Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

00118

Caricato da

sivavalaiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

00118

Caricato da

sivavalaiCopyright:

Formati disponibili

90

Chapter 9

- The engineering and construction contracting strategies have been

established.

- The timing of environmental and construction permits has been firmed

up with the pertinent agencies. However,thepreparationofexecutionplans is abootstrapoperation,wherea preliminary plan must first be developed to make the execution decisions, which in turnmayimpacttheoriginaldataanddeterminethefirmexecutionplan.The information required to prepare a preliminary project execution plan is essentially the same as that required forthe initial planofactiondiscussed in Chapter 5, except that it is now based on more accurate data. Whereas the latter is based on conceptual data and educated guesses, the preliminary execution plan must reflect, at least, a Phase 0 design and a preliminary or conceptual cost estimate. The annotated equipment list developed in the Phase 0 design (see equipment list and cost estimate in Appendix L) will permit the Project Manager to prepare, as indicated in Section 19.1 a conceptual cost estimate including:

- Equipment cost. - Engineering cost and hours.

- Total direct construction hours broken down

activities.

by major construction

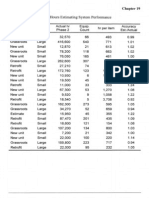

Such an estimate, for the case study, is illustrated in Table 9.1 It must be noted at this point that Fig. 5.1 is based on total field hours, direct andindirect,andthattheconstructionhoursshown in theestimatesmustbe adjusted before being used to determine project durations. The direct hours must be adjusted by adding 15% to account for supervision and miscellaneous indirect craft labor plus the contingency or growth factor included in the estimate. Project durations and peak engineering and construction staffing can now be estimated with the aidof Fig. 5.1 and the pertinent rules of thumb in Section 5.1. With this information on hand the Project Manager can check the Validity of the conceptual data developed at the project onset with the Order of Magnitude (OOM) estimate.

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Cost Estimate Summary Case: Estimating 119Documento1 paginaCost Estimate Summary Case: Estimating 119sivavalaiNessuna valutazione finora

- Phases The Startup: of An For ofDocumento1 paginaPhases The Startup: of An For ofsivavalaiNessuna valutazione finora

- Semi-Detailed Estimating System: M LabDocumento1 paginaSemi-Detailed Estimating System: M LabsivavalaiNessuna valutazione finora

- Hours: Table 19.25 Engineering Estimating System PerformanceDocumento1 paginaHours: Table 19.25 Engineering Estimating System PerformancesivavalaiNessuna valutazione finora

- Communications 241: 17.2 Documentation ChecklistDocumento1 paginaCommunications 241: 17.2 Documentation ChecklistsivavalaiNessuna valutazione finora

- Project Control: Plant LayoutDocumento1 paginaProject Control: Plant LayoutsivavalaiNessuna valutazione finora

- This Page Intentionally Left BlankDocumento1 paginaThis Page Intentionally Left BlanksivavalaiNessuna valutazione finora

- 3 - Shakedown Areas.: Construction ManagementDocumento1 pagina3 - Shakedown Areas.: Construction ManagementsivavalaiNessuna valutazione finora

- Project Control Problem Correction: During ConstructionDocumento1 paginaProject Control Problem Correction: During ConstructionsivavalaiNessuna valutazione finora

- 15.5 Control During Construction: 80% of Bulk Materials Normally SuppliedDocumento1 pagina15.5 Control During Construction: 80% of Bulk Materials Normally SuppliedsivavalaiNessuna valutazione finora

- 14.3 Construction Management ActivitiesDocumento1 pagina14.3 Construction Management ActivitiessivavalaiNessuna valutazione finora

- 2 - Drawings.: 3 - SpecificationsDocumento1 pagina2 - Drawings.: 3 - SpecificationssivavalaiNessuna valutazione finora

- Speclfic To Project: 2 - Depth and BreadthDocumento1 paginaSpeclfic To Project: 2 - Depth and BreadthsivavalaiNessuna valutazione finora

- All Equipment Should Be Accessible by Either Crane or Lift TruckDocumento1 paginaAll Equipment Should Be Accessible by Either Crane or Lift TrucksivavalaiNessuna valutazione finora

- Estimating Methods: Engineering EstimatesDocumento1 paginaEstimating Methods: Engineering EstimatessivavalaiNessuna valutazione finora

- Agreement: ContractingDocumento1 paginaAgreement: ContractingsivavalaiNessuna valutazione finora

- Process Design Phaseolphasel: Phase 1 SpecificationsDocumento1 paginaProcess Design Phaseolphasel: Phase 1 SpecificationssivavalaiNessuna valutazione finora