Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2007 ATRA Seminar Manual

Caricato da

troublezaurDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2007 ATRA Seminar Manual

Caricato da

troublezaurCopyright:

Formati disponibili

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

2

This manual has been developed by the Automatic Transmission Rebuilders Asso-

ciation (ATRA) Technical Department to be used by qualified transmission techni-

cians in conjunction with ATRAs technical seminars. Since the circumstances of

its use are beyond ATRAs control, ATRA assumes no liability for the use of such

information or any damages incurred through its use and application. Nothing

contained in this manual is to be considered contractual or providing some form

of warranty on the part of ATRA. No part of this program should be construed as

recommending any procedure which is contrary to any vehicle manufacturers

recommendations. ATRA recommends only qualified transmission technicians

perform the procedures in this manual.

This manual contains copyrighted material belonging to ATRA. No part of this

manual may be reproduced or used in any form or by any means graphic,

electronic or mechanical, including photocopying, recording, electronic or infor-

mation storage and retrieval without express written permission from the ATRA

Board of Directors.

Public exhibition or use of this material for group training or as part of a school

curriculum, without express written permission from the ATRA Board of Directors

is strictly prohibited.

ATRA and the ATRA logo are registered trademarks of the Automatic Transmission

Rebuilders Association.

Portions of materials contained herein have been reprinted with permission of

General Motors Corporation, Service Technology Group Agreement # 0610228.

Portions of materials contained herein have been reprinted with permission of

Ford Motor Company.

Portions of materials contained herein have been reprinted with permission of

Daimler Chrysler Corporation.

The

Automatic Transmission Rebuilders Association

2400 Latigo Avenue

Oxnard, CA 93030

Phone: (805) 604-2000 Fax: (805) 604-2005

http://www.atraonline.com

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

3

Dennis Madden

Chief Executive Officer

Dennis Madden,

ATRA, CEO

Welcome to the 2007 ATRA Technical Seminar!

Lance Wiggins and the ATRA Technical staff have really worked hard to get you

the most up-to-date and relevant technical information that you can put to work

right away and again, in full color!

For those of you who have attended past ATRA seminars youll be delighted to

know this seminar material is just what you expected from ATRA, or even more. If

youve never attended an ATRA seminar before youre in for a treat.

This seminar, along with everything else at ATRA is a group effort, with a lot of

people working in the background to make this seminar a success. I am honored

to be part of such a worthy organization and to work with such great people.

ATRA is changing all the time. Not only with the way we distribute technical

material, but in almost every area where we serve our members, and the industry

at large.

On behalf of the ATRA staff, and the ATRA Chapters that work so hard to bring

you this seminar, welcome.

Sincerely,

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

4

Lance Wiggins

Technical Director

The ATRA Technical Department is pleased to present its 2007 Technical Semi-

nar. Packed with countless hours of research and development, writing, editing,

photography and layout, this years seminar will stand out as one of the most

demanding and useful technical training programs ever developed for this indus-

try.

Once again, this years technical manual has been produced in full color. With

over 250 pages of up-to-the-minute technical information, the 2007 Technical

Seminar Manual will remain a valuable resource long after the seminar is just a

memory.

Were confident that youll find this years seminar presentation and technical

manual both informative and profitable. In fact, were so sure youll be satisfied

with what you learn in this program, we guarantee it!

On behalf of the entire ATRA staff, the International Board of Directors, and all of

the ATRA members worldwide, wed like to thank you for helping to make every

day memorable.

Lance Wiggins

ATRA Technical Director

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

5

ATRA Technical Team (continued)

Pete Huscher

Technical Advisor

David Skora

Senior Technician,

Seminar Speaker

Mike VanDyke

Technical Advisor and

Seminar Speaker

Mike Brown

Technical Advisor

Randall Schroeder

Senior Technician

and Seminar Speaker

Steve Garrett

Service Engineer, Technical

Advisor, and Seminar

Speaker

Weldon Barnett

Technical Advisor and

Seminar Speaker

Bill Brayton

Technical Advisor and

Seminar Speaker

Chris Ondersma

Technical Advisor

The most advanced features for the most affordable price!

Upgrade Features include:

Motorized tailstock and lift hoist -add safety and efficiency while lifting and mounting heavy transmissions

Optional Adjustable eddy current load cells -simulate real-world load applications and are always consistent

regardless of wear or ambient air conditions

Air Load Cells - Up to 1,000 lbs of torque, adjustable, and less cost to maintain

TRUE FIND Laser Alignment Tool -now easier than ever to insure a perfect motor-to-torque converter align-

ment; even takes the guess work out of accurate alignment of FWD style transmissions

Data Acquisition Computer System with color printer -the most advanced and affordable transmission diag-

nostic aid available

- The ALL NEW G-TEC Data Acquisition Computer System precisely monitors temperature, cooler pressure, input/

output RPMs, and gear ratios using 4 included pressure ports with the option to add 4 more.

- The AUTO-RUN Test automatically controls RPMs and shift patterns using pre-loaded data for all available trans-

missions. Simply mount the transmission, put it in Drive, and press start!

- The AUTO-RUN and manual test modes allow full solenoid testing including current and amperage testing and ma-

nipulation for up to 8 solenoids.

- The ALL NEW G-TEC Data Acquisition Computer System displays the transmissions information on a cutting

edge interface of virtual gauges, dials, color-coded pass/fail indicators, and real-time moving graphs.

Contact us:800-725-6499

Phone:417-725-6400

Fax: 417-725-3577

www.g-tec.com

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

8

ATRA Staff

A lot of work goes into producing the ATRA Seminar Manuals each year. The

ATRA staff pulls togather with research, writing, photos, and the editing process.

Ch ief Execu t ive Officer : Dennis Madden

GEARS Ma ga zin e : Rodger Bland, Managing Editor

Frank Pasley

Jeanette Troub

Even t s Cor din at or : Vanessa Velasquez, Manager

Kim Paris

Member s h ip Ser vices : Kelly Hilmer, Director

Kim Brattin

Deon Olmos

Lori Fortune

Tom Fortune

Tom Hall

Jim Spitsen

Accou n t in g Ser vices : Jody Wintermute

Rosa Smith

Valerie Mitchell

ATRA Book s t or e: Shaun Velasquez, Manager

Ron Brattin

Without the ATRA team, it would be very hard to accomplish the task at hand.

Please enjoy the seminar.

Lance Wiggins

ATRA Technical Director

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

9

ATRA would like to thank the following

companies for their continued support!

iv

Now theres no faster way to get transmission repair solutions.

www.transmissionkits.com

From the worldwide leader in

quality-tested domestic and foreign

transmission repair kits, comes a vital

new resource for you on the

Worldwide Web, featuring:

Video seminars from leading

transmission expert

John Parmenter!

Owner of a transmission shop and

prominent industry authority, John knows

first-hand the challenges you face every

day. Through this series of informative

video seminars (with new ones added each month), he presents helpful

solutions to many of todays most prevalent transmission repair problems.

Frequently asked questions that can give you

instant answers!

Youve got questions, weve got answers. Not just any answers either,

but well-researched and proven to work! The kind that can save you

a lot of time, money and headaches.

Introducing Precision Internationals new,

totally redesigned website with informative video seminars!

The Problem Solvers.

New York Headquarters:

(631) 567-2000 Fax (631) 567-2640 Toll Free: 800-872-6649

Florida Office:

(954) 509-9950 Fax (954) 509-9945

E-mail: sales@transmissionkits.com

www.transmissionkits.com

206-PRE-038 Precision International Ad Trim Size: 8.125 x 10.875 4/C Gears 2007 Atra Seminar Manual

John Parmenter

Precisions complete catalog

and ordering information!

Whatever make, model or year

transmission youre working on,

weve got the best parts to fix it.

All crosschecked against the latest

OEM specs (with changes noted and

made). All OE quality or better.

And all guaranteed to work. In addition, our huge inventory virtually

assures immediate delivery.

Plus, other great news and views that will keep you

coming back for more!

206PRE-FasterWay-038 12/27/06 9:02 AM Page 1

Maximum Performance.

In response to the industrys need

for a dependable solution to faulty

speed sensors, Raybestos Powertrain

has developed an Output Speed

Sensor that is superior, even to OE,

in eliminating limp mode comebacks.

This patent-pending design is fully

encapsulated, completely impervious

to moisture and contamination and

resistant to cracking.

Plastic fully supports the coil for

maximum vibration protection.

Plastic encapsulates the lead wire,

terminal and all internal components,

making it impervious to

contamination.

The extended Sure-Signal tip

ensures stronger signal.

The Teflon-coated silicone O-ring is

color-coded to the application for easy

identification.

100% function tested prior to

packaging for reliability.

964 East Market St., Crawfordsville, IN 47933 Toll Free: 800-729-7763 Fax: 765-364-4576 Email: raypt@raybestospowertrain.com

Our patent-pending encapsulated design

eliminates limp mode comebacks

OE

RAYBE ST OS

POWE RT RAI N

OT HE R

AF T E RMARKE T

Plastic fully

encloses

lead wire

for support

Plastic fully

surrounds coil

Extended

Sure-Signaltip

ensures stronger

signal

Windings &

terminal

connections

impervious to

contamination

Failure 1

Failure 2

Failure 3

Failure 3

Failure 1

Failure 2

T: 419.499.2502 F: 419.499.3337

www.TransTec.com Milan, OH 44846

1. Better Parts

Nobody makes transmission parts more

dependable. Cortecos Technology Center

houses 70 engineering and materials pro-

fessionals that have developed hundreds

of patents and proprietary compounds that

improve gasket and seal performance. Our globally integrated

supply of products from 85 auto-

motive operations in 27 countries

insures that we produce the best

gaskets and seals.

2. More Parts.

We offer more parts and sell more parts than any other kit supplier.

Every 12.7 seconds someone, somewhere,

rebuilds a transmission with a TransTec kit.

Thats 24 hours a day, 7 days a week, 365 days a

year... and that doesnt even include our O.E.

service kits.

3. History of Satisfied Customers

The companies that formed to bring you TransTec kits have a

long history of serving satisfied customers. In fact,

weve been an O.E. supplier as long as there

have been cars!

4. Lowest Overall Cost

Add it all up and youll find TransTec

kits have the lowest overall cost.

Better parts and better performance

means less chance of a comeback. Get

it all with TransTec transmission kits

from Corteco, the O.E. supplier with

aftermarket vision.

Our Kits.

1. Price

Their Kits.

Its a tough decision.

Take your time.

transtec-corteco placed4-05.qxd 3/14/05 10:27 AM Page 9

eSource is a powerful new electronic catalog

and e-commerce system that gives you instant

access to parts information, ordering and account

management information. Just log in and nd

your parts by make, model and transmission type,

or view parts in detailed schematics and order

by clicking on their picture. You can check price

and inventory status in real time. It even shows

which parts are available for same day delivery!

Get started by calling your Axiom representative

or go to www.axiom.com.

REAL TIME. REAL FAST.

Axiom

Axiom

REAL TIME. REAL FAST.

eSource is a powerful new electronic catalog

and e-commerce system that gives you instant

access to parts information, ordering and account

management information. Just log in and nd

your parts by make, model and transmission type,

or view parts in detailed schematics and order

by clicking on their picture. You can check price

and inventory status in real time. It even shows

which parts are available for same day delivery!

Get started by calling your Axiom representative

or go to www.axiom.com.

V

E

R

S

I

O

N

3

F

A

S

T

E

R

! E

A

S

IE

R

!

IN

C

L

U

D

E

S

T

O

R

Q

U

E

C

O

N

V

E

R

T

E

R

S

.

sonnax

eSource Ad updated.indd 1 12/14/06 1:22:21 PM

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

14

GM Table of Contents

GM TOC ................................. 23

Allis on LCT 1 0 0 0

Torque Converter Leaks ......... 24

M74 Grade Breaking.............. 25

Updates.................................. 26

6 L5 0 / 6 L9 0

New Transmission

Introduction ........................... 29

Ratios, Applications ............... 30

IMS Logic ............................... 32

Speed Sensors ....................... 34

Pressure Switches .................. 36

Clutch Range Ref. Chart ........ 36

Shift Solenoid Operation........ 37

Solenoid Cleaning Process ..... 38

Solenoid Diagnostics.............. 39

Adaptive Learning .................. 41

4 L6 0 E/ 6 5 E/ 7 0 E

Input Speed Sensor ............... 42

Pump cover Updates............... 44

Speedometer Inop,

3rd Gear Starts ...................... 49

4 L8 0 E/ 4 L6 0 E

Mutiple DTCs G-Van ............. 50

4 L8 0 E

Hummer H1 DLC Location..... 52

Shift Solenoid Operation........ 71

Solenoid Cleaning Process ..... 72

Solenoid Assembly and TCM.. 74

Adaptive Learning .................. 75

New Ser vice Man u al Pr oces s

New Proceedures.................... 76

4 T8 0 E

Updates.................................. 61

6 T7 0 / 6 T7 5 For d 6 F5 5

New Trasmission Introduction 63

Features................................. 65

Ratios..................................... 66

IMS ...................................... 67

Speed Sensor ......................... 69

Pressure Switch and Clutch

Range Reference .................... 70

4 T4 0 / 4 T4 5 E

Updates.................................. 53

Low Power, APP DTCs set ...... 57

Mutiple DTCs A Body.......... 58

4 T6 5 E

Slips/Wrong Gear Starts/

Erratic Shifts/Lack of Power

P0753/P0758/P1860............. 59

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

15

Ford Table of Contents

Ford TOC ................................... 85

Tor qs h ift

TCC Operation ........................... 86

No Lock-up before or

After the Rebuild ....................... 88

Lock-up Test Tool ....................... 89

P1744 TCC Performance ............ 92

TCC Stuck ON............................ 94

Cooling and Filtration ................ 95

Spin-On Filters .......................... 96

In-Line Filters ............................ 97

OTA Coolers ............................... 98

Pump Failures............................ 99

PCM Pin Charts ....................... 101

PCM Location........................... 103

TR Sensor Readings ................. 104

Codes ..................................... 106

Rear Planetary Failure ............. 108

Delayed Forward Engagements 109

Delayed Reverse Engagemnets 110

Delayed Reverse with

No Engine Braking in

Manual 1 ................................. 111

Erratic Shifts and/or

Early and Late Shifts ............... 112

All For d Tr an s mis s ion s

Transmission Fluid Chart......... 113

4 X4 Tow Feat u r es (All For d)

Neutral Tow Capabilities .......... 117

5 R4 4 / 5 5 E

Shifter Syuck in the Park

Position.................................... 119

6 R6 0

Transmission Descrition........... 120

FNR5

Transmission Description......... 122

Lever Position and Operations . 124

Valve Body ............................... 125

TCM ..................................... 127

TCM Location ........................... 128

Electronic Syncronous Shift

Control (ESSC) ......................... 129

Inputs ..................................... 131

TR Sensor, TFT Sensor ............. 132

Speed Sensors ......................... 133

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

16

Chrysler Table of Contents

Chrysler TOC ................................ 151

4 5 RFE/ 5 4 5 RFE

New Solenoid Assembly ................ 152

Stalls The Engine In Drive............. 154

RE Ser ies Gover n or Diagn os is

Governor Diagnosis ....................... 156

Pressure Testing the Governor

Circuit........................................... 157

Computer Conectors ..................... 158

Case Connectors ........................... 159

Output Speed Sensors .................. 160

Governor Solenoid ........................ 161

Governor Pressure Sensor............. 162

Vehicle Speed Sensor ................... 163

Throttle Position Sensor ................ 164

Engine RPM Sensor ...................... 165

ECT and TFT Sensors .................... 166

Park Neutral Sensor ...................... 167

Transmission Range Sensor .......... 168

Wiring Diagrams ........................... 169

Quick Reference Signal Voltages

For The Governor Control .............. 171

In-Shop Testing............................. 173

Volt Meter Test Procedures ........... 174

6 2 TE

Introduction .................................. 176

Accumulator ID............................. 177

Solenoid ID and Function ............. 178

Check Ball ID and Location........... 179

4 8 RE

Out of Park Sense Alarm............... 180

4 2 LE

Transfer Gear Whine ..................... 181

4 2 RLE

Adapter Shaft Retaining Clip ........ 182

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

17

Scan Tool Communication

and Network Diagnostics

Table of Contents

Scan Tool Communication and

Network Diagnostics TOC.......... 187

OEM Ser vice In for mat ion

OEM Service Information .......... 188

OEM Scan Tools ........................ 189

After Market Scan Tools ............ 190

Scan Tool and Network

Communication Essentials........ 191

J 1 9 6 2 OBD II Con n ect or

Breakout Box ............................ 192

Ford SCP................................... 193

Ford Network Wiring ................. 195

GM Class 2/Chrysler PCI .......... 196

GM Class 2 Network Wiring ...... 197

Chrysler PCI Network Wiring .... 198

GM Class2/Chrysler PCI

Diagnosis .................................. 199

Chrysler CCD............................ 200

Chrysler CCD Bus .................... 201

Chrysler SCI ............................. 202

Chrysler SCI Data Link ............. 203

CAN ........................................ 204

CAN Wiring Diagram................. 205

CAN Interface............................ 206

Vehicles Requiring Interface ..... 207

ISO 9 1 4 1 (K Lin e)

ISO ........................................ 208

ISO Wiring Diagram .................. 209

J 2 5 3 2 In t er face

J2534 Interface .................... 212

Recalibr at ion PC Set -Up

Recalibration PC Set-Up....... 213

Recalibration TSBs .............. 214

GM Recalibration ................. 218

Ford Recalibration ............... 222

Chryslare Recalibration ....... 228

Toyota Recalibration ............ 232

Resetting the Shift Adapts ... 235

Recalibration

Table of Contents

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

18

Mercedes Table of Contents

Mercedes 722.6 TOC............................ 237

Identification........................................ 238

Output Shaft Planetarey Failure .......... 240

Rear Planetary Gearset Durability ....... 241

Transmission Fuilds ............................. 242

Clutch Pack Clearence Tool .................. 244

No Upshift ............................................ 245

Solenoid Operation .............................. 246

Solenoid Operation Chart .................... 248

Shifter Assembly .................................. 249

Harsh 3-2 Downshift ............................ 250

Early/Late harsh Shifts or

Soft Up/Down Shifts ............................ 251

2007 ATRA. All Rights Reserved.

2007 TECHNICAL SEMINAR

19

Hyundai Table of Contents

A4 AF3 , A4 BF2 TOC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Clutch and Band Application ..................... 254

Transaxle Identification.............................. 255

Pressure Testing ........................................ 256

Shift Feel ................................................... 258

Check Ball Locations ................................. 259

Valve Body Exploded Views ........................ 260

Solenoid Identification ............................... 262

Testing the Transaxle Operation ................ 263

Forcing the Shift ........................................ 264

No Reverse ................................................. 265

Harsh 2-3 or 2-3 Slide Bump ..................... 266

Shifts 1-3 ................................................... 267

Neutrals on the 3-4 Shift or No 4th Gear ... 268

Failed End Clutch Hub Bearing ................. 269

800-451-3115

www.superior-traosissioo.co

683(5,25

7XUQV$

&5$3

6+227

,QWR$

685(

7+,1*

Introducing The New Superior 4L30-E Kit

InstaII the 4L30-E Shift

Correction Package in

your next 4L30-E rebuiId

and take the "gambIe" out

of working on the 4L30-E.

Superior's newest entry to

its popuIar Iine of Shift

Correction packages

deIivers a more stabIe,

better operating, reIiabIe

transmission, reducing

comebacks and increasing

customer satisfaction.

BeII-housing gasket

bIowout

Repairs case Ieakage in

servo core

Weak shifts

Lock-up chatter

Better Lube

Premature cIutch and

band faiIure

ReguIar & Heavy Duty

appIications

Improves overaII

performance

The 4L30-E Shift Correction Package Corrects or

Prevents the foIIowing ProbIems:

Savings in a box Savings in a box

Sonnax I ndust r i es, I nc. Aut omat i c Dr i ve P. O. Box 440 Bel l ows Fal l s, VT 05101

802-463-9722 800-843-2600 fax: 802-463-4059 www.transmissionspecialty.com info@sonnax.com

2

0

0

7

S

o

n

n

a

x

I

n

d

u

s

t

r

i

e

s

,

I

n

c

.

D E S I G N E D T O S A V E

SC-096/097/098** NEW

SC-01M/01N/01P** NEW

SC-AX4N* NEW

SC-AODE (95 & earlier)

SC-AODE-1 (96 & up)

SC-AXODE

SC-4R100HD

SC-E4OD

SC-4ITE

SC-42RHE

SC-46/47RHE

*Requires tooling

**Requires VB-FIX

SC-TAAT*

Full compatibility with TAAT Type II valve bodies.

Helps cure:

Delayed or harsh reverse

High or low line pressure

Low line rise

Soft shifts

Clutch failure

SC-4L60E*

Full compatibility in units 1995-up

with PWM/EC

3

control.

Helps cure:

Code 1870

Harsh 1-2

Falling out of lockup

Clutch and band failure

Poor 2-3, 3-2 shifts

Wrong gear starts

Poor line rise

Excessive endplay

Sonnax offers seven different Sure Cure

Kits to cure whatever ails

your GM unit. These complete transmission reconditioning

units combine the best Sonnax products in one box to

cure a host of shift concerns. Save time, save

money and reduce comebacks!

Also available for GM:

SC-4T65E** SC-4T60E* (93-96)

SC- 4L60* SC-4T60E-1* (97 & up)

SC-4L80E* (* Requires tooling)

Also available:

SC-GM-ATRA 07 12/20/06 5:04 PM Page 1

2 3

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

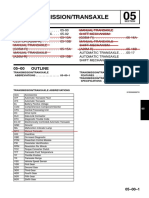

GM Table of Contents

GM TOC ................................. 23

Allis on LCT 1 0 0 0

Torque Converter Leaks ......... 24

M74 Grade Breaking.............. 25

Updates.................................. 26

6 L5 0 / 6 L9 0

New Transmission

Introduction ........................... 29

Ratios, Applications ............... 30

IMS Logic ............................... 32

Speed Sensors ....................... 34

Pressure Switches .................. 36

Clutch Range Ref. Chart ........ 36

Shift Solenoid Operation........ 37

Solenoid Cleaning Process ..... 38

Solenoid Diagnostics.............. 39

Adaptive Learning .................. 41

4 L6 0 E/ 6 5 E/ 7 0 E

Input Speed Sensor ............... 42

Pump cover Updates............... 44

Speedometer Inop,

3rd Gear Starts ...................... 49

4 L8 0 E/ 4 L6 0 E

Mutiple DTCs G-Van ............. 50

4 L8 0 E

Hummer H1 DLC Location..... 52

Shift Solenoid Operation........ 71

Solenoid Cleaning Process ..... 72

Solenoid Assembly and TCM.. 74

Adaptive Learning .................. 75

New Ser vice Man u al Pr oces s

New Proceedures.................... 76

4 T8 0 E

Updates.................................. 61

6 T7 0 / 6 T7 5 For d 6 F5 5

New Trasmission Introduction 63

Features................................. 65

Ratios..................................... 66

IMS ...................................... 67

Speed Sensor ......................... 69

Pressure Switch and Clutch

Range Reference .................... 70

4 T4 0 / 4 T4 5 E

Updates.................................. 53

Low Power, APP DTCs set ...... 57

Mutiple DTCs A Body.......... 58

4 T6 5 E

Slips/Wrong Gear Starts/

Erratic Shifts/Lack of Power

P0753/P0758/P1860............. 59

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 24

2007 ATRA. All Rights Reserved.

Outside of the typical front seal/pump bolt and pump leakage the LCT 1000

applications have developed another area where leakage commonly occurs. The

leakage can be temperature sensitive and may be difficult to locate. The converter

lugs tend to crack at the welds and may start to leak. If a leak is discovered in

this area the converter will require replacement. GM has a tool that allows you to

pressurize the converter to inspect for leakage once the converter is on the bench,

the part number is (J-21369-F)

LCT 1000

Torque Converter Leaks

2 5

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

On Allison applications, the grade braking software program is designed to reduce

wear on the vehicles braking system when decelerating. The grade braking fea-

ture will automatically downshift the transmission to provide engine braking thus

reducing wear on the brakes while improving the drivers control of the vehicle.

The grade braking system is not designed to reduce the need for the customer to

maintain control of the vehicle during deceleration. To accomplish this task the

TCM monitors several inputs including:

* TP position and TP Delta

* PRNDL Position (NSBU or IMS)

* Brake Switch Status

* Calculated grade and load (MAP/MAF/RPM)

* Vehicle Speed and wheel speed

* Tow/Haul Switch Position

The grade braking feature is transparent to the customer as the TCM deter-

mines if grade braking is required or not based on the input data received. The

grade braking feature cannot be shut off by the customer although it can be

overridden by simply stepping on the accelerator pedal.

For the grade braking feature to operate the TCM monitors the PRNDL position,

engine/vehicle load, brake switch position, vehicle/wheel speed and engine RPM.

For grade braking to function, the brake pedal must be depressed. Grade brak-

ing can operate while in either tow/haul mode or normal mode. If the vehicle

is operating in normal mode, the vehicle will downshift from high gear to the next

lowest gear range. If the vehicle is being operated in tow/haul mode the vehicle

can downshift to a range as low as 2

nd

gear, one range at a time. The system will

not skip shifts/ranges and the shift points will vary based on load and RPM in-

puts. The grade braking system does not require any customer action to activate

the feature.

LCT 1000

M74 Grade Braking

The TCM calculates the information received from its inputs. Those factors are

calculated, weighted and then the sum is calculated. If the calculated sum ex-

ceeds the predetermined threshold the TCM will command a downshift and grade

braking will become active, overriding the PRNDL position.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 26

2007 ATRA. All Rights Reserved.

SHIFT MAX Transmission Output Speed

5-4 4017

4-3 2832

3-2 2196

2-1 1214

6.6L DURAMAX 3.73 RATIO

SHIFT MAX Transmission Output Speed

5-4 4624

4-3 3266

3-2 2543

2-1 1474

8.1 L GAS 4.10/3.73 REAR AXLE RATIO

The actual shift speeds cannot exceed predetermined engine RPM values. If the

TCM determines that the engine speed would be too high if a downshift was com-

manded, the downshift will be inhibited. (4650 RPM L18 Gas Application, 4000

RPM LB7 Diesel Applications) Conversely, if the load and engine speed continue

to increase beyond predetermined limits while decelerating, the TCM will com-

mand an upshift to occur. (5000 RPM L18 Gas Application, 4800 RPM LB7 Diesel

Applications)

NOTE: The engine is designed to operate in the Dashed Red zone of the tachom-

eter during grade braking. The engine should not be allowed to operate in the

Solid Red zone at any time or engine damage may occur. The TCM software has

some predetermined maximum downshift points. The shift points are determined

by monitoring road speed via the vehicle speed sensor. The following represents

the maximum VSS values the vehicle can be operated at before grade braking will

be inhibited.

LCT 1000

M74 Grade Braking

The grade braking feature may function even if the vehicle is being operated on

level roads. In addition the system is able to calculate any additional loads such

as when pulling a trailer.

If the vehicle is being operated on snow or ice covered roads the feature may be

disabled if the EBCM determines tire slippage is occurring. The TCM receives

information from the EBCM regarding the calculated slip (Wheel speed sensors

and VSS) If wheel slippage is occurring the TCM will command the transmission

into a higher gear.

(continued)

2 7

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

Several updates were implemented into production for the Mid-2006-2007 model

years. They include:

T 5 bear in g- Impr oved du r abilit y

P2 Car r ier - Requ ir ed for t h e T-5 bear in g u pdat e

P2 Su n gear - Requ ir ed for t h e T-5 bear in g u pdat e

Sh aft s eal r in gs -Impr ove du r abilit y/ n ew mat er ial

Mid-2006-2007 LCT 1000

Updates

The Sun/Carrier/T-5 went into production in Sept 2006 starting serial #

6310696028 The Rings went into production in May 2006 starting serial #

6310656923,6320768550, 6320768663.

Dimension

Changes

Thickness No if used by itself

Increased by

.45mm

Yes if used with the

updated carrier and

sun gear assembly

OD decreased by

.55mm

ID decreased by

4.15 mm

Shaft area no

longer under cut.

OD of shaft are

decreased by 2.15

mm

No if used by itself

Pocket depth

increased by

Yes if used with the

updated sun gear

and T-5 bearing

1.2 mm

Pocket decreased

by

No if used by itself

3.6mm Yes if used with the

updated carrier and

T-5 bearing

29538941 29538158

29538942 29531038

All the updated

rings come in the

kit part number

29536406

PART OLD NUMBER NEW NUMBER Interchangeability

T-5

bearing

29531095 29541702

P2 Carrier 29536971 29545240

End gap on rings

have changed

from a Double

lap joint design

to a butt cut

style. In addition

the material has

also changed

Fully

interchangeable

P2 Sun 29543208 29545931

Sealing

Rings

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 28

2007 ATRA. All Rights Reserved.

Mid-2006-2007 LCT 1000

Updates (continued)

P2 Ca r r i e r

T5 Bear in g

P2 Su n Gear

2 9

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

6L50/6L90

Introduction

Two more 6 speed rearwheel drive automatic transmissions have been released by

GM for the 2007 model year. The 6L50 (MYB) was introduced in the Cadillac SRX

and STS. The 6L90 (MYD) was introduced in the Chevrolet Silverado HD and GMC

Sierra HD applications.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 30

2007 ATRA. All Rights Reserved.

The 6L50/6L90 transmissions share many parts with the 6L80. This reduces the

production cost of the units and improves serviceability. The diagnostic processes

and tools are also shared between the 6L50, 6L80 and 6L90. The 6L50 and 6L90

are the latest rearwheel drive 6 speeds to be introduced by GM but they certainly

will not be the last. The 6L45 will also make its way shortly into the market place.

Like the 6L50/6L80 and 6L90 the 6L45 will also share the same component

architecture.

RPO Code:

6L50-MYB

6L90-MYD

Gear 6L50 6L90

1st 4.06-1 4.03-1

2nd 2.37-1 2.36-1

3rd 1.55-1 1.53-1

4th 1.16-1 1.15-1

5th .85-1 .85-1

6th .67-1 .67-1

Reverse 3.02-1 3.02-1

Ratios

2 0 0 7 Applicat ion s :

6L50 Cadillac SRX, STS, BMW X3, X5,

328 coupe

6L90 C/K HD models with 6.0L LY6

engine

In pu t Tor qu e Capacit y:

6L50332 lb-ft (450 Nm)

6L90531 lb-ft (720 Nm)

Ou t pu t Tor qu e Capacit y:

6L50480 lb ft (651 Nm)

6L90885 lb ft (1200 Nm)

6L50/6L90

Introduction

(continued)

3 1

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

Maximum shift speed 6500 RPM

Maximum GVW 6L9015000 lb 6L506613 lb

Maximum GCVW 6L9021000 lb 6L5012505 lb

PRNDL positions P, R, N, D, (S or M)

2 shift solenoids used (On/Off Design), SS1,SS2

6 Variable bleed solenoids, PCS, PCS2, PCS3, PCS4, PCS5, TCC

A Bosch built 32 bit TCM (TEHCM) mounted internal to the transmission on

the valve body (Referred to as the control solenoid valve assembly) TCM

(TEHCM) incorporates Solenoids, pressure switches, TFT and it is bolted to

the valve body using 6 bolts.

Dry weight 6L50 198 lbs (90 kg) 6L90 243 lbs (110 kg)

EC3 Converter 258 twin plate/280mm 6L50 300mm 6L90

Fluid required, Dexron VI

Fluid capacity: 6L50 Pan removal 7.25 qts (6.83 liters) Overhaul 10.68 qts

(10.10 liters) 6L90 Pan removal 6.3 qts (6.0 liters) Overhaul 10.5 qts (9.9

liters)

Clutch to clutch shifts, 5 clutches (3 stationary, 2 driving), 1 sprag

Planetary assemblies, input (Simpson) Output ( Dual pinion design)

Vane style oil pump

Internally mounted TISS and TOSS hall effect type speed sensors

Internal Mode Switch (IMS) equipped

Performance Algorithm Shifting (PAS) programming

Performance Algorithm Lift foot (PAL) programming

Sport mode and TAP shift equipped

Adaptive Strategies with fast learn capabilities

Reverse lock out feature

Grade braking

6L50/6L90

Introduction

(continued)

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 32

2007 ATRA. All Rights Reserved.

6L50/6L90

The 6L50/6L90 internal mode switch is mounted to the valve body and it is con-

nected mechanically to the manual valve. Electrically the IMS operates similar to

other GM IMS applications. The TCM sends a bias voltage to the IMS on 4 cir-

cuits, A, B, C, P. Pin N is used for Park/Neutral starting operations and is sup-

plied by the ECM. As the range selector is moved the IMS will ground/un-ground

the circuits or circuit required to indicate the specific manual valve position. By

noting the voltage sequence produced, the TCM will be able to identify the range

that was selected.

Internal Mode Switch Logic

Valve Body an d TCM

IMS As s embly

3 3

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

Selector Position Range A Range B Range C Range P

Park Low High High Low

Park/Reverse Low Low High Low

Reverse Low Low High High

Reverse/Neutral High Low High High

Neutral High Low High Low

Neutral/D6 High Low Low Low

D6 High Low Low High

D6/D4 Low Low Low High

D4 Low Low Low Low

D4/D3 Low High Low Low

D3 Low High Low High

D3/D2 High High Low High

D/2 High High Low Low

Illegal High High High High

Illegal Low High High High

Low = Grounded (0Volts)

High= Open (Source Voltage)

6L50/6L90

Internal Mode Switch Logic

(continued)

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 34

2007 ATRA. All Rights Reserved.

6L50/6L90

Speed Sensors

The speed sensors are hall effect style assemblies and are mounted to the con-

trol valve assembly (Valve Body). The TCM provides a signal voltage of 8.3-9.3 volts

for the sensor operation. As the clutch housings rotate the sensors will produce a

square wave signal. The TCM will monitor the frequency of the signal to deter-

mine the input or output speed. Input Speed Sensor signals are generated by the

rotation of the 1-2-3-4 & 3-5-R clutch assemblies and is used to calculate gear

ratio and slip rates. The Output Speed Sensor signal is generated by the rotation

of the Output Ring gear. The OSS is used for indicating Vehicle speed for shift

pattern control as well as Ratio calculations.

Shift @ TP KM/H MPH OSS (RPM)

1-2 @ 12.5 TP 10.1 6 242

2-1 @ 12.5 TP 6.9 4 165

2-3 @ 12.5 TP 18.1 11 434

3-2 @ 12.5 TP 16.1 10 386

3-4 @ 12.5 TP 27.3 17 654

4-3 @ 12.5 TP 23.5 15 563

4-5 @ 12.5 TP 35.3 22 846

5-4 @ 12.5 TP 32.1 20 769

5-6 @ 12.5 TP 46.6 29 1117

6-5 @ 12.5 TP 40.7 25 975

1-2 @ 25 TP 12.9 8 309

2-1 @ 25 TP 6.9 4 165

2-3 @ 25 TP 24.7 15 592

3-2 @ 25 TP 16.1 10 386

3-4 @ 25 TP 36.5 23 875

4-3 @ 25 TP 25.4 16 609

4-5 @ 25 TP 47.7 30 1143

5-4 @ 25 TP 32.1 20 769

5-6 @ 25 TP 71.5 44 1713

6-5 @ 25 TP 40.7 25 975

NOTE: Th e 6 L5 0 s h ift s peed ch ar t is bas ed on s t ock t ir es / wh eels

an d 3 . 2 3 -1 fin al dr ive r at io

6L50 Shift Speed Chart

3 5

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

6L50/6L90

Speed Sensors

Shift @ TP KM/H MPH OSS (RPM)

1-2 @ 12.5 TP 15 9 347

2-1 @ 12.5 TP 10 6 232

2-3 @ 12.5 TP 27 17 625

3-2 @ 12.5 TP 10 6 232

3-4 @ 12.5 TP 43 27 996

4-3 @ 12.5 TP 32 20 741

4-5 @ 12.5 TP 57 35 1320

5-4 @ 12.5 TP 46 29 1065

5-6 @ 12.5 TP 80 50 1852

6-5 @ 12.5 TP 60 37 1389

1-2 @ 25 TP 16 10 370

2-1 @ 25 TP 10 6 232

2-3 @ 25 TP 30 19 695

3-2 @ 25 TP 10 6 232

3-4 @ 25 TP 49 30 1134

4-3 @ 25 TP 35.4 22 820

4-5 @ 25 TP 61.5 38 1424

5-4 @ 25 TP 49 30 1134

5-6 @ 25 TP 83.25 52 1927

6-5 @ 25 TP 65 40 1505

NOTE: Th e 6 L9 0 s h ift s peed ch ar t is bas ed on s t ock t ir es / wh eels

an d 3 . 7 3 -1 or 4 . 1 0 -1 fin al dr ive r at io

6L90 Shift Speed Chart

(continued)

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 36

2007 ATRA. All Rights Reserved.

PARK

1

ST

NEUTRAL

BRK

1-2-3-4 CLUTCH ON ON ON ON ON

3-5 REV

CLUTCH

4-5-6 CLUTCH ON ON ON

LOW/REV

CLUTCH

2-6 CLUTCH ON ON

LOW SPRAG ON ON

ON ON ON

ON ON ON

3

RD

4

TH

5

TH

6TH COMPONENT REV

1

ST

2

ND

6L50/6L90

The pressure switches are housed as part of the control solenoid valve assembly.

Four switches are used, 1,3,4 and 5. The switches act as an input to the TCM and

are used for 2 basic purposes:

To mon it or clu t ch r egu lat or valve an d clu t ch h ydr au lic oper at ion

To mon it or clu t ch CVI (Adapt ive lear n in g)

Pressure Switches and Clutch Range

Reference Charts

TFP

Switch

Clutch/Circuit

Monitored

1 3-5 clutch

3 2-6 clutch

4 1-2-3-4 clutch

5 4-5-6 and L/R Clutch

Clu t ch Ran ge Refer en ce Ch ar t s

Pr e s s u r e Swi t c h e s

3 7

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

6L50/6L90

Shift Solenoid Operation

PCS 2 PCS3 PCS4 PCS5

(N.H.) (N.H.) ( N.L.) (N.L)

PARK ON ON OFF ON OFF OFF

REVERSE ON OFF ON ON OFF OFF

NEUTRAL ON ON OFF ON OFF OFF

1

ST

ENG BRK

ON ON OFF ON OFF ON

1

ST

OFF ON OFF OFF OFF ON

2

ND

OFF ON OFF OFF ON ON

3

RD

OFF ON ON OFF OFF ON

4

TH

OFF ON OFF ON OFF ON

5

TH

OFF ON ON ON OFF OFF

6

TH

OFF ON OFF ON ON OFF

GEAR SS1 SS2

Shift solenoid and PCS operation is controlled by the TEHCM (TCM). The TCM

regulates the feed voltage to the solenoids to a value between 8.3-9.3V. The TCM

then regulates the current flow through the solenoids. The shift solenoids are

On/Off design with the TCM controlling the power for the solenoid. The pressure

control solenoids are high side PWM controlled. The TCM is over current and

overtemp protected.

Bosch refers to the solenoids by their state, NL or NH. Normally High (N.H.) is

used to describe a solenoid that allows pressure to travel to the clutch when the

solenoid is turned off. Normally Low (N.L.) is used to describe a solenoid that

prevents pressure from getting to a clutch when the solenoid is turned off.

The solenoids are protected by the filter plate. The filter plate is housed between

the valve body and the control solenoid valve assembly (TEHCM) and must be

replaced anytime the valve body or control solenoid valve assembly (TEHCM) is

replaced or unbolted from each other. The Filter plate is serviced with the control

solenoid valve assembly (TEHCM) but it must be ordered separately if you are

ordering valve body.

NOTE: If t h e Con t r ol valve body as s embly is r emoved fr om t h e

cas e t h e s u ppor t s eals locat ed in t h e cas e mu s t als o be r eplaced.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 38

2007 ATRA. All Rights Reserved.

6L50/6L90

An automated process is available that aids in cleaning debris from the solenoid

assembly. Your scan tool will instruct the TCM (TEHCM) to cycle the solenoids

while the system is pressurized to clean the solenoids. The transmission does not

need to be disassembled to perform the cleaning process. Simply follow the in-

structions on the scan tool to activate the cleaning program. This process should

be completed prior to attempting to diagnose the transmission with part# DT-

47825-1 tools as described below. If the cleaning process is unsuccessful then

you should diagnose the concern with part# DT-47825-1

Solenoid Cleaning Process

3 9

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

6L50/6L90

Like other GM transmissions, diagnosis is designed around the use of a quality

scan tool. With the 6L50/6L90 this could not be more true as the need to access

scan data is critical. Unlike other GM transmissions you have become accus-

tomed to working with over the years, the 6L50/6L90 internal electrical compo-

nents are not hard wired to the rest of the vehicle via the transmission harness.

This means that the diagnostic process has changed considerably. Diagnosis is

divided into 2 categories , scan diagnostics and test plate/air check diagnostics.

Solenoid and valve body diagnosis requires the following tools:

A quality scan tool capable of communicating and commanding the TCM

and its solenoids.

Tool number DT 47825-1 Solenoid test plate and jumper harness

Remove the Control Solenoid Valve Assembly from the transmission. Install tool

DT 47821-1 onto the Control Solenoid Valve Assembly (5Nm 44 Lb In). Apply

regulated shop air (90-100 psi) to the tool. Connect the scan tool to the Control

Solenoid Valve Assembly.

Command the solenoid ON/OFF air pressure should be present on the gauge and

then it should exhaust as the solenoid is cycled. If the solenoid or valve are mal-

functioning the gauge pressure will not change as you cycle the solenoid. If a

malfunction is determined to be present, replace the complete Control Solenoid

Valve Assembly.

If the solenoid checked OK, install the gauge on another solenoid port and com-

mand that solenoid ON/OFF with the scan to repeat the process.

Solenoid Diagnostics

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 40

2007 ATRA. All Rights Reserved.

6L50/6L90

Solenoid Diagnostics (continued)

Solenoid

Test Plate

Port

Key On, Engine

Off (KOEO)

Normal State

Line PC

Solenoid 1 G No flow to gage

PC Solenoid 2 C No flow

On - Full

flow Off - No flow

PC Solenoid 3 A Full flow

On - Full

flow Off - No flow

PC Solenoid 4 B No flow

On - Full

flow Off - No flow

PC Solenoid 5 F No flow

On - Full

flow Off - No flow

Shift Solenoid 1 H No flow Off - No flow On - Full flow

Shift Solenoid 2 D No flow Off - No flow On - Full flow

TCC PC

Solenoid E No flow

On - Full

flow Off - No flow

Commanded State

On - 68-103 Kpa (10-15 psi)

per Commanded Amp

NOTE: If t h e s olen oid or valve is malfu n ct ion in g t h e gau ge

pr es s u r e will n ot ch an ge as you cycle t h e s olen oid. If a

malfu n ct ion is det er min ed t o be pr es en t , r eplace t h e complet e

Con t r ol Solen oid Valve As s embly.

NOTE: Th e TCM (TEHCM) will n or mally cycle s ever al of t h e

s olen oids ON/ OFF t o h elp k eep t h e s olen oids an d t h e valves fr ee

of debr is . Th er efor e t h is clean in g fu n ct ion (Dit h er ) may cau s e t h e

gau ge t o flick er wh en t h e TCM is clean in g t h e s olen oid you ar e

t e s t i n g.

4 1

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

The 6L50/6L90 are fully equipped with several adaptive learning strategies. As

with some other GM applications you will need to erase the adaptive values and

perform a Fast Learn prior to operating the vehicle. Adapts and fast learn proce-

dures should be perform if any of the following occur:

Internal Transmission repairs have been performed

The valve body was replaced

The Control Solenoid valve assembly was replaced

The TCM was recalibrated

Internal repairs were performed that could effect shift quality

NOTE: Fas t lear n is n ot r equ ir ed if a GM New or Rebu ilt 6 L5 0 /

6 L9 0 is u s ed. Th e t r an s mis s ion is fas t lear n ed pr ior t o it bein g

s h ipped fr om t h e plan t

To perform a fast learn:

Use a scan tool capable of performing the fast learn procedure

TFT 158-230F (70-110C), Move the selector in/out of gear 3 times

Select the fast learn process from the scan tool menu

Place the transmission in Drive with the vehicle stationary. The TCM will

individually apply the clutches and calculate the clutch volume Place the

transmission in Reverse with the vehicle stationary. The TCM will individu-

ally apply the clutches and calculate the clutch volume

Shut off the engine for at least 30 seconds, open and close the door to allow

RAP to expire or false DTCs may set, After a minimum of 30 seconds the

car can be restarted , power off the scanner

The process is now complete

The fast learn procedure will not run if:

DTCs are set

TFT is not between 158-230 F (70-110C)

The brake switch is not working

TP is 0% but engine RPM increases during the test

P/N switch is improperly adjusted or is not functioning correctly

Line pressure control system is malfunctioning

6L50/6L90

Adaptive Learning

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 42

2007 ATRA. All Rights Reserved.

The 2005 and 2006 ATRA seminars covered the changes involved with the addi-

tion of the input speed sensor in the 4L60E/65E and 4L70E applications (RPOs

M30,M32, M33, M70). The input speed sensor was not used on all 2006-2007

applications so some confusion may occur regarding build combinations for these

products. Some of the parts from the ISS equipped applications and a Non ISS

equipped applications cannot be intermixed.

A failure to identify the build combination you are working with may result in line

pressure, TCC and/or Clutch apply/release/cross leak concerns. Five design

variations have occurred between Non ISS applications and the final fully func-

tional ISS applications. These changes include the following:

Redesigns of the turbine shaftRepositioning of the seal rings on the shaft,

adding a ISS toothed wheel.

Redesign of the pump cover- Updating the passage design and passage

position in the stator support sleeve. Adding a boss to the cover for the ISS.

Shortening the P/R valve train to make room for the input speed sensor

wiring and connector.

Updating the wiring harness for the input speed sensor.

Adding DTCs for ISS diagnostics.

4L60E/65E/70E

Input Speed Sensor

4 3

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

4L60E/65E/70E

Input Speed Sensor

Design Variation Turbine Shaft:

Fou r NON ISS s h aft s izes ar e available t h ey ar e:

245mm/258mm shaft (Part # 17803688)

280mm/300mm shaft (Part # 17803687)

300mm HD/300mm M70 ( Part #17803686)

258mm PHT (Part # 17803685)

Th r ee ISS equ ipped s h aft s ar e available, t h ey ar e:

245mm/258mm (Part #24232438)

280mm/300mm (Part # 24230653)

300mm HD/M70 (Part #24230654)

(continued)

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 44

2007 ATRA. All Rights Reserved.

The design of the shaft can be identified by the ID marks on the shaft. The ID

mark is simply a 9.5mmX.5mm groove that located on the shaft. Some shafts

have ID marks while others do not.

Pu mp Cover : 5 pu mp cover s ar e available, t h ey ar e:

1997-2005 model: No input sensor boss, used 1

st

design stator support bushing

and 1st design P/R valve train.

4L60E/65E/70E

Pump Cover

4 5

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

2005 I model: No input sensor boss, used 1

st

design stator support bushing and

2

nd

design P/R valve train.

2005 I model: Includes a input speed sensor boss, but the boss is not drilled, 1

st

design stator support sleeve and 2

nd

design P/R valve train.

Pump Cover

4L60E/65E/70E

(continued)

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 46

2007 ATRA. All Rights Reserved.

4L60E/65E/70E

Pump Cover (continued)

4 7

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

Pump Cover

4L60E/65E/70E

Pump cover kits:

1998-2005: 12491417, 12491421

2006 and later Non PHT: 24236486, 24236489

2006/07 PHT: 24239202

Reverse boost valve kits:

2005 and earlier (Long valve train): 24234396 regular, 24234397 High Perf

Short valve train 24234396 regular, 24234397 High Perf

2006: The input speed sensor boss was drilled on those models that used an ISS.

A 2

nd

design stator support sleeve and a 2

nd

design P/R valve train were used.

This combination requires the ISS shaft design or a shaft design that relocates

the turbine seal ring position.

2006 and later: All models of pumps use the input speed sensor boss and all of

the bosses are drilled. If the ISS is not used a rubber plug will be used in the ISS

hole. A 2

nd

design stator support sleeve and a 2

nd

design P/R valve train were

used. This combination requires the ISS shaft design or a shaft design that relo-

cates the turbine seal ring position.

(continued)

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 48

2007 ATRA. All Rights Reserved.

Pump Cover

4L60E/65E/70E

(continued)

4 9

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

Some customers may complain that their Speedometer is inoperative and the

transmission may be starting in 3

rd

gear. In addition a Body code B0540 may be

set. The ABS and SES lights may be illuminated. Transmission DTCs will not

typically be set and you may be unable to communicate with the TCM. This condi-

tion applies to all V-8 (5.3L/6.0L) S/T truck applications as they use a stand

alone TCM which is wired differently when compared to the 4.2L applications

Inspect fuse #53 (15 A Trans) in the under hood junction block. If the fuse is

blown inspect circuit #139 for a short to ground.

4L60E/4L65E/4L70E

Speedometer Inop, 3rd Gear Starts

S/T Truck 5.3L/6.0L

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 50

2007 ATRA. All Rights Reserved.

Some 1996-2006 G-van (Express/ Savanna) Applications may set various engine

and/or transmission related DTCs. The DTCs may vary regarding the number of

DTCs set, as well as their type and description. The DTCs may be intermittent in

nature. The type and number of DTCs set will depend on which and how many

circuits were damaged.

A common cause for this concern is the wiring harness for the PCM. The PCM is

mounted on the drivers side inner fender well. The harness faces the vehicle

chassis. The steering gear power steering line is designed to be routed under the

PCM harness. If the line is routed on top of the harness or if the clips holding the

harness are missing or broken the harness can contact the frame or upper

control arm leading to harness damage. Repair the damage and reroute the

harness to repair this condition.

4L80E/4L60E

Multiple DTCs G-Van

WARNING: Wiring harness IN-CORRECTLY installed

5 1

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

Another common issue on this application is road splash or windshield run off

penetrating the PCM connector. This may cause the PCM terminals and harness

pins to corrode. If corrosion is present the PCM and the damaged harness

terminals will need to be replaced. If corrosion is present inspect for the presence

of a harness deflector and road splash shield. If the shields are not present they

will need to be installed.

1996-99- Install harness deflector Part# 15091839, Splash shield Part# 15183966

and bracket 15766026

2000-2002- Built prior to December 2001. Install harness deflector Part#

15091839, Splash shield Part# 15183966

2002 and later- Built after December 2001. On these applications the deflectors

were installed at the plant but they were greatly modified to aid the assembly

process. This may compromise the effectiveness of the shield/deflector so you

may need to install new ones. Install harness deflector Part# 15091839, Splash

shield Part# 15183966

4L80E/4L60E

Multiple DTCs G-Van

(continued)

This is the CORRECT routing of the wirning harness

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 52

2007 ATRA. All Rights Reserved.

Some confusion has occurred regarding where the DLC is located on the Hummer

H1 application. The DLC location is different depending on the year of the ve-

hicle. On 94-95 applications the DLC is located on top of the drivers side Hush

Panel. To access the DLC it may be necessary remove the plastic hush panel to

gain access. Many times the connector is simple laying on top of the panel and

you will need to look for it after you have removed the panel. On some applica-

tions the DLC can be accessed by opening the access door in the hush panel,

sticking your hand up through the access hole to locate the connector.

On 96 -06 applications the DLC is located on the drivers side A pillar. The con-

nector can be accessed easily without removing any panels. In many instances

the DLC has been removed from its factory location so a brake controller can be

installed in the factory DLC location. If the DLC is not in the factory location the

hush panel will need to be removed to locate the connector.

4L80E

Hummer H1 DLC Location

5 3

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

4T45E

Updates

Several updates have been made to some 4T45E applications for the 2007 model

year. These updates include:

A 4-3 downshift solenoid was added

New spacer plates, valve body and channel plate

An auxiliary fluid pump was added

A new design PSM

7/8" Drive chain

4 new DTCs were added

A hybrid design vehicle application was released for the 2007 model year which

utilizes the 4T45E transmission. Known as BAS (Belt Alternator Starter) the

hybrid design was introduced in the Saturn Vue. Other passenger car models

such as the Malibu are scheduled for release utilizing the same BAS system.

The BAS system utilizes a new type of generator which is also capable of acting as

the vehicles starter during specific driving maneuvers. The hybrid applications

are equipped with an AUTO STOP feature to improve fuel economy. To initiate the

auto stop feature simply step on the brake and bring the vehicle to a stop. With

the vehicle stopped, while in OD range the engine will automatically shut off.

This feature will operate unless one of the following conditions occurs:

The engine/transmission or hybrid battery are not fully warmed up

Outside temp is above 95F (35C) and the A/C or defrost modes are

selected

The shift lever is in a range other than OD

The hybrid battery charge is low

High charging system voltages are required

The hood is not fully closed

The engine will automatically restart when the brake pedal is released and the

accelerator pedal is depressed. The engine may also automatically restart if any

of the following occur:

The shifter is moved from OD to Park, Neutral, Intermediate, Low or Reverse

The A/C mode is selected

The hybrid battery charge is low

The auto stop time exceeds 2 minutes

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 54

2007 ATRA. All Rights Reserved.

A 4-3 downshift solenoid was added to the BAS applications. The solenoid is

mounted to the channel plate. The solenoid is designed to improve the 4-3 down-

shift by delaying the pressure to the coast clutch during a manual shift. (Pre-

vents tie up with band is coming off and clutch is coming on) During a 4-3 shift

the solenoid is energized (ON). During all other shifts the solenoid is de-ener-

gized (OFF).

An update to the drive chain occurred. The new chain is 7/8" wide and is made

of 8600 grade material. A 32/38 drive and driven sprocket ratio is used with this

chain application.

The BAS designed pressure switch assembly is color coded to prevent interchange

problems. It contains an additional pressure switch (PRND4). The PRNDL pres-

sure switch lets the TCM know when the driver commands neutral. This logic is

used by the TCM to prevent a false pump DTC from setting. The updated PSM is

not interchangeable with Non BAS applications.

The BAS system utilizes a new design spacer plate, channel plate and valve body.

The new plate is a bonded design and is used for BAS equipped transmissions.

The updated channel plate and valve body are designed for the BAS applications.

The updated plate, channel plate and valve body are not interchangeable with

Non BAS applications.

4T45E

Updates

The case was updated to house a new auxiliary pump. The new case casting

includes a new line pressure tap, a feed boss for the pump and 4 mounting holes

on the side of the case for the pump. A line connects the pump to the line pres-

sure feed on the side of the case. The line contains a cartridge check valve to

prevent drain back. The pump is required to prevent the transmission from drop-

ping out of gear when the vehicle is in auto stop. The pump will run anytime

auto stop is active, once the engine starts running the pump will be shut off. The

updated case is not interchangeable with Non BAS applications.

(continued)

Cas e As s embly

BAS (Belt Alt er n at or St ar t er )

P S A

4 -3 Down s h ift Solen oid

Dr ive Ch ain

5 5

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

P0787 will set if:

The 4-3 shift solenoid is commanded OFF and the feed back voltage is low

The condition exists for longer than 4 seconds

If a P0787 is set the TCM will:

The TCM will command maximum line pressure

The TCM will freeze shift adaptive values and store the operating conditions

as failure record information

A P0788 will set if:

The 4-3 shift solenoid is commanded ON and the feed back voltage is high

The condition exists for longer than 150 milliseconds

If a P0788 is set the TCM will:

The TCM will freeze shift adaptive values and store the operating conditions

as failure record information

4T45E

Updates

4 new DTCs were added to aid in diagnosis of the auxiliary pump. The

include:

P0787- 4-3 Downshift solenoid circuit voltage Low

P0788- 4-3 Downshift solenoid circuit voltage High

P2796- Aux pump circuit voltage Low

P2797- Aux pump performance

(continued)

P2796 will set if:

The pump relay is commanded OFF and the feed back voltage is low

If a P2796 is set the TCM will:

Illuminate the SES light on the second consecutive failure (Type B DTC)

The Starter Generator Control Module (SGCM) will inhibit auxiliary

operation

The TCM will store failure record information

P2797 will set if:

The auxiliary pump is commanded ON

The PSM indicates the pump is not running

The condition lasts longer than 30 seconds

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 56

2007 ATRA. All Rights Reserved.

If a P2797 sets the TCM will:

Illuminate the SES light on the second consecutive failure (Type B DTC)

The Starter Generator Control Module (SGCM) will inhibit auxiliary

operation

The TCM will store failure record information

The SGCM will inhibit auto stop mode

4T45E

Updates (continued)

5 7

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

A low power complaint along with some APP DTCs may occur on some 4T40/45E

A body (Chevrolet HHR/Cobalt, Saturn Ion, Pontiac Pursuit) applications. Any

or all of the following DTCs may be set:

P2120 APP 1 Circuit

P2122 APP 1 Circuit Low Voltage

P2123 APP 1 Circuit High Voltage

P2125 APP 2 Circuit

P2127 APP 2 Circuit Low Voltage

P2128 APP 2 Circuit High Voltage

P2138 APP 1&2 Correlation

The engine harness may be chaffing on the canister purge solenoid bracket.

Inspect, repair and reroute the harness. You can add a piece of heater hose to the

harness to prevent further damage

4T40/45E

Low Power, APP DTCs Set

ABody

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 58

2007 ATRA. All Rights Reserved.

Some A body (Cobalt, Pursuit, Ion, HHR, Rendezvous) applications may exhibit

any or all of the following DTCs, P0700, P0712, P0713, P0717, P00842,P0843,

P0961, P0973, P0974, P0976, P0977. It is common for the concern to be inter-

mittent.

The DTCs relate to transmission related concerns.

P0700- General Transmission DTC, Faults Present

P0712-P0713- TFT Voltage Concerns

P0717- Input Speed Sensor Voltage Concern

P0842/P0843- TCC Release Switch Circuit Voltage Concerns

P0961- PCS Voltage Concern

P0973/P0974- 1-2 Shift Solenoid/Circuit Voltage Concerns

P0976/P0977- 2-3 Shift Solenoid/Circuit Voltage Concerns

Inspect the transmission wiring harness as it runs toward the engine block near

the oil filter for damage/rub thru. As the harness exits the transmission, it can

come into contact with engine block as it travels toward the TCM located in the

left strut tower area. Inspect the harness for damage, repair and reroute the

harness to prevent future damage.

4T40/45E

A Body

Multiple DTCs

5 9

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

C/H car ( Bonneville, Park Avenue, LeSabre) 4T65E applications may exhibit any

or all of the following conditions:

The transmission starts in 3

rd

gear, which may be interpreted by the

customer as a slip related concern or a lack of power complaint.

If the condition is intermittent the customer may state that the vehicle is

shifting erratically without input from the driver (Shift hunt)

Possible DTCs such as P0753, P1860, P0758

Inspect Circuit 239, IGNFD fuse 10 Amp (Connector C-2 Pin E4) (Park Avenue) at

the left under hood fuse block for a poor connection. Inspect circuit 739, Trans

fuse 13 10 Amp( Connector C-3 Pin E7) LeSabre/Bonneville applications for a

poor connection. Generally the terminal is damaged or incorrectly crimped. If a

poor connection is found repair or replace the terminal.

4T65E

Slips/Wrong Gear Starts/Erratic

Shifts/Lack of Power P0753/P0758/

P1860

Par k Aven u e

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 60

2007 ATRA. All Rights Reserved.

4T65E

Slips/Wrong Gear Starts/Erratic

Shifts/Lack of Power P0753/P0758/

P1860

La Sabr e, Bon n eville

6 1

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

Several updates were implemented on the 4T80E applications, they include:

A 6 track IMS

A New manual valve link and retainer

Updated wiring harness and pass through connector

Updated lower wiring harness

6 Tr ack IMS (In t er n al Mode Swit ch )

The 6

th

track adds a stand alone P/N signal circuit (1786) to the IMS function. The

6 track IMS is wider than the 5 track version it replaces. The 6 track will back

service earlier transmissions if the link and retainer are used, although the 6

th

track will not function. The 6 track IMS requires a new tool, DT 47707-1 to prop-

erly align the assembly.

4T80E

Updates

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 62

2007 ATRA. All Rights Reserved.

Man u al Lin k an d Ret ain er

A new manual link and retainer were required for the wider 6 track IMS. The

second design link can be used with the 5 track IMS. The updated retainer is

required with the new IMS and it to can back service a 5 track IMS.

4T80E

Updates

(continued)

Wir in g Ha r n e s s

The updated wiring harness is required with the new design IMS. The updated

harness will back service the previous IMS design.

Th e 6 t r ack IMS r equ ir es a

n ew t ool, DT 4 7 7 0 7 -1 t o

pr oper ly align t h e as s embly.

6 3

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

The first in a series of new 6 speed front wheel drive transmissions was

introduced for the 2007 model year. The 6T70 and 6T75 entered into the GM

lineups with several vehicles such as the Saturn Aura, Pontiac G6 for the car

lines, and the GMC Acadia and Saturn Outlook in the truck lines. This

generation of transmissions was co-developed with Ford and will enter the Ford

line up with the model name 6F55. Many but not all of the components are

shared between the Ford and GM versions of the transmissions. By co-developing

the transmission R&D costs were significantly reduced.

The 6T70/6T75 improve fuel economy and average of 4 % while performance was

improved 8% on average. The 6T70/6T75 share the same architecture and most of

the parts are the same. The primary difference is the 6T75 is a heavy duty version

of the 6T70. The heavy duty parts in the 6T75 include:

A shot peened output carrier

5 Pinion carrier

Transfer Gear is wider

Differential carrier is heavier duty

Heavier ribbed case

6T70/6T75 Ford 6F55

Introduction

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS 64

2007 ATRA. All Rights Reserved.

6T70/6T75 Ford 6F55

Introduction

HYDRA-MATIC 6T70/75

MANUAL SHIFT

DETENT LEVER

ASSEMBLY

(w/SHAFT POSITION SWITCH)

MANUAL VALVE

CONTROL SOLENOID

VALVE ASSEMBLY

(w/BODY AND TCM)

CONTROL VALVE

CHANNEL PLATE

ASSEMBLY

CONTROL VALVE

UPPER BODY

ASSEMBLY

CONTROL VALVE

LOWER BODY

ASSEMBLY

CONTROL VALVE

BODY COVER

INPUT SHAFT

SPEED SENSOR

RELUCTOR WHEEL

TRANSMISSION

FLUID LEVEL

INDICATOR

REACTION

CARRIER

ASSEMBLY

INPUT

CARRIER

ASSEMBLY

OUTPUT

CARRIER

ASSEMBLY

FLUID PUMP

DRIVE LINK

ASSEMBLY

PARK PAWL

PARK PAWL

ACTUATOR

ASSEMBLY

TORQUE

CONVERTER

ASSEMBLY

FRONT

DIFFERENTIAL

TRANSFER DRIVE

GEAR SUPPORT

ASSEMBLY

FRONT

DIFFERENTIAL

TRANSFER DRIVE

GEAR

FRONT

DIFFERENTIAL

TRANSFER

DRIVEN

GEAR

FRONT

DIFFERENTIAL

DRIVE PINION

GEAR

PARK GEAR

TORQUE CONVERTER

AND SUPPORT AND

FLUID PUMP

HOUSING ASSEMBLY

FRONT

DIFFERENTIAL

CARRIER ASSEMBLY

FRONT

DIFFERENTIAL

CARRIER BAFFLE

FRONT

DIFFERENTIAL

RING GEAR

1-2-3-4

CLUTCH

ASSEMBLY

2-6

CLUTCH

ASSEMBLY

4-5-6

CLUTCH

ASSEMBLY

INPUT

SPEED

SENSOR

CASE

COVER

ASSEMBLY

3-5 REVERSE

CLUTCH

ASSEMBLY

LOW AND

REVERSE

CLUTCH

LOW AND REVERSE

CLUTCH ASSEMBLY

(OWC)

FRONT

DIFFERENTIAL

DRIVE PINION

GEAR LUBE TUBE

OUTPUT

SPEED

SENSOR

FLUID

PUMP

ASSEMBLY

(NOT SHOWN)

6 5

2007 ATRA. All Rights Reserved.

GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS GENERAL MOTORS

Fluid TypeDexron VI

Fluid capacity Valve body cover removal5.3-7.4 qts (5-7 liters)

Fluid capacity fluid change4.2-6.3 qts (4-6 liters)

Fluid capacity Overhaul 7.4-9.5 qts (7-9 liters)

The vent for the transmission is incorporated into the dipstick

EC3 246 mm hyper elliptical furnace brazed torque converter. Torque

converter contains a lip seal that will be damaged if the converter is

removed or installed in any position other than vertical. Special tools are

available J46409

5 clutches (3 holding, 2 driving) clutch to clutch shifting

1 diode/ratchet type one way clutch

2 shift solenoids used (On/Off Design), SS1,SS2