Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chem Resistance Chart

Caricato da

gshdavidCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chem Resistance Chart

Caricato da

gshdavidCopyright:

Formati disponibili

CONLEY

CORPORATION

CHEMICAL RESISTANCE

GUIDE

2795 E. 91

ST

St., TuIsa, OK 74137 (800) 331-5502 10/98

CONTENTS

CHEMICAL RESISTANCE OF CONLEY PIPING SYSTEMS

The information contained in this literature is based upon case histories, field experience, cooperative

testing, and the evaluation of the Conley Technical Committee. Conley Piping Systems have performed

satisfactorily in corrosive chemical environments for nearly half a century. The success of any installation

requires, however, proper system design, fabrication and application of our products.

The information in the following tables is for recommendation only and not a warranty for which Conley

assumes responsibility. Conley Corporation offers a limited warranty of its products, which is in the Terms

and Conditions of Sale. The information contained in the literature and catalogs furnished by Conley

Corporation cannot ensure, of itself, a successful installation and is offered to customers subject to these

limitations and explanations.

As an integral part of our ongoing quality policy and our Commitment to Excellence, Conley Corporation will

strive to improve our products continually. The company therefore reserves the right, without notice, to

change specifications and/or design at any time without incurring an obligation for equipment previously sold.

Descriptions contained in our literature are for the purpose of identification and neither limits nor extends

the standard product limited warranty set forth in the Terms and Conditions of Sale and Trade Customs.

As it is readily discerned by the chemical resistance tables, there is broad overlap in resin system

performance. Many customers use our products in combinations of chemical service that may magnify the

corrosive nature of the media. Generally therefore, recommendations are based upon the system that

provides optimum performance in a particular environment or has a long history of successful service in that

industry. Multiple uses would be a reason to consider the versatility of the resin system. n addition, there

are many media not listed or not recommended for which our products may be suitable due to very low

concentrations or brief periods of exposure.

Further, organic chemical environments are so varied as to be nearly infinite due to the possible

combinations of chemicals. Furan resin piping is specifically designed to perform in organic media such as

aggressive solvents including chlorinated materials, as well as acids and bases. These applications are such

as those commonly found in the pharmaceutical industry. Generally acceptable media for Furan laminates

include:

Acids (Strong & Weak) Bases (Strong & Weak) Ketones

Chlorinated Solvents Ethers Acrylates

Acetates Styrene Benzene

Toluene Xylene Carbon Disulfide

Furfural Furfural Alcohol Tetrahydrofuran

t is standard procedure at Conley Corporation to interface with end users and design groups to assist in the

selection of the corrosion barrier resin and piping schedule that will provide optimum performance in a given

chemical environment. We welcome customers to discuss their applications with our Technical Committee

by phone @ 800-331-5502, fax @ 918-299-5907, or e-mail Conley@webzone.net.

CONTENTS

CHEMICAL RESISTANCE OF CONLEY PIPING SYSTEMS

MAXMUM RECOMMENDED SERVCE TEMPERATURE, DEG. F

CHEMCAL ENVRONMENT CONLEY CONLEY CONLEY CONLEY CONLEY

CONC. EPOXY VE 411 VE441-400 VE 470 FURAN

*CM = CONTACT MANUFACTURER 800-331-5502

N = NOT TESTED / NR = NOT RECOMMENDED This information is for recommendation only, NOT A GUARANTEE

ACETALDEHYDE ALL N NR NR N 200

ACETC ACD 0-25 150 210 210 210 230

ACETC ACD 25-50 125 180 180 180 230

ACETC ACD 50-75 100 150 150 150 230

ACETC ANHYDRDE ALL 100 NR NR 100 150

ACETONE 5 150 N 180 180 BP 133

ACETONE 10 120 N 180 180 BP 133

ACETONE 100 125 NR NR NR BP 133

ACETYL CHLORDE 100 N N N N 180

ACETYLENE DCHLORDE 100 N N N N 230

ACETYLSALCYLC ACD 100 N N N N 230

ACRYLC ACD 25 N 100 100 100 100% AMB

ACRYLONTRLE 100 100 80 80 80 100% AMB

ADPC ACD SOL SAT 250 180 180 210 N

ALCOHOL, AMYL 200 120 180 210 230

ALCOHOL, BUTYL 200 120 120 120 230

ALCOHOL, ETHYL 10 180 150 150 150 BP173

ALCOHOL, ETHYL 100 180 80 80 80 BP 173

ALCOHOL, SOBUTYL 100 180 80 80 100 230

ALCOHOL, SOPROPYL ALL 180 120 120 150 230

ALCOHOL, METHYL 10 150 120 120 120 BP150

ALCOHOL, METHYL 100 150 NR NR 100 BP 150

ALCOHOL, n-BUTYL 150 120 120 120 230

ALCOHOL, SECONDARY BUTYL 10 150 150 150 150 230

ALPHATC HYDROCARBONS N N N N 230

ALUM ALL 280 210 250 250 N

ALUMNUM BROMDE ALL N N N N 230

ALUMNUM CHLORHYDRATE ALL 210 210 210 210 230

ALUMNUM CHLORDE ALL 280 210 250 250 230

ALUMNUM FLUORDE ALL 150 80 80 80 150

ALUMNUM HYDROXDE ALL 200 180 180 200 150

ALUMNUM NTRATE ALL 250 180 180 180 230

ALUMNUM SULFATE ALL 280 210 250 250 230

AMMONA, GAS 150 100 100 100 N

AMMONA, LQUD 125 NR NR NR N

AMMONUM BROMDE 43 N 160 160 160 150

AMMONUM CARBONATE ALL 200 150 150 150 230

AMMONUM CHLORDE ALL 270 210 210 210 220

AMMONUM FLUORDE >25 100 150 150 150 230

AMMONUM FLUORDE 25 150 150 150 150 230

AMMONUM HYDROXDE 0-5 200 180 180 180 120

AMMONUM HYDROXDE 20 200 150 150 150 N

AMMONUM HYDROXDE 29 200 100 100 100 N

AMMONUM NTRATE ALL 255 210 250 250 220

AMMONUM PERSULFATE ALL 255 180 180 180 180

AMMONUM PHOSPHATE 65 200 210 210 210 190

AMMONUM PHOSPHATE SAT 200 210 210 210 N

AMMONUM SULFATE ALL 280 210 250 250 220

AMMONUM SULFDE SAT 100 120 120 120 230

AMMONUM THOCYANATE 20 155 210 210 210 N

AMMONUM THOGLYCOLATE 8 100 100 100 100 N

AMMONUM THOSULFATE 60 150 100 100 100 N

AMYL ACETATE 100 100 70 70 120 200

ANLNE 100 75 NR NR 70 150

CONTENTS

CHEMICAL RESISTANCE OF CONLEY PIPING SYSTEMS

MAXMUM RECOMMENDED SERVCE TEMPERATURE, DEG. F

CHEMCAL ENVRONMENT CONLEY CONLEY CONLEY CONLEY CONLEY

CONC. EPOXY VE 411 VE441-400 VE 470 FURAN

*CM = CONTACT MANUFACTURER 800-331-5502

N = NOT TESTED / NR = NOT RECOMMENDED This information is for recommendation only, NOT A GUARANTEE

ANLNE HYDROCHLORDE 100 N 180 180 180 N

ANTMONY TRCHLORDE SAT 225 200 200 200 N

ARSENC ACD ALL 180 100 100 100 N

BARUM CARBONATE ALL 255 210 250 250 N

BARUM CHLORDE SAT 250 210 210 210 N

BARUM HYDROXDE SAT 200 150 150 N N

BARUM HYDROXDE 1-10 200 150 150 150 N

BARUM SULFATE ALL 255 210 250 250 N

BARUM SULFDE ALL 255 180 180 180 150

BEER 200 120 120 120 N

BENZALDEHYDE 100 100 NR NR 70 150

BENZENE 100 125 NR NR 100 150

BENZENE N KEROSENE 5 200 200 200 210 200

BENZENE SULFONC ACD 50 225 150 150 150 200

BENZOC ACD ALL 225 210 210 210 200

BENZOTRCHLORDE 100 N N N N 150

BENZOYL CHLORDE 100 N NR NR 80 150

BENZYL ALCOHOL 100 N NR 80 100 200

BENZYL CHLORDE 100 N NR NR 70 150

BLACK LQUOR PULP MLL 200 180 180 180 N

BORAX 255 210 210 210 150

BORC ACD SAT 65 200 210 210 210 200

BORC ACD 225 210 210 210 N

BROMNE, LQUD 100 N NR NR NR N

BROMNE, WATER SAT 100 100 100 100 N

BROMNE, WATER <5 150 100 100 100 N

BUTADENE 150 N N N N

BUTANE 150 N N N N

BUTYL ACETATE 100 150 NR 80 80 150

BUTYL CELLOSOLVE 100 150 100 100 100 113

BUTYL ETHER 100 N N N N BP

BUTYRC ACD 0-25 200 210 210 210 120

BUTYRC ACD 50 150 210 210 210 N

BUTYRC ACD 100 N 80 120 120 N

CALCUM BSULFTE ALL 200 180 180 180 N

CALCUM CARBONATE ALL 280 180 180 180 N

CALCUM CHLORATE ALL 205 210 250 250 N

CALCUM CHLORDE ALL 280 200 250 250 N

CALCUM HYDROXDE 0-25 200 180 180 180 N

CALCUM HYDROXDE 100 200 210 250 250 N

CALCUM HYPOCHLORTE ALL 150 180 180 150 N

CALCUM NTRATE ALL 255 210 210 210 N

CALCUM SULFATE ALL 255 210 250 250 N

CALGON SAT N 120 120 N N

CARBTON 100 N N N N N

CARBON DOXDE 255 210 300 300 230

CARBON DSULFDE 100 75 NR NR NR 115

CARBON TETRACHLORDE 100 150 150 180 180 170

CARBONC ACD 180 180 180 180 200

CASTOR OL 200 160 160 160 N

CATECHOL 100 N N N N 230

CAUSTC SODA & POTASH SAT 205 180 180 180 N

CHLORAL SAT N N N N N

CHLORNE DOXDE 15 80 200 200 180 N

CONTENTS

CHEMICAL RESISTANCE OF CONLEY PIPING SYSTEMS

MAXMUM RECOMMENDED SERVCE TEMPERATURE, DEG. F

CHEMCAL ENVRONMENT CONLEY CONLEY CONLEY CONLEY CONLEY

CONC. EPOXY VE 411 VE441-400 VE 470 FURAN

*CM = CONTACT MANUFACTURER 800-331-5502

N = NOT TESTED / NR = NOT RECOMMENDED This information is for recommendation only, NOT A GUARANTEE

CHLORNE DOXDE, WET GAS 100 N 200 200 210 LS 150

CHLORNE WATER SAT N 180 200 210 N

CHLORNE, GAS DRY 100 125 210 250 250 N

CHLOROACETC ACD 25 100 120 120 120 N

CHLOROACETC ACD 50 200 100 100 100 N

CHLOROACETC ACD CONC N NR 80 100 N

CHLOROBENZENE 100 100 NR 80 100 230

CHLOROFORM LQ 100 NR NR NR 80

CHLOROFORM VAPOR N N N N 230

CHLORONAPTHALENE 100 N N N N 150

CHLOROPHENOL 100 N N N N 100% AMB

CHLOROSULFONC ACD SAT N NR NR NR N

CHROMC ACD 5 125 150 150 150 N

CHROMC ACD 10 100 150 150 150 N

CHROMC ACD 20 80 120 150 150 N

CHROMUM SULFATE SAT 125 180 180 180 N

CTRC ACD SAT 250 210 210 210 190

COPPER ACETATE SAT 180 160 160 160 N

COPPER CHLORDE SAT 255 210 250 250 N

COPPER FLUORDE ALL 255 200 210 210 N

COPPER NTRATE SAT 255 210 210 210 N

COPPER SULFATE SAT 255 210 250 250 N

CUMENE 100 N 80 120 120 N

CYCLOHEXANE 100 150 120 150 150 150

DBUTYL PHTHALATE 100 N 180 180 210 230

DCHLOROBENZENE 100 120 NR 100 120 120

DESEL FUEL 250 180 210 210 150

DETHANOLAMNE NR 120 120 120 150

DETHYL KETONE 100 NR NR NR 80 BP

DETHYLAMNE 100 NR N N N 100% AMB

DETHYLENE GLYCOL 100 200 150 150 150 230

DETHYLENE GLYCOL MONOETHYL 100 N N N N 230

DMETHYL ANLNE 100 N N N N N

DMETHYL FORMAMDE **CM NR NR NR NR NR **CM

DMETHYL PHTHALATE 100 100 150 180 180 230

DOXANE 100 N N N N N

DMA4 WEED KLLER 2,4,D N 120 150 150 N

DMA6 WEED KLLER N 120 150 150 N

ETHYL ACETATE SAT 150 NR NR 70 171 BP

ETHYL ALCOHOL 100 150 80 80 100 173 BP

ETHYL ALCOHOL 50 180 100 100 150 173 BP

ETHYL AMNE 100 N NR NR 80 AMB

ETHYL BROMDE SAT N NR NR NR 150

ETHYL CELLUSOLVE 150 N N N N

ETHYL CHLORDE 100 80 NR 80 80 230

ETHYL ETHER 100 100 NR NR NR BP

ETHYL SULFATE SAT N 100 100 100 230

ETHYL SULFURC ACD SAT N N N N N

ETHYLENE CHLORDE 100 N NR NR NR 150

ETHYLENE DSULFONC ACD SAT N N N N 230

ETHYLENE GLYCOL 100 200 210 210 210 230

ETHYLENE OXDE 100 N N N N N

FATTY ACDS SAT 225 210 250 250 230

FERRC CHLORDE SAT 280 200 210 210 N

CONTENTS

CHEMICAL RESISTANCE OF CONLEY PIPING SYSTEMS

MAXMUM RECOMMENDED SERVCE TEMPERATURE, DEG. F

CHEMCAL ENVRONMENT CONLEY CONLEY CONLEY CONLEY CONLEY

CONC. EPOXY VE 411 VE441-400 VE 470 FURAN

*CM = CONTACT MANUFACTURER 800-331-5502

N = NOT TESTED / NR = NOT RECOMMENDED This information is for recommendation only, NOT A GUARANTEE

FERRC NTRATE SAT 250 210 210 210 N

FERRC SULFATE SAT 200 210 210 210 N

FERRC, FERROUS CHLORDE 255 210 230 230 N

FERROUS CHLORDE 100 255 210 210 210 N

FERROUS SULFATE 100 200 210 210 210 N

FLUE GAS N 325 350 400 N

FLUE GAS WET N 180 210 210 N

FLUOBORC ACD SAT N 210 210 210 150

FLUORNE GAS 100 N 80 80 80 N

FLUOSLCC ACD 10 200 180 180 180 150

FLUOSLCC ACD 25 150 100 100 100 N

FLUOSLCC ACD 35 125 100 100 100 N

FLUOSLCC ACD FUMES SAT N 180 180 180 200

FORMALDEHYDE 37 150 150 150 150 150

FORMALDEHYDE 52 N 150 150 150 150

FORMC ACD 100 100 NR NR 100 100

FORMC ACD 10 10 140 180 180 180 150

FREON 150 80 100 100 230

FURFURAL 100 NR NR NR NR 100% AMB

FURFURAL ALCOHOL 100 N NR NR 80 100% AMB

GALLC ACD SAT N N N 100 230

GAS, NATURAL 200 NR NR 100 230

GASOHOL 10%ALCOHOL 125 100 100 120 AMB

GASOLNE AVATON 180 180 180 180 AMB

GASOLNE LEADED 100 225 180 180 180 AMB

GASOLNE UNLEADED 225 225 120 150 150 AMB

GASOLNE, SOUR 100 250 180 180 180 194

GLUCOSE 250 210 250 250 N

GLYCERNE 280 210 210 210 230

GLYCOLC ACD (HYDROXYACETC 70%) N 100 100 100 230

HEPTANE 100 200 210 210 210 230

HEXANE 150 160 160 160 200

HEXYLENE GLYCOL 150 150 150 150 230

HYDRAULC FLUD 250 180 180 180 N

HYDRAZNE SULFATE SAT NR N N N 230

HYDRODC ACD 40 N 150 150 150 N

HYDROBROMC ACD 0-25 150 180 180 180 N

HYDROBROMC ACD 48 150 150 150 150 AMB

HYDROBROMC ACD 62 100 100 100 100 N

HYDROCHLORC ACD 20 205 180 230 230 150

HYDROCHLORC ACD 37 205 150 180 180 N

HYDROCHLORC ACD+FREE CL2 200 180 230 230 N

HYDROCHLORC ACD+ORGANCS N NR NR 150 N

HYDROCYANC ACD SAT N 210 210 210 N

HYDROFLUORC ACD 10 N 150 150 150 N

HYDROFLUORC ACD 20 N 100 100 100 N

HYDROGEN BROMDE WET GAS 100 180 180 180 N

HYDROGEN CHLORDE WET GAS N 210 300+ 300+ N

HYDROGEN CHOLORDE DRY GAS 150 210 300+ 300+ N

HYDROGEN FLUORDE VAPOR N 180 180 180 N

HYDROGEN PEROXDE 0-30 80 150 150 150 N

HYDROGEN PEROXDE 35 80 N N N N

HYDROGEN SULFDE 100 255 180 300+ 300+ 230

HYPOCHLOROUS ACD 10 150 150 180 180 N

CONTENTS

CHEMICAL RESISTANCE OF CONLEY PIPING SYSTEMS

MAXMUM RECOMMENDED SERVCE TEMPERATURE, DEG. F

CHEMCAL ENVRONMENT CONLEY CONLEY CONLEY CONLEY CONLEY

CONC. EPOXY VE 411 VE441-400 VE 470 FURAN

*CM = CONTACT MANUFACTURER 800-331-5502

N = NOT TESTED / NR = NOT RECOMMENDED This information is for recommendation only, NOT A GUARANTEE

HYPOPHOSPHORUS ACD 50 N 120 120 120 200

JET FUEL JP4 255 180 180 180 230

KEROSENE 255 180 180 180 N

LACTC ACD SAT 225 210 210 210 N

LAURC ACD SAT 225 200 200 200 N

LAURYL CHLORDE 100 225 210 210 210 N

LEAD ACETATE ALL 250 210 230 230 N

LEVULNC ACD ALL 250 210 230 230 N

LTHUM BROMDE SAT 225 210 210 250 N

LTHUM CARBONATE SAT 140 180 180 180 N

LTHUM CHLORDE SAT 225 210 210 210 230

LTHUM HYDROXDE SAT 200 180 180 150 N

MAGNESUM NTRATE 100 280 210 210 210 N

MAGNESUM SULFATE SAT 225 210 250 250 N

MALEC ACD SAT N 210 250 250 N

MANGANESE CHLORDE SAT 225 210 210 210 N

MANGANESE OXDE SAT N N N N N

MANGANESE SULFATE SAT 250 210 210 210 N

MERCURC CHLORDE SAT 225 210 210 210 N

MERCURY 100 280 210 250 250 N

METAPHOSPHORC ACD 100 N N N N N

METHACRYLC ACD NR NR NR NR N

METHYL CYCLOHEXANOL 100 80 N N N 200

METHYL ETHYL KETONE MEK 100 100 NR NR 70 175

METHYL SOBUTYL CARBTOL N N N N N

METHYL TERT-BUTYL ETHER MTBE ALL N N N N 97% AMB

METHYLACETATE 100 N N N N 150

MONOCHLOROBENZENE N NR 80 120 230

MYRSTC ACD 100 N 210 250 250 N

NAPHTHA 100 250 180 210 210 150

NAPHTHALENE 200 210 210 210 150

NAPTHOL SULFONC ACD 100 N N N N 230

NCKEL NTRATE SAT 250 210 210 210 N

NCKEL SULFATE SAT 250 210 210 210 N

NTRC ACD * CM 20 N 120 120 150 NR

NTRC ACD 10 120 150 150 150 5% 150

NTROBENZENE 100 N NR 80 100 150

NTROPHENOL 100 N N N N N

OL, ANMAL 255 200 210 210 230

OL, MNERAL 280 210 250 250 230

OL, SOUR CRUDE 225 210 250 250 N

OL, SWEET CRUDE 225 210 250 250 N

OL, VEGETABLE 250 210 210 210 230

OLEC ACD 100 220 210 210 200 N

OXALC ACD ALL 250 120 120 120 215

OZONE * CM 5 N 140 140 140 NR

PENTACHLOROETHANE 100 N 80 120 120 230

PERCHLORC ACD * CM 30 75 100 100 100 NR

PERCHLORC ACD * CM 10 75 150 150 150 NR

PHENOL (CARBOLC ACD) 5 100 N N 120 150

PHENOL SULFONC ACD 65 N NR NR 80 150

PHENYL ETHER 100 N N N N N

PHOSPHORC ACD ALL 100 210 210 210 150

PHOSPHOROUS TRCHLORDE 100 N NR NR NR 150

CONTENTS

CHEMICAL RESISTANCE OF CONLEY PIPING SYSTEMS

MAXMUM RECOMMENDED SERVCE TEMPERATURE, DEG. F

CHEMCAL ENVRONMENT CONLEY CONLEY CONLEY CONLEY CONLEY

CONC. EPOXY VE 411 VE441-400 VE 470 FURAN

*CM = CONTACT MANUFACTURER 800-331-5502

N = NOT TESTED / NR = NOT RECOMMENDED This information is for recommendation only, NOT A GUARANTEE

PHOSPHORUS ACD SAT N 100 100 100 150

PHOSPHORUS PENTOXDE FUME 0-54 200 200 230 230 N

PHTHALC ACD ALL N 210 210 210 225

PCRC ACD SAT 100 NR NR 100 165

POLYPHOSPHORC ACD 115 N 210 210 210 150

POTASSUM BROMDE SAT 220 100 100 120 150

POTASSUM CARBONATE SAT 255 180 180 180 150

POTASSUM CHLORATE SAT 280 N N N N

POTASSUM CHLORDE SAT 280 210 210 210 150

POTASSUM DCHROMATE ALL 250 210 210 210 N

POTASSUM FERRCYANDE ALL 250 210 210 210 150

POTASSUM FERROCYANDE SAT 250 210 210 210 150

POTASSUM HYDROXDE 45 200 180 180 180 150

POTASSUM HYDROXDE 0-25 200 150 150 150 150

POTASSUM NTRATE SAT 280 210 210 210 N

POTASSUM OXALATE SAT 250 150 150 N N

POTASSUM PERMANGANATE SAT 200 210 210 210 N

POTASSUM PERSULFATE SAT 250 210 210 210 N

POTASSUM SULFATE SAT 200 210 210 210 N

PROPONC ACD 50 100 180 180 180 N

PROPYLENE GLYCOL ALL N 210 210 210 150

PULP MLL LQUOR BLACK 200 180 180 180 150

PULP MLL LQUOR GREEN 180 180 180 180 150

PULP MLL LQUOR RED N 180 180 180 150

PULP MLL LQUOR WHTE 200 180 180 180 150

QUATERNARY AMNE SALTS N 120 150 150 N

RESORCNOL 100 N N N N N

SALCYLC ACD ALL 250 140 140 N N

SALT BRNE 30 280 210 250 250 N

SLCC ACD 250 200 210 210 N

SLCON TETRACHLORDE 100 N N N N 140

SLVER NTRATE ALL 250 210 210 210 N

SODUM ACETATE 100 250 210 210 210 225

SODUM ACD PHOSPHATE SAT N N N N 190

SODUM BCARBONATE 100 275 180 180 180 225

SODUM BSULFATE SAT 255 210 210 210 225

SODIUM BISULFATE 255 210 210 210 N

SODUM BSULFTE SAT 250 210 210 210 225

SODUM BROMATE 5 180 140 150 150 150

SODUM CARBONATE SAT 255 180 180 180 150

SODUM CHLORATE SAT 255 210 210 210 N

SODUM CHLORDE ALL 280 210 250 250 225

SODUM CHROMATE 50 155 210 210 210 150

SODUM CYANDE SAT 255 210 210 210 225

SODUM DCHROMATE ALL 255 210 210 210 N

SODUM FERROCYANDE ALL 255 210 210 210 N

SODUM FLUORDE ALL 200 180 180 180 N

SODUM HYDROXDE 0-10 200 180 180 150 150

SODUM HYDROXDE 25 200 180 180 180 150

SODUM HYDROXDE 50 200 210 210 180 150

SODUM HYPOCHLORTE ** CM 0-10 80 120 120 120 AMB

SODUM METHOXDE 40 150 N N N 200

SODUM NTRATE SAT 255 210 210 210 N

SODUM OXALATE SAT 210 210 210 210 N

CONTENTS

CHEMICAL RESISTANCE OF CONLEY PIPING SYSTEMS

MAXMUM RECOMMENDED SERVCE TEMPERATURE, DEG. F

CHEMCAL ENVRONMENT CONLEY CONLEY CONLEY CONLEY CONLEY

CONC. EPOXY VE 411 VE441-400 VE 470 FURAN

*CM = CONTACT MANUFACTURER 800-331-5502

N = NOT TESTED / NR = NOT RECOMMENDED This information is for recommendation only, NOT A GUARANTEE

SODUM PHOSPHATE 200 210 210 210 150

SODUM SLCATE ALL 150 210 210 210 160

SODUM SULFATE SAT 280 210 210 210 N

SODUM SULFDE SAT 200 210 210 210 N

SODUM SULFTE ALL 200 210 210 210 N

SODUM THOSULFATE SAT 150 180 180 180 N

STANNC CHLORDE SAT 200 210 210 210 N

STEARC ACD SAT 200 210 210 210 230

STYRENE 100 100 NR 100 120 100% AMB

STYRENE ACRYLC EMULSON N 100 120 120 100

STYRENE BUTADENE LATEX N 130 130 N N

SUGAR BEET LQUOR 200 180 180 180 N

SUGAR CANE LQUOR ALL 200 180 180 180 N

SUGAR, SUCROSE ALL 255 210 210 210 N

SULFAMC ACD 10 125 210 210 210 N

SULFAMC ACD 25 125 150 150 150 N

SULFTE/SULFATE LQUOR (PULP MLL) N 200 200 200 N

SULFUR (MOLTEN) 100 N N 250 300 230

SULFUR CHLORDE FUMES 100 N 200 200 200 200

SULFUR CHLORDE MONO 100 N N N N N

SULFUR DOXDE (WET OR DRY) 100 150/200 210 210 250 N

SULFURC ACD 25 200 210 210 210 150

SULFURC ACD 50 150 180 180 180 100

SULFURC ACD 70 N 180 180 180 NR

SULFUROUS ACD 10 200 120 120 120 N

SUPERPHOSPHORC 76%P2O5 105 N 210 210 210 N

TANNC ACD SAT 200 210 210 210 N

TARTARC ACD SAT 250 210 210 210 N

TETRACHLOROETHANE 100 N NR 80 120 225

TETRAHYDROFURAN N NR NR N 100% AMB

TETRAHYDROFURFURYL ALCOHOL 100 N N N N 150

TETRAPOTASSUM PYROPHOSPHATE 60 N 130 150 150 150

THONYL CHLORDE N NR NR NR 100% AMB

TN CHLORDES SAT N N N N N

TN SULFATES SAT N N N N N

TTANUM CHLORDE 80 180 180 210 N

TTANUM DOXDE 210 180 180 210 N

TTANUM SULFATE SAT N N N N N

TOLUENE (TULOUL) 100 150 80 100 120 230

TOLUENE SULFONC ACD 100 N 210 210 210 180

TOMATO SAUCE 250 190 210 N 220

TRCHLOROACETC ACD (TCA) 50 N 210 210 210 AMB

TRCHLOROBENZENE 100 N N N N 230

TRCHLOROETHANE 100 N 100 100 120 100% AMB

TRCHLOROETHYLENE 100 150 NR NR NR 189 BP

TRETHANOLAMNE 150 120 120 120 150

TRETHYLAMNE 100 120 120 120 150

TRSODUM PHOSPHATE SAT N 210 250 250 150

TRSODUM PHOSPHATE 25 200 210 250 250 150

TURPENTNE 150 155 210 210 N

UREA 50 150 150 150 150 160

URC ACD CONC N N N N N

VNEGAR 200 210 210 210 230

WATER TAP 255 200 200 200 212

CONTENTS

CHEMICAL RESISTANCE OF CONLEY PIPING SYSTEMS

MAXMUM RECOMMENDED SERVCE TEMPERATURE, DEG. F

CHEMCAL ENVRONMENT CONLEY CONLEY CONLEY CONLEY CONLEY

CONC. EPOXY VE 411 VE441-400 VE 470 FURAN

*CM = CONTACT MANUFACTURER 800-331-5502

N = NOT TESTED / NR = NOT RECOMMENDED This information is for recommendation only, NOT A GUARANTEE

WATER, DEMNERALZED 255 180 180 180 212

WATER, DSTLLED 255 180 180 180 212

WATER, FRESH 255 200 200 200 212

WATER, SALT 280 180 180 180 212

WATER, SALT BRNE 280 180 180 180 212

WATER, SEA 280 180 180 180 212

WATER, STEAM CONDENSATE 255 180 180 180 N

WHTE LQUOR (PULP MLL) 100 200 200 180 150

XYLENE (XYLOL) 100 150 80 100 120 230

ZNC CHLORDE SAT 250 210 250 250 N

ZNC NTRATE SAT 200 200 250 250 N

ZNC SULFATE SAT 250 210 250 250 N

CONTENTS

Potrebbero piacerti anche

- Basket Strainer Intro PDFDocumento4 pagineBasket Strainer Intro PDFgshdavidNessuna valutazione finora

- Worksafe Bulletin: Safe Procedures For Vacuum Truck OperationsDocumento2 pagineWorksafe Bulletin: Safe Procedures For Vacuum Truck OperationsgshdavidNessuna valutazione finora

- Inspection and Testing of Piping Systems ES-14-602-02Documento44 pagineInspection and Testing of Piping Systems ES-14-602-02Edmund MoraldeNessuna valutazione finora

- Crude Oil Properties (Laboratory)Documento15 pagineCrude Oil Properties (Laboratory)gshdavidNessuna valutazione finora

- 007 UTube CleaningDocumento2 pagine007 UTube CleaninggshdavidNessuna valutazione finora

- Code Pid PDFDocumento6 pagineCode Pid PDFMejdi Sylas ToudjiNessuna valutazione finora

- Hot Tapping: Typical Hot Tap ApplicationDocumento1 paginaHot Tapping: Typical Hot Tap ApplicationgshdavidNessuna valutazione finora

- Pages: 20-25 May, 2000: By: Bill RockwellDocumento7 paginePages: 20-25 May, 2000: By: Bill RockwellgshdavidNessuna valutazione finora

- P&ID SymbolDocumento18 pagineP&ID SymbolBagus Okti100% (1)

- Hot Tap ProcedureDocumento21 pagineHot Tap ProcedureImanuel Sitepu100% (1)

- Hot Tapping GuideDocumento3 pagineHot Tapping GuidegshdavidNessuna valutazione finora

- Catalyst in Refining PetrochemicalsDocumento5 pagineCatalyst in Refining PetrochemicalsgshdavidNessuna valutazione finora

- Mesh Size EquivalentsDocumento2 pagineMesh Size EquivalentsFrancisco Chavez ContrerasNessuna valutazione finora

- Tatoray ReacrorsDocumento2 pagineTatoray ReacrorsgshdavidNessuna valutazione finora

- Munters High Temp Psych ChartDocumento2 pagineMunters High Temp Psych ChartaniruddhaskNessuna valutazione finora

- Proposed Basket StrainerDocumento1 paginaProposed Basket StrainergshdavidNessuna valutazione finora

- Minimum Oil Circuit BreakerDocumento4 pagineMinimum Oil Circuit BreakergshdavidNessuna valutazione finora

- Filtration System Without BypassDocumento1 paginaFiltration System Without BypassgshdavidNessuna valutazione finora

- Chemical Engineering Objective Type Questions Matls of ConstructionDocumento14 pagineChemical Engineering Objective Type Questions Matls of ConstructiongshdavidNessuna valutazione finora

- Filtration System With BypassDocumento1 paginaFiltration System With BypassgshdavidNessuna valutazione finora

- Pyrophoric Vessel HandlingDocumento4 paginePyrophoric Vessel HandlinggshdavidNessuna valutazione finora

- Portable 8X8X10: Command ContainerDocumento9 paginePortable 8X8X10: Command ContainergshdavidNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- ReviewerDocumento2 pagineReviewerAra Mae Pandez HugoNessuna valutazione finora

- Revit 2019 Collaboration ToolsDocumento80 pagineRevit 2019 Collaboration ToolsNoureddineNessuna valutazione finora

- Projects: Term ProjectDocumento2 pagineProjects: Term ProjectCoursePinNessuna valutazione finora

- Communication On The Telephone InfoDocumento30 pagineCommunication On The Telephone Infomelese100% (1)

- Question Paper: Hygiene, Health and SafetyDocumento2 pagineQuestion Paper: Hygiene, Health and Safetywf4sr4rNessuna valutazione finora

- Digital Documentation Class 10 NotesDocumento8 pagineDigital Documentation Class 10 NotesRuby Khatoon86% (7)

- Tracker Pro Otm600 1.5Documento19 pagineTracker Pro Otm600 1.5Camilo Restrepo CroNessuna valutazione finora

- CEA 4.0 2022 - Current Draft AgendaDocumento10 pagineCEA 4.0 2022 - Current Draft AgendaThi TranNessuna valutazione finora

- Review of Accounting Process 1Documento2 pagineReview of Accounting Process 1Stacy SmithNessuna valutazione finora

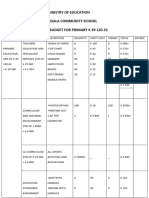

- Ministry of Education Musala SCHDocumento5 pagineMinistry of Education Musala SCHlaonimosesNessuna valutazione finora

- TT Class XII PDFDocumento96 pagineTT Class XII PDFUday Beer100% (2)

- Proposal For Chemical Shed at Keraniganj - 15.04.21Documento14 pagineProposal For Chemical Shed at Keraniganj - 15.04.21HabibNessuna valutazione finora

- Admissibility of Whatsapp Messages in Court For Family MattersDocumento3 pagineAdmissibility of Whatsapp Messages in Court For Family Mattersnajihah adeliNessuna valutazione finora

- Modulation and Frequency Synthesis X Digital Wireless RadioDocumento233 pagineModulation and Frequency Synthesis X Digital Wireless Radiolcnblzr3877Nessuna valutazione finora

- MLT Torque Ring Field Make-Up HandbookDocumento44 pagineMLT Torque Ring Field Make-Up HandbookKolawole Adisa100% (2)

- The Concept of Crisis PDFDocumento10 pagineThe Concept of Crisis PDFJohann RestrepoNessuna valutazione finora

- Chapter 2 A Guide To Using UnixDocumento53 pagineChapter 2 A Guide To Using UnixAntwon KellyNessuna valutazione finora

- Accounting II SyllabusDocumento4 pagineAccounting II SyllabusRyan Busch100% (2)

- Management in English Language Teaching SummaryDocumento2 pagineManagement in English Language Teaching SummaryCarolina Lara50% (2)

- SettingsDocumento3 pagineSettingsrusil.vershNessuna valutazione finora

- Rs 422Documento1 paginaRs 422rezakaihaniNessuna valutazione finora

- Fr-E700 Instruction Manual (Basic)Documento155 pagineFr-E700 Instruction Manual (Basic)DeTiEnamoradoNessuna valutazione finora

- Class 11 Accountancy NCERT Textbook Chapter 4 Recording of Transactions-IIDocumento66 pagineClass 11 Accountancy NCERT Textbook Chapter 4 Recording of Transactions-IIPathan KausarNessuna valutazione finora

- MEMORANDUMDocumento8 pagineMEMORANDUMAdee JocsonNessuna valutazione finora

- CavinKare Karthika ShampooDocumento2 pagineCavinKare Karthika Shampoo20BCO602 ABINAYA MNessuna valutazione finora

- Science News Explores-June July 2023Documento36 pagineScience News Explores-June July 2023Tobei AchimNessuna valutazione finora

- VISCOROL Series - Magnetic Level Indicators: DescriptionDocumento4 pagineVISCOROL Series - Magnetic Level Indicators: DescriptionRaduNessuna valutazione finora

- Amel Forms & Logging SheetsDocumento4 pagineAmel Forms & Logging SheetsisaacNessuna valutazione finora

- YeetDocumento8 pagineYeetBeLoopersNessuna valutazione finora

- Study of Risk Perception and Potfolio Management of Equity InvestorsDocumento58 pagineStudy of Risk Perception and Potfolio Management of Equity InvestorsAqshay Bachhav100% (1)