Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Deaerator Design Calculation Report

Caricato da

mayurjannuCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Deaerator Design Calculation Report

Caricato da

mayurjannuCopyright:

Formati disponibili

DOC. NO.

: 2011-83-1-86811-342-0

REV.: 0

PAGE

OF

152

CALCULATION SHEET FOR SPINNING-MEMBRANE DEAERATOR

(JOB NO.: 86811-345) (DRAWING NO.: HMC-250(13)-00. REV. 0)

3 2 1 0 REVISION DATE DESCRIPTION DESIGNED BY ENGINEER TECHNOLOGY DEPT. MANAGER

QINGDAO CHANGLONG POWER EQUIPMENT Co. Ltd .

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

OF

152

TABLE OF CONTENTS

1 2 3 4 5 6 7 8 9 10 11 12 13

DESIGN DATA MAX. ALLOWABLE STRESS AT DESIGN TEMPERATURE THICKNESS OF CYLINDRICAL SHELL UNDER INTERAL PRESSURE THICKNESS OF ELLIPSOIDAL HEADS, PRESSURE ON CONCAVE SIDE THICKNESS OF NOZZLE NECK UNDER INTERNAL PRESSURE MAX. ALLOWABLE WORKING PRESSURE HYDROSTATIC TEST PRESSURE AND TEMPERATURE REINFORCEMENT FOR OPENINGS PRESSURE-TEMPERATURE RATING FOR ASME FLANGE THE CALCULATION OF LIFTING LUG CHECK FOR STRENGTH AND STABILITY OF THE HORIZONTAL VESSEL CHECK FOR POST WELD HEAT TREATMENT EVALUATION OF IMPACT TEST REQUIREMENT

3 6 7 9 12 21 22 23 139 140 148 152 152

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

OF

152

1. DESIGN DATA:

ASME BOILER AND PRESSURE VESSELS CODE APPLICABLE CODE (1) CUSTOMER SPECIFICATION PED 97/23/EC DOC. NO. (2) (3) (4) (5) (6) (7) (8) DESIGN PRESSURE DESIGN TEMPERATURE TYPE OF JOINTS OF CATEGORIES A AND B RADIOGRAPHY JOINT EFFICIENCY CORROSION ALLOWANCE(TANK/TOWER) MATERIAL 2011-83-1-86811-345-0/Rev 0 SECTION DIVSION 1 2010 EDITION AND

INTERNAL 0.65 MPa 300 TYPE NO.1 SPOT PER UW-11(b) SHELL: 0.85, HEAD: 0.85, SHELL to HEAD: 0.85 2.6 mm / 3.5 mm. SHELL & HEAD :SA-516MGr.485 NOZZLE: SA-106Gr.B FLANGE: SA-105M

(9)

MAX.

ALLOWABLE

STRESS

AT

DESIGN

SA-105: 129.3MPa at 300 SA-106Gr.B: 125.3MPa at 300 SA-516MGr.485: 136MPa at 300

TEMPERATURE(SEE TABLE 2.1 )

(10) (11) (12) (13) (14) (15)

HEAD TYPE CAPACITY (TANK / TOWER) SERVICE FLUID MIN. SERVICE TEMPERATURE THE LOADING CONSIDERED IN DESIGNING VESSEL DIMENSIONS

2:1 Standard Ellipsoidal Head 64.9 m3 /6.7 m3 WATER AND STEAM (no lethal) -10 SEE TABLE 1-1 SEE FIG. 1-1

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

OF

152

TABLE 1.1 LOADING CONSIDERED IN DESIGNING

DEAERATORS TANK DEAERATORS TOWER

Item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Description Internal pressure External pressure Weight of vessel Weight of normal contents under operation conditions Weight of normal contents under test conditions Superimposed static reactions from weight of attached equipment The attachments of internals The attachments of vessel supports (skirt, legs, saddles etc.) The attachments of hanger Cyclic and dynamic reactions due to pressure Cyclic and dynamic reactions due to thermal variations Cyclic and dynamic reactions due to equipment mounted on the vessel Cyclic and dynamic reactions due to mechanical loadings Wind reactions Snow reactions Seismic reactions Impact reactions, such as those due to fluid shock Temperature gradients Differential thermal expansion Abnormal pressure, such as those caused by deflagration Test pressure and coincident static head acting during the test (See UG-99)

Yes [] [ ] [] [] [] [ ] [ ] [] [] [ ] [ ] [ ] [ ] [ [ [ [ [ [ [ ] ] ] ] ] ] ]

No [ ] [] [ ] [ ] [ ] [] [] [ ] [ ] [] [] [] [] [] [] [] [] [] [] [] [ ]

Yes [] [ ] [] [ ] [] [ ] [ ] [] [] [ ] [ ] [ ] [ ] [ [ [ [ [ [ [ ] ] ] ] ] ] ]

No [ ] [] [ ] [ ] [ ] [] [] [ ] [ ] [] [] [] [] [] [] [] [] [] [] [] [ ]

[ ]

[ ]

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

OF

152

LIST OF NOZZLES TABLE 1.2

NOZZLE A1 A2 B C1-2 D1-2 E F G H I J K L M N O P1-2 Q R S T1-2 NO. QTY 1 1 1 2 2 1 1 1 1 1 1 1 1 1 1 1 2 1 1 1 2 SIZE DN500 DN450 DN200 DN80 DN150 DN100 DN150 DN80 DN200 DN150 DN80 DN200 DN100 DN80 DN150 DN250 DN10 DN200 DN250 DN100 DN50 TYPE CLASS150 SO RF CLASS150 SO RF WELDING WELDING CLASS150 SO RF WELDING CLASS150 SO RF CLASS150 SO RF WELDING WELDING WELDING WELDING WELDING WELDING WELDING WELDING WELDING WELDING WELDING WELDING CLASS150 SO.RF DESCRIPTION MANHOLE MANHOLE STEAM CONNECT NOZZLE RECYCLING NOZZLE SAFETY VALVE NOZZLE HP DRAIN INLET CHECK-UP NOZZLE EXHAUST NOZZLE FEED WATER INLET SUPPLY WATER INLET

SECONDARY STEAM INLET

REMARKS SA-516MGr.485 SA-516MGr.485 SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B

STEAM INLET

STEAM LEAKING FROM GATE POLE

REBOILING NOZZLE OUTFALL NOZZLE

DEAERATED WATER OURLET SAMPLING WATER NOZZLE WATER CONNECT NOZZLE DEAERATED WATER OURLET HIGH LEVEL ELECTRIC OFFLET

ELECTRIC CONTACT LEVEL GAUGE NOZZLE

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

OF

152

NOZZLE U1-4 V1-2 V3 W1-2 W3 X1-2 Y1 Z1-2 Y2

NO.

QTY 4 2 1 2 1 2 1 2 1

SIZE DN50 DN20 DN20 DN15 DN10 DN50 DN100 DN50 DN80

TYPE CLASS150 SO RF

INTERNAL THREAD INTERNAL THREAD INTERNAL THREAD

DESCRIPTION EQUALIZER NOZZLE

BIMETALLIC THERMOMETER NOZZLE

REMARKS SA-106Gr.B SA-105M SA-105M SA-105M SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B SA-106Gr.B

RESISTANCE THERMOMETER NOZZLE

PRESSURE GAUGE

PRESSURE SIGNAL NOZZLE

WELDING CLASS150 PL. RF WELDING CLASS150 SO RF WELDING

LEVEL GAUGE NOZZLE

DRAIN INLET

ELECTRIC CONTACT LEVEL GAUGE NOZZLE

WATER FROM SLAG-COOLER INLET

Note: Bolt holes of flanges shall straddle center line of the vessel.

FIG.1-1 Brief Drawing of Shell

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

OF

152

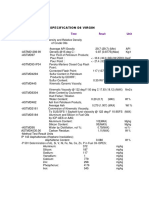

2. MAX. ALLOWABLE STRESS AT DESIGN TEMPERATURE TABLE 2.1

ALLOWABLE STRESS VALUE (MPa) ASME 300 SHELL AND HEAD MATERIAL SA-516MGr.485 PIPE MATERIAL SA-106Gr.B FLANGE MATERIAL SA-105 BOLT MATERIAL SA-193.B7 136 118 129 130 20 138 118 138 130 PED 300 136 125.3 129.3 287 20 174.6 160.6 165.3 287 YIELD STRENGTH VALUE (MPa) ASME 300 204 188 194 595 20 262 241 248 724 300 483 414 483 689 TENSILE STRENGTH VALUE (MPa) ASME 20 483 414 483 689

/NOTE: 1 PED/97/23/EC :

MATERIAL ALLOWANCE STRESS VALUE IS IN ACCORDANCE WITH PED/97/23/EC REGULATION ANNEX : 1. /FOR MATERIAL SA-516MGr.485: Re/t=204MPa, Rm/20=483MPa, Sd=MIN{Re/t2/3, Rm/205/12}=136 MPa 2. /FOR MATERIAL SA-106Gr.B: Re/t=188MPa, Rm/20=414MPa, Sd=MIN{Re/t 2/3, Rm/205/12}=125.3 MPa 3. /FOR MATERIAL SA-105: Re/t=194MPa, Rm/20=483MPa, Sd=MIN{Re/t2/3, Rm/20 5/12}=129.3 MPa 4. /FOR MATERIAL SA-193.B7: Re/t=595MPa, Rm/20=689MPa, Sd=MIN{Re/t2/3, Rm/20 5/12}=287 MPa

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

OF

152

3. THICKNESS OF CYLINDRICAL SHELL UNDER INTERNAL PRESSURE 3-1 DEAERATORS TANK: ASME SEC. DIV.1 UG-27 z Part z Design pressure z Design temperature z Material z Maximum allowable stress value at design temperature Sd z Maximum allowable stress value at test temperature z Height to point under consideration z Density of test medium (water) at test temperature z Type of welded joints in TABLE UW-12 z Radiographic examination St H (MPa) (MPa) (m) P (MPa) () : : : : : : : : : : Shell of tank 0.65 300

SA-516MGr.485

136 174.6 6.769 1000 Type No. (1)

SPOT Per UW-11(b)

(kg/m3)

z Joint efficiency (specified in UW-12) z Negative Deviation: z Corrosion allowance (designated by customer) z Nominal shell thickness z Inside radius corroded z Final center line radius z Original center line radius (specified in UCS-79) z Shell length z Total weight z Reaction at each saddle z Head depth z Saddle to tangent line (1)

E C1 C2 tn R (mm) (mm) (mm) (mm)

: : :

0.85 0.3 2.6 16

: : : : : : : :

1402.6 1408 (Infinity 9280 95000 465975 700 1140

Rf (mm) Ro (mm) L (mm) WT (kg) Q (N) H (mm) A (mm)

Thickness calculation for shells under internal pressure with supplemental loading. Here three cases must be investigated: (a) (b) circumferential stress due to internal pressure longitudinal tensile stress due to bending must be added to the longitudinal stress due to

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

OF

152

internal pressure. (c) Longitudinal compressive stress due to bending.

Case 1 circumferential tensile stress. In this horizontal vessel; the equation in UG-27 (c)(1) is used: P = 0.65 + gH/106 = 0.65 + 10009.816.769/106 = 0.7165 MPa

t1 =

PR 0.7165 1402.6 = = 8.73mm S d E 0.6 P 136 0.85 0.6 0.7165

Case 2 longitudinal tensile stress. The following equation combines longitudinal tensile stress due to pressure with the longitudinal tensile stress due to bending at the midpoint between two saddles:

2( R 2 H 2 ) 1+ 2 QL 4A PR L t2 = 4H L 2SE + 0.4 P 4 R 2 SE 1+ 3L

=

0.7165 1402.6 2 136 0.85 + 0.4 0.7165

2(1402.62 7002 ) 1+ 2 465975 9280 4 1140 9280 4 700 4 9280 1402.62 136 0.85 1+ 3 9280

= 4.35 1.514(0.9242-0.4914) = 4.35 0.656 = 5.006 mm Case 3 Longitudinal compressive stress. First determine the allowable compressive stress [see UG-23(b)] A=

0.125 0.125 = = 0.00141 RO / t 1418.6 / 16

B= 70 MPa (from Fig. CS-2) The general equation for thickness is the same as for longitudinal tensile stress except the pressure portion drops out since the most servere condition occurs when there is no pressure in the vessels.

2( R 2 H 2 ) 1 + 2 4 A QL L t3 = 2 4H 4 R SE L 1+ 3 L

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

10

OF

152

2(1402.62 7002 ) 1 + 2 465975 9280 4 1140 9280 = 4 700 4 9280 1402.6 2 70 0.85 1+ 3 9280

= 2.94(0.9242-0.4914) = 1.28 mm (2) Design thickness Required minimum shell thickness including allowance t = max(t1,t2,t3) + C1+C2 = 8.73+0.3+2.6 = 11.63 mm (3) Provided thickness Nominal thickness (mm) 16 > t (4) OK

Check minimum required thickness for paragraph UG-16 (b) (4) Minimum thickness required (including corrosion allowance) : 2.5 + 2.6 = 5.1 mm, nominal thickness is 16 mm > 5.1 mm, OK

(5)

Check extreme fiber elongation for paragraph UCS-79 Maximum allowable fiber elongation without post weld heat treatment is based on the following formula: For single curvature

r=

50t R f 50 16 1408 1 %= 1 % = 0.569% < 5% Rf R0 1408

None of the conditions in UCS-79 (1~5) apply, so no heat treatment after cold forming need to apply.

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

11

OF

152

3-2 DEAERATORS TOWER: ASME SEC. DIV.1 UG-27 z Part z Design pressure z Design temperature z Material z Maximum allowable stress value at design temperature Sd z Maximum allowable stress value at test temperature z Height to point under consideration z Density of test medium (water) at test temperature z Type of welded joints in TABLE UW-12 z Radiographic examination St H (MPa) (MPa) (m) P (MPa) () : : : : : : : : : : Shell of tower 0.65 300

SA-516MGr.485

136 174.6 2.950 1000 Type No. (1)

SPOT Per UW-11(b)

(kg/m3)

z Joint efficiency (specified in UW-12) z Negative Deviation: z Corrosion allowance (designated by customer) z Nominal shell thickness z Inside radius corroded z Final center line radius z Original center line radius (specified in UCS-79) (1)

E C1 C2 tn R (mm) (mm) (mm) (mm)

: : :

0.85 0.3 3.5 12

: : :

903.5 906 Infinity

Rf (mm) Ro (mm)

Required minimum shell thickness excluding allowance (circumferential stress) 0.385SE = 0.3851360.85=44.506> P (a) For design condition according to UG-27(b)&(c)

tmin 1 =

(b)

PR 0.65 903.5 = = 5.10mm S d E 0.6 P 136 0.85 0.6 0.65

For hydrostatic test condition

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

12

OF

152

tmin 2 =

PR (9.81H / 106 ) R + St E 0.6 P St E 0.6(9.81H / 106 )

0.65 903.5 9.81 2.95 1000 / 106 903.5 = + 174.6 0.85 0.6 0.65 174.6 0.85 0.6 (9.81 2.95 1000 / 106 ) = 3.97 + 0.15 = 4.12mm

(2) Design thickness Required minimum shell thickness including allowance T = max(tmin1,tmin2)+C1+C2 = 5.10 + 0.3 + 3.5 = 8.9 mm (3) Provided thickness Nominal thickness (mm) 12 > t (4) OK

Check minimum required thickness for paragraph UG-16 (b) (4) Minimum thickness required (including corrosion allowance) : 2.5 + 3.5 = 6.0 mm, nominal thickness is 12 mm> 6.0 mm, OK

(5)

Check extreme fiber elongation for paragraph UCS-79 Maximum allowable fiber elongation without post weld heat treatment is based on the following formula: For single curvature

r=

50t R f 50 12 906 1 %= 1 % = 0.663% < 5% Rf R0 906

None of the conditions in UCS-79 (1~5) apply, so no heat treatment after cold forming need to apply.

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

13

OF

152

4. THICKNESS OF ELLIPSOIDAL HEAD, PRESSURE ON CONCAVE SIDE 4-1 DEAERATORS TANK: ASME SEC. DIV.1 UG-32

Part Design Design

: pressure temperature P (MPa) () : : : allowable stress value at design temperature allowable stress value at test temperature (left head) (right head) Sd St H H (MPa) (MPa) (m) (m) : : : : : : :

Heads of tank 0.65 300 SA-516MGr.485 136 174.6 6.769 6.769 1000 Type No. (1)

SPOT Per UW-11(b)

Material Maximum Maximum Height Height

to point under consideration to point under consideration

Density

of test medium at test temperature

(kg/m3)

Type of welded joints in TABLE UW-12 Radiographic examination

Weld

joining heads to shell

Type No. (1) SPOT UW-11(b) Per

Joint

efficiency (specified in UW-12(d))

E C1 C2 D R (mm) (mm) (mm)

: : :

0.85 0.3 2.6 2805.2

Negative Deviation:

Corrosion Inside Inside

allowance (designated by customer)

diameter of ellipsoidal head (corroded) spherical radius of hemispherical head final centerline radius (specified in UG-32(d)

: :

1402.6 2528

Crown

Rf (mm)

and UCS-79)

Knuckle

final centerline radius (specified in UG-32(d)

rf

(mm)

482.96

and UCS-79)

Original

center line radius (specified in UCS-79)

R0 (mm)

Infinity

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

14

OF

152

(1)

Required minimum head thickness Without joint, according to UW-12(d), E=0.85, L = 0.9D = 0.92805.2 = 2524.68 mm ts/L = 13.92/2524.68=0.00552 > 0.002 (a) For the left head according to UG-32(d) (a-1) for design condition Required minimum head thickness excluding allowance tmin according to UG-32(d)

tmin 1 =

PD 0.65 2805.2 = = 7.90mm 2S d E 0.2 P 2 136 0.85 0.2 0.65

(b) For the right head (b-1) for design condition Required minimum head thickness excluding allowance tmin

tmin 2 =

PD 0.65 2805.2 = = 7.90mm 2S d E 0.2 P 2 136 0.85 0.2 0.65

(b-2) for hydrostatic test condition (Due to same dimension for ellipsoidal heads, the bottom head will be applied for calculation)

tmin 3 = =

PD (9.81H / 106 ) D + 2St E 0.2 P 2St E 0.2(9.81H / 106 )

0.65 2805.2 9.81 6.769 1000 / 106 2805.2 + 2 174.6 0.85 0.2 0.65 2 174.6 0.85 0.2 (9.81 6.769 1000 / 106 ) = 6.15 + 0.63 = 6.78mm

(2) Design thickness Required minimum head thickness including allowance t= max(tmin1,tmin2,tmin3) + C1+C2 = 7.90 + 0.3 + 2.6 = 10.8 mm (3) Provided thickness Nominal thickness (mm) 16 Minimum thickness after forming (mm) 13.92 t OK (4) Check minimum head thickness for hemispherical head from paragraph UG-32 (b) & (f) 0.665SE = 0.665 136 0.85 = 76.874 MPa >P

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

15

OF

152

Required minimum hemispherical head thickness

tmin h =

PL 0.65 2524.68 = = 7.11mm 2SE 0.2 P 2 136 0.85 0.2 0.65

Tr = tminh/E= 7.11/0.85 = 8.37 mm < 13.92 mm OK

(5) Check minimum required thickness for paragraph UG-16(b)(4) Minimum thickness required (including corrosion allowance) : 2.5+2.6 = 5.1mm, minimum thickness after forming is 13.92 mm.> 5.1 mm (6) Check extreme fiber elongation for paragraph UCS-79 Maximum allowable fiber elongation without heat treatment is based on the following formula: For double curvature Crown radius elongation OK

r=

75t R f 75 16 2528 1 %= 1 % = 0.475% < 5% Rf R0 2528

Knuckle radius elongation

r=

rf 75t 75 16 482.96 1 %= 1 % = 2.49% < 5% rf R0 482.96

None of the conditions listed in UCS-79(d)(1) through (5) exist, so no heat treatment of heads after cold forming need to apply for SA-516MGr.485 (P-NO.1 Group NO.2).

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

16

OF

152

4-2

DEAERATORS TOWER: ASME SEC. DIV.1 UG-32

Part Design Design

: pressure temperature P (MPa) () : : : allowable stress value at design temperature allowable stress value at test temperature (bottom head) (top head) Sd St H H (MPa) (MPa) (m) (m) : : : : : : :

Heads of tower 0.65 300 SA-516MGr.485 136 174.6 3.437 0.787 1000 Type No. (1)

SPOT Per UW-11(b)

Material Maximum Maximum Height Height

to point under consideration to point under consideration

Density

of test medium at test temperature

(kg/m3)

Type of welded joints in TABLE UW-12 Radiographic examination

Weld

joining heads to shell

Type No. (1) SPOT UW-11(b) Per

Joint

efficiency (specified in UW-12(d))

E C1 C2 D R (mm) (mm) (mm)

: : :

0.85 0.3 3.5 1807

Negative Deviation:

Corrosion

allowance (designated by customer)

Inside diameter of ellipsoidal head (corroded) Inside spherical radius of hemispherical head Crown final centerline radius and UCS-79)

Knuckle

: :

903.5 1626

(specified in UG-32(d)

Rf (mm)

final centerline radius (specified in UG-32(d)

rf

(mm)

311.22

and UCS-79)

Original

center line radius (specified in UCS-79)

R0 (mm)

Infinity

(1)

Required minimum head thickness Without joint, according to UW-12(d), E = 0.85, L=0.9D = 0.91807 = 1626.3mm

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

17

OF

152

ts/L = 10.44/1626.3 =0.00642 > 0.002 (a) For the top head according to UG-32(d)

according to UG-32(d)

(a-1) for design condition Required minimum head thickness excluding allowance tmin

tmin 1 =

PD 0.65 1807 = = 5.09mm 2S d E 0.2 P 2 136 0.85 0.2 0.65

(b) For the bottom head (b-1) for design condition Required minimum head thickness excluding allowance tmin

tmin 2 =

PD 0.65 1807 = = 5.09mm 2 S d E 0.2 P 2 136 0.85 0.2 0.65

(b-2) for hydrostatic test condition (Due to same dimension for ellipsoidal heads, the bottom head will be applied for calculation)

tmin 3 =

PD (9.81H / 106 ) D + 2St E 0.2 P 2St E 0.2(9.81H / 106 )

0.65 1807 9.81 3.437 1000 / 106 1807 = + 2 174.6 0.85 0.2 0.65 2 174.6 0.85 0.2 (9.81 3.437 1000 / 106 ) = 3.96 + 0.21 = 4.17 mm

(2) Design thickness Required minimum head thickness including allowance t=max(tmin1,tmin2,tmin3)+C1+C2= 5.09 + 0.3+3.5 = 8.89 mm (3) Provided thickness Nominal thickness (mm) 12 Minimum thickness after forming (mm) 10.44 t OK (4) Check minimum head thickness for hemispherical head from paragraph UG-32 (b) & (f) 0.665SE = 0.665 136 0.85 =76.874 MPa >P

Required minimum hemispherical head thickness

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

18

OF

152

tmin h =

PL 0.65 1626.3 = = 4.58mm 2SE 0.2 P 2 136 0.85 0.2 0.65

tr=tminh/E= 4.58/0.85 = 5.39 mm < 10.44 mm OK

(5) Check minimum required thickness for paragraph UG-16(b)(4) Minimum thickness required (including corrosion allowance) : 2.5 + 3.5 = 6.0 mm, minimum thickness after forming is 10.44 mm.> 6.0 mm (6) Check extreme fiber elongation for paragraph UCS-79 Maximum allowable fiber elongation without heat treatment is based on the following formula: For double curvature Crown radius elongation OK

r=

75t R f 75 12 1626 1 %= 1 % = 0.554% < 5% Rf R0 1626

Knuckle radius elongation

r=

r 75t 75 12 311.22 1 f %= 1 % = 2.892% < 5% rf R0 311.22

None of the conditions listed in UCS-79(d)(1) through (5) exist, so no heat treatment of heads after cold forming need to apply for SA-516MGr.485 (P-NO.1 Group NO.2).

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

19

OF

152

5. THICKNESS OF NOZZLE NECK INTERNAL PRESSURE 5-1 DEAERATORS TANK: 5-1-1 FOR NOZZLE A1 pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 174.6 SA-516M Gr.485 : 136 ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-516M Gr.485

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of head

Allowable stress of shell (or head) at design Ss (MPa) H (m) (k/m3) : : : 136 6.387 1000 Type No. (1)

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE

UW-12

Radiographic Joint

examination of nozzle neck E C1 (mm) : : : : : : : :

SPOT Per UW-11(b) 0.85 0.3 2.6 254 244.6 1402.6 248 (Infinity)

efficiency of nozzle neck (specified in UW-12) Deviation: allowance (designated by customer)

Negative

Corrosion Outside Inside Inside Final

C2 (mm) Ro (mm)

radius of nozzle neck

radius of nozzle corroded radius of shell corroded

R (mm) Rs (mm)

center line radius of nozzle center line radius of nozzle

Rf (mm) R0 (mm)

Original

(1)

Minimum required thickness of nozzle par. UG-45 (a) and UG-27 (c) (1)

0.385SE = 0.3851360.85 = 44.506 > P

(a) under design condition

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

20

OF

152

Required minimum thickness including allowance

tmin 1 =

PR 0.65 244.6 +C = + 0.3 + 2.6 = 1.39 + 2.9 = 4.29mm S d E 0.6 P 136 0.85 0.6 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2

=

PR (9.81H / 106 ) R = + +C St E 0.6 P St E 0.6(9.81H / 106 )

0.65 244.6 9.81 6.387 1000 / 106 244.6 + + 0.3 + 2.6 174.6 0.85 0.6 0.65 174.6 0.85 0.6 (9.81 6.387 1000 / 106 ) = 1.08 + 0.11 + 2.9 = 4.09mm (c) With supplemental loading by flange and cover

Weight of flange and cover

W = 250 kg

Bending moment due to supplemental loading Under operating condition Under cover opened condition M1 = 2509.810.166= 408 Nm M2 = 2509.810.466=1143 Nm

Per UG-27(c) and Appendix L, Use S = 136 1.5 = 204 MPa (see UG-23(c))

t3 =

PR M + 21 +C 2SE + 0.4 P R SE 0.65 244.6 408 = + + 0.3 + 2.6 2 2 204 0.85 + 0.4 0.65 244.6 204 0.85 = 0.46 + 0.000013 + 2.9 3.4mm M2 1143 +C = + 0.3 + 2.6 = 0.00004 + 2.9 3.0mm 2 R SE 244.6 2 204 0.85

OK

t4 =

(2)

Provided thickness Nominal thickness (mm) 12 > tmin1,tmin2,t3,t4

(3)

Check extreme fiber elongation for paragraph UCS-79 Maximum allowable fiber elongation without post weld heat treatment is based on the following formula: for single curvature

r=

50t R f 50 12 248 1 %= 1 % = 2.42% < 5% Rf R0 248

None of the condition list in UCS-79 (d) (1-5) exists, so no heat treatment after cold forming need to apply.

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

21

OF

152

5-1-2 FOR NOZZLE

Design Design

B.K

ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

pressure temperature of nozzle neck stress of nozzle neck material at design

Material

Allowable

temperature

Allowable

Sd (MPa) stress of nozzle neck material at test St (MPa)

125.3

temperature

Material

: :

160.6 SA-516MGr.485

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 3.953 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 2.6 109.55 8.18 1402.6

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 109.55 +C = + 2.6 = 3.17mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

22

OF

152

tmin 2 =

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 109.55 9.81 3.953 1000 / 106 109.55 = + + 2.6 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 3.953 1000 / 106 ) = 0.45 + 0.03 + 2.6 = 3.08mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 8.18 + 2.6 = 9.76 mm t = (the smaller value of ts or tp) = 9.33 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 12.7 Minimum thickness (mm) 12.70.875 = 11.11 t 5-1-3 FOR NOZZLE pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-516MGr.485 : 125.3 C1-2. .M OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

per UG-45(b)

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 3.953 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

23

OF

152

UW-12

Joint

: E C (mm) : : : : :

Seamless 1.0 2.6 44.45 5.49 1402.6

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 44.45 +C = + 2.6 = 2.84mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 44.45 9.81 3.953 1000 / 106 44.45 + + 2.6 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 3.953 1000 / 106 ) = 0.18 + 0.02 + 2.6 = 2.8mm

Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

(2)

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 5.49 + 2.6 = 7.41 mm t = (the smaller value of ts or tp) = 7.41 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 11.13 Minimum thickness (mm) 11.130.875 = 9.74 t OK

per UG-45(b)

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

24

OF

152

5-1-4

FOR NOZZLE pressure temperature of nozzle neck

D1

ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

Design Design

Material

Allowable

stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-516MGr.485 : 125.3

temperature

Allowable

temperature

Material

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 3.953 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 2.6 84.15 7.11 1402.6

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 84.15 +C = + 2.6 = 3.04mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

25

OF

152

tmin 2 =

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 84.15 9.81 3.953 1000 / 106 84.15 = + + 2.6 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 3.953 1000 / 106 ) = 0.35 + 0.03 + 2.6 = 2.98mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 7.11 + 2.6 = 8.82 mm t = (the smaller value of ts or tp) = 8.82 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 10.97 Minimum thickness (mm) 10.970.875 = 9.6 t 5-1-5 FOR NOZZLE pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-516MGr.485 : 125.3 L OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

per UG-45(b)

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 3.953 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

26

OF

152

UW-12

Joint

: E C (mm) : : : : :

Seamless 1.0 2.6 57.15 6.02 1402.6

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 57.15 +C = + 2.6 = 2.9mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 57.15 9.81 3.953 1000 / 106 57.15 + + 2.6 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 3.953 1000 / 106 ) = 0.24 + 0.02 + 2.6 = 2.86mm

Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

(2)

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 6.02 + 2.6 = 7.87 mm t = (the smaller value of ts or tp) = 7.87 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 11.13 Minimum thickness (mm) 11.130.875 = 9.74 t OK

per UG-45(b)

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

27

OF

152

5-1-6 FOR NOZZLE

Design Design

ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

pressure temperature of nozzle neck stress of nozzle neck material at design

Material

Allowable

temperature

Allowable

Sd (MPa) stress of nozzle neck material at test St (MPa)

125.3

temperature

Material

: :

160.6 SA-516MGr.485

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 6.919 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 2.6 84.15 7.11 1402.6

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 84.15 +C = + 2.6 = 3.04mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

28

OF

152

tmin 2 =

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 84.15 9.81 6.919 1000 / 106 84.15 = + + 2.6 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 6.919 1000 / 106 ) = 0.35 + 0.04 + 2.6 = 2.99mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 7.11 + 2.6 = 8.82 mm t = (the smaller value of ts or tp) = 8.82 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 10.97 Minimum thickness (mm) 10.970.875 = 9.6 t 5-1-7 FOR NOZZLE pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-516MGr.485 : 125.3 O.R OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

per UG-45(b)

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 6.919 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

29

OF

152

UW-12

Joint

: E C (mm) : : : : :

Seamless 1.0 2.6 136.5 9.27 1402.6

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 136.5 +C = + 2.6 = 3.31mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 136.5 9.81 6.919 1000 / 106 136.5 + + 2.6 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 6.919 1000 / 106 ) = 0.56 + 0.06 + 2.6 = 3.22mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 9.27 + 2.6 = 10.7 mm t = (the smaller value of ts or tp) = 9.33 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 12.7 Minimum thickness (mm) 12.70.875 = 11.11 t OK

per UG-45(b)

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

30

OF

152

5-1-8

FOR NOZZLE pressure temperature of nozzle neck

ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

Design Design

Material

Allowable

stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-516MGr.485 : 125.3

temperature

Allowable

temperature

Material

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 6.919 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 2.6 57.15 6.02 1402.6

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 57.15 +C = + 2.6 = 2.9mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

31

OF

152

tmin 2 =

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 57.15 9.81 6.919 1000 / 106 57.15 = + + 2.6 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 6.919 1000 / 106 ) = 0.24 + 0.03 + 2.6 = 2.87 mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 6.02 + 2.6 = 7.87 mm t = (the smaller value of ts or tp) = 7.87 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 11.13 Minimum thickness (mm) 11.130.875 = 9.74 t 5-1-9 FOR NOZZLE

Design Design

per UG-45(b)

OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

pressure temperature of nozzle neck stress of nozzle neck material at design

Material

Allowable

temperature

Allowable

Sd (MPa) stress of nozzle neck material at test St (MPa)

125.3

temperature

Material

: :

160.6 SA-516MGr.485

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 6.919 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

32

OF

152

UW-12

Joint

: E C (mm) : : : : :

Seamless 1.0 2.6 109.55 8.18 1402.6

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 109.55 +C = + 2.6 = 3.17mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 109.55 9.81 6.919 1000 / 106 109.55 + + 2.6 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 6.919 1000 / 106 ) = 0.45 + 0.05 + 2.6 = 3.1mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 8.18 + 2.6 = 9.76 mm t = (the smaller value of ts or tp) = 9.33 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 12.7 Minimum thickness (mm) 12.70.875 = 11.11 t OK

per UG-45(b)

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

33

OF

152

5-1-10

Design Design

FOR NOZZLE T1.U1.U3.Z1.X1 pressure temperature of nozzle neck stress of nozzle neck material at design

ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

Material

Allowable

temperature

Allowable

Sd (MPa) stress of nozzle neck material at test St (MPa)

125.3

temperature

Material

: :

160.6 SA-516MGr.485

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 4.284 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 2.6 30.15 3.91 1402.6

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 30.15 +C = + 2.6 = 2.76mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

34

OF

152

tmin 2 =

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 30.15 9.81 4.284 1000 / 106 30.15 = + + 2.6 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 4.284 1000 / 106 ) = 0.13 + 0.008 + 2.6 = 2.738mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 3.91 + 2.6 = 6.02 mm t = (the smaller value of ts or tp) = 6.02 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 8.74 Minimum thickness (mm) 8.740.875 = 7.65 t 5-1-11

Design Design

per UG-45(b)

OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

FOR NOZZLE T2.U2.U4.Z2.X2 pressure temperature of nozzle neck stress of nozzle neck material at design

Material

Allowable

temperature

Allowable

Sd (MPa) stress of nozzle neck material at test St (MPa)

125.3

temperature

Material

: :

160.6 SA-516MGr.485

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 6484 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

35

OF

152

UW-12

Joint

: E C (mm) : : : : :

Seamless 1.0 2.6 30.15 3.91 1402.6

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 30.15 +C = + 2.6 = 2.76mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 30.15 9.81 6.484 1000 / 106 30.15 + + 2.6 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 6.484 1000 / 106 ) = 0.13 + 0.02 + 2.6 = 2.75mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 3.91 + 2.6 = 6.02 mm t = (the smaller value of ts or tp) = 6.02 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 8.74 Minimum thickness (mm) 8.740.875 = 7.65 t OK

per UG-45(b)

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

36

OF

152

5-1-12

Design Design

FOR NOZZLE W2 pressure temperature of nozzle neck stress of nozzle neck material at design

ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-105M

Material

Allowable

temperature

Allowable

Sd (MPa) stress of nozzle neck material at test St (MPa)

129.3

temperature

Material

: :

165.3 SA-516MGr.485

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 5364 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 2.6 17.5 2.77 1402.6

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 129.3 1.00 = 49.78 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 17.5 +C = + 2.6 = 2.69mm S d E + 0.4 P 129.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

37

OF

152

tmin 2 =

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 17.5 9.81 5.364 1000 / 106 17.5 = + + 2.6 165.3 1 + 0.4 0.65 165.3 1 + 0.4 (9.81 5.364 1000 / 106 ) = 0.07 + 0.006 + 2.6 = 2.676mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 2.77 + 2.6 = 5.02 mm t = (the smaller value of ts or tp) = 5.02 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 6.5 t 5-1-13

Design Design

per UG-45(b)

OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-105M

FOR NOZZLE V2-3 pressure temperature of nozzle neck stress of nozzle neck material at design

Material

Allowable

temperature

Allowable

Sd (MPa) stress of nozzle neck material at test St (MPa)

129.3

temperature

Material

: :

165.3 SA-516MGr.485

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 5378 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : Seamless

UW-12

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

38

OF

152

Joint

efficiency of nozzle neck allowance (designated by customer)

E C (mm)

: : : : :

1.0 2.6 25 2.87 1402.6

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 129.3 1.00 = 49.78 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 25 +C = + 2.6 = 2.73mm S d E + 0.4 P 129.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2

PRo (9.81H / 106 ) Ro = + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 25 9.81 5.378 1000 / 106 25 = + + 2.6 165.3 1 + 0.4 0.65 165.3 1 + 0.4 (9.81 5.378 1000 / 106 ) = 0.1 + 0.008 + 2.6 = 2.708mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 2.87 + 2.6 = 5.12 mm t = (the smaller value of ts or tp) = 5.12 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 11.0 t OK 5-1-14

Design

per UG-45(b)

FOR NOZZLE P1-2 pressure

ASME SEC. DIV.1 UG-45 P (MPa) : 0.65

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

39

OF

152

Design

temperature of nozzle neck stress of nozzle neck material at design

T ()

: :

300 SA-105M

Material

Allowable

temperature

Allowable

Sd (MPa) stress of nozzle neck material at test St (MPa)

129.3

temperature

Material

: :

165.3 SA-106Gr.B 125.3 6852 1000

of shell(nozzle R.O) stress of shell at design temperature Ss (MPa) H (m) (kg/m3)

Allowable Height

: : :

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 2.6 12.5 2.31 126.4

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 129.3 1.00 = 49.78 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 12.5 +C = + 2.6 = 2.67mm S d E + 0.4 P 129.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2

=

PRo (9.81H / 106 ) Ro = + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 12.5 9.81 6.852 1000 / 106 12.5 + + 2.6 165.3 1 + 0.4 0.65 165.3 1 + 0.4 (9.81 6.852 1000 / 106 ) = 0.05 + 0.006 + 2.6 = 2.656mm

Minimum required thickness of shell (nozzle R.O) for par. UG-45 (b) (1), and UG-16 (b) (4),

(2)

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

40

OF

152

Es = 1.00

ts =

PRs 0.65 126.4 +C = + 2.6 = 3.26mm 2.5+2.6 = 5.1 mm S s Es + 0.4 P 125.3 1 + 0.4 0.65

ts = 5.1 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 2.31 + 2.6 = 4.62 mm t = (the smaller value of ts or tp) = 4.62 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 7.5 t 5-1-15 TOWER

Design Design

per UG-45(b)

OK ASME SEC. DIV.1 UG-45

FOR ANNECTENT NOZZLE OF TANK AND

pressure temperature of nozzle neck stress of nozzle neck material at design

P (MPa) T ()

: : :

0.65 300 SA-516MGr.485

Material

Allowable

temperature

Allowable

Sd (MPa) stress of nozzle neck material at test St (MPa)

136

temperature

Material

: :

174.6 SA-516MGr.485

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 4015 1000 Type No. (1) : examination :

SPOT Per UW-11(b)

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE

UW-12

Radiographic

Joint

efficiency (specified in UW-12)

0.85

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

41

OF

152

Corrosion Outside

allowance (designated by customer)

(mm)

: : : : : :

2.6 406.4 9.53 1402.6 398.4 (Infinity)

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside Final

radius of shell corroded

center line radius of nozzle center line radius of nozzle

Rf (mm) R0 (mm)

Original

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 136 0.85 = 44.506 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PR 0.65 406.4 +C = + 2.6 = 2.3 + 2.6 = 4.9mm S d E 0.6 P 136 0.85 0.6 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PR (9.81H / 106 ) R + +C St E 0.6 P St E 0.6(9.81H / 106 )

0.65 406.4 9.81 4.015 1000 / 106 406.4 + + 2.6 174.6 0.85 0.6 0.65 174.6 0.85 0.6 (9.81 4.015 1000 / 106 ) = 1.79 + 0.11 + 2.6 = 4.5mm

(2)

Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 1402.6 +C = + 2.6 = 6.73 + 2.6 = 9.33mm2.5 + 2.6 = 5.1 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 9.33 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 9.53 + 2.6 = 10.94 mm t = (the smaller value of ts or tp) = 9.33 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 16.0 t OK (5) Maximum allowable fiber elongation without post weld heat treatment is based on the following formula: for single curvature

per UG-45(b)

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

42

OF

152

r=

50t R f 50 16 398.4 1 %= 1 % = 2.1% < 5% Rf R0 398.4

None of the condition list in UCS-79 (d) (1-5) exists, so no heat treatment after cold forming need to apply. 5-2 5-2-1 DEAERATORS TOWER: FOR NOZZLE pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-516MGr.485 : 125.3 E ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 2.378 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 3.5 57.15 6.02 903.5

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

43

OF

152

tmin 1 =

PRo 0.65 57.15 +C = + 3.5 = 3.8mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 57.15 9.81 2.378 1000 / 106 57.15 + + 3.5 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 2.378 1000 / 106 ) = 0.24 + 0.01 + 3.5 = 3.75mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 903.5 +C = + 3.5 = 4.34 + 3.5 = 7.84mm2.5 + 3.5 = 6.0 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 7.84 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 6.02 + 3.5 = 8.77 mm t = (the smaller value of ts or tp) = 7.84 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 11.13 Minimum thickness (mm) 11.130.875 = 9.74 t 5-2-2 FOR NOZZLE pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-516MGr.485 : 125.3 Y2 OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

per UG-45(b)

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of shell

Allowable stress of shell (or head) at design

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

44

OF

152

temperature

Height

Ss (MPa) H (m) (kg/m3)

: : :

136 1.165 1000

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 3.5 44.45 5.49 903.5

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 44.45 +C = + 3.5 = 3.74mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 44.45 9.81 1.165 1000 / 106 44.45 + + 3.5 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 1.165 1000 / 106 ) = 0.18 + 0.004 + 3.5 = 3.684mm

Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

(2)

ts =

PRs 0.65 903.5 +C = + 3.5 = 4.34 + 3.5 = 7.84mm2.5 + 3.5 = 6.0 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 7.84 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 5.49 + 3.5 = 8.31 mm t = (the smaller value of ts or tp) = 7.84 mm. > tmin1,tmin2 per UG-45(b)

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

45

OF

152

(4)

Provided thickness Nominal thickness (mm) 11.13 Minimum thickness (mm) 11.130.875 = 9.74 t 5-2-3 FOR NOZZLE pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-516MGr.485 : 125.3 J OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 1.445 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 3.5 44.45 5.49 903.5

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 44.45 +C = + 3.5 = 3.74mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

46

OF

152

Required minimum thickness including allowance

t min 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 44.45 9.81 1.445 1000 / 106 44.45 + + 3.5 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 1.445 1000 / 106 ) = 0.18 + 0.004 + 3.5 = 3.684mm

Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

(2)

ts =

PRs 0.65 903.5 +C = + 3.5 = 4.34 + 3.5 = 7.84mm2.5 + 3.5 = 6.0 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 7.84 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 5.49 + 3.5 = 8.31 mm t = (the smaller value of ts or tp) = 7.84 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 11.13 Minimum thickness (mm) 11.130.875 = 9.74 t 5-2-4 FOR NOZZLE pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-516MGr.485 : 125.3 F OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

per UG-45(b)

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 1.205 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

47

OF

152

Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 3.5 84.15 7.11 903.5

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 84.15 +C = + 3.5 = 3.94mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 84.15 9.81 1.205 1000 / 106 84.15 + + 3.5 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 1.205 1000 / 106 ) = 0.35 + 0.007 + 3.5 = 3.857mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 903.5 +C = + 3.5 = 4.34 + 3.5 = 7.84mm2.5 + 3.5 = 6.0 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 7.84 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 7.11 + 3.5 = 9.73 mm t = (the smaller value of ts or tp) = 7.84 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 11.13 Minimum thickness (mm) 11.130.875 = 9.74 t OK

per UG-45(b)

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

48

OF

152

5-2-5

FOR MANHOLE NOZZLE pressure temperature of nozzle neck

A2

ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-516MGr.485

Design Design

Material

Allowable stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test temperature St (MPa) H (m) (kg/m3) : : : 136 174.6 2166 1000 Type No. (1) SPOT Per UW-11(b) E C1 (mm) : : : : : : : : 0.85 0.3 3.5 228.5 220 1803.5 222.5 (Infinity)

temperature

Allowable Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE UW-12 examination of nozzle neck

Radiographic Joint

efficiency of nozzle neck (specified in UW-12) Deviation: allowance (designated by customer)

Negative

Corrosion Outside Inside Inside Final

C2 (mm) Ro (mm)

radius of nozzle neck

radius of nozzle corroded radius of shell corroded

R (mm) Rs (mm)

center line radius of nozzle center line radius of nozzle

Rf (mm) R0 (mm)

Original

(1) Minimum required thickness of nozzle par. UG-45 (a) and UG-27 (c) (1)

0.385SE = 0.3851360.85 = 44.506 > P

(a) under design condition Required minimum thickness including allowance

tmin 1 =

PR 0.65 220 +C = + 0.3 + 3.5 = 1.25 + 3.8 = 5.05mm S d E 0.6 P 136 0.85 0.6 0.65

(b)under hydrostatic test condition Required minimum thickness including allowance

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

49

OF

152

tmin 2 =

PR (9.81H / 106 ) R + +C St E 0.6 P St E 0.6(9.81H / 106 )

0.65 220 9.81 2.166 1000 / 106 220 = + + 0.3 + 3.5 174.6 0.85 0.6 0.65 174.6 0.85 0.6 (9.81 2.166 1000 / 106 ) = 0.97 + 0.032 + 3.8 = 4.802mm (c) With supplemental loading by flange and cover

Weight of flange and cover

W = 193 kg

Bending moment due to supplemental loading Under operating condition Under cover opened condition M1 = 1939.810.162 = 307 Nm M2 = 1939.810.462 =875 Nm

Per UG-27(c) and Appendix L, Use S = 136 1.5 = 204 MPa (see UG-23(c))

t3 =

PR M + 21 +C 2SE + 0.4 P R SE 0.65 220 307 = + + 0.3 + 3.5 2 2 204 0.85 + 0.4 0.65 220 204 0.85 = 0.42 + 0.00002 + 3.8 4.23mm M2 875 +C = + 0.3 + 3.5 = 0.000034 + 3.8 3.81mm 2 2 R SE 220 204 0.85

OK

t4 =

(2) Provided thickness Nominal thickness (mm) 12.0 > tmin1, tmin2, t3, t4

(3) Check extreme fiber elongation for paragraph UCS-79 Maximum allowable fiber elongation without post weld heat treatment is based on the following formula: for single curvature

r=

50t R f 50 12 222.5 1 %= 1 % = 2.70% < 5% Rf R0 222.5

None of the condition list in UCS-79 (d) (1-5) exists, so no heat treatment after cold forming need to apply. 5-2-6 FOR NOZZLE W1 pressure temperature of nozzle neck stress of nozzle neck material at design ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-105M

Design Design

Material

Allowable

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

50

OF

152

temperature

Allowable

Sd (MPa) stress of nozzle neck material at test St (MPa)

129.3

temperature

Material

: :

165.3 SA-516MGr.485

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 1745 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 3.5 17.5 2.77 903.5

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 129.3 1.00 = 49.78 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 17.5 +C = + 2.6 = 3.59mm S d E + 0.4 P 129.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 17.5 9.81 1.745 1000 / 106 17.5 + + 3.5 165.3 1 + 0.4 0.65 165.3 1 + 0.4 (9.81 1.745 1000 / 106 ) = 0.07 + 0.002 + 3.5 = 3.572mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 903.5 +C = + 3.5 = 4.34 + 2.6 = 7.84mm2.5 + 3.5 = 6.0 mm S s Es 0.6 P 136 1 0.6 0.65

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

51

OF

152

ts = 7.84 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 2.77 + 2.6 = 5.02 mm t = (the smaller value of ts or tp) = 5.02 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 6.5 t 5-2-7 FOR NOZZLE V1 pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 165.3 SA-516MGr.485 : 129.3 OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-105M

per UG-45(b)

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of shell

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 136 1752 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 3.5 25 2.87 903.5

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 129.3 1.00 = 49.78 > P (a) under design condition Appendix 1-1

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

52

OF

152

Required minimum thickness including allowance

tmin 1 =

PRo 0.65 25 +C = + 3.5 = 3.63mm S d E + 0.4 P 129.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2

=

PRo (9.81H / 106 ) Ro = + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 25 9.81 1.752 1000 / 106 25 + + 3.5 165.3 1 + 0.4 0.65 165.3 1 + 0.4 (9.81 1.752 1000 / 106 ) = 0.1 + 0.003 + 3.5 = 3.603mm

Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

(2)

ts =

PRs 0.65 903.5 +C = + 3.5 = 4.34 + 2.6 = 7.84mm2.5 + 3.5 = 6.0 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 7.84 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 2.87 + 2.6 = 5.12 mm t = (the smaller value of ts or tp) = 5.12 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 11.0 t OK 5-2-8 FOR NOZZLE W3 pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : Ss (MPa) : 165.3 SA-516MGr.485 : 129.3 ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-105M

per UG-45(b)

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of shell stress of shell at design temperature

Allowable

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

53

OF

152

136

Height

to point under consideration of test medium at test temperature (water)

H (m) (kg/m3)

: :

1740 1000

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 3.5 12.5 2.31 903.5

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 129.3 1.00 = 49.78 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 12.5 +C = + 3.5 = 3.57mm S d E + 0.4 P 129.3 1 + 0.4 0.65

(b) under hydrostatic test condition Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 12.5 9.81 1.74 1000 / 106 12.5 + + 3.5 165.3 1 + 0.4 0.65 165.3 1 + 0.4 (9.81 1.74 1000 / 106 ) = 0.05 + 0.002 + 3.5 = 3.552mm

(2) Minimum required thickness of shell (nozzle R.O) for par. UG-45 (b) (1), and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 903.5 +C = + 3.5 = 4.34 + 2.6 = 7.84mm2.5 + 3.5 = 6.0 mm S s Es 0.6 P 136 1 0.6 0.65

ts = 7.84 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 2.31 + 2.6 = 4.62 mm t = (the smaller value of ts or tp) per UG-45(b)

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

54

OF

152

= 4.62 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 7.5 t 5-2-9 FOR NOZZLE pressure temperature of nozzle neck stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-106Gr.B : 125.3 Y1 OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

Design Design

Material

Allowable

temperature

Allowable

temperature

Material

of shell (nozzle H)

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 125.3 1.178 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 3.5 57.15 6.02 170.17

UW-12

Joint

efficiency of nozzle neck allowance (designated by customer)

Corrosion Outside

radius of nozzle neck thickness of the standard wall pipe(B36.10M)

Ro (mm) tstd (mm) Rs (mm)

Nominal Inside

radius of shell corroded

(1)

Minimum required thickness of nozzle neck for par. UG-45 (a) 0.385SE = 0.385 125.3 1.00 = 48.2405 > P (a) under design condition Appendix 1-1 Required minimum thickness including allowance

tmin 1 =

PRo 0.65 57.15 +C = + 3.5 = 3.8mm S d E + 0.4 P 125.3 1 + 0.4 0.65

(b) under hydrostatic test condition

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

55

OF

152

Required minimum thickness including allowance

tmin 2 =

=

PRo (9.81H / 106 ) Ro + +C St E + 0.4 P St E + 0.4(9.81H / 106 )

0.65 57.15 9.81 1.178 1000 / 106 57.15 + + 3.5 160.6 1 + 0.4 0.65 160.6 1 + 0.4 (9.81 1.178 1000 / 106 ) = 0.24 + 0.01 + 3.5 = 3.75mm

(2) Minimum required thickness of shell for par. UG-45 (b) (1),and UG-16 (b) (4), Es = 1.00

ts =

PRs 0.65 170.17 +C = + 3.5 = 4.39mm 2.5 + 3.5 =6.0 mm S s Es + 0.4 P 125.3 1 + 0.4 0.65

ts = 6.0 mm

(3) Minimum thickness of standard wall pipe including allowance for par. UG-45 (b) (4)

tp = 0.875tstd + C = 0.875 6.02 + 3.5 = 8.77 mm t = (the smaller value of ts or tp) = 6.0 mm. > tmin1,tmin2

(4) Provided thickness Nominal thickness (mm) 11.13 Minimum thickness (mm) 11.130.875 = 9.74 t 5-2-10

Design Design

per UG-45(b)

OK ASME SEC. DIV.1 UG-45 P (MPa) T () : : : 0.65 300 SA-106Gr.B

FOR NOZZLE pressure temperature of nozzle neck

Material

Allowable

stress of nozzle neck material at design Sd (MPa) stress of nozzle neck material at test St (MPa) : : 160.6 SA-106Gr.B : 125.3

temperature

Allowable

temperature

Material

of shell (nozzle H)

Allowable stress of shell (or head) at design Ss (MPa) H (m) (kg/m3) : : : 125.3 1.205 1000

temperature

Height

to point under consideration of test medium at test temperature (water)

Density

DOC. NO.: 2011-83-1-86811-342-0

REV.: 0

PAGE

56

OF

152

Type

of welded joints of nozzle neck in TABLE : E C (mm) : : : : : Seamless 1.0 3.5 84.15 7.11 170.17

UW-12