- Leathercraft - Materials and Tools, Construction Methods, General Working Hints and Forms of DecorationDa EverandLeathercraft - Materials and Tools, Construction Methods, General Working Hints and Forms of DecorationNessuna valutazione finora

- Conversion ChartDocumento8 pagineConversion Chartzelgor100% (2)

- Stohlman - The Art of Hand Sewing Leather - 1977Documento72 pagineStohlman - The Art of Hand Sewing Leather - 1977Onan Onanonan100% (4)

- Leather From the Raw Material to the Finished ProductDa EverandLeather From the Raw Material to the Finished ProductValutazione: 5 su 5 stelle5/5 (1)

- Tandy LF 2013 PDFDocumento172 pagineTandy LF 2013 PDFKevin Hulu100% (2)

- The Bark Tanning Process - A Collection of Historical Articles on Leather ProductionDa EverandThe Bark Tanning Process - A Collection of Historical Articles on Leather ProductionNessuna valutazione finora

- Leather Wallets PatternDocumento15 pagineLeather Wallets PatternTexuCrafts LeatherGoods100% (2)

- Tandy LeatherDocumento172 pagineTandy LeatherAlek Phabiovsky93% (15)

- Vintage Leather Briefcasesatchel PART 2Documento90 pagineVintage Leather Briefcasesatchel PART 2Loredana Morosanu100% (3)

- Leather Leaders GuideDocumento6 pagineLeather Leaders GuideJairo Newcar100% (3)

- Leather MouldingDocumento19 pagineLeather Mouldingjokersu100% (2)

- Russian LeatherCrafting 01 2016 HQDocumento64 pagineRussian LeatherCrafting 01 2016 HQindiana.jey100% (8)

- Take Out BoxDocumento4 pagineTake Out Boxdoris_marleneNessuna valutazione finora

- Lesson 2: Making Leather Patterns: Instructables ClassesDocumento21 pagineLesson 2: Making Leather Patterns: Instructables ClassesCarlCordNessuna valutazione finora

- 00 Figure Carving Finesse by Al StohlmanDocumento137 pagine00 Figure Carving Finesse by Al StohlmanAnonymous Hz5fBwKmR100% (1)

- DIY Leather Tablet CaseDocumento71 pagineDIY Leather Tablet CaseNewvov100% (2)

- PatternsDocumento16 paginePatternszelgor80% (5)

- Sculpted Leather Tech CasesDocumento30 pagineSculpted Leather Tech CasesRodolfoPerezEscalonaNessuna valutazione finora

- 2012 Ozark Leather Company CatalogDocumento355 pagine2012 Ozark Leather Company CatalogOzarkLeather0% (1)

- Instructions For French Glove MakingDocumento22 pagineInstructions For French Glove MakingAnonymous KMWzXegk100% (1)

- SportBase - SportBase SpecificationDocumento1 paginaSportBase - SportBase SpecificationAnonymous KMWzXegkNessuna valutazione finora

- 02408148193D Modeling in SiloBDocumento334 pagine02408148193D Modeling in SiloBAnonymous KMWzXegkNessuna valutazione finora

- 30 30 Web Manual PDFDocumento11 pagine30 30 Web Manual PDFAnonymous KMWzXegkNessuna valutazione finora

- ZBrushWorkshops Anatomy of Face V1 Skull Beta 2Documento69 pagineZBrushWorkshops Anatomy of Face V1 Skull Beta 2Weisz-Cucoli Alexandru-Iorgu82% (11)

- CatalogDocumento23 pagineCatalogAnonymous KMWzXegkNessuna valutazione finora

- Patron Bourse Ronde Simple Medieval Reconstitution Cuir Lacet Point Sellier TithouanDocumento1 paginaPatron Bourse Ronde Simple Medieval Reconstitution Cuir Lacet Point Sellier TithouanAnonymous KMWzXegkNessuna valutazione finora

- T3424-380-02 Overheads ENDocumento98 pagineT3424-380-02 Overheads ENAnonymous KMWzXegkNessuna valutazione finora

- Rezacky Zkracovacky Nastroje Pro UpravuDocumento8 pagineRezacky Zkracovacky Nastroje Pro UpravuAnonymous KMWzXegkNessuna valutazione finora

- Kiselev A P Algebra - IIDocumento250 pagineKiselev A P Algebra - IIAnonymous KMWzXegkNessuna valutazione finora

- Drawing ChildrenDocumento94 pagineDrawing Childrenaleah100% (2)

- FeatureCAM 2017 GS RussianDocumento112 pagineFeatureCAM 2017 GS RussianAnonymous KMWzXegkNessuna valutazione finora

- What's New in Aspire 8: A Quick Start Guide For Aspire UpgradersDocumento36 pagineWhat's New in Aspire 8: A Quick Start Guide For Aspire UpgradersKarlita PerezNessuna valutazione finora

- T3426-380-01 SG-Ins Exc ENDocumento63 pagineT3426-380-01 SG-Ins Exc ENAnonymous KMWzXegkNessuna valutazione finora

- T3406-380-02 SG-Ins Lec ENDocumento572 pagineT3406-380-02 SG-Ins Lec ENAnonymous KMWzXegkNessuna valutazione finora

- T3426-380-01 SG-Ins Lec ENDocumento137 pagineT3426-380-01 SG-Ins Lec ENAnonymous KMWzXegkNessuna valutazione finora

- T3408-380-01 SG-Ins Lec ENDocumento322 pagineT3408-380-01 SG-Ins Lec ENAnonymous KMWzXegkNessuna valutazione finora

- T3408-380-01 SG-Ins Exc ENDocumento121 pagineT3408-380-01 SG-Ins Exc ENAnonymous KMWzXegkNessuna valutazione finora

- T4010 Train The TrainerDocumento9 pagineT4010 Train The TrainerAnonymous KMWzXegkNessuna valutazione finora

- Behavioral Modeling Using Creo ParametricDocumento48 pagineBehavioral Modeling Using Creo ParametricAnonymous KMWzXegkNessuna valutazione finora

- T3408-380-01 Overheads ENDocumento123 pagineT3408-380-01 Overheads ENAnonymous KMWzXegkNessuna valutazione finora

- T3406-380-02 SG-Ins Exe ENDocumento85 pagineT3406-380-02 SG-Ins Exe ENAnonymous KMWzXegkNessuna valutazione finora

- T3427-380-01 SG-Ins Lec ENDocumento192 pagineT3427-380-01 SG-Ins Lec ENAnonymous KMWzXegkNessuna valutazione finora

- T3425-380-01 Overheads ENDocumento114 pagineT3425-380-01 Overheads ENAnonymous KMWzXegkNessuna valutazione finora

- TRN 4010 003 02 - SG Ins - Exc - ENDocumento114 pagineTRN 4010 003 02 - SG Ins - Exc - ENAnonymous KMWzXegkNessuna valutazione finora

- General Ornamental Ironworks 0001Documento15 pagineGeneral Ornamental Ironworks 0001Anonymous KMWzXegkNessuna valutazione finora

- TRN 4010 003 01 - SG Ins - Lec - ENDocumento257 pagineTRN 4010 003 01 - SG Ins - Lec - ENAnonymous KMWzXegk100% (1)

- TRN 4010 003 01 - SG Ins - Lec - ENDocumento257 pagineTRN 4010 003 01 - SG Ins - Lec - ENAnonymous KMWzXegk100% (1)

- TRN 4010 003 02 - Overheads - ENDocumento124 pagineTRN 4010 003 02 - Overheads - ENAnonymous KMWzXegkNessuna valutazione finora

- Materialy Po Istorii Russkikh Odezhd I Obstanovki Zhizni Narodnoy 1Documento236 pagineMaterialy Po Istorii Russkikh Odezhd I Obstanovki Zhizni Narodnoy 1Anonymous KMWzXegkNessuna valutazione finora

- Fashion Accessories & Footwear PDFDocumento186 pagineFashion Accessories & Footwear PDFNenad NikolićNessuna valutazione finora

- Marketing Plan-Oxfam AustraliaDocumento11 pagineMarketing Plan-Oxfam Australiahandyjohn123Nessuna valutazione finora

- A 360 Approach To Time: CAS EDocumento12 pagineA 360 Approach To Time: CAS EArpit SrivastavaNessuna valutazione finora

- BSM Tutorial Ses 1&2Documento32 pagineBSM Tutorial Ses 1&2darl1Nessuna valutazione finora

- Factors Influencing Fabric CostDocumento21 pagineFactors Influencing Fabric CostannieNessuna valutazione finora

- Apparel Internship Report at Richa Global GurgaonDocumento51 pagineApparel Internship Report at Richa Global GurgaonSwapnilNessuna valutazione finora

- Garment Sewing DepartmentDocumento22 pagineGarment Sewing DepartmentSauumye Chauhan100% (1)

- Alcovy Prom General Information 2018Documento2 pagineAlcovy Prom General Information 2018Matthew Anthony PinoNessuna valutazione finora

- Internship Report For Compounding Department at General Tyre & Rubber Company of PakistanDocumento22 pagineInternship Report For Compounding Department at General Tyre & Rubber Company of PakistanZeeshan Zahid0% (1)

- Commercial Invoice: Industrial Bank of Korea Seo Cho Dong 066-093524-56-00014 Ibkokrsexxx Jinhao Korea IncDocumento3 pagineCommercial Invoice: Industrial Bank of Korea Seo Cho Dong 066-093524-56-00014 Ibkokrsexxx Jinhao Korea IncAndry GallardoNessuna valutazione finora

- Chapter 1: Background of The Campany: 1.1 Brief HistoryDocumento41 pagineChapter 1: Background of The Campany: 1.1 Brief HistoryBona TolosaNessuna valutazione finora

- 50 Short Questions For MerchandisersDocumento8 pagine50 Short Questions For MerchandisersSîronamHin MonirNessuna valutazione finora

- Cambodia Garment PDFDocumento33 pagineCambodia Garment PDFtarekZADNessuna valutazione finora

- WhichPLM Annual Review 2014Documento78 pagineWhichPLM Annual Review 2014email2jha1740Nessuna valutazione finora

- Grasim ReportDocumento24 pagineGrasim ReportHimanshi GoelNessuna valutazione finora

- Land of Leisure Market 2018 Proposal TenantDocumento17 pagineLand of Leisure Market 2018 Proposal TenantLaura RoesyellaNessuna valutazione finora

- National Subscribed: (Journals /magazines at LibraryDocumento10 pagineNational Subscribed: (Journals /magazines at LibraryMuhammad SalmanNessuna valutazione finora

- Jossel Ojt Report For SofttttttttttDocumento61 pagineJossel Ojt Report For SofttttttttttGlyzel EscrimadoraNessuna valutazione finora

- Technical Datasheet - English - Parathane MatDocumento2 pagineTechnical Datasheet - English - Parathane MatMaris FlorinNessuna valutazione finora

- S.No. Company Division Company Address Name of HR Board-Line NumberDocumento8 pagineS.No. Company Division Company Address Name of HR Board-Line NumberRajiv RanjanNessuna valutazione finora

- Fast Fashion EssayDocumento12 pagineFast Fashion EssayPutu Cista Deviutami SukmaNessuna valutazione finora

- Letter Head and AgendaDocumento4 pagineLetter Head and Agendaapi-250055372Nessuna valutazione finora

- Rising Opportunity in Technical Textiles 2020-2026Documento19 pagineRising Opportunity in Technical Textiles 2020-2026Savan GajjarNessuna valutazione finora

- US-China Trade War Impact On IndiaDocumento15 pagineUS-China Trade War Impact On IndiaAgney KudekarNessuna valutazione finora

- Arts and Crafts of LuzonDocumento37 pagineArts and Crafts of LuzonMa Gliza TanNessuna valutazione finora

- Architects Town Planning Module 2Documento8 pagineArchitects Town Planning Module 2Shivaraju HNessuna valutazione finora

- The Orkney HoodDocumento10 pagineThe Orkney HoodJugurtha1782Nessuna valutazione finora

- Foreign Trade Policy 2009-14: Agneshwar Sen JT - DGFT KolkataDocumento28 pagineForeign Trade Policy 2009-14: Agneshwar Sen JT - DGFT KolkatandipdubeyNessuna valutazione finora

- Project - Branding of Khadi in International and Domestic MarketsDocumento40 pagineProject - Branding of Khadi in International and Domestic MarketsPooja Sawant0% (1)

- Delhi Haat INA Case StudyDocumento29 pagineDelhi Haat INA Case StudyVishwajeet Singh Chauhan100% (6)

- House Rules: How to Decorate for Every Home, Style, and BudgetDa EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNessuna valutazione finora

- The Fitness Mindset: Eat for energy, Train for tension, Manage your mindset, Reap the resultsDa EverandThe Fitness Mindset: Eat for energy, Train for tension, Manage your mindset, Reap the resultsValutazione: 4.5 su 5 stelle4.5/5 (31)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiDa Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiValutazione: 5 su 5 stelle5/5 (2)

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeDa EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeValutazione: 5 su 5 stelle5/5 (2)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldDa EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldValutazione: 3.5 su 5 stelle3.5/5 (5)

- Eat That Frog!: 21 Great Ways to Stop Procrastinating and Get More Done in Less TimeDa EverandEat That Frog!: 21 Great Ways to Stop Procrastinating and Get More Done in Less TimeValutazione: 4.5 su 5 stelle4.5/5 (3226)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Da EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Valutazione: 4 su 5 stelle4/5 (17)

- Simplified Organization: Learn to Love What Must Be DoneDa EverandSimplified Organization: Learn to Love What Must Be DoneNessuna valutazione finora

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyDa EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyValutazione: 4 su 5 stelle4/5 (277)

- Lightly: How to Live a Simple, Serene & Stress-free LifeDa EverandLightly: How to Live a Simple, Serene & Stress-free LifeValutazione: 4 su 5 stelle4/5 (12)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingDa EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingValutazione: 4.5 su 5 stelle4.5/5 (845)

- How To Win Friends And Influence PeopleDa EverandHow To Win Friends And Influence PeopleValutazione: 4.5 su 5 stelle4.5/5 (6513)

- The Hidden Life of Trees: What They Feel, How They CommunicateDa EverandThe Hidden Life of Trees: What They Feel, How They CommunicateValutazione: 4 su 5 stelle4/5 (1002)

- Root to Leaf: A Southern Chef Cooks Through the SeasonsDa EverandRoot to Leaf: A Southern Chef Cooks Through the SeasonsValutazione: 4.5 su 5 stelle4.5/5 (3)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsDa EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsValutazione: 4.5 su 5 stelle4.5/5 (2)

- Mini Farming: Self-Sufficiency on 1/4 AcreDa EverandMini Farming: Self-Sufficiency on 1/4 AcreValutazione: 4 su 5 stelle4/5 (76)

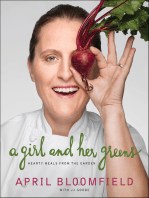

- A Girl and Her Greens: Hearty Meals from the GardenDa EverandA Girl and Her Greens: Hearty Meals from the GardenValutazione: 3.5 su 5 stelle3.5/5 (7)

- Aristotle and Dante Discover the Secrets of the UniverseDa EverandAristotle and Dante Discover the Secrets of the UniverseValutazione: 4.5 su 5 stelle4.5/5 (2341)

- The Martha Manual: How to Do (Almost) EverythingDa EverandThe Martha Manual: How to Do (Almost) EverythingValutazione: 4 su 5 stelle4/5 (11)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterDa EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterValutazione: 4 su 5 stelle4/5 (467)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiDa EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiValutazione: 4 su 5 stelle4/5 (3)

- Crochet Impkins: Over a million possible combinations! Yes, really!Da EverandCrochet Impkins: Over a million possible combinations! Yes, really!Valutazione: 4.5 su 5 stelle4.5/5 (10)

- Martha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesDa EverandMartha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesValutazione: 4 su 5 stelle4/5 (11)

- Gardening Hacks: 300+ Time and Money Saving HacksDa EverandGardening Hacks: 300+ Time and Money Saving HacksValutazione: 5 su 5 stelle5/5 (1)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeDa EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeValutazione: 5 su 5 stelle5/5 (1)