Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Beading Tool

Caricato da

ibis_pilotCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Beading Tool

Caricato da

ibis_pilotCopyright:

Formati disponibili

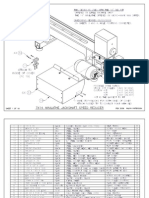

BEADING TOOL INSTRUCTIONS

Bill of material: 1 pc 1 pc 1 pc 1 pc 1 pc 1 pc 2 pc 2 pc 2 pc 1 pc 1/2" x 1/2" steel square stock 6" long 5/8" x 1/16" wall square steel tube 1-3/4" long 3/4" x 1/16" wall round steel tube 3" long 1/2" steel round approx 3" long 3/4" steel round approx 3" long 1/4" x 1" truss head machine screw AN 364-428A nut AN 960-4 thin washer AN 4-14A or longer bolt (cut to 1-5/16" long) 1/4" socket head cap screw with approx 1/2" of grip length (cut to 1")

- Drill and tap the frame as required. - Round off the corners of the outside end of the frame to allow handle to slide freely over the frame. (Only remove material from the outer 3".) - Dress the frame and slide to allow for free movement but minimal play. - Remove 11/16" of wall from one end of the slide. (This allows the outside rollers to lay tight against the frame.) - Cut studs, position and weld to slide. (It is critical that the studs be welded square to the frame and each other.) - Weld the truss head machine screw to the end of the handle. - Machine the rollers. (For this operation, grind a 1/8" wide round nose tool bit. Machine the bead and grooves in the exact center of the rollers and do not exceed .045" for the height/depth of the cuts.) - Assemble such that all parts move freely but have minimum "play". - For the "professional" finish, dip the handle in plastic coating material. This tool is to be used on soft materials only. Do not try to bead material with wall thicknesses greater than 1/6". The material should have a square end and be held firmly against the frame when starting the bead. Do not try to squeeze out a really tall bead

as this will swage the tubing out to a larger diameter.

Potrebbero piacerti anche

- The Infinite Oval: Tools For WoodworkingDocumento2 pagineThe Infinite Oval: Tools For Woodworkingoqab18Nessuna valutazione finora

- WorksupportstandDocumento1 paginaWorksupportstandFrenchwolf420Nessuna valutazione finora

- Box Cart PlansDocumento4 pagineBox Cart PlansPaulDahlbergNessuna valutazione finora

- Valet StandDocumento9 pagineValet StandflerziNessuna valutazione finora

- Router Table Fence PlansDocumento9 pagineRouter Table Fence PlansAfonso PraganaNessuna valutazione finora

- ATI Alum Hole Fab 2009 PDFDocumento12 pagineATI Alum Hole Fab 2009 PDFinammurad12Nessuna valutazione finora

- Cost EstimationDocumento4 pagineCost EstimationPronob DasNessuna valutazione finora

- Grade 9 MetalworkDocumento13 pagineGrade 9 MetalworkAidan O'HaraNessuna valutazione finora

- Dog Tag/ Key ChainDocumento13 pagineDog Tag/ Key ChainAidan O'HaraNessuna valutazione finora

- Vertical Rev HDocumento10 pagineVertical Rev HMiguel OyarzabalNessuna valutazione finora

- 32 Ford Final Pattern PDFDocumento1 pagina32 Ford Final Pattern PDFMarian VoicuNessuna valutazione finora

- Contemporary Coffee Table: Project 17631EZDocumento5 pagineContemporary Coffee Table: Project 17631EZBSulliNessuna valutazione finora

- Blue Stem Really Basic Lap Steel PlanDocumento1 paginaBlue Stem Really Basic Lap Steel PlanJuan Marcos Pancino100% (1)

- Engine Stand PlansDocumento23 pagineEngine Stand PlansJoey WilletNessuna valutazione finora

- Belt Sander 0001Documento5 pagineBelt Sander 0001wienslaw5804Nessuna valutazione finora

- Cutter Making David CreedDocumento19 pagineCutter Making David CreedBruno Delsupexhe100% (1)

- Indexable Turning Tools ProjectsDocumento21 pagineIndexable Turning Tools ProjectsEmijo.ANessuna valutazione finora

- 22 Twist Barrel Derringer - Upload by SteyrDocumento6 pagine22 Twist Barrel Derringer - Upload by SteyrRadek Bust100% (1)

- 22 Twist-Barrel DerringerDocumento5 pagine22 Twist-Barrel Derringerangelines12380% (15)

- Free Deer Stand PlansDocumento10 pagineFree Deer Stand PlansloktakwahNessuna valutazione finora

- Coil WinderDocumento15 pagineCoil Winderkokomore100% (1)

- Parts List (One Target)Documento7 pagineParts List (One Target)nan214Nessuna valutazione finora

- My Hovercraft Build DiaryDocumento74 pagineMy Hovercraft Build DiaryLeonel Rodriguez100% (2)

- Make A Rocking Muskoka Chair Out of Composite Wood 2 PDFDocumento8 pagineMake A Rocking Muskoka Chair Out of Composite Wood 2 PDFCocis CosminNessuna valutazione finora

- How To Build A Tube Bender WWDocumento9 pagineHow To Build A Tube Bender WWmikefcebuNessuna valutazione finora

- Grinder PlansDocumento21 pagineGrinder Plansmanometro80% (5)

- Grinder PlansDocumento17 pagineGrinder PlansRobert Steven Ciaccio100% (1)

- Saw PlansDocumento19 pagineSaw PlansAnthony TwardowskiNessuna valutazione finora

- "Om-1" Kickover Tool: The "OM-1" Kickover Tool Is Used To Install and Retrieve Devices in 1 1/2" Side Pocket MandrelsDocumento1 pagina"Om-1" Kickover Tool: The "OM-1" Kickover Tool Is Used To Install and Retrieve Devices in 1 1/2" Side Pocket MandrelsEdwin AbelloNessuna valutazione finora

- Workshop AssignmentDocumento11 pagineWorkshop AssignmenttechnologicaluniversityyangonNessuna valutazione finora

- Kreg Mini Jig Product ManualDocumento2 pagineKreg Mini Jig Product ManualajaxleonNessuna valutazione finora

- Build ADIYLaminatorDocumento22 pagineBuild ADIYLaminatoredwin delgado riosNessuna valutazione finora

- Homemade GunDocumento2 pagineHomemade GunAldwin Apostol0% (2)

- Fazer ParafusoDocumento10 pagineFazer ParafusoZarcano FariasNessuna valutazione finora

- Jaco Mini PistolDocumento4 pagineJaco Mini Pistolmistermo100% (2)

- Podkop 1Documento20 paginePodkop 1Olin Stej80% (5)

- Home-Made Under Water Dredge 3" & 4": by Dale RussellDocumento1 paginaHome-Made Under Water Dredge 3" & 4": by Dale RussellJacqueline GordonNessuna valutazione finora

- Drill Organizer and BatteryDocumento6 pagineDrill Organizer and BatteryGhislainTremblayNessuna valutazione finora

- BG-272 Belt Grinder Bill of Materials - R1Documento7 pagineBG-272 Belt Grinder Bill of Materials - R1Leandro Bueno100% (1)

- 2pt4GHz Pringles Can AntennaDocumento2 pagine2pt4GHz Pringles Can Antennaanon-849268100% (2)

- Farm Equipment Welding PlansDocumento100 pagineFarm Equipment Welding Plansb0beiii100% (4)

- Steel Repair SleevesDocumento7 pagineSteel Repair SleevesErickNessuna valutazione finora

- OMC Roller Catalog PDFDocumento77 pagineOMC Roller Catalog PDFMarco ViniciusNessuna valutazione finora

- ATI Hole Micro Counter 2009 PDFDocumento11 pagineATI Hole Micro Counter 2009 PDFinammurad12Nessuna valutazione finora

- Home Made Faceting MachineDocumento7 pagineHome Made Faceting MachineGianluca Salvato100% (4)

- A Do-It-Yourself Manual Tire ChangerDocumento4 pagineA Do-It-Yourself Manual Tire ChangerHamzaNouman50% (2)

- 0987 C0 FF EETABleDocumento11 pagine0987 C0 FF EETABleKarel TrommelNessuna valutazione finora

- Tools and Materials:: Rojects Online: Building A Six-Sided GazeboDocumento8 pagineTools and Materials:: Rojects Online: Building A Six-Sided GazeboMara_Traistaru_808Nessuna valutazione finora

- The Pochade and Wet Panel Carrier Do It Yourself PlanDa EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanValutazione: 4 su 5 stelle4/5 (1)

- A Method of Dividing The Circumference of A CircleDocumento3 pagineA Method of Dividing The Circumference of A CirclekokiskoNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- SMD Electrolysis PDFDocumento1 paginaSMD Electrolysis PDFkokiskoNessuna valutazione finora

- Ball Turner Prints PDFDocumento10 pagineBall Turner Prints PDFkokiskoNessuna valutazione finora

- Ball Turner PrintsDocumento10 pagineBall Turner PrintskokiskoNessuna valutazione finora

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaDocumento32 pagineQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoNessuna valutazione finora

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaDocumento32 pagineQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoNessuna valutazione finora

- 1769 Compound Rest AssyDocumento1 pagina1769 Compound Rest AssykokiskoNessuna valutazione finora

- Anti-Gravity PropulsionDocumento16 pagineAnti-Gravity PropulsionTony FreelandNessuna valutazione finora

- Anti-Gravity PropulsionDocumento16 pagineAnti-Gravity PropulsionTony FreelandNessuna valutazione finora

- Assessing Potential Propulsion Breakthroughs: Marc G. MillisDocumento21 pagineAssessing Potential Propulsion Breakthroughs: Marc G. MillisnenucarqNessuna valutazione finora

- Mysteries of The Unknown - The UFO PhenomenonDocumento162 pagineMysteries of The Unknown - The UFO Phenomenonanaximandre06100% (3)

- UFODocumento2 pagineUFOkokiskoNessuna valutazione finora

- WO9010337 Magnetic MotorDocumento23 pagineWO9010337 Magnetic MotorAndras KondratNessuna valutazione finora

- Evading Thermal Imaging and Radar Detection-1Documento8 pagineEvading Thermal Imaging and Radar Detection-1kokiskoNessuna valutazione finora

- Cross Slide Nut ModificationDocumento3 pagineCross Slide Nut ModificationkokiskoNessuna valutazione finora

- RB 7x12 Minilathe BedwaysDocumento2 pagineRB 7x12 Minilathe BedwayskokiskoNessuna valutazione finora

- Drive TroubleshootingDocumento9 pagineDrive TroubleshootingkokiskoNessuna valutazione finora

- GAA Bortone June02Documento2 pagineGAA Bortone June02kokiskoNessuna valutazione finora

- Ralph Patterson Speed Reducer 2Documento27 pagineRalph Patterson Speed Reducer 2kokiskoNessuna valutazione finora

- Spindle, 7x10, 12 Mini LatheDocumento1 paginaSpindle, 7x10, 12 Mini LatheramaaramaaNessuna valutazione finora

- Ralph Patterson Tailstock Camlock 2Documento13 pagineRalph Patterson Tailstock Camlock 2supremesportsNessuna valutazione finora

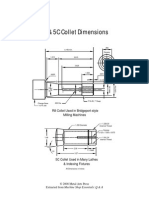

- r8 5c Collet DimensionsDocumento2 paginer8 5c Collet Dimensionskokisko100% (1)

- Morse Taper Dimensions and Drill Chuck ArborsDocumento4 pagineMorse Taper Dimensions and Drill Chuck ArborskokiskoNessuna valutazione finora

- Change Gears Charts For Metric Threading On The 7x MiniDocumento2 pagineChange Gears Charts For Metric Threading On The 7x MinikokiskoNessuna valutazione finora

- Rollies Dads MethodDocumento4 pagineRollies Dads Methodctin12Nessuna valutazione finora

- Ball Turning Toolpost - Complete PDFDocumento5 pagineBall Turning Toolpost - Complete PDFRamanujam O SNessuna valutazione finora

- How To Make Economical BateryDocumento85 pagineHow To Make Economical BaterykokiskoNessuna valutazione finora

- Drilling SpeedsDocumento3 pagineDrilling SpeedskokiskoNessuna valutazione finora

- Perreault, Bruce A. U.S. Patent Application Filed May 04, 2007Documento9 paginePerreault, Bruce A. U.S. Patent Application Filed May 04, 2007kokiskoNessuna valutazione finora