Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Separator Calcs

Caricato da

Honey TiwariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Separator Calcs

Caricato da

Honey TiwariCopyright:

Formati disponibili

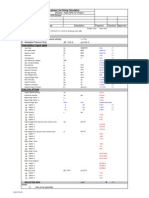

EXAMPLE 1: SIZE A 2-PHASE VERTICAL SEPARATOR

JOB SPECIFICATIONS: GAS Flow, MMSCFD MW Temp, deg F Pres, PSIG compressibility factor viscosity, cp ATM PRES PSIA LIQUID Flow, BPD specific gravity minimum level, in. SEPARATION remove drops >__micron Flow Character (slug, free, entrained, mist) APPLICATION TYPE: TYPE OF VESSEL: VESSEL CONFIGURATION: MIST EXTRACTOR: CALCULATIONS: 1. Calculate design specification information pg = (P+Pa)(MW) 10.73*(T+460)*(z) pl = 62.4(sp. gr.) Dp= 0.00003937(micron)/12 m=MMSCFD(1e6)(MW) 379.4(24)(3600) Qa=m/pg Ql=42W/7.481/86400 Qm=Qa+Ql pm=(pl*Ql+pg*Qg)/Qm 2. Calculate minimum diameter for gas capacity Method 1a: Equation 10 and Figure 8 CDRe^2 (Eq. 10) CD from Fig 8 Vt = (4gDp (rl-rg)/3CDrg)^0.5

2

12 22 120 600 0.9 0.012 14.7 50 0.5 8 150 free liquid intercept knockout vertical no

(shaded cells require input)

2.41 lb/cu ft 31.20 lb/cu ft 0.000492 ft 8.05 lb/sec 3.34 0.0032 3.34 2.44 acfs cu ft/sec cu ft/sec lb/cu ft

5464.84 1.70 0.38 ft/sec 39.9 in 3.5 ft

Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 Method 1b: Stokes' Law, Newton's Law, Intermediate Stokes' Law Re = 1488(DpVtrg)/m Vt = 1488gDp (rl-rg)/18m

2

Stokes' Law Not Applicable 227.85 1.546 ft/sec 19.9 in 2 ft

Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5

Newton's Law Re = 1488(DpVtrg)/m Vt = 1.74(gDp(rl-rg)/rg)^0.5 Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 Intermediate Range - Iteration Trial No. Assume CD Vt = (4gDp(rl-rg)/3CDrg)^0.5 Re = 1488(DpVtrg)/m Calculated CD Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5

Newton's Law Not Applicable 111.43 0.756 ft/sec 28.4 in 2.5 ft Intermediate Range Is Applicable 3 4 5 0.96 1.00 1.01 0.51 75.51 1.00 3 ft 0.50 73.84 1.01 0.50 73.43 1.02

1 0.34 0.86 126.82 0.80 35.0 in

2 0.80 0.56 82.90 0.96

3. Calculate vessel liquid capacity requirements Method 3a: Arnold-Stewart Vessel Diameter, dv Residence Time, t Liquid Height, h Lss = (h+76)/12 Lss = (h + dv + 40)/12 Vessel height S/S L/D Method 3b: Svrcek-Monnery Vessel Diameter hold up time, t1 hold up volume, Vh=60Ql*t1 surge time, t2 surge volume, Vs=60Ql*t2 low liquid level, Hlll norm liq level, Hh = Hnll-Hlll = 4*12Vh/pDv^2 high liquid level, Hs = Hhll-Hnll = 4*12Vs/pDv^2 inlet nozzle, dn=(4Qm/(p*60/pm^0.5))^0.5*12 centerline inlet, Hlin-Hhll=12+dn disengagement, Hd-Hlin=36+dn/2 mist extractor, Hme Vessel height, Ht=Hlll+Hnll+Hlin+Hdme L/D Method 3c. GPSA Engineering Databook Vessel Diameter Mist Extractor Depth Inlet Nozzle Diameter Mist Extractor Btm to Top Seam Disengagement Area = Greater of Dv or 24" inlet nozzle area, 2*(4Qm/(p*60/pm^0.5))^0.5*12 Level Gauge to Hi-Level SD (12-inch Min.) Level Gauge & Controller (12-inch Min.) Lo-Level SD to Level Gauge (12-inch Min.) Minimum Level Vessel height S/S L/D

36 3 0.965 6.4 6.4 6.4 2.167

in min in ft ft ft

6.5 ft

3 3 0.585 3 0.585 8 0.993 0.993 3.99 15.99 38.00 0.00 63.98 1.833

ft min cu ft min cu ft in in in in in in in in

5.5 ft

36 in 0 in 4 in 0 36 8 12 12 12 8 in in in in in in in

Time 36.3 min 36.3 min 36.3 min

88 in 2.500

7.5 ft

Not Applicable

ange Is Applicable 6 1.02 0.50 73.33 1.02

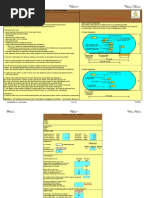

EXAMPLE 2: COMPARE 4 METHODS FOR DETERMINING DIAMETER

JOB SPECIFICATIONS: GAS Flow, MMSCFD MW Temp, deg F Pres, PSIG compressibility factor viscosity, cp ATM PRES PSIA LIQUID Flow, BPD specific gravity SEPARATION remove drops >__micron Flow Character (slug, free, entrained, mist) APPLICATION TYPE: TYPE OF VESSEL: VESSEL CONFIGURATION: MIST EXTRACTOR: CALCULATIONS: 1. Calculate design specification information pg = (P+Pa)(MW) 10.73*(T+460)*(z) pl = 62.4(sp. gr.) Dp= 0.00003937(micron)/12 m=MMSCFD(1e6)(MW) 379.4(24)(3600) Qa=m/pg Ql=42W/7.481/86400 Qm=Qa+Ql pm=(pl*Ql+pg*Qg)/Qm 2. Calculate minimum diameter for gas capacity Method 1: Equation 10 and Figure 8 CDRe^2 (Eq. 10) CD from Fig 8 Vt = (4gDp (rl-rg)/3CDrg)^0.5

2

12 22 120 600 0.9 0.012 14.7 50 0.5 150 free liquid intercept knockout vertical no

(shaded cells require input)

2.41 lb/cu ft 31.20 lb/cu ft 0.000492 ft 8.05 lb/sec 3.34 0.0032 3.34 2.44 acfs cu ft/sec cu ft/sec lb/cu ft

5464.84 1.30 0.44 ft/sec 37.3 in 3.5 ft

Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 Method 2: Souders-Brown with and without demister With Demister K (From Table) Vt=K((pl-pg)/pg)^0.5 Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 Without Demister K (From Table) Vt=K((pl-pg)/pg)^0.5

0.18 0.622 ft/sec 31.4 in 0.09 0.311 ft/sec 3 ft

Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 Method 3: Newton's Law Re = 1488(DpVtrg)/m Vt = 1.74(gDp(rl-rg)/rg)^0.5 Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 Method 4: Stokes' Law Re = 1488(DpVtrg)/m Vt = 1488gDp2(rl-rg)/18m Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 Intermediate Range - Iteration Trial No. Assume CD Vt = (4gDp(rl-rg)/3CDrg)^0.5 Re = 1488(DpVtrg)/m Calculated CD Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5

44.4 in

4 ft Newton's Law Not Applicable

111.43 0.756 ft/sec 28.4 in 2.5 ft Stokes' Law Not Applicable 227.85 1.546 ft/sec 19.9 in 2 ft Intermediate Range Is Applicable 3 4 0.96 1.00 0.51 75.51 1.00 3 ft 0.50 73.84 1.01

1 0.34 0.86 126.82 0.80 35.0 in

2 0.80 0.56 82.90 0.96

d cells require input)

n's Law Not Applicable

' Law Not Applicable

ediate Range Is Applicable 5 6 1.01 1.02 0.50 73.43 1.02 0.50 73.33 1.02

EXAMPLE 3: EXISTING SEPARATOR

JOB SPECIFICATIONS: GAS Flow, MMSCFD MW Temp, deg F Pres, PSIG compressibility factor viscosity, cp ATM PRES PSIA LIQUID Flow, BPD specific gravity SEPARATION diameter, ft CALCULATIONS: 1. Calculate design specification information pg = (P+Pa)(MW) 10.73*(T+460)*(z) pl = 62.4(sp. gr.) m=MMSCFD(1e6)(MW) 379.4(24)(3600) Qa=m/pg Ql=42W/7.481/86400 Qm=Qa+Ql pm=(pl*Ql+pg*Qg)/Qm 2. Calculate actual velocity Vt = Qa/A 3. Assume C D and calculate Dp until converged Trial No. Assume CD Dp = 3CDpgVt2/4g(pl-pg) Re = 1488(DpVtrg)/m Calculated CD Dp dm

12 22 120 600 0.9 0.012 14.7 50 0.5 3

(shaded cells require input)

2.41 lb/cu ft 31.20 lb/cu ft 8.05 lb/sec 3.34 0.0032 3.34 2.44 acfs cu ft/sec cu ft/sec lb/cu ft

0.47 ft/sec

1 0.34 20.90 2.14

2 2.14 131.82 0.78

3 0.78 48.15 1.27

4 1.27 78.11 0.99

0.000148 0.000933

0.000341 0.000553

0.000466 ft 142 micron

cells require input)

5 0.99 60.65 1.12

6 1.12 68.90 1.05

7 1.05 64.52 1.09

8 1.09 66.72 1.07

9 1.07 65.58 1.08

10 1.08 66.16 1.07

11 1.07 65.86 1.07

0.000429 0.000488 0.000457 0.000472 0.000464 0.000468 0.000466

EXAMPLE 4: SIZE A 2-PHASE HORIZONTAL SEPARATOR

JOB SPECIFICATIONS: GAS Flow, MMSCFD MW Temp, deg F Pres, PSIG compressibility factor viscosity, cp ATM PRES PSIA LIQUID Flow, BPD specific gravity minimum level, in. SEPARATION remove drops >__micron residence Time, min Flow Character (slug, free, entrained, mist) APPLICATION TYPE: TYPE OF VESSEL: VESSEL CONFIGURATION: MIST EXTRACTOR: CALCULATIONS: 1. Calculate design specification information pg = (P+Pa)(MW) 10.73*(T+460)*(z) pl = 62.4(sp. gr.) Dp= 0.00003937(micron)/12 m=MMSCFD(1e6)(MW) 379.4(24)(3600) Qa=m/pg Ql=42W/7.481/86400 Qm=Qa+Ql pm=(pl*Ql+pg*Qg)/Qm 2. Calculate minimum diameter for gas capacity Method 1a: Equation 10 and Figure 8 Souders-Brown K (From Table) Vt=K((pl-pg)/pg)^0.5 Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 Stokes' Law Re = 1488(DpVtrg)/m Vt = 1488gDp2(rl-rg)/18m Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 Newton's Law Re = 1488(DpVtrg)/m

12 22 120 600 0.9 0.012 14.7 5 0.5 8 150 3 free liquid intercept Inlet sep horizontal yes

(shaded cells require input)

API

151.5

2.41 lb/cu ft 31.20 lb/cu ft 0.000492 ft 8.05 lb/sec 3.34 0.0003 3.34 2.42 acfs cu ft/sec cu ft/sec lb/cu ft

0.4 1.381 ft/sec 21.0 in 2 ft Stokes' Law Not Applicable 227.85 1.546 ft/sec 19.9 in 2 ft Newton's Law Not Applicable 111.43

Vt = 1.74(gDp(rl-rg)/rg)^0.5 Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 Intermediate Range - Iteration Trial No. Assume CD Vt = (4gDp(rl-rg)/3CDrg)^0.5 Re = 1488(DpVtrg)/m Calculated CD Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 3. Calculate vessel liquid capacity requirements Leff and Lss for Gas Capacity Vessel Full - beta alpha dvLeff Leff Lss Leff and Lss for Liquid Capacity d^2*Leff Leff Lss Lss Lss/Dv

0.756 ft/sec 28.4 in 2.5 ft Intermediate Range Is Applicable 3 4 0.96 1.00 0.51 75.51 1.00 3 ft 0.50 73.84 1.01

1 0.34 0.86 126.82 0.80 35.0 in

2 0.80 0.56 82.90 0.96

50% 0.50 102.10 2.91 5.9

6 ft

21.4 0.02 0.02 6 2

0.5 ft

d cells require input)

' Law Not Applicable

n's Law Not Applicable

ediate Range Is Applicable 5 6 1.01 1.02 0.50 73.43 1.02 0.50 73.33 1.02

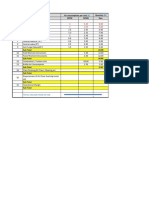

EXAMPLE 4: SIZE A 3-PHASE HORIZONTAL SEPARATOR

Gas Flowrate (MMSCFD) Oil Flowrate (BOPD) Water Flowrate (BWPD) Total Liquid (BPD) ATM Press. Op Press (psig) Op Temp (F) Gas Compressibility Z Retention Time (min) t Remove drops >__micron from gas Remove H2O drops >__micron from oil Remove oil drops >__micron from H2O Vessel Liquid Level - beta 1. Calculate design specification information rg = (P+Pa)(MW) 10.73*(T+460)*(z) rl = 62.4(sp. gr.) rw = 62.4(sp. Gr H2O.) Dp= 0.00003937(micron)/12 Dw= 0.00003937(micron)/12 Do = 0.00003937(micron)/12 m=MMSCFD(1e6)(MW) 379.4(24)(3600) Qa=m/rg Ql Qw Qm=Qa+Ql+Qw pm=(rl*Ql+rg*Qg+rw*Qw)/Qm Fractional area of liquids - alpha 2. Calculate C D and min diameter Trial No. Assume CD Vt = (4gDp(rl-rg)/3CDrg)^0.5 Re = 1488(DpVtrg)/m Calculated CD Minimum dia.= 12*(TZQg/2.4Vt(P+Pa))^0.5 3. Determine the fractional height of water in the vessel Fractional area of water aw=atQw/t(Qw+Ql) 0.250 Fractional height of water bw 0.298 Fractional area of water aw 0.250 4. Calculate max vessel diameter for water settling Vtw = 1488gDw2(pw-pl)/18ml 0.03 Max Height of Oil Pad, Ho 57.93 Maximum diameter = Ho/(b-bw) 287 12.00 500 500 1000.00 14.7 600.00 120 0.90 3.00 150 500 200 50% Gas MW Oil S.G. Water S.G. 22 0.5 1.1

2.41 31.20 68.64 0.000492 0.001640 0.000656 8.05 3.34 0.0325 0.0325 3.40 3.32 0.50

lb/cu ft lb/cu ft lb/cu ft ft ft ft lb/sec acfs cu ft/sec cu ft/sec cu ft/sec lb/cu ft

1 2.01 0.35 52.16 1.22 35.1 in

2 1.22 0.46 67.07 1.06

3 1.06 0.49 71.69 1.03 36

change until above matches below

ft/sec in max in max

5. Calculate max vessel diameter for oil settling Vtw = 1488gDw2(pw-pl)/18mw Max Height of water, Hw Maximum diameter = Hw/bw Maximum Vessel Diameter

0.0429 92.68 311 287

ft/sec in max in max 282

6. Calculate vessel gas and liquid capacity requirements dvLeff (for gas capacity) 102.12 dv^2*Leff (for liquid capacity) 4286 7. Determine appropriate diameter and S-S length Diameter (in) Leff (gas) Lss (gas) Leff (liquid) Lss (liquid) Lss (ft) L/D

36 2.84 5.84 3.31 4.41 6 2.00

42 2.43 5.93 2.43 3.24 6 1.71

48 2.13 6.13 1.86 2.48 7 1.63

Gas Viscosity m Oil Viscosity ml H2O Viscosity mw

0.012 10 1

cp cp cp

4 1.03 0.49 72.89 1.02 in

5 1.02 0.50 73.20 1.02

6 1.02 0.50 73.27 1.02

matches below

in

54 1.89 6.39 1.47 1.96 7 1.44

60 1.70 6.70 1.19 1.59 7 1.40

66 1.55 7.05 0.98 1.31 8 1.36

Potrebbero piacerti anche

- 3 Phase Separator SpreadsheetDocumento5 pagine3 Phase Separator SpreadsheetMaryJane Ayisha Sado-Obah100% (1)

- Demister Sizing Using Normal Flow Conversion:: Customer: Enquiry No: Item No: DateDocumento3 pagineDemister Sizing Using Normal Flow Conversion:: Customer: Enquiry No: Item No: Daterakesh3487100% (2)

- Seperator Sizing v3Documento5 pagineSeperator Sizing v3camasa2011Nessuna valutazione finora

- CBE 417 FlashDrumSizing WankatDocumento7 pagineCBE 417 FlashDrumSizing WankatRahmansyah GaekNessuna valutazione finora

- Vertical Separator SizingDocumento4 pagineVertical Separator SizingSyed Waqas HaiderNessuna valutazione finora

- HX Design v1Documento12 pagineHX Design v1mansourotaibiNessuna valutazione finora

- Separator SizingDocumento9 pagineSeparator SizingTolstoy LeoNessuna valutazione finora

- Horizontal Three Phase Separator vap-IPDocumento5 pagineHorizontal Three Phase Separator vap-IPasifhameed1100% (8)

- Spreadsheet To Design SeparatorsDocumento21 pagineSpreadsheet To Design SeparatorsreninbabaskiNessuna valutazione finora

- Three Phase Separator Sizing - Overflow WeirDocumento2 pagineThree Phase Separator Sizing - Overflow WeirSaeid Rahimi MofradNessuna valutazione finora

- Three Phase Separator Sizing (Double Weir 2)Documento3 pagineThree Phase Separator Sizing (Double Weir 2)12377466790% (2)

- Line Sizing With Api RP 14E Sizing For Liquid LinesDocumento5 pagineLine Sizing With Api RP 14E Sizing For Liquid LinesArief Rahman DhuhriNessuna valutazione finora

- Datasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsDocumento1 paginaDatasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsAnonymous LLLK3pq50% (2)

- Vertical Knock Out Drum With Wire Mesh For NDocumento1 paginaVertical Knock Out Drum With Wire Mesh For Nteegala_1950% (2)

- Three Phase Separator Sizing (Double Weir 1)Documento3 pagineThree Phase Separator Sizing (Double Weir 1)Saeid Rahimi MofradNessuna valutazione finora

- Liquid Hold Up Change and Slug Catcher SizingDocumento2 pagineLiquid Hold Up Change and Slug Catcher SizingEbby Onyekwe100% (1)

- Three Phase Separator Sizing - Submerged WierDocumento2 pagineThree Phase Separator Sizing - Submerged WierSaeid Rahimi MofradNessuna valutazione finora

- Horizontal 2 Phase Separator SizingDocumento10 pagineHorizontal 2 Phase Separator SizingJermaine Heath100% (1)

- Filter Separator SizingDocumento3 pagineFilter Separator SizingChem.EnggNessuna valutazione finora

- Knock Out KO Drum SizingDocumento10 pagineKnock Out KO Drum SizingJermaine HeathNessuna valutazione finora

- Fuel Gas ScrubberDocumento2 pagineFuel Gas ScrubberToyin100% (3)

- Heater Treater CalculationDocumento12 pagineHeater Treater Calculationwahyu100% (1)

- Flare Ko Drum SizingDocumento5 pagineFlare Ko Drum SizingSujith Sekar100% (2)

- Three Phase Separator Sizing - Bucket & PipeDocumento2 pagineThree Phase Separator Sizing - Bucket & PipeSaeid Rahimi MofradNessuna valutazione finora

- Gas-Liquid Line SizingDocumento1 paginaGas-Liquid Line Sizingagusnnn100% (2)

- Two Phase Beggs BrillDocumento4 pagineTwo Phase Beggs BrillOsmund MwangupiliNessuna valutazione finora

- Pump (English) TemplateDocumento1 paginaPump (English) TemplateMichael HaiseNessuna valutazione finora

- Three Phase Separator Sizing - Boot & WeirDocumento2 pagineThree Phase Separator Sizing - Boot & WeirSaeid Rahimi MofradNessuna valutazione finora

- Gas-Liquid Vertical Separator PDFDocumento2 pagineGas-Liquid Vertical Separator PDFRathish RagooNessuna valutazione finora

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocumento5 pagineSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierNessuna valutazione finora

- Three Phase Separator Sizing - No InternalDocumento2 pagineThree Phase Separator Sizing - No InternalSaeid Rahimi MofradNessuna valutazione finora

- Fdocuments - in Separator Sizing SpreadsheetDocumento31 pagineFdocuments - in Separator Sizing SpreadsheetGabrielito PachacamaNessuna valutazione finora

- Spreadsheet To Design SeparatorsDocumento21 pagineSpreadsheet To Design Separatorsgrabetty100% (3)

- Data Sheet Ejector PDFDocumento1 paginaData Sheet Ejector PDFAishwaria KhanNessuna valutazione finora

- Line Sizing - 2PHASEDocumento11 pagineLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Master - Three Phase Horizontal Separator Rev 0Documento6 pagineMaster - Three Phase Horizontal Separator Rev 0Naeem HussainNessuna valutazione finora

- FGCP Line Sizing CalculationsDocumento86 pagineFGCP Line Sizing CalculationsToyinNessuna valutazione finora

- Separator DesignDocumento3 pagineSeparator Designsondung4ver80% (5)

- Vertical Separator SizingDocumento4 pagineVertical Separator SizingnemprrNessuna valutazione finora

- Slug CatcherDocumento2 pagineSlug CatcherToyinNessuna valutazione finora

- KIRK Sep-Calc SoftwareDocumento4 pagineKIRK Sep-Calc Softwaredhl_tuNessuna valutazione finora

- API 12j SizingDocumento8 pagineAPI 12j SizingsegunoyesNessuna valutazione finora

- Liquid Line SizingDocumento12 pagineLiquid Line Sizinglolofm25Nessuna valutazione finora

- Heat Conduction Pipe InsulationDocumento1 paginaHeat Conduction Pipe InsulationJogender DhayalNessuna valutazione finora

- HCL Scrubber DesignDocumento5 pagineHCL Scrubber DesignManish0301198375% (4)

- Maz - Design - Separator Capacity EvaluationDocumento5 pagineMaz - Design - Separator Capacity EvaluationNaeem HussainNessuna valutazione finora

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Documento1 paginaTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456Nessuna valutazione finora

- Flare KOD SizingDocumento4 pagineFlare KOD SizingSaid Ahmed Salem100% (1)

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDocumento20 pagineExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsLeonardo Ramirez GuzmanNessuna valutazione finora

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDocumento20 pagineExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsagusnnnNessuna valutazione finora

- 432 ProjectDocumento19 pagine432 ProjectjnmanivannanNessuna valutazione finora

- Spice ModelDocumento13 pagineSpice ModelJoyprakash LairenlakpamNessuna valutazione finora

- Solution Ch8Documento15 pagineSolution Ch8Anonymous ou6LhnW6qv100% (2)

- Drilling Formulars 2Documento4 pagineDrilling Formulars 2Ebenezer Amoah-KyeiNessuna valutazione finora

- CALIB053 - Mathcad 15 EquationsDocumento8 pagineCALIB053 - Mathcad 15 Equationsilie_vlassaNessuna valutazione finora

- R-Pump Cal Sheet2Documento3 pagineR-Pump Cal Sheet2ggdgdfgdfgdfgdgddddNessuna valutazione finora

- Tema Nozzle LoadDocumento4 pagineTema Nozzle LoadkanhuNessuna valutazione finora

- Orifice Size Calculation: A. Input DataDocumento5 pagineOrifice Size Calculation: A. Input DatakangrimNessuna valutazione finora

- Chapter 12 SolutionsDocumento27 pagineChapter 12 Solutionsantant30520% (1)

- Fluid Mechanics D203 Sae Solutions Tutorial 2 - Applications of Bernoulli Self Assessment Exercise 3Documento5 pagineFluid Mechanics D203 Sae Solutions Tutorial 2 - Applications of Bernoulli Self Assessment Exercise 3nanduslns07Nessuna valutazione finora

- PPP Prospectus 8 12 19 1Documento18 paginePPP Prospectus 8 12 19 1Honey Tiwari100% (1)

- Air Cooled HX Data SheetDocumento1 paginaAir Cooled HX Data SheetHoney TiwariNessuna valutazione finora

- PRESS RELEASE Round3 RFQ PDFDocumento2 paginePRESS RELEASE Round3 RFQ PDFHoney TiwariNessuna valutazione finora

- As On 31.01.2014 Target For 31.03.2017: 1. Facts & FiguresDocumento2 pagineAs On 31.01.2014 Target For 31.03.2017: 1. Facts & FiguresHoney TiwariNessuna valutazione finora

- Fluor Daniel India Private LimitedDocumento1 paginaFluor Daniel India Private LimitedHoney Tiwari100% (1)

- Compressor Capacity CalculationDocumento4 pagineCompressor Capacity CalculationHoney Tiwari100% (1)

- Seal Gas Conditioning Skid To Solar Tie-In DWG No. 3P961-149446 / SHEET 8 OF 20 Rev BDocumento1 paginaSeal Gas Conditioning Skid To Solar Tie-In DWG No. 3P961-149446 / SHEET 8 OF 20 Rev BHoney TiwariNessuna valutazione finora

- Emission Standards Diesel Engin Upto 800 PDFDocumento4 pagineEmission Standards Diesel Engin Upto 800 PDFHoney TiwariNessuna valutazione finora

- Ventilation Calculation For Inverter RoomDocumento1 paginaVentilation Calculation For Inverter RoomHoney TiwariNessuna valutazione finora

- Heat Load CalculationsDocumento6 pagineHeat Load CalculationsHoney Tiwari0% (1)

- Rules of Thumb PDFDocumento2 pagineRules of Thumb PDFHoney Tiwari100% (1)

- Coulson& Richardson - Cap.10 Gas-Liquid Separation PDFDocumento6 pagineCoulson& Richardson - Cap.10 Gas-Liquid Separation PDFHoney TiwariNessuna valutazione finora

- CPCB DG Set Noise Emission NormsDocumento6 pagineCPCB DG Set Noise Emission NormsRSNessuna valutazione finora

- Stack SpecDocumento10 pagineStack SpecHoney TiwariNessuna valutazione finora

- Elite Cranes - Hoists Catalogue PDFDocumento2 pagineElite Cranes - Hoists Catalogue PDFHoney TiwariNessuna valutazione finora

- Pressure Drop AND HEADDocumento2 paginePressure Drop AND HEADHoney TiwariNessuna valutazione finora

- Air Cooled Condenser ACC PDFDocumento3 pagineAir Cooled Condenser ACC PDFHoney TiwariNessuna valutazione finora

- Title of Proposal in Initial Capital Letters: Times New Roman (18 Point Boldface)Documento8 pagineTitle of Proposal in Initial Capital Letters: Times New Roman (18 Point Boldface)AidaAkieNessuna valutazione finora

- Selecting A Cooling Fan: Device CharacteristicsDocumento4 pagineSelecting A Cooling Fan: Device CharacteristicsGary KerrNessuna valutazione finora

- Curve of MD Fire Main PumpDocumento1 paginaCurve of MD Fire Main PumpHoney TiwariNessuna valutazione finora

- L Ecture III Signoracci PDFDocumento25 pagineL Ecture III Signoracci PDFArmagaddonNessuna valutazione finora

- Symmetry Boundary ConditionsDocumento9 pagineSymmetry Boundary ConditionsJohn ChivNessuna valutazione finora

- Deflection of Structures Using Modified Betti's TheoremDocumento5 pagineDeflection of Structures Using Modified Betti's TheoremfaumijkNessuna valutazione finora

- Soal Midtest - Okt-20091 PDFDocumento1 paginaSoal Midtest - Okt-20091 PDFOtta Gaima SembiringNessuna valutazione finora

- Unit 10-Short QuestionsDocumento5 pagineUnit 10-Short QuestionssajjaddrNessuna valutazione finora

- Module 5.2b: Gas Laws Part 2Documento26 pagineModule 5.2b: Gas Laws Part 2Ryan PazonNessuna valutazione finora

- Tzempelikos D. Et Al - Airflow Patterns in A Laboratory Batch-Type, Tray Air Dryer - Ic-Scce2012 - ProceedingsDocumento10 pagineTzempelikos D. Et Al - Airflow Patterns in A Laboratory Batch-Type, Tray Air Dryer - Ic-Scce2012 - ProceedingsAndronikos FiliosNessuna valutazione finora

- Lecture3 PartBDocumento61 pagineLecture3 PartBDiogo CecinNessuna valutazione finora

- Module 8 - FrictionDocumento17 pagineModule 8 - FrictionMadelar, Arc Francis C.Nessuna valutazione finora

- ForensicPhysics - Falls From HeightDocumento5 pagineForensicPhysics - Falls From HeightSanja KrajinovicNessuna valutazione finora

- Second and Third Laws of Thermo 2020Documento100 pagineSecond and Third Laws of Thermo 2020Michael AttehNessuna valutazione finora

- WTT 2 MarksDocumento10 pagineWTT 2 MarksSwetha SharmaNessuna valutazione finora

- Shaft Design Flow ChartDocumento49 pagineShaft Design Flow ChartalexwnNessuna valutazione finora

- Physics 712 ND LE1 Stsem 20112012Documento12 paginePhysics 712 ND LE1 Stsem 20112012Alexis Julia CanariaNessuna valutazione finora

- 7,3 020ROUGS4 Chapter7 PavementDesign Part3Documento27 pagine7,3 020ROUGS4 Chapter7 PavementDesign Part3fadi eidNessuna valutazione finora

- Lecture Notes 6: The Method of ImagesDocumento20 pagineLecture Notes 6: The Method of ImagesZoricaNessuna valutazione finora

- Defect Types and Non-Destructive Testing Techniques For Composites and Bonded JointsDocumento19 pagineDefect Types and Non-Destructive Testing Techniques For Composites and Bonded JointsShanker PandeyNessuna valutazione finora

- Temp Measurement PPT 2020Documento57 pagineTemp Measurement PPT 20202K18/AE/049 SARTHAK THAREJANessuna valutazione finora

- Ec. de Martin PDFDocumento17 pagineEc. de Martin PDFMaggyBalcazarNessuna valutazione finora

- Mini Frac Test ProjectDocumento32 pagineMini Frac Test Projectgodrich1Nessuna valutazione finora

- PDF 2 DocxDocumento3 paginePDF 2 DocxArsal MaqboolNessuna valutazione finora

- Van Deemter EquationDocumento19 pagineVan Deemter EquationAsif AliNessuna valutazione finora

- Module 2 Answered 1Documento35 pagineModule 2 Answered 1Ralph A. PastranaNessuna valutazione finora

- Step 1: Join Here! For Free Chegg Unlocks Wallstreetbets - Https://Discord - Gg/Upqesafsyu (Https://Discord - Gg/Upqesafsyu)Documento5 pagineStep 1: Join Here! For Free Chegg Unlocks Wallstreetbets - Https://Discord - Gg/Upqesafsyu (Https://Discord - Gg/Upqesafsyu)Muhammad AsifNessuna valutazione finora

- Trihedron TNB Frame PDFDocumento43 pagineTrihedron TNB Frame PDFAneelaNessuna valutazione finora

- IIT-Madras, Momentum Transfer: July 2005-Dec 2005Documento23 pagineIIT-Madras, Momentum Transfer: July 2005-Dec 2005Rehan UmerNessuna valutazione finora

- Effective-Stress Analysis of Berm-Supported Retaining WallsDocumento10 pagineEffective-Stress Analysis of Berm-Supported Retaining WallsDerek WongNessuna valutazione finora

- Solutions: Please Direct Any Questions To The Forum On The Openedx Courseware PageDocumento3 pagineSolutions: Please Direct Any Questions To The Forum On The Openedx Courseware PageMazen A. TaherNessuna valutazione finora

- Faustus Teacher GuideDocumento14 pagineFaustus Teacher GuideZACHARY DENGNessuna valutazione finora