Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

7 Tank Process PDF

Caricato da

Parm S ChanderTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

7 Tank Process PDF

Caricato da

Parm S ChanderCopyright:

Formati disponibili

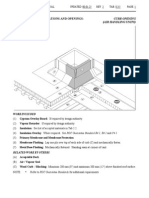

TANK-1 TANK-2 TANK-3 TANK-4 TANK-5 TANK-6 TANK-7 TANK-8 DEGREASING

DEGREASING WATER RINSE-I DERUSTING WATER RINSE-II SURFACE ACTIVATION PHOSPHATING WATER RINSE-III PASSIVATION Room Temperature Process, Duration-30-40 Minutes, For-Cleaning the Sheet Metal Surface of grease, oils, soils, lubricants, oxide films, Heat Treatment/welding Scales etc. by ALKALINE DEGREASER. Rinsing Process is Carried out. Room Temperature Process, Duration-20 Minutes, For-Cleaning The Sheet Metal Surface of Rust by Mixed HYDROCHLORIC ACID. Rinsing Process is Carried out. Room Temperature Process, Duration-20 Minutes, For-Activating the Sheet Metal Surface for Zn & Mn phosphate Coating by ACTIVATION CHEMICALS

WATER RINSE-I DERUSTING WATER RINSE-II SURFACE ACTIVATION

PHOSPHATING

Room Temperature Process, Duration-5-20 Minutes, For-Smooth & Uniform Coating of Sheet Metal Surface with Zn Phosphate by ZINC PHOSPHATE SOLUTION Rinsing Process is Carried out. Room Temperature Process, Duration-15-20 Minutes, For-Sealing Pores of Sheet Metal Surface for obtaining Maximum Corrosion Resistance over Phosphate Coating by DECXYLITE SOLUTION 150 Deg c Process, Duration-10-20 Minutes, For- Drying Sheet Metal Parts by HOT AIR. Done within 24 Hrs of Oven Drying, Sheet Metal parts are Coated with Powder of shade desired by client through Spraying in Spray Booths, and than Epoxy-Powder Coated/Sprayed Sheet Metal parts are BAKED in Electrically Fired Oven at 140-150 Deg c for 10-15 Minutes.

WATER RINSE-III PASSIVATION

OVEN DRYING POWDER COATING

Potrebbero piacerti anche

- BOM E - Bike Electrical V1.0Documento10 pagineBOM E - Bike Electrical V1.0SHUBHAM SRIVASTAVA100% (1)

- Project Report On Galvanisation PlantDocumento6 pagineProject Report On Galvanisation PlantEIRI Board of Consultants and PublishersNessuna valutazione finora

- Fevi KwikDocumento3 pagineFevi Kwiksuchisdhal100% (4)

- Acid ZN Plating Troubleshooting PDFDocumento2 pagineAcid ZN Plating Troubleshooting PDFhumbertotorresr71% (7)

- PPT Paint IndustryDocumento11 paginePPT Paint IndustryMohitNessuna valutazione finora

- Premie 300 User Manual (Secure), BGX501-747-R04Documento41 paginePremie 300 User Manual (Secure), BGX501-747-R04stark200671% (24)

- Comet New Gland Selection Chart PDFDocumento10 pagineComet New Gland Selection Chart PDFabhi05019185% (13)

- Project Report On Marketing of Industrial Paint 1Documento55 pagineProject Report On Marketing of Industrial Paint 1Pravin Patil100% (3)

- A List of Paint Companies in IndiaDocumento3 pagineA List of Paint Companies in Indiashabbir27110% (4)

- ME Report - Asian Paints - Sec F - Group 1 PDFDocumento12 pagineME Report - Asian Paints - Sec F - Group 1 PDFMaitresh Agarwal100% (2)

- Phenyl MakingDocumento4 paginePhenyl MakingVikram Ullal100% (6)

- MINDA Project ReportDocumento43 pagineMINDA Project ReportRupam10740100% (3)

- BSK 46 Materials - For - Automobiles11Documento62 pagineBSK 46 Materials - For - Automobiles11shuklahouse100% (1)

- Is 8811 1998Documento11 pagineIs 8811 1998kannankriv33% (3)

- 1977Documento11 pagine1977Vineet Krishan67% (3)

- Densons Cable Jointing Kit Price List PDFDocumento20 pagineDensons Cable Jointing Kit Price List PDFVishal Thakur100% (6)

- Sursulf Arcor enDocumento8 pagineSursulf Arcor enSinan YıldızNessuna valutazione finora

- Inspection and Test Plan For Piping (PP/FRP Piping)Documento2 pagineInspection and Test Plan For Piping (PP/FRP Piping)Anonymous EyK4vt6Y100% (1)

- Work Instruction GalDocumento31 pagineWork Instruction Galjasminnee100% (1)

- 05 Oct 2016 162027010RMERA9IVProjectReport-200000KLPAPaintPlantsmallDocumento45 pagine05 Oct 2016 162027010RMERA9IVProjectReport-200000KLPAPaintPlantsmallhamooyNessuna valutazione finora

- CedDocumento3 pagineCedMITHUN KUMAR BEHERA100% (1)

- NEW MPCB Selection ChartDocumento6 pagineNEW MPCB Selection ChartSamarendu Baul0% (1)

- APFC-Panel CalculationsDocumento4 pagineAPFC-Panel CalculationsJoshua Cm67% (3)

- Is 5 Shade CardDocumento23 pagineIs 5 Shade CardA.Subin Das50% (2)

- BOM FOR 300KVAr APFC PANELDocumento1 paginaBOM FOR 300KVAr APFC PANELHytech Pvt. Ltd.Nessuna valutazione finora

- Is 277 Galvanised Steel Sheets StandardsDocumento10 pagineIs 277 Galvanised Steel Sheets StandardsvikrantathavaleNessuna valutazione finora

- DWC ElecConduit Is 16205 P24 2018Documento11 pagineDWC ElecConduit Is 16205 P24 2018Vamsi Manoj60% (5)

- Is 694 2010Documento32 pagineIs 694 2010Rajdeep Adhya60% (5)

- Kranti List Feb 2021Documento1 paginaKranti List Feb 2021Himank Gupta0% (1)

- Ather Porosity Standard: Type Root Cause FeaturesDocumento8 pagineAther Porosity Standard: Type Root Cause FeaturesmaheshNessuna valutazione finora

- Masibus Digital Controller 5002uDocumento20 pagineMasibus Digital Controller 5002uSOURISH100% (2)

- SZ5 Leaflet PDFDocumento2 pagineSZ5 Leaflet PDFBS100% (1)

- PFI Step Calculation & Materials List With New PriceDocumento4 paginePFI Step Calculation & Materials List With New PriceMd. Biplob HossainNessuna valutazione finora

- Asian Paints: Submitted byDocumento10 pagineAsian Paints: Submitted byDeepak KumarNessuna valutazione finora

- Asian Paints ProjectDocumento23 pagineAsian Paints ProjectAbhishek Jagwani83% (6)

- CRCA (Cold Rolled Close Annealed Coils) Specifications: As Per IsDocumento2 pagineCRCA (Cold Rolled Close Annealed Coils) Specifications: As Per Isray_k_9177100% (9)

- Painting of BridgesDocumento4 paginePainting of Bridgesradhakrishnang100% (1)

- Ae 9000 Users ManualDocumento30 pagineAe 9000 Users ManualBhushan PAwar80% (5)

- TANK-1 TANK-2 TANK-3 TANK-4 TANK-5 TANK-6 TANK-7 TANK-8 DegreasingDocumento1 paginaTANK-1 TANK-2 TANK-3 TANK-4 TANK-5 TANK-6 TANK-7 TANK-8 DegreasingtooltechNessuna valutazione finora

- Analisa Laju Korosi Pada Baja Karbon Rendah Yang Dilapisi Seng Dengan Metode Hot Dip GalvanizingDocumento5 pagineAnalisa Laju Korosi Pada Baja Karbon Rendah Yang Dilapisi Seng Dengan Metode Hot Dip GalvanizingAlda Sadilillah RNessuna valutazione finora

- Low-Temperature Salt Bath Nitriding of SteelsDocumento5 pagineLow-Temperature Salt Bath Nitriding of SteelsUriel PeñaNessuna valutazione finora

- Powder Coating TrainingDocumento22 paginePowder Coating Trainingakash.vd.1603Nessuna valutazione finora

- Ceramic CoatingDocumento6 pagineCeramic Coatingemi222222Nessuna valutazione finora

- Spe 182514 MSDocumento15 pagineSpe 182514 MSJhormanNessuna valutazione finora

- Furnace Atmospheres No. 3: Gas Nitriding and NitrocarburisingDocumento48 pagineFurnace Atmospheres No. 3: Gas Nitriding and NitrocarburisingukalNessuna valutazione finora

- Surface TreatmentDocumento35 pagineSurface TreatmentAnshul VermaNessuna valutazione finora

- Thermal Fatigue Cracking of Surface Engineered Hot Work Tool SteelsDocumento12 pagineThermal Fatigue Cracking of Surface Engineered Hot Work Tool SteelsMely ReynaNessuna valutazione finora

- 7 Tank ProcessDocumento4 pagine7 Tank ProcessJalagandeeswaran Kalimuthu100% (1)

- Liquid NitridingDocumento7 pagineLiquid NitridingSenthil_kumar_palaniNessuna valutazione finora

- Innovative Technologies in Mould Release Agents: G.Natesh, A. ColoriDocumento4 pagineInnovative Technologies in Mould Release Agents: G.Natesh, A. ColoriLilian Jefferson MalavaziNessuna valutazione finora

- Modern Practices of Post Taphole Operation in Ferro Chrome Production and Its AdvantagesDocumento10 pagineModern Practices of Post Taphole Operation in Ferro Chrome Production and Its Advantagesschakra14Nessuna valutazione finora

- Painting Specification and ProcedureDocumento2 paginePainting Specification and Proceduresabir hussainNessuna valutazione finora

- Nitro Car Buri ZingDocumento9 pagineNitro Car Buri ZingJesus Alberto Perez AlvarezNessuna valutazione finora

- Aluminium Die Casting Lubrication Technology and Trends en v1Documento6 pagineAluminium Die Casting Lubrication Technology and Trends en v1g_nazario100% (1)

- Dip Zinc 7-Tank ProcessDocumento3 pagineDip Zinc 7-Tank ProcessAmit Chauhan100% (1)

- Copper Losses To Slags Obtained From The El Teniente ProcessDocumento6 pagineCopper Losses To Slags Obtained From The El Teniente ProcessCamila Espinoza SalasNessuna valutazione finora

- Chem 311 - Ceramics ReportDocumento35 pagineChem 311 - Ceramics ReportKier Deo NitafanNessuna valutazione finora

- Mscii 2Documento9 pagineMscii 2Vlad RytovNessuna valutazione finora

- Mscii 2Documento9 pagineMscii 2Sinan YıldızNessuna valutazione finora

- Debinding and Sintering Solutions For Metals and CeramicsDocumento8 pagineDebinding and Sintering Solutions For Metals and CeramicsdtkraeutNessuna valutazione finora

- Surface & Sub Surface Control of Cast Iron ComponentsDocumento22 pagineSurface & Sub Surface Control of Cast Iron ComponentsAditya PratapNessuna valutazione finora

- BS 5911-230-1994Documento19 pagineBS 5911-230-1994laurentiuNessuna valutazione finora

- JL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Documento20 pagineJL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Dong-Yong KimNessuna valutazione finora

- On Base PlateDocumento20 pagineOn Base PlateHemant SonawadekarNessuna valutazione finora

- CH 02 Load EstimationDocumento19 pagineCH 02 Load EstimationMuhammed FekryNessuna valutazione finora

- Material Science Cheatsheet For Midterm (NEWEST)Documento1 paginaMaterial Science Cheatsheet For Midterm (NEWEST)DillNessuna valutazione finora

- ASME General 100 QuestionsDocumento54 pagineASME General 100 Questionsatulpatil99100% (2)

- Technicalpresentation Mineraladmixtures 180611161645Documento20 pagineTechnicalpresentation Mineraladmixtures 180611161645Shubham ParmarNessuna valutazione finora

- No.2 Calculation of Pump Head. (Condenser Water) Air-Conditioning SystemDocumento1 paginaNo.2 Calculation of Pump Head. (Condenser Water) Air-Conditioning SystemRey ObiasNessuna valutazione finora

- Mahesabu Mikocheni - July2018Documento10 pagineMahesabu Mikocheni - July2018David SabaflyNessuna valutazione finora

- Solution of Shellside Pressure Drop and Heat Transfer by Stream Analysis MethodDocumento6 pagineSolution of Shellside Pressure Drop and Heat Transfer by Stream Analysis MethodacckypenrynNessuna valutazione finora

- Monitoring Pekerjaan Dan MaterialDocumento3 pagineMonitoring Pekerjaan Dan MaterialHarits Angga KusumaNessuna valutazione finora

- Socket Weld Fittings: ASME B16.11-2009 (Revision of ASME B16.11-2005)Documento1 paginaSocket Weld Fittings: ASME B16.11-2009 (Revision of ASME B16.11-2005)SIMON S. FLORES G.Nessuna valutazione finora

- Sifat Dan Pengujian RefraktoriDocumento28 pagineSifat Dan Pengujian RefraktoriAnggi ApriansyahNessuna valutazione finora

- PB02-HRH-001 Hot Reheat Steam SystemDocumento1 paginaPB02-HRH-001 Hot Reheat Steam SystemzhangNessuna valutazione finora

- Plasma or Flame Spraying SynthesisDocumento6 paginePlasma or Flame Spraying SynthesisOmeyya TanveerNessuna valutazione finora

- Slickline Basics.11 20Documento10 pagineSlickline Basics.11 20Rio de MarioNessuna valutazione finora

- Cyprus National Annex en 1993-1-1Documento11 pagineCyprus National Annex en 1993-1-1Atalay YordamNessuna valutazione finora

- RCABC Roof Curb Pentrations and OpeningsDocumento13 pagineRCABC Roof Curb Pentrations and OpeningsdomcristiniNessuna valutazione finora

- Blasting Painting ProcedureDocumento4 pagineBlasting Painting ProcedureRyanNessuna valutazione finora

- Significance of The Ratio of Tensile StrengthDocumento6 pagineSignificance of The Ratio of Tensile StrengthPaul Pinos-anNessuna valutazione finora

- The Impact of Using Specialist Geotechnical Software in Modeling of Pile Raft Foundation (PRF)Documento94 pagineThe Impact of Using Specialist Geotechnical Software in Modeling of Pile Raft Foundation (PRF)Haytham AlmaghariNessuna valutazione finora

- Green Buildings & Green Hospitals: 26 March 2010 KochiDocumento32 pagineGreen Buildings & Green Hospitals: 26 March 2010 KochiSrinivas GoudNessuna valutazione finora

- Astm A307Documento1 paginaAstm A307SAlman Khan100% (1)

- Construction Cost MonitoringDocumento13 pagineConstruction Cost MonitoringOng George Sammy100% (1)

- Daya Dukung - Pondasi DangkalDocumento34 pagineDaya Dukung - Pondasi DangkalRaditya PurnamahadiNessuna valutazione finora

- Equal Size PVC and XLPE Cable Comparison PDFDocumento1 paginaEqual Size PVC and XLPE Cable Comparison PDFMURALINessuna valutazione finora

- 3450 1 PDFDocumento20 pagine3450 1 PDFKen WalkerNessuna valutazione finora

- Astm D2447 (2001)Documento8 pagineAstm D2447 (2001)moustafaNessuna valutazione finora

- Welding Questions 1Documento26 pagineWelding Questions 1dselvakuuNessuna valutazione finora