Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WPS 316 L

Caricato da

laz_kCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WPS 316 L

Caricato da

laz_kCopyright:

Formati disponibili

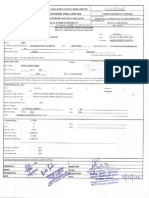

WELDING PROCEDURE SPECIFICATION (ASME SECTION IX)

Form No. ASME WPS, Rev. 11/09

WPS No. GT-SM-5B(F43)

Manual GTAW & SMAW Welding of P5B (5 & 9 Cr, Mo) Steels 1/16 to 0.560 Inch Thick (Open Root or Metal Backing) Without Postweld Heat Treatment Using Inconel Filler Metal for ASME B31.3 Process Piping Applications Only Project: General Distribution Notch Toughness Qualified: No Issue Date: 11/13/2009 Abstracts: Format & Code Updates Revision No: 4 Supporting PQRs: ... GT-SM-5B(F43)-0.280 Joints (QW-402): 12 Scope:

Page 1 of 2

(Refer to drawings for weld sizes and additional joint details)

Joint Design: Single & Double-V, J or U Groove, Fillet & Socket Welds, Slot & Plug Welds, Seal Welds Metal Backing: Optional (See Notes) Alignment: +/- 1/16" or per Construction Drawings Nonmetalic / Nonfusing Backing or Retainers: Not Permitted Root Opening: w/o Backing: 1/16" - 3/16" w/Backing: 1/8" - 1/4" Code Application: Restricted to ASME B31.3 Use Only Note 1: Metal backing may be used when permitted by project specifications. Backing materials shall consist of the same P number as the base material. When using split-type backing rings in pipe, tack welding across the split is not permitted. Backing rings in pipe and tube shall be securely tacked on the upstream side of the joint to prevent dislodgement in service.

Base Metals (QW-403): P-No: 5B - Group No: 1 (Note 2) ... to ... P-No: 5B - Group No: 1 (Note 2) Base Metal Thickness Range, Groove: 1/16 - 0.560 in. Deposited Weld Metal Limit, Groove: GTAW: 0.280 in. SMAW: 0.280 in. Fillets: Unlimited Pipe Diameter Range, Groove: Unlimited Note 2: Fillets: Unlimited Fillets: Unlimited Max. Single Pass Thickness: 0.28 in.

Excludes grades 91, P91, T91, F91, WP91, FP91. This WPS applies only to B31.3 Process Piping applications where the engineer or project specification specifically requires the joining of 5% or 9% chromium alloys without heat treatment.

Filler Metals (QW-404): SFA Specification: GTAW: SFA-5.14 SMAW: SFA-5.11 Product Form: GTAW: Solid Rod AWS Classification: GTAW: ERNiCr-3 (Inconel Filler Metal 82) SMAW: ENiCrFe-3 (Inconel 182) Supplemental Filler / Alloying: Not Permitted F No: F-No.43 (Both) Analysis: UNS N06082 & W86182 Consumable Insert: Not Permitted Welding Positions (QW-405): Groove: All Positions Vertical Progression: Vertical Uphill Preheat (QW-406): Minimum Preheat Temperature Thickness Range, in. All B31.3 Process Piping 350 F B31.1 Power Piping N/A F ASME I Pipes / Tubes N/A F ASME I Shells / Heads N/A F ASME VIII Pipes / Tubes N/A F ASME VIII Shells / Heads N/A F Maximum Interpass Temperature 500 F Fillets: All Positions

WELDING PROCEDURE SPECIFICATION (ASME SECTION IX)

Form No. ASME WPS, Rev. 11/09

WPS No. GT-SM-5B(F43)

Preheat Maintenance: Allow joint to cool under insulation wrap. Postweld Heat Treatment (QW-407): PWHT Temperature, F Thickness, Pipe and Tube Drums, Shells inches (all applications) and Heads All Welding Gas (QW-408): Welding Process GTAW SMAW Note 3: SFA-5.32 Class or Mixture SG-A N/A Torch or Nozzle Flow Rate Preflow Postflow (CFH) (Seconds) (Seconds) 15-30 N/A N/A N/A N/A N/A Cup (Linde) or Nozzle Dia., in. No. 5 to 10 N/A Trailing Gas SFA-5.32 Flow Rate Class or Mixture (CFH) None N/A N/A N/A None None Minimum Holding Time @ Temp B31.3 Process Piping N/A B31.1, ASME I and ASME VIII N/A

Page 2 of 2

Maximum Rate of Heating / Cooling B31.1 and B31.3 Above 600 F N/A ASME I and VIII Above 800 F N/A

Backing Gas SFA-5.32 Flow Rate Class or Mixture (CFH) SG-A N/A 5-50 N/A

Backing gas shall be used on the first two layers on groove welds welded from one side. Flow shall be adjusted to provide positive pressure to the root side of the joint without influencing the shape of the root deposit.

Welding Process Wire or Electrode Parameters Diam (in.) 3/32 1/8 3/32 1/8 Wire Feed Tungsten Rate Range Class EWTh-2 EWth-2 N/A N/A DCEN = Electrode Negative DCEP = Electrode Positive ipm = Inches per Minute Current Travel Start Current, Decay Current, Other Speed % of Main and % of Main and Volts Amps Time Time 10-14 10-14 18-24 18-26 75-160 95-180 60-120 70-130 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 1 ipm min. 2 ipm min. As Req'd As Req'd Note 4 Note 4

Electrical Characteristics (QW-409):

Weld Layer Process, Current or Transfer Mode and Polarity GTAW GTAW Continuous DCEN Continuous DCEN

Open Root & GTAW Layers SMAW Layers

SMAW Continuous DCEP SMAW Continuous DCEP

Technique (QW-410): Single or Multiple Electrode: Single Electrode Spacing: N/A Multiple or Single Pass per Side: As Required Peening: None String or Weave Bead: String or Slight Weave Oscillation: N/A Contact Tube to Work Distance: N/A Initial Cleaning: File, grind, chip or machine surfaces to be welded plus one-half inch on either side of the anticipated toe of the weld. Remove oil, grease and other contaminants using approved solvents. Method of Backgouging: For double-welded joints, back-gouge to sound weld metal using mechanical or thermal methods before welding second side. Interpass Cleaning: Chip, file, grind and/or brush each layer as needed. Inspect and remove defects prior to depositing next pass. Final Cleaning: Chip and wire brush. Note 4: Use an adequate amount of filler metal and avoid concave root deposits which could cause center-line cracking because of the thermal contraction characteristics of the Inconel fillet metal.

Approved By:

Signature on File

Date:

Friday, November 13, 2009

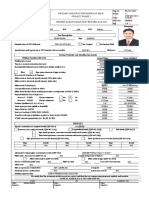

Welding Procedure Qualification Record (PQR) ASME Section IX PQR No.

GENERAL

PQR Date: 4/18/2003 Welding Process(es): Type (Manual, Automatic, Semiauto): Welding Procedure Specification Used: Gas Tungsten-Arc (GTAW) and Shielded Metal-Arc (SMAW) Welding Manual GT-SM-5B(F43)

GT-SM-5B(F43)-0.28

JOINT DESIGN (QW-402)

Groove Design of Test Coupon

Coupon Thickness (t, in.): Backing Type & Material: Land (Ld, in.): Bevel Angles (Bl, Degrees): Root Opening, (Ro, in.):

0.28 None 0 37.5 0.125"

Actual deposit thickness of each process or filler metal used, in. GTAW SMAW 0.140 0.140

BASE METALS (QW-403)

Base Metal Specification: Type or Grade: 5B P-No. Thickness of Test Coupon: Maximum Pass Thickness: Other: 6 NPS SA-335 to SA-335 Grade 9 5B to P-No. 0.28" N/A Shielding:

GAS (QW-407)

Gas / Gas Mixture Welding Grade Argon Flow Rate 28 N/A N/A

Trailing: None Backing: None Not Recorded Nozzle Diam: Contact Tube to Work Distance: N/A Other:

FILLER METALS (QW-404)

GTAW: SFA-5.14 / SMAW: SFA-5.11 SFA Specification: GTAW: ERNiCr-3 / SMAW: ENiCrFe-3 AWS Classification: F-No. 43 (Both) Filler Metal F-No. Inconel 182 (UNS N06082 & W86182) Weld Metal Analysis: 1/8" (Both) Size of Filler Metal: Midalloy Solid Rod GMAW / GTAW Product Form: None Supplemental Filler / Alloying: Other:

TECHNIQUE (QW-410)

Travel Speed: GTAW: 2.5 - 3.3 ipm / SMAW: 1.9 ipm String or Weave Bead: Oscillation: Both N/A GMAW / FCAW Transfer Mode: N/A Multi or Single Pass: Single / Multi Electrode: Single Multipass N/A GMAW, FCAW, SAW Wire Feed Rate: GTAW: 51,480 joules per inch Heat Input Rate: SMAW: 62,526 joules per inch Other:

POSITION (QW-405)

Position of Groove: Vertical Welding Progression Other: 1G-Flat N/A

ELECTRICAL CHARACTERISTICS (QW-409)

GTAW: (DCEN) / SMAW: (DCEP) Current & Polarity: GTAW: 145 - 160 / SMAW: 80 - 90 Amps: GTAW: 11 - 13 / SMAW: 18 - 22 Volts: 1/8" EWTh-2 (2% Thoriated) Tungsten Electrode Type & Size:

PREHEAT (QW-406)

Preheat Temp. 192 Deg. F. Preheat Maintenance: Other: Interpass Temp: None 434 Deg. F.

POSTWELD HEAT TREATMENT (QW-407)

PWHT: Temperature: Time: Heating & Cooling Rate: Other: None N/A N/A N/A

Scheck Mechanical Corporation, Scheck Mechanical Wisconsin Corporation, Scheck Technical Services, Inc., Scheck Industrial Corporation

Welding Procedure Qualification Record (PQR) ASME Section IX PQR No.

Specimen Width, in. Thickness or No. ("0" if turned) Diameter, in.

T1 T2 0.6210 0.8920 0.2380 0.2400

GT-SM-5B(F43)-0.28

Ultimate Unit Stress, psi

76,604 76,632

Area, Square in.

0.1478 0.2141

Tensile Tests (QW-150) Yield Load, Yield Point, Fail Load, lbs. psi lbs.

N/A N/A N/A N/A 11,322 16,407

Type of Failure & Failure Location

Ductile, Weld Metal Ductile, Weld Metal

Guided Bend Tests (QW-160) Type

Transverse Face Bend Transverse Root Bend Transverse Face Bend Transverse Root Bend

Figure No.

Qw-462.3(a) Qw-462.3(a) Qw-462.3(a) Qw-462.3(a)

Defects

No Defects No Defects No Defects 1/32" poor

Results

Acceptable Acceptable Acceptable Acceptable

Specimen No.

Notch Location

Notch Type

Toughness Tests (QW-170) Impact Test Values Temp.

Lateral Expansion % Shear Mils

Drop Weight Break No Break

Result - Satisfactory: Macro - Results

Yes

N/A

No

Fillet Weld Tests (QW-180) Penetration into Parent Metal: Yes

N/A

N/A

No

Other Tests Hardness Survey (BHN): Deposit Analysis:

N/A P-5B HAZ: 191,196, 191 BHN

Other: Welder's Name Test Conducted By

Dave Marquardt Tech Aid Laboratory

S.S. No.

398-74-5562

Symbol:

TA-030102-1

DM

Laboratory Test No.

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the requirements of Section IX of the ASME Code.

Scheck Mechanical Corporation By:

Signature on File

Date:

April 18, 2003

Scheck Mechanical Corporation, Scheck Mechanical Wisconsin Corporation, Scheck Technical Services, Inc., Scheck Industrial Corporation

Potrebbero piacerti anche

- Wps 316L SMAW+GTAW R00Documento2 pagineWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- P 91 - Welding WPSDocumento2 pagineP 91 - Welding WPSSuhailshah123475% (4)

- WPS FormatDocumento2 pagineWPS FormatAmit SarkarNessuna valutazione finora

- WPS 304L &316LDocumento2 pagineWPS 304L &316LShakeel Memon100% (1)

- Qw-482 Welding Procedure Specification (WPS)Documento4 pagineQw-482 Welding Procedure Specification (WPS)Aldeline SungahidNessuna valutazione finora

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Documento5 pagineWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Welding Proposed Pwps For Our Jubail WorkDocumento2 pagineWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Documento5 paginePage No: 01: SA 240 GR 304 SA 240 GR 304jobertNessuna valutazione finora

- WPS & WPQR (Asme Section IX)Documento7 pagineWPS & WPQR (Asme Section IX)Rizaldy PhoenksNessuna valutazione finora

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocumento5 pagineWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNessuna valutazione finora

- According To ASME IX: Welding Procedure Specification (W.P.S)Documento4 pagineAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNessuna valutazione finora

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 pagineIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPS Sitelca S002Documento2 pagineWPS Sitelca S002Jose Antonio GomezNessuna valutazione finora

- WPS PQR-09Documento11 pagineWPS PQR-09Ranjan KumarNessuna valutazione finora

- Reports - QAQC - R0Documento10 pagineReports - QAQC - R0talupurumNessuna valutazione finora

- Wps For Carbon Steel THK 7.11 GtawDocumento1 paginaWps For Carbon Steel THK 7.11 GtawAli MoosaviNessuna valutazione finora

- Sample Welder ID As Per ASME Section IXDocumento99 pagineSample Welder ID As Per ASME Section IXVivek Jadhav100% (1)

- Ami-003 WPSDocumento2 pagineAmi-003 WPSBenjamin BrownNessuna valutazione finora

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Documento14 pagineList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNessuna valutazione finora

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Documento12 paginePT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNessuna valutazione finora

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocumento1 paginaWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNessuna valutazione finora

- PQR Gmaw3gDocumento4 paginePQR Gmaw3gdevendrasingh2021100% (3)

- WPS Dissimilar UpdatedDocumento3 pagineWPS Dissimilar UpdatedVimin Prakash100% (1)

- WPQ Formats NEWDocumento4 pagineWPQ Formats NEWMANABENDRA MAITRANessuna valutazione finora

- Wps For SS 304Documento3 pagineWps For SS 304MuraliKrishna87% (23)

- WQTDocumento1 paginaWQTRamkunwar YadavNessuna valutazione finora

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocumento4 pagine163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Documento2 pagineWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Documento2 pagineWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNessuna valutazione finora

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- Val Caraig WPQTDocumento1 paginaVal Caraig WPQTMark Jason M. BrualNessuna valutazione finora

- WPS For A333 ADocumento1 paginaWPS For A333 ARamzi BEN AHMED100% (1)

- WPS-PQR Gmaw LtiDocumento2 pagineWPS-PQR Gmaw Ltibgonzalez198150% (2)

- PQRDocumento2 paginePQRSreenivas Kamachi Chettiar100% (1)

- WPS-PQR (Er309l Mo)Documento4 pagineWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- For Fillet Weld Joint Project:Production ManifoldDocumento1 paginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- WPSDocumento6 pagineWPSYASH BARDHAN SinghNessuna valutazione finora

- WPS PQR A36.20Documento5 pagineWPS PQR A36.20gchaves504100% (2)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocumento3 pagineWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNessuna valutazione finora

- Wps 1010 IfrDocumento28 pagineWps 1010 IfrSyed Mahmud Habibur RahmanNessuna valutazione finora

- WPS PQRDocumento23 pagineWPS PQRHashim Khan88% (8)

- 19403955-WPS M.S. Is 2062Documento10 pagine19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- 37507022-WPS-PQR-SS-316 LDocumento5 pagine37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- WPQT CertificateDocumento104 pagineWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Documento6 pagineMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNessuna valutazione finora

- Piping WpsDocumento37 paginePiping WpsZulfokar FahdawiNessuna valutazione finora

- Wqt-Visual-Mag - BS 2Documento24 pagineWqt-Visual-Mag - BS 2KyNessuna valutazione finora

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocumento6 pagineWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNessuna valutazione finora

- A 36 WPSDocumento2 pagineA 36 WPSNaqqash Sajid100% (1)

- WPS 03Documento2 pagineWPS 03mansoor_an100% (1)

- WPS MigDocumento3 pagineWPS MigAJOJOY00960% (5)

- P-WPS 135 - MAG (GR 316)Documento9 pagineP-WPS 135 - MAG (GR 316)Tarun PatelNessuna valutazione finora

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Documento2 pagine(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPSDocumento6 pagineWPSNur Wijianto100% (1)

- Welding Procedure SpecificationDocumento5 pagineWelding Procedure SpecificationFranklin londono0% (1)

- WPS GTAW Stainless SteelDocumento4 pagineWPS GTAW Stainless SteelAnand NarayananNessuna valutazione finora

- WPS (AsmeDocumento8 pagineWPS (AsmeMohammad Elhedaby100% (6)

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Documento24 paginePrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNessuna valutazione finora

- WPSDocumento2 pagineWPSJuli Agus50% (2)

- Trade of Vehicle Body Repair: MIG - Welding FabricationDocumento149 pagineTrade of Vehicle Body Repair: MIG - Welding Fabricationlaz_kNessuna valutazione finora

- Datasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1Documento3 pagineDatasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1laz_kNessuna valutazione finora

- Chem Iii-Amines-P255 JOB DescriptionDocumento1 paginaChem Iii-Amines-P255 JOB Descriptionlaz_kNessuna valutazione finora

- Bonney Forge BrochureDocumento22 pagineBonney Forge BrochureAnonymous dvrhf5Nessuna valutazione finora

- Socket Weld LeakDocumento5 pagineSocket Weld Leaklaz_k100% (1)

- Datasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1Documento3 pagineDatasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1laz_kNessuna valutazione finora

- PWHT Responsibility Assignment Matrix: SR Topic Tasks DetailsDocumento6 paginePWHT Responsibility Assignment Matrix: SR Topic Tasks Detailslaz_kNessuna valutazione finora

- Electrical Maintenance TechniciancvDocumento3 pagineElectrical Maintenance Techniciancvlaz_k100% (1)

- Carber Service CatalogDocumento32 pagineCarber Service Cataloglaz_kNessuna valutazione finora

- Personnel, Consumable & ToolsDocumento3 paginePersonnel, Consumable & Toolslaz_kNessuna valutazione finora

- EN 1090 White Paper17 119019 PDFDocumento24 pagineEN 1090 White Paper17 119019 PDFZaza PokumbaNessuna valutazione finora

- Asset Integrity EngineerDocumento4 pagineAsset Integrity Engineerlaz_kNessuna valutazione finora

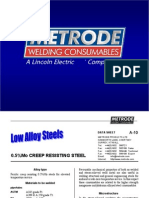

- Metrode ConsumablesDocumento309 pagineMetrode Consumablesrodofgod100% (1)

- AIChE Wilhelm April 08 Process SafetyDocumento16 pagineAIChE Wilhelm April 08 Process Safetymostafa_1000Nessuna valutazione finora

- Portfolio Storage&Drying Control ProcedureDocumento4 paginePortfolio Storage&Drying Control Procedurelaz_kNessuna valutazione finora

- Welded Steel Pipe Design ManualDocumento93 pagineWelded Steel Pipe Design ManualfileseekerNessuna valutazione finora

- Offshore ProtectionDocumento334 pagineOffshore ProtectionSumit PardeshiNessuna valutazione finora

- Pipe LineDocumento62 paginePipe LineBahtiar Anak LaNang100% (1)

- Electrical Maintenance Supervisor CVDocumento3 pagineElectrical Maintenance Supervisor CVlaz_k100% (1)

- Weld Filler WireDocumento37 pagineWeld Filler WireSiva Raman MurugesanNessuna valutazione finora

- RBI Corrosion Calculation Day2Documento7 pagineRBI Corrosion Calculation Day2laz_kNessuna valutazione finora

- Bicine - AmineDocumento14 pagineBicine - Aminelaz_kNessuna valutazione finora

- Stainless Steel Dissimilar Welding ChartDocumento1 paginaStainless Steel Dissimilar Welding Chartlaz_kNessuna valutazione finora

- Methodology For Petrophysical and Geomechanical Analysis of Shale Plays. Study Case: La Luna and Capacho Formations, Maracaibo Basin. Presentation of Paper SPE-185606-MSDocumento24 pagineMethodology For Petrophysical and Geomechanical Analysis of Shale Plays. Study Case: La Luna and Capacho Formations, Maracaibo Basin. Presentation of Paper SPE-185606-MSCarlos LoboNessuna valutazione finora

- Flootank® Catalogue 2022Documento21 pagineFlootank® Catalogue 2022Anindra Ahmad FarrasNessuna valutazione finora

- Formula Writing - CambridgeDocumento5 pagineFormula Writing - CambridgeQusai Saify100% (3)

- Royal Ultra 865MDocumento9 pagineRoyal Ultra 865Mjuanfdez42368Nessuna valutazione finora

- Simulation of Reactive Distillation ColumnDocumento6 pagineSimulation of Reactive Distillation ColumnthanhndbNessuna valutazione finora

- Paint Master Bonding Liquid - SDSDocumento3 paginePaint Master Bonding Liquid - SDSMichael JoudalNessuna valutazione finora

- Leaf Spring AnalysisDocumento9 pagineLeaf Spring AnalysisThilli KaniNessuna valutazione finora

- Formation of PrecipitationDocumento2 pagineFormation of PrecipitationArianne May Amosin50% (2)

- 11718-Article Text-42418-1-10-20161220Documento7 pagine11718-Article Text-42418-1-10-20161220BibahNessuna valutazione finora

- Engineering Critical Analyses To BS 7910Documento15 pagineEngineering Critical Analyses To BS 7910Mas Arman TewoNessuna valutazione finora

- Carbon NanotubesDocumento15 pagineCarbon NanotubesLaraib HabibNessuna valutazione finora

- Determination of Water Potential in A Plant PartDocumento3 pagineDetermination of Water Potential in A Plant PartMishti2Nessuna valutazione finora

- 3000 Series RespiratorDocumento2 pagine3000 Series Respiratortry lestari kusuma putriNessuna valutazione finora

- Florgard Epu SL - TDSDocumento3 pagineFlorgard Epu SL - TDSGabriel GabeNessuna valutazione finora

- Ne335 Macro Lab1Documento17 pagineNe335 Macro Lab1Moeen Khan RisaldarNessuna valutazione finora

- BIO Advancing The Biobased Economy 2016Documento84 pagineBIO Advancing The Biobased Economy 2016unicornmfkNessuna valutazione finora

- TDS-Dow SPECFIL FT630 & SPECFIL FE100-EN - 20181226Documento2 pagineTDS-Dow SPECFIL FT630 & SPECFIL FE100-EN - 20181226Mallampati RamakrishnaNessuna valutazione finora

- Models For Volcanic-Hosted Epithermal Precious Metal Deposits A ReviewDocumento11 pagineModels For Volcanic-Hosted Epithermal Precious Metal Deposits A ReviewOrlando B Santa CruzNessuna valutazione finora

- Aldehyde and Ketones Tollen TestDocumento9 pagineAldehyde and Ketones Tollen TestGule RashNessuna valutazione finora

- Sample Paper For ChemistryDocumento23 pagineSample Paper For ChemistryAmit joshiNessuna valutazione finora

- Cargo Conditioning, Reliquefaction and Boil-Off Control Requirement For A Liquefied Gas CarrierDocumento7 pagineCargo Conditioning, Reliquefaction and Boil-Off Control Requirement For A Liquefied Gas Carrierarlucky5459Nessuna valutazione finora

- Thermodynamic Analysis of EAF Electrical Energy deDocumento17 pagineThermodynamic Analysis of EAF Electrical Energy deRafaela PradeNessuna valutazione finora

- Acid SlurryDocumento8 pagineAcid SlurryVinod GoelNessuna valutazione finora

- Bioinorganic ChemistryDocumento12 pagineBioinorganic Chemistrycrisanto valdezNessuna valutazione finora

- Biological and Physicochemical Indicators of Water Quality in Libreville and Its SurroundingsDocumento7 pagineBiological and Physicochemical Indicators of Water Quality in Libreville and Its SurroundingsInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Protein MetabolismDocumento6 pagineProtein MetabolismGeline Dela RosaNessuna valutazione finora

- Pinch Technology/ Process Optimization: 8: Case Study United Refining CompanyDocumento80 paginePinch Technology/ Process Optimization: 8: Case Study United Refining CompanyAnonymous jlLBRMAr3ONessuna valutazione finora

- Spectrometric Identification of Organic CompoundsDocumento466 pagineSpectrometric Identification of Organic CompoundsMarie L100% (5)

- Materials and Processes For Agricultural and Biosystems EngineeringDocumento17 pagineMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioNessuna valutazione finora

- Denso Protal 7200 Brush Application SpecDocumento2 pagineDenso Protal 7200 Brush Application SpecTino VelázquezNessuna valutazione finora