Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PLC Presentation 1

Caricato da

Prittam Kumar JenaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PLC Presentation 1

Caricato da

Prittam Kumar JenaCopyright:

Formati disponibili

Programmable Logic Controller

EVOLUTION OF PLC HARD WIRED CONTROL HARD WIRED SOLID STATE CONTROLLER PROGRAMMABLE LOGIC CONTROLLER HARD-WIRED CONTROL THE CONTROL TASKS WERE SOLVED WITH CONTACTOR OR RELAY CONTROL. CIRCUIT DIAGRAM HAD TO BE DESIGNED. ELECTRICAL COMPONENT INSTALLED. WIRING LIST CREATED. WIRE THE COMPONENTS NECESSARY TO PERFORM A SPECIFIC TASK.

Programmable Logic Controller

HARD-WIRED CONTROL

THE CONTROL TASKS WERE SOLVED WITH CONTACTOR OR RELAY CONTROL. CIRCUIT DIAGRAM HAD TO BE DESIGNED. ELECTRICAL COMPONENT TO BE INSTALLED. WIRING LIST TO BE CREATED. WIRE THE COMPONENTS NECESSARY TO PERFORM A SPECIFIC TASK.

Programmable Logic Controller

HARD-WIRED CONTROL ADVANTAGE

RELATIVELY SIMPLE LOW INITIAL COST SMALL LOGIC COULD BE IMPLEMENTED MUCH FASTER.

DISADVANTAGE

CHANGE IN FUNCTION OR SYSTEM EXPANSION REQUIRED EXTENSIVE COMPONENT CHANGE AND REWIRING. SPACE REQUIRED IS MORE. DIAGNOSTICS BECOMES DIFFICULT FOR COMPLEX LOGIC

Programmable Logic Controller

HARDWIRED SOLID STATE CONTROLLER SYSTEM CONSISTING OF ELECTRONIC LOGIC DEVICES HARDWIRED IN A SPECIFIC CONFIGURATION. ADVANTAGES SMALLER IN SIZE COMPARED TO RELAY LOGIC LOW POWER CONSUMPTION. ALLOWS ON LINE TESTING OF I/O CIRCUITS MANUALLY OR AUTOMATICALLY. DISADVANTAGES DISCRETE COMPONENTS. CONTROLLED ENVIRONMENT NEEDED. NO WATCH DOG TIMER AVAILABLE.

Programmable Logic Controller

DEFINITION :

A PROGRAMMABLE CONTROLLER IS A SOLID STATE CONTROLLER THAT MONITORS THE STATUS OF DEVICES CONNECTED AS INPUTS. BASED UPON A USER WRITTEN PROGRAM, STORED IN ITS MEMORY, IT CONTROLS THE STATUS OF DEVICES CONNECTED AS OUTPUTS.

Programmable Logic Controller

PLC INTRODUCTION:

MODICON INTRODUCED THE FIRST PLC IN 1969 AS A REPLACEMENT FOR THE MASSIVE, HARDWIRED RELAY PANELS USED IN MANUFACTURING PLANTS TO CONTROL MACHINE TOOLS AND ASSEMBLY LINES. THE NOVEL FEATURE OF THIS NEW DEVICE IS THAT IT IS PROGRAMMABLE. IT SAVES FACTORY FLOOR SPACE BY REPLACING THE RELAY BASED SYSTEM. IT IS ALSO RE-PROGRAMMABLE FOR A DIFFERENT APPLICATION. AN IMPROVEMENT OVER HARD-WIRED SYSTEMS.

Programmable Logic Controller

ADVANTAGES

COST EFFECTIVE FOR CONTROLLING COMPLEX SYSTEMS. FLEXIBLE AND CAN BE REAPPLIED TO CONTROL OTHER SYSTEMS QUICKLY AND EASILY. COMPUTATIONAL ABILITIES ALLOW MORE SOPHISTICATED CONTROL. TROUBLESHOOTING AIDS MAKE PROGRAMMING EASIER AND REDUCE DOWNTIME. RELIABLE COMPONENTS MAKE THESE LIKELY TO OPERATE FOR YEARS BEFORE FAILURE. PLCS HAVE INTEGRATED DIAGNOSTICS AND OVERRIDE FUNCTIONS. DIAGNOSTICS ARE CENTRALLY AVAILABLE.

Programmable Logic Controller

ARCHITECTURE

Communication Port

PUSH BUTTON PROXIMITY SWITCH

I N P U T S

CENTRAL PROCESSOR

O U T P U T S

SOLENOID VALVE LAMP

High Voltage MEMORY

High Voltage

Program Low Voltage AC Power Supply 85264 VAC, 50/60Hz OR

Data

DC power Supply

Programmable Logic Controller

PLC OPERATING CYCLE

START House Keeping

Input Scan

Output Scan

Program Scan

Programmable Logic Controller

INPUT PROCESSING:

DURING I/P SCAN THE PLC READS THE ON/OFF STATUS OF INPUTS & STORES THEM IN THE I/P IMAGE MEMORY BEFORE EXECUTION OF PROGRAM.THIS INFORMATION IS STORED & HELD VALID TILL THE NEXT SCAN OF INPUT MODULE.NO CHANGE IN STATUS IS ACKNOWLEDGED IN BETWEEN SCAN SEQUENCE.

Inputs

I/P MODULE

Read in

I/P IMAGE MEMORY IN CPU

Programmable Logic Controller

PROGRAM PROCESSING:

THE PLC EXECUTES THE USER PROGRAM TAKING INTO CONSIDERATION THE STATUS FROM IMAGE MEMORIES & NOT THAT OF ACTUAL PHYSICAL ELEMENTS. DEPENDING UPON THE LOGIC,THE O/P IMAGE MEMORY IS UPDATED AS THE PROGRAM EXECUTION PROGRESSES & RESULT IS CONVEYED TO THE CPU MEMORY FOR INTERMEDIATE STORAGE. I/P IMAGE MEMORY IN CPU LOGIC PROCESSING IN UMC O/P IMAGE MEMORY IN CPU

Programmable Logic Controller

OUTPUT PROCESSING:

ON COMPLETING THE EXECUTION OF ALL INSTRUCTIONS (LOGIC SCAN) THE ABOVE STORED OUTPUT IMAGE MEMORY IS TRANSFERRED TO OUTPUT MODULE WHICH WILL PHYSICALLY CHANGE THE STATUS OF THE OUTPUT ON THE PLC MODULE. O/P IMAGE MEMORY IN IN CPU

Write out

O/P MODULE

Output

Programmable Logic Controller

FLOW CHART:

A FLOW CHART IS A GRAPHICAL TOOL USED TO CREATING THE STRUCTURE OF A PROGRAM. A FLOW CHART OF A SINGLE SCAN ALWAYS BEGINS WITH READING THE INPUTS & UPDATING THE INPUT IMAGE,OR BUFFER,& ENDS WITH READING THE OUTPUT IMAGE & UPDATING THE OUTPUTS. THE FLOW OF INFORMATION,PRODUCT,TIME CAN ALSO SHOWN AS LINE LEADING FROM ONE EVENT OR PROCESS TO ANOTHER.

Programmable Logic Controller

FLOW CHART OF A PLC SCAN

READ INPUTS

UPDATE INPUT IMAGE

EVALUATE LADDER LOGIC UPDATE OUTPUT IMAGE

READ OUTPUT IMAGE

UPDATE OUTPUTS

Programmable Logic Controller

PLC LADDER LOGIC IS A COMPUTER PROGRAM USED TO REPRESENT THE LOGIC TO BE EXECUTED. THE LADDER LOGIC IS EXECUTED SEQUENTIALLY AND REPETITIVELY. THE INPUT CANNOT PRODUCE AN RESPONSE UNTIL THE PLC HAS COMPLETED THE SEQUENCE OF OPERATION

Programmable Logic Controller

RELAY LOGIC LADDER LOGIC

REPRESENTATION OF REPRESENTATION OF LOGIC IS FROM TOP LOGIC IS FROM LEFT TO TO BOTTOM RIGHT THE EXECUTION OF THE EXECUTION OF LOGIC IS LOGIC IS SIMULTANEOUSLY SEQUENTIALLY AND REPETITIVELY CALCULATION,COMP CALCULATION,COMPAR ARISION IS NOT ISION IS POSSIBLE IN POSSIBLE IN RELAY LADDER LOGIC LOGIC

Programmable Logic Controller

APPLICATION EXAMPLE:

START\STOP CIRCUIT FOR MOTOR: THIS IS USED TO START A DEVICE WITH A MOMENTARY INPUT. ONCE START PUSHBUTTON IS PRESSED,THE INPUT ENERGIZE INSTRUCTION WILL STAY ON UNTIL THE MOMENTARY STOP PUSHBUTTON IS PRESSED. OPERATION: TURN ON AN OUTPUT WITH A MOMENTARY INPUT, & KEEP IT ON UNTIL INSTRUCTED TO TURN IT OFF.

Programmable Logic Controller

START THE MOTOR BY PRESSING THE START PUSHBUTTON. KEEP THE MOTOR RUNNING UNTIL STOP PUSHBUTTON IS PRESSED.

STOP I0

START

I1

O/0

( )

O/0

MOTOR STARTER

Programmable Logic Controller

Ladder Logic:

The logic used to perform this consist of one rung. In this example the stop push button is normally closed switch but is programmed as a normally open instruction.

Rung 0

Before any instructions are activated N.O. instruction I\O is true(since a N.C. pushbutton is wired to a input terminal I\O & that pushbutton has not been pushed) & N.O. instruction I\I is false.

Programmable Logic Controller

RUNG 0 WHEN THE START PUSH BUTTON IS PRESSED N.O. INSTRUCTION I\I BECOMES TRUE, ENERGISING OUTPUT O\0. THE TRUE STATUS OF CONTROL INSTRUCTION O\0 IS REFLECTED IN N.O.CONDITION INSTRUCTION O\0,WHICH IS PROGRAMMED IN PARALLEL WITH THE START INSTRUCTION. THIS KEEPS THE OUTPUT ON EVEN WHEN I\I IS NO LONGER TRUE. WHEN THE STOP BUTTON IS PRESSED,N.O. INSTRUCTION I\O BECOMES FALSE, & THE OUTPUT IS DE-ENERGISED.

Programmable Logic Controller

Typical Input Card Circuit:

Opto Isolation 1 2

Processing Circuit 3

To-Processor 4

Field device & Input Filtering

LED Indication

Programmable Logic Controller

Typical Output Card Circuit:

Output Driving Circuit

Processing Circuit

1 2

Opto Isolation

3

Processor (CPU)

LED Indication

Programmable Logic Controller

APPLICATIONS OF PLC:

BUILDING CONTROLS: ANTI- THEFT SYSTEMS, ESCALATORS, GARAGE DOOR OPENERS, INDUSTRIAL ELEVATORS AND LIFTS, LIGHTING CONTROL. CHEMICAL PROCESSING EQUIPMENT: ANODIZING EQUIPMENT, ASPHALT EQUIPMENT & CHEMICAL KILNS. CIVIL ENGINEERING APPLICATIONS: AUTOMATIC WINDOW WASHERS, LOCK CONTROLS, PARKING LOT CONTROL, RAILROAD CROSSING CONTROL, STREET LIGHTING & TRAFFIC CONTROL. FURNACES , BURNERS , AND DRYERS: BOILER & BURNER MANAGEMENT , DRYING EQUIPMENT, INDUSTRIAL PROCESS FURNACES. GENERAL INDUSTRY EQUIPMENT: AIR COMPRESSOR, BOTTLE FILLERS, INDUSTRIAL CENTRIFUGES, LABELLING MACHINERY, PACKING MACHINERY& VACUUM SYSTEMS.

Programmable Logic Controller

MAGNETIC FORCE MOES SPRING CONTACT DOWM WHEN THE COIL IS ENERGISED SPRING CONTACT

NORMALLY CLOSED CONTACT

NORMALLY OPEN CONTACT

COIL

RELAY

Programmable Logic Controller

RELAY

REMOTE CONTROLLED SWITCH. CONTACTS ARE ACTIVATED BY ENERGISING THE COIL. COIL CREATES A MAGNETIC FIELD WHICH MOVES THE SPRING DOWNWARD ENERGISING THE COIL BREAKS THE NC CONTACT AND MAKES THE NO CONTACTS. SPRING RETURNS TO ITS INITIAL POSITION WHEN THE COIL IS DE-ENERGISED

Programmable Logic Controller

TASK :- DUST SILO MOTOR TO BE RUN IN BOTH FORWARD AND REVERSE DIRECTION

Programmable Logic Controller

RELAY LOGIC FOR ROTATING MOTOR IN FORWARD AND REVERSE DIRECTION

P STOP PUSH BUTTON FORWARD PUSH BUTTON

REVERSE PUSH BUTTON (RL-1) (RL-2)

REVERSE CONTACT

FORWARD CONTACT

FORWARD RELAY (RL-1) N

REVERSE RELAY (RL-2)

Programmable Logic Controller

LADDER LOGIC FOR ROTATING MOTOR IN FORWARD AND REVERSE DIRECTION

24 V +

I 1.1 I 1.3 O 0.2 O 0.1

24 V -

I 1.2

I 1.3

O 0.1

O 0.2

I 1.1 I 1.3 O 0.2 O 0.1 I 1.2 I 1.3 O 0.1 O 0.2

FORWARD PUSH BUTTON INPUT STOP PUSH BUTTON INPUT REVERSE NC CONTACT FORWARD OUTPUT COIL REVERSE PUSH BUTTON INPUT STOP PUSH BUTTON INPUT FORWARD NC CONTACT REVERSE OUTPUT COIL

Potrebbero piacerti anche

- Real-Time Simulation Technology for Modern Power ElectronicsDa EverandReal-Time Simulation Technology for Modern Power ElectronicsNessuna valutazione finora

- Electronic Devices and Circuits: Course DescriptionDocumento4 pagineElectronic Devices and Circuits: Course DescriptionSubas ShresthaNessuna valutazione finora

- On Basic PLCDocumento18 pagineOn Basic PLCpadala harishnath100% (1)

- Mechatronics - PLC ReportDocumento51 pagineMechatronics - PLC ReportEarl FloresNessuna valutazione finora

- Introduction To Automatic ControlDocumento10 pagineIntroduction To Automatic ControlFatih YıldızNessuna valutazione finora

- Introduction To Electro-PneumaticsDocumento40 pagineIntroduction To Electro-Pneumaticssultan1786Nessuna valutazione finora

- Programmable Logic Controller (PLC)Documento16 pagineProgrammable Logic Controller (PLC)Manish Kumar sharma100% (19)

- PLC Report TimerDocumento5 paginePLC Report TimersadmanNessuna valutazione finora

- Manual PLC FestoDocumento77 pagineManual PLC Festoul15e5100% (1)

- Introduction of Control Systems and Basic TerminologyDocumento12 pagineIntroduction of Control Systems and Basic TerminologyShivaji ThubeNessuna valutazione finora

- PLC SlidesDocumento46 paginePLC SlidesdonatchangeNessuna valutazione finora

- Interfacing Techniques Topic 4Documento23 pagineInterfacing Techniques Topic 4Jovel Jhon OpianaNessuna valutazione finora

- Computer Applications in Power Systems: By: DB&DGDocumento106 pagineComputer Applications in Power Systems: By: DB&DGNatinaelNessuna valutazione finora

- Electrical Drives and Control Important QuestionsDocumento1 paginaElectrical Drives and Control Important QuestionsBala Kumar100% (1)

- PLC Lab PDFDocumento14 paginePLC Lab PDFsivaeinfoNessuna valutazione finora

- Introduction To Sensors in MechatronicsDocumento20 pagineIntroduction To Sensors in MechatronicsRadhaMadhavNessuna valutazione finora

- Electricity Distribution and SafetyDocumento14 pagineElectricity Distribution and SafetyMuhammadHafizBaharuddin0% (1)

- Input - Output Devices Used With PLCDocumento23 pagineInput - Output Devices Used With PLCmoney_kandan2004Nessuna valutazione finora

- 4 PLCDocumento31 pagine4 PLCThakur Dhananjay PratapNessuna valutazione finora

- Seth Jai Parkash Mukand Lal Institute of Engg. and Technology (Jmit) Radaur YAMUNA NAGAR (2011-2015)Documento46 pagineSeth Jai Parkash Mukand Lal Institute of Engg. and Technology (Jmit) Radaur YAMUNA NAGAR (2011-2015)dinesh66jattNessuna valutazione finora

- Presentation On PLCDocumento27 paginePresentation On PLCTyrone Michaels100% (1)

- Logic Circuits and Switching Theory CPE 004 (TIP Reviewer)Documento4 pagineLogic Circuits and Switching Theory CPE 004 (TIP Reviewer)James LindoNessuna valutazione finora

- Timers and Counters Instruction PLC TutorialDocumento26 pagineTimers and Counters Instruction PLC TutorialAlpha75% (4)

- PLC Ladder Diagram: BY Nalini MC 20GAEL1008Documento10 paginePLC Ladder Diagram: BY Nalini MC 20GAEL1008NALINI MCNessuna valutazione finora

- Assignment - PLC ProgrammingDocumento6 pagineAssignment - PLC ProgrammingSrinivas ShareNessuna valutazione finora

- Lab 1: PLC Hardware FamiliarizationDocumento5 pagineLab 1: PLC Hardware FamiliarizationTee CubeNessuna valutazione finora

- Chapter 2. Sensors and ActuatorsDocumento58 pagineChapter 2. Sensors and ActuatorsTesfaye Olana100% (1)

- PLC Question BankDocumento3 paginePLC Question BankAjay kumarNessuna valutazione finora

- Automation Using PLCDocumento32 pagineAutomation Using PLCRamashish KumarNessuna valutazione finora

- Actuators: Electromagnetic RelayDocumento19 pagineActuators: Electromagnetic Relaymanjunath100% (1)

- Programmable Logic ControllersDocumento220 pagineProgrammable Logic ControllersAnees SujiNessuna valutazione finora

- 1 AC and DC Circuit No Multiple ChoiceDocumento147 pagine1 AC and DC Circuit No Multiple ChoiceJimuelle CallejoNessuna valutazione finora

- 22534-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Documento32 pagine22534-2019-Winter-Model-Answer-Paper (Msbte Study Resources)rashmi patil100% (1)

- Agni PPT Presentation On PLCDocumento19 pagineAgni PPT Presentation On PLCAgni BhattacharjeeNessuna valutazione finora

- PLCDocumento58 paginePLCR.Deepak KannaNessuna valutazione finora

- Control Exp 7 Student ManualDocumento10 pagineControl Exp 7 Student ManualrakibNessuna valutazione finora

- Eee de Lab Manual DiplomaDocumento80 pagineEee de Lab Manual Diplomasiri.pogula0% (1)

- Unit 15 - PLC - Assignment - 19EDDocumento5 pagineUnit 15 - PLC - Assignment - 19EDvan hangNessuna valutazione finora

- Automation and PLC LAB FileDocumento68 pagineAutomation and PLC LAB FileAyush NegiNessuna valutazione finora

- 2-Lecture 02 Electrical Networks Transfer FunctionDocumento18 pagine2-Lecture 02 Electrical Networks Transfer FunctionHamza KhanNessuna valutazione finora

- Setting Up Electronically Controlled Complex SystemsDocumento61 pagineSetting Up Electronically Controlled Complex Systemsfrezer mesfin100% (1)

- LAB - 3 - Limit Switches Interfacing Using PLC PDFDocumento5 pagineLAB - 3 - Limit Switches Interfacing Using PLC PDFAamir MansoorNessuna valutazione finora

- Presentation 2 (PLC)Documento42 paginePresentation 2 (PLC)Amit SinghNessuna valutazione finora

- Activity 1 - Introduction To Motor ControlDocumento4 pagineActivity 1 - Introduction To Motor ControlAJ Luna100% (1)

- Nns Notes Ie PLCDocumento13 pagineNns Notes Ie PLCNarendra SinhaNessuna valutazione finora

- 2021-02 PEE Online ExaminationsDocumento4 pagine2021-02 PEE Online ExaminationsFerdinand Ramos EspirituNessuna valutazione finora

- Mechatronics Unit 1Documento53 pagineMechatronics Unit 1ஷாம்லி100% (2)

- Ecen 30012 Basic Electronics 1 CompressDocumento82 pagineEcen 30012 Basic Electronics 1 CompressAbonin, Carl Ivan D.L.Nessuna valutazione finora

- Advantages of PLC Used in System Over Relay SystemsDocumento1 paginaAdvantages of PLC Used in System Over Relay Systemssiva kumar100% (1)

- Control DevicesDocumento19 pagineControl DevicesSuzaini SupingatNessuna valutazione finora

- EE306 Power System Analysis Hadi SaadatDocumento18 pagineEE306 Power System Analysis Hadi SaadatGayathri S. NairNessuna valutazione finora

- 3way Traffic Light Ladder LogicDocumento5 pagine3way Traffic Light Ladder LogicM. Umair WaheedNessuna valutazione finora

- PLC Reviewer PDFDocumento6 paginePLC Reviewer PDFDhafnylynn MacasaetNessuna valutazione finora

- Module 3 Intro To ElectroPneumaticsDocumento8 pagineModule 3 Intro To ElectroPneumaticsIvy Totanes TaborNessuna valutazione finora

- MC PLC Lab 2013Documento37 pagineMC PLC Lab 2013sivaeeinfoNessuna valutazione finora

- Six Week Training Presentation On: Programmable Logic ControllerDocumento23 pagineSix Week Training Presentation On: Programmable Logic ControllerShrutiPargaiNessuna valutazione finora

- PLC and Its ApplicationDocumento19 paginePLC and Its ApplicationAasshimaa TanejaNessuna valutazione finora

- Programmable Logic ControllersDocumento35 pagineProgrammable Logic ControllersBin MassoudNessuna valutazione finora

- C&IDocumento120 pagineC&IDeepak JayNessuna valutazione finora

- Pneumatic ControlsDocumento46 paginePneumatic ControlsAditya KumarNessuna valutazione finora

- AMC Agreement 167Documento6 pagineAMC Agreement 167Prittam Kumar JenaNessuna valutazione finora

- WebbrmanualDocumento184 pagineWebbrmanualRam NepaliNessuna valutazione finora

- Àÿç'Ÿæáÿœÿæ Ó Æ'Ÿlÿ Àÿófê Ÿ Ÿçé Æáÿ Ó Æ'Ÿlÿ Ÿç Ÿ Æ Ÿœÿ Þüÿæ Æ Ÿ÷ ÷óæàÿ ÷'ÿê© Lëÿþæàÿ (Àÿzÿæ Ÿçjæ Œÿ Óë Ÿ÷ Ÿ 'Ÿæó ÷Bÿ'Ÿ Äê (Àÿæ'ŸDocumento48 pagineÀÿç'Ÿæáÿœÿæ Ó Æ'Ÿlÿ Àÿófê Ÿ Ÿçé Æáÿ Ó Æ'Ÿlÿ Ÿç Ÿ Æ Ÿœÿ Þüÿæ Æ Ÿ÷ ÷óæàÿ ÷'ÿê© Lëÿþæàÿ (Àÿzÿæ Ÿçjæ Œÿ Óë Ÿ÷ Ÿ 'Ÿæó ÷Bÿ'Ÿ Äê (Àÿæ'ŸPrittam Kumar JenaNessuna valutazione finora

- Quantitative Method CP 102Documento5 pagineQuantitative Method CP 102Prittam Kumar JenaNessuna valutazione finora

- India Business Last Previous Highest Lowest UnitDocumento4 pagineIndia Business Last Previous Highest Lowest UnitPrittam Kumar JenaNessuna valutazione finora

- Reinforcing SteelDocumento8 pagineReinforcing SteelPrittam Kumar JenaNessuna valutazione finora

- Tharmal 2Documento48 pagineTharmal 2Prittam Kumar JenaNessuna valutazione finora

- Shunt Capacitor Bank Fundamentals and Protection (PresentatioDocumento29 pagineShunt Capacitor Bank Fundamentals and Protection (PresentatioPrittam Kumar Jena100% (2)

- An Obstacle Detection System For Blind PeopleDocumento1 paginaAn Obstacle Detection System For Blind PeoplePrittam Kumar JenaNessuna valutazione finora

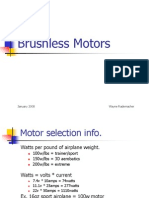

- Brushless Motors: January 2008 Wayne RademacherDocumento27 pagineBrushless Motors: January 2008 Wayne RademacherPrittam Kumar JenaNessuna valutazione finora

- Hho 2Documento5 pagineHho 2Prittam Kumar JenaNessuna valutazione finora

- Hydrogen VechileDocumento22 pagineHydrogen VechilePrittam Kumar JenaNessuna valutazione finora

- Heat Exchanger 3Documento20 pagineHeat Exchanger 3spruhatech2013Nessuna valutazione finora

- Conveyer Belt With 2-Link Robotic ArmDocumento2 pagineConveyer Belt With 2-Link Robotic ArmPrittam Kumar JenaNessuna valutazione finora

- Schunk Carbon-Brush Brush PressureDocumento8 pagineSchunk Carbon-Brush Brush PressurePrittam Kumar JenaNessuna valutazione finora

- AS-400 Course DetailsDocumento2 pagineAS-400 Course DetailsPrittam Kumar JenaNessuna valutazione finora

- Power Saver For Industries & Commercial EstablishmentsDocumento2 paginePower Saver For Industries & Commercial EstablishmentsPrittam Kumar Jena100% (2)

- Simatic S7-300: The PLC For With As Focal PointDocumento28 pagineSimatic S7-300: The PLC For With As Focal PointPrittam Kumar JenaNessuna valutazione finora

- Imparting Training On: Prolific Systems &technologies Pvt. LTDDocumento18 pagineImparting Training On: Prolific Systems &technologies Pvt. LTDPrittam Kumar Jena100% (2)

- Outerstellar Self-Impose RulesDocumento1 paginaOuterstellar Self-Impose RulesIffu The war GodNessuna valutazione finora

- 6.003 Homework #12 Solutions: ProblemsDocumento9 pagine6.003 Homework #12 Solutions: ProblemsSamu PacurucuNessuna valutazione finora

- Types of WinesDocumento91 pagineTypes of Winesrajanrld19880% (1)

- B.Pharm - Semester - III-10.07.2018Documento16 pagineB.Pharm - Semester - III-10.07.2018SAYAN BOSENessuna valutazione finora

- Problem-Based Learning ReportDocumento24 pagineProblem-Based Learning Reporterdayu86Nessuna valutazione finora

- Human Eye 5Documento7 pagineHuman Eye 5NanditaNessuna valutazione finora

- 3592 Operator GuideDocumento103 pagine3592 Operator GuideNaim GhattasNessuna valutazione finora

- Lesson PlanDocumento18 pagineLesson PlanYasmin Abigail AseriosNessuna valutazione finora

- Annie Ovenden Exibition 2017Documento19 pagineAnnie Ovenden Exibition 2017Vitaliy ChuenkoNessuna valutazione finora

- Digital ElectronicsDocumento18 pagineDigital ElectronicsHarry BeggyNessuna valutazione finora

- Chapter 9 Material ChangesDocumento6 pagineChapter 9 Material ChangesFitria Istikomah DewiNessuna valutazione finora

- PT4115EDocumento18 paginePT4115Edragom2Nessuna valutazione finora

- A Collection of Ideas For The Chemistry Classroom by Jeff HepburnDocumento14 pagineA Collection of Ideas For The Chemistry Classroom by Jeff HepburnPaul SchumannNessuna valutazione finora

- Osce05ans 110918053819 Phpapp01Documento20 pagineOsce05ans 110918053819 Phpapp01masood alamNessuna valutazione finora

- OLFACTIVE TRAINING 101 by SozioDocumento36 pagineOLFACTIVE TRAINING 101 by SoziojaviercdeaeNessuna valutazione finora

- Unit 3 InfiltrationDocumento5 pagineUnit 3 InfiltrationHRIDYA MGNessuna valutazione finora

- Health Problems Vocabulary Esl Matching Exercise Worksheet For KidsDocumento2 pagineHealth Problems Vocabulary Esl Matching Exercise Worksheet For KidsTarisubhNessuna valutazione finora

- Geology of Johannesburg ReadingDocumento2 pagineGeology of Johannesburg ReadingKavish DayaNessuna valutazione finora

- Charles Haanel - The Master Key System Cd2 Id1919810777 Size878Documento214 pagineCharles Haanel - The Master Key System Cd2 Id1919810777 Size878Hmt Nmsl100% (2)

- Nitofloor NDocumento3 pagineNitofloor Nkiranmisale7Nessuna valutazione finora

- Boyle's Law 2023Documento6 pagineBoyle's Law 2023Justin HuynhNessuna valutazione finora

- Bitsat Paper 5Documento19 pagineBitsat Paper 5pranka5240100% (1)

- Good Practices in Tray DesignDocumento7 pagineGood Practices in Tray Designmehul10941100% (2)

- Aci 522R-06 PDFDocumento25 pagineAci 522R-06 PDFaldi raimon100% (2)

- Mono 108Documento438 pagineMono 108pasaricaNessuna valutazione finora

- Chemical Process DebottleneckingDocumento46 pagineChemical Process DebottleneckingAhmed Ansari100% (2)

- American Pile Driving Equipment Equipment CatalogDocumento25 pagineAmerican Pile Driving Equipment Equipment CatalogW Morales100% (1)

- Course On Quantum ComputingDocumento235 pagineCourse On Quantum ComputingAram ShojaeiNessuna valutazione finora

- The Earth's SubsystemsDocumento17 pagineThe Earth's SubsystemsAndevie Balili Iguana100% (1)

- MAP V6.3: Reference ManualDocumento106 pagineMAP V6.3: Reference ManualGkou DojkuNessuna valutazione finora