Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

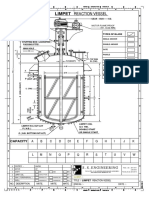

Limpet Coil Design

Caricato da

maheshspawarDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Limpet Coil Design

Caricato da

maheshspawarCopyright:

Formati disponibili

Date Rev No.

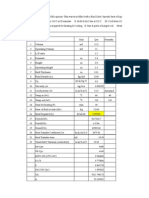

9/7/2013 0 DESIGN OF LIMPET COIL AS PER APPENDIX -EE

The maximum permissible pressure " P' " in half-pipe jackets shall be determined from the following formula: P' = F/K P1 P' = Half pipe jacket Internal pressure = The Maximum permissible pressure in half pipe Jacket Since P' is greater than half pipe jacket pressure (P1) Hence shell thickness is safe for external pressure

F K

= 1.5S -S' =

( F SHALL NOT EXCEED 1.5 X S)

Factor obtained from Fig. EE-2 (Considering 3 inch pipe) (For respective shell Inner diameter and shell thickness value of Parameter "K")

= Maximum Allowable Tensile stress at design temperature (220 C) of shell or head material , psi (Refer Tank calculation for allowable stress) = Actual longitudinal tensile stress in shell or head due to internal pressure and other axial forces, psi. When axial forces are negligible , S' shall be taken as PR / 2t. When the combination of axial forces & pressure stress (PR/2t) is such that S' would be a negative number, then S' shall be taken as zero.

S'

S' = PR/2t where P = Internal design pressure

Inside shell or head radius

2R

(Diameter of shell )

t C.A.

= Thickness of Shell

(In corroded condition)

= Corrosion Allowance for tank shell is

t (asbuilt)= Actual Thickness of shell Thickness of Half Pipe Jacket

= P1 X r 0.85S1-0.6P1

Considered SCH 5 ( 2 mm thick ) Pipe for 3 inch pipe. T r S1 P1 = Minimum thickness of half pipe jacket in = Inside radius of jecket defined in fig EE-3 inch = = Allowable tensile stress of jacket material at design temperature , psi Design pressure in jacket, psi( P1 shall not exceed P')

Considering pitch of coil 135 mm for 3 inch size , the weight of coil would be around

Prepared By Checked By

Approved

PENDIX -EE Psi

= = =

15 213.3 280.36

kg/cm2 Psi Psi

= =

30214.26 107.77

Psi

20142.84

Psi

138.88 Mpa

wable stress)

INTERPOLATION = = = 0 0 0 Psi Kg/cm2 Psi m mm inch m inch mm inch mm mm x1 x2 x3 y2 = 0 10 27.09 30

= 1.5 = 1500 = 59.06 = 3 = 118.110236 = = = = 6.000 0.236 2.000 8.000

= =

0.026 0.658

inch mm

1.75

inch

1202.245 kg/cm2 = 17095.9239 psi 213.3 psi

1400

kg (approx)

INTERPOLATION y1 y2 y3 0 0

Date Rev No.

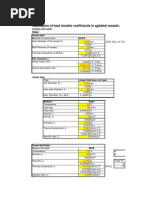

9/7/2013 0 DESIGN OF LIMPET COIL AS PER APPENDIX -EE

The maximum permissible pressure " P' " in half-pipe jackets shall be determined from the following formula: P' = F/K P1 P' = Half pipe jacket Internal pressure = The Maximum permissible pressure in half pipe Jacket Since P' is greater than half pipe jacket pressure (P1) Hence shell thickness is safe for external pressure

F K

= 1.5S -S' =

( F SHALL NOT EXCEED 1.5 X S)

Factor obtained from Fig. EE-2 (Considering 3 inch pipe) (For respective shell Inner diameter and shell thickness value of Parameter "K")

= Maximum Allowable Tensile stress at design temperature (220 C) of shell or head material , psi (Refer Tank calculation for allowable stress) = Actual longitudinal tensile stress in shell or head due to internal pressure and other axial forces, psi. When axial forces are negligible , S' shall be taken as PR / 2t. When the combination of axial forces & pressure stress (PR/2t) is such that S' would be a negative number, then S' shall be taken as zero.

S'

S' = PR/2t where P = Internal design pressure

Inside shell or head radius

2R

(Diameter of shell )

t C.A.

= Thickness of Shell

(In corroded condition)

= Corrosion Allowance for tank shell is

t (asbuilt)= Actual Thickness of shell Thickness of Half Pipe Jacket

= P1 X r 0.85S1-0.6P1

Considered SCH 5 ( 2 mm thick ) Pipe for 3 inch pipe. T r S1 P1 = Minimum thickness of half pipe jacket in = Inside radius of jecket defined in fig EE-3 inch = = Allowable tensile stress of jacket material at design temperature , psi Design pressure in jacket, psi( P1 shall not exceed P')

Considering pitch of coil 135 mm for 3 inch size , the weight of coil would be around

Prepared By Checked By

Approved

PENDIX -EE Psi

= = =

15 213.3 188.84

kg/cm2 Psi Psi

= =

30214.26 160

Psi

20142.84

Psi

138.88 Mpa

wable stress)

INTERPOLATION = = = 0 0 0 Psi Kg/cm2 Psi m mm inch m inch mm inch mm mm x1 x2 x3 y2 = 0 10 27.09 30

= 1.5 = 1500 = 59.06 = 3 = 118.110236 = = = = 4.000 0.157 2.000 6.000

= =

0.026 0.658

inch mm

1.75

inch

1202.245 kg/cm2 = 17095.9239 psi 213.3 psi

1400

kg (approx)

INTERPOLATION y1 y2 y3 0 0

Potrebbero piacerti anche

- Limpet Coil CalculationDocumento1 paginaLimpet Coil Calculationkirandas_mullassery100% (1)

- Half Coil For VersselDocumento1 paginaHalf Coil For VersselhuangjlNessuna valutazione finora

- Coil DesignDocumento7 pagineCoil DesignSajal Kulshrestha100% (3)

- Limpet Coil Area CalculationDocumento6 pagineLimpet Coil Area CalculationPraveen Prajapati100% (4)

- Jacket and Coils of Agitated Vessels PDFDocumento2 pagineJacket and Coils of Agitated Vessels PDFlolofm25Nessuna valutazione finora

- Heat Transfer in Jacketed VesselDocumento2 pagineHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Limpet Coil Reactor - 28-05Documento3 pagineLimpet Coil Reactor - 28-05AJAY138150% (2)

- Tank Coils - Design and UseDocumento7 pagineTank Coils - Design and UseMartin DanzeNessuna valutazione finora

- Half Pipe CalculationDocumento3 pagineHalf Pipe CalculationCaptainTonies0% (1)

- Heating Coil Sizing For Fuel Oil TankDocumento2 pagineHeating Coil Sizing For Fuel Oil TankAhmed Mujtaba93% (14)

- Agitator - Anchor - Highly ViscousDocumento2 pagineAgitator - Anchor - Highly ViscousWade ColemanNessuna valutazione finora

- Calculation Overall Heat TransferDocumento4 pagineCalculation Overall Heat TransferDavid LambertNessuna valutazione finora

- AgitatorDocumento6 pagineAgitatorSung Woong MoonNessuna valutazione finora

- Weir Plate or Baffle Plate CalculationDocumento2 pagineWeir Plate or Baffle Plate CalculationamaNessuna valutazione finora

- Limpet Reaction Vessel PDFDocumento1 paginaLimpet Reaction Vessel PDFarajamani78Nessuna valutazione finora

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Documento42 pagine8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- Design Calculations of Pitch Blade TurbineDocumento6 pagineDesign Calculations of Pitch Blade TurbineAyaz_HasanjiNessuna valutazione finora

- Calculate The Wall Thickness of Methanol Storage TankDocumento4 pagineCalculate The Wall Thickness of Methanol Storage TankhaidirNessuna valutazione finora

- Jacketed VesselDocumento4 pagineJacketed Vesselnithansa100% (1)

- Leg CalculationDocumento10 pagineLeg Calculationmashudi_fikriNessuna valutazione finora

- Jacketed VesselsDocumento9 pagineJacketed VesselsParikshit Shahane67% (3)

- Internal Coil CalculationDocumento19 pagineInternal Coil CalculationMr Incognito100% (3)

- Dimpled Jacket 2Documento4 pagineDimpled Jacket 2grincheu7050% (2)

- "Design and Fabrication of Agitated Thin Film Dryer": Bhushan M. Thengre, Sulas G. BorkarDocumento11 pagine"Design and Fabrication of Agitated Thin Film Dryer": Bhushan M. Thengre, Sulas G. BorkarshirinNessuna valutazione finora

- Dimple Jacket Heat Transfer EstimationDocumento3 pagineDimple Jacket Heat Transfer EstimationicingrockNessuna valutazione finora

- External Pressure DesignDocumento395 pagineExternal Pressure DesignrsubramaniNessuna valutazione finora

- Agitated VesselsDocumento24 pagineAgitated VesselsAnuj Kumar100% (1)

- Sizing of Steam Coil of Insulated Tank Rev 3Documento2 pagineSizing of Steam Coil of Insulated Tank Rev 3ypatels50% (2)

- Small Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFDocumento6 pagineSmall Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFhussamammarNessuna valutazione finora

- Key Process Indicators-Falling Film EvaporatorsDocumento20 pagineKey Process Indicators-Falling Film Evaporatorscgoveia3Nessuna valutazione finora

- Limpet Coil On Dish Design As Per PD5500Documento1 paginaLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENessuna valutazione finora

- TankjktDocumento57 pagineTankjktAnonymous 20VAru100% (2)

- Agitator Design CalculationDocumento21 pagineAgitator Design CalculationRupesh Ubale94% (36)

- UHX CalcsDocumento5 pagineUHX CalcsJ.SIVIRA100% (2)

- API CalculationsDocumento11 pagineAPI CalculationsMohammed Illiasuddin100% (1)

- Asme Ug-27, Ug-32 & Appendix 1Documento5 pagineAsme Ug-27, Ug-32 & Appendix 1แบด พิษ100% (2)

- Apendice EE Calculo ChaquetaDocumento6 pagineApendice EE Calculo ChaquetaOrlando NavarreteNessuna valutazione finora

- Design (Valve)Documento12 pagineDesign (Valve)zmetheuNessuna valutazione finora

- Stiffening Ring Cal For Exteneral Press.Documento11 pagineStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)

- Vessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure VesselDocumento19 pagineVessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure Vesselbhalchandrak1867Nessuna valutazione finora

- Calculation API 650Documento78 pagineCalculation API 650jamil93% (14)

- Super CalculationsDocumento9 pagineSuper CalculationsNoé MarínNessuna valutazione finora

- Appendix G - Nonmandatory Examples Illustrating The Application of Code Formulas and RulesDocumento20 pagineAppendix G - Nonmandatory Examples Illustrating The Application of Code Formulas and Rulesel_koptan00857693Nessuna valutazione finora

- Thickness API 510Documento11 pagineThickness API 510Aleiser Quevedo Acuña100% (1)

- Thin WallDocumento4 pagineThin WallBryan EweNessuna valutazione finora

- Element AssignmentDocumento9 pagineElement Assignmentamanuelfitsum589Nessuna valutazione finora

- Asme Sec Viii D1 Nma App EeDocumento6 pagineAsme Sec Viii D1 Nma App EeADRIANNessuna valutazione finora

- ASME VIII CalculationDocumento15 pagineASME VIII CalculationJoao Osmar Correa100% (1)

- E4.5 Flange Cover CalcDocumento10 pagineE4.5 Flange Cover CalcTanCM100% (1)

- Pressuire VesselsDocumento10 paginePressuire Vesselsjojo258Nessuna valutazione finora

- Notes 1 PDFDocumento261 pagineNotes 1 PDFSachin5586100% (3)

- Penstock Embedded DesignDocumento6 paginePenstock Embedded Designgrahazen50% (2)

- 03 - Lifting Lug - 2nd Stage Separator (New)Documento5 pagine03 - Lifting Lug - 2nd Stage Separator (New)Alessio BarboneNessuna valutazione finora

- Mathcad - 539900-050-130 Padeye Pulling Skid 9.5 TDocumento7 pagineMathcad - 539900-050-130 Padeye Pulling Skid 9.5 TPablo Diego Didoné100% (1)

- IndexDocumento36 pagineIndexthewallstreetNessuna valutazione finora

- ASME VIII CalculationDocumento14 pagineASME VIII CalculationWan Wei100% (1)

- Asme-Viii Re-Pad Calc's and MoreDocumento15 pagineAsme-Viii Re-Pad Calc's and MoreDavid LambertNessuna valutazione finora

- Cylinders, Compound Cylinders, Press & Shrink FitsDocumento9 pagineCylinders, Compound Cylinders, Press & Shrink Fitstvsaagar100% (1)

- Simple Stress: Analysis of Internal ForcesDocumento12 pagineSimple Stress: Analysis of Internal ForcesLester Neil LomodNessuna valutazione finora

- ASME Air Tank DesignDocumento2 pagineASME Air Tank Designchethan100% (1)

- Rsti 69 CCDocumento4 pagineRsti 69 CCGuilherme VillaçaNessuna valutazione finora

- Tempering Process-SOPDocumento2 pagineTempering Process-SOPSelvakumar MNessuna valutazione finora

- Dunlop Rubber Cover Grade QualitiesDocumento1 paginaDunlop Rubber Cover Grade Qualitiesjonodo89Nessuna valutazione finora

- 3D Effects of Taylor FlowDocumento8 pagine3D Effects of Taylor FlowShreyank Deepali GoelNessuna valutazione finora

- Questions For PHD Entrance in Civil Engineering 2015-2016Documento14 pagineQuestions For PHD Entrance in Civil Engineering 2015-2016grkvani10Nessuna valutazione finora

- Inspection Certificate: Ensa de Traccion I Tensile TestDocumento8 pagineInspection Certificate: Ensa de Traccion I Tensile TestАнна КокоеваNessuna valutazione finora

- Silicon On PlasticDocumento4 pagineSilicon On PlasticRajesh Yenugula100% (1)

- Petronas Technical StandardsDocumento44 paginePetronas Technical StandardsĐạt TrầnNessuna valutazione finora

- Epass Summative Week 1 &2Documento2 pagineEpass Summative Week 1 &2ANA REIZA ZAFRANessuna valutazione finora

- 11.1.2 Faradays Law Part 2Documento7 pagine11.1.2 Faradays Law Part 2FishBowl GangNessuna valutazione finora

- Column DesignDocumento36 pagineColumn DesignGaurav KashyapNessuna valutazione finora

- Multiple Chioce Questions ThermoDocumento8 pagineMultiple Chioce Questions ThermoRose Belle A. GarciaNessuna valutazione finora

- The Art of Designing Ductile Concrete in The Past 50 Years: The Impact of The PCA Book and Mete A. Sozen, Part 1Documento6 pagineThe Art of Designing Ductile Concrete in The Past 50 Years: The Impact of The PCA Book and Mete A. Sozen, Part 1masteriragaNessuna valutazione finora

- Dynamic Contact Angle Hysteresis in Liquid Bridges: Graphical AbstractDocumento25 pagineDynamic Contact Angle Hysteresis in Liquid Bridges: Graphical AbstractMaja VuckovacNessuna valutazione finora

- Stefan's ContDocumento8 pagineStefan's Contuyoi onaNessuna valutazione finora

- 10.1007@978 3 030 36540 0 PDFDocumento1.008 pagine10.1007@978 3 030 36540 0 PDFdavibraga8041100% (1)

- PolymerTestingDSC PDFDocumento25 paginePolymerTestingDSC PDFBrandon RichardsonNessuna valutazione finora

- Evaluation of The VDA 238-100 Tight Radius Bending Test Using Digital Image Correlation Strain MeasurementDocumento9 pagineEvaluation of The VDA 238-100 Tight Radius Bending Test Using Digital Image Correlation Strain MeasurementR JNessuna valutazione finora

- Solution Manual For Introductory Chemistry An Atoms First Approach 1st Edition Burdge Driessen 0073402702 9780073402703Documento26 pagineSolution Manual For Introductory Chemistry An Atoms First Approach 1st Edition Burdge Driessen 0073402702 9780073402703stevenNessuna valutazione finora

- Corrapol Clear Corrugated Sheet Ranges Technical GuideDocumento8 pagineCorrapol Clear Corrugated Sheet Ranges Technical GuideDavid Galvis VelozaNessuna valutazione finora

- Rigid Tubes Used For Electrical Insulation: Standard Test Methods ForDocumento6 pagineRigid Tubes Used For Electrical Insulation: Standard Test Methods Forasma hamzaNessuna valutazione finora

- 07 Fracture 1-18 PDFDocumento18 pagine07 Fracture 1-18 PDFDepi WayatiNessuna valutazione finora

- Contactless Voltage Relay PDFDocumento9 pagineContactless Voltage Relay PDFvasiliy vasilievichNessuna valutazione finora

- Magnetic Bead-Magic Bullet: MicromachinesDocumento17 pagineMagnetic Bead-Magic Bullet: MicromachineslotannaNessuna valutazione finora

- Finite Element Analysis of Saturated Sand Layer Under Earhtquake LoadingDocumento14 pagineFinite Element Analysis of Saturated Sand Layer Under Earhtquake LoadingJorge PalominoNessuna valutazione finora

- CIVILMEET2023 Paulo DE MORAISDocumento12 pagineCIVILMEET2023 Paulo DE MORAISPaulo MoraisNessuna valutazione finora

- Fuselage Stress AnalysisDocumento3 pagineFuselage Stress Analysisbenandbergen100% (4)

- ProQuestDocuments 2024 04 04Documento2 pagineProQuestDocuments 2024 04 04Theodøros D' SpectrøømNessuna valutazione finora

- ENGG1500 Module 8 Tute SolutionsDocumento15 pagineENGG1500 Module 8 Tute SolutionsKevin MalarkeyNessuna valutazione finora

- Different Types of Microscope and UsesDocumento3 pagineDifferent Types of Microscope and UsesVienna TulauanNessuna valutazione finora