Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PQR SAW Process

Caricato da

devendrasingh2021Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PQR SAW Process

Caricato da

devendrasingh2021Copyright:

Formati disponibili

ANNEX N

AWS D1.1/D1.1M:2010

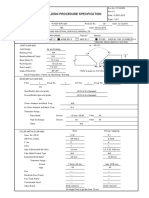

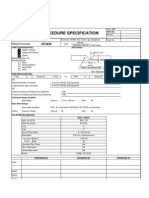

PROCEDURE QUALIFICATION RECORD (PQR)

Company Name: Welding Process Submerged Arc Welding Supporting PQR No. MPS-PQR-6

. .

Identification # Revision 00 Authorized by Type- Manual Mechanized

Date:

1/30/2013 By

Date: 30/01/2013 Semiautomatic Automatic

JOINT DESIGN USED Type: Butt Tee Corner

Lap Edge Single Double Weld Backing: YES NO Backing Material NA Root Opening 1 mm Root Face Dimension NA Radius (J-U) NA Groove Angle: NA Back Gouging: Yes NO Method NA .

POSITION

Position of Groove: NA Vertical Progression: Up . Fillet: Down 2F .

Electrical Characteristics

Transfer Mode (GMAW) Short-Circuiting Globular Spray Current: AC DCEP DCEN PULSED Other _____________ __________________ Tungsten Electrode (GTAW) Size: _____NA __ Type: ____NA ___

BASE METALS

Material Spec. IS 2062/EQ to IS 2062 Type of grade Grade B* Thickness: Groove NA Fillet 8mm . Diameter (Pipe) NA

TECHNIQUE FILLER METALS

AWS Specification AWS A 5.17 AWS Classification F-7AZ-EL8 Stringer or Weave Bead: WEAVE Multi -Pass or Single Pass (per side) SINGLE PASS Number of Electrodes One Electrode Spacing Longitudinal NA Lateral NA Angle NA . Contact Tube to work Distance 30mm Peening NA Interpass Cleaning: NA . . .

SHIELDING

Flux Gas NA Composition NA Electrode-Flux (Class) F-7A4EL-8 / 7P4EL-8 Flow Rate NA Gas Cup Size NA . . . .

. . .

POST WELD HEAT TREATMENT Preheat

Preheat Temp. Min Interpass Temp. Min. 10 C . 10 C . Max. NA . Temp. Time NA NA . .

WELDING PROCEDURE Filler Metals Pass or Class Diam. Weld Larer(s) Process 1 SAW EL-8 3.15mm Current Type & Polarity DCEP

Amps or Wire Feed Speed Travel Speed

Volts

25-28

325-335

(IPM) 25-27

Joint Details

12mm

12mm

* Material chemical composition is (C%= 0.22max, Mn%= 1.50max, P%= 0.045max, S%=0.045, Si%= 0.03-0.4max), CE%= 0.41max

Potrebbero piacerti anche

- Wps SawDocumento2 pagineWps Sawdevendrasingh2021100% (6)

- WPS PQR A36.20Documento5 pagineWPS PQR A36.20gchaves504100% (2)

- WPS 316 LDocumento4 pagineWPS 316 Llaz_k100% (2)

- WPSDocumento6 pagineWPSNur Wijianto100% (1)

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocumento3 pagineSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013Nessuna valutazione finora

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Documento6 pagineMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNessuna valutazione finora

- PQRDocumento2 paginePQRalokbdasNessuna valutazione finora

- WPS Multi GMAW FCAW PDFDocumento2 pagineWPS Multi GMAW FCAW PDFwentroprem75% (4)

- PQRDocumento2 paginePQRSreenivas Kamachi Chettiar100% (1)

- WPS and PQRDocumento4 pagineWPS and PQRdandiar1Nessuna valutazione finora

- Super Duplex Stainless SteelDocumento1 paginaSuper Duplex Stainless SteelUma Shankar100% (1)

- WPS PQR WPQ PeiplDocumento16 pagineWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- GTAW Welding Procedure SpecificationDocumento3 pagineGTAW Welding Procedure SpecificationVimin Prakash100% (1)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Documento5 pagineWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- 03 WPS PQR For FCAWDocumento3 pagine03 WPS PQR For FCAWBrijesh Yadav100% (1)

- WPS - 024Documento4 pagineWPS - 024MAT-LIONNessuna valutazione finora

- Aws d1.1 WPS, PQR & WQTDocumento4 pagineAws d1.1 WPS, PQR & WQTWeld Bro SandeepNessuna valutazione finora

- WPS & PQRDocumento46 pagineWPS & PQRJohn Candidate CIns88% (8)

- WPS GmawDocumento2 pagineWPS Gmawasikur100% (6)

- WQTDocumento1 paginaWQTRamkunwar YadavNessuna valutazione finora

- WPS For Smaw06-001 (Pipe 6G CS)Documento10 pagineWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- WPS, PQR & WPQ - Duplex 2205Documento20 pagineWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS-PQR (Er309l Mo)Documento4 pagineWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS MigDocumento3 pagineWPS MigAJOJOY00960% (5)

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- WPS Format For AWS D1.1 - PQR - SMAWDocumento3 pagineWPS Format For AWS D1.1 - PQR - SMAWThe Welding Inspections Community100% (3)

- Welder Performance Qualification-Interactive Form QW-484ADocumento1 paginaWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WELDING PROCEDURE SPECIFICATION DETAILSDocumento2 pagineWELDING PROCEDURE SPECIFICATION DETAILStuatk60% (5)

- PQR - 152Documento3 paginePQR - 152MAT-LIONNessuna valutazione finora

- WPS PQR FormatDocumento1 paginaWPS PQR FormatJatin Kamdar100% (2)

- WPS Sitelca S002Documento2 pagineWPS Sitelca S002Jose Antonio GomezNessuna valutazione finora

- Page No: 01: SA 240 GR 304 SA 240 GR 304Documento5 paginePage No: 01: SA 240 GR 304 SA 240 GR 304jobertNessuna valutazione finora

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocumento2 pagineProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNessuna valutazione finora

- WPSDocumento3 pagineWPSKhurram Burjees100% (1)

- Wps Gmaw SawDocumento2 pagineWps Gmaw Sawupedro26Nessuna valutazione finora

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocumento4 pagineWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNessuna valutazione finora

- According To ASME IX: Welding Procedure Specification (W.P.S)Documento4 pagineAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNessuna valutazione finora

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Documento12 paginePT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNessuna valutazione finora

- PWPS WPS PQR WPQDocumento21 paginePWPS WPS PQR WPQcsolanki658688% (8)

- Wps For Aluminium WeldingDocumento8 pagineWps For Aluminium Weldingvishal bailur50% (2)

- Sample API 1104 WpsDocumento6 pagineSample API 1104 Wpsjacquesmayol100% (2)

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- ASME IX QW (Welding General Requirements)Documento12 pagineASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- LBW WOPQ REV. 2010a Interactive FormDocumento1 paginaLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- Clad PQRDocumento5 pagineClad PQRRinshadNessuna valutazione finora

- Gtaw WPQDocumento3 pagineGtaw WPQMuhammadShabbirNessuna valutazione finora

- Qw-482 Welding Procedure Specification (WPS)Documento4 pagineQw-482 Welding Procedure Specification (WPS)Aldeline Sungahid100% (2)

- WPQR Welding Procedure Qualification RecordsDocumento3 pagineWPQR Welding Procedure Qualification Recordsramesh rajaNessuna valutazione finora

- PQR Gmaw3gDocumento4 paginePQR Gmaw3gdevendrasingh2021100% (3)

- WPS - D1.1Documento1 paginaWPS - D1.1Nam_HitechNessuna valutazione finora

- WPS GTAW Stainless SteelDocumento4 pagineWPS GTAW Stainless SteelAnand NarayananNessuna valutazione finora

- MRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDocumento5 pagineMRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDeepak100% (1)

- PQR-WPS-WPQR XXX Rev 0Documento6 paginePQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONSDocumento12 paginePREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONSwalitedisonNessuna valutazione finora

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleDocumento8 pagineApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12Nessuna valutazione finora

- Weld Joint 1Documento81 pagineWeld Joint 1rajibali27100% (1)

- WPS, PQR 041Documento21 pagineWPS, PQR 041swamykommula100% (1)

- WPS GTAW Stainless SteelDocumento2 pagineWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Documento2 pagineWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNessuna valutazione finora

- Welding FormDocumento4 pagineWelding FormAnand SomanNessuna valutazione finora

- Offer List Vinayak Transo Limited: Date: 22-04-2021Documento1 paginaOffer List Vinayak Transo Limited: Date: 22-04-2021devendrasingh2021Nessuna valutazione finora

- Non Confirming IssuesDocumento1 paginaNon Confirming Issuesdevendrasingh2021Nessuna valutazione finora

- Offer List Vinayak Transo Limited: Date: 22-04-2021Documento1 paginaOffer List Vinayak Transo Limited: Date: 22-04-2021devendrasingh2021Nessuna valutazione finora

- Non Confirming IssuesDocumento1 paginaNon Confirming Issuesdevendrasingh2021Nessuna valutazione finora

- Standard Testing Procedure - Tensile TestingDocumento3 pagineStandard Testing Procedure - Tensile Testingdevendrasingh2021100% (1)

- Sr. No. Sample Name Cast Number Sample Size Thickness Observations (MM) 1 2 3 4 5 6 7 8 9 10 Average ThicknessDocumento1 paginaSr. No. Sample Name Cast Number Sample Size Thickness Observations (MM) 1 2 3 4 5 6 7 8 9 10 Average Thicknessdevendrasingh2021Nessuna valutazione finora

- Non Confirming IssuesDocumento1 paginaNon Confirming Issuesdevendrasingh2021Nessuna valutazione finora

- Non Confirming IssuesDocumento1 paginaNon Confirming Issuesdevendrasingh2021Nessuna valutazione finora

- Non Confirming IssuesDocumento1 paginaNon Confirming Issuesdevendrasingh2021Nessuna valutazione finora

- (A) Dimensions: (D) Cupping TestDocumento5 pagine(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- Disclosure To Promote The Right To InformationDocumento18 pagineDisclosure To Promote The Right To InformationRatnakumarChittoorNessuna valutazione finora

- Comparision of Steel PropertyDocumento2 pagineComparision of Steel Propertydevendrasingh2021Nessuna valutazione finora

- Comparision of Steel PropertyDocumento2 pagineComparision of Steel Propertydevendrasingh2021Nessuna valutazione finora

- wqt4 Gmaw 4gDocumento2 paginewqt4 Gmaw 4gdevendrasingh20210% (1)

- Welder Id SampleDocumento1 paginaWelder Id Sampledevendrasingh202157% (7)

- PQR Gmaw3gDocumento4 paginePQR Gmaw3gdevendrasingh2021100% (3)

- Kic API X70Documento8 pagineKic API X70Ivan SilveiraNessuna valutazione finora

- Corner Cast in Place AnchorDocumento7 pagineCorner Cast in Place Anchorwaweng22Nessuna valutazione finora

- Diamondchaincoctalogo PDFDocumento151 pagineDiamondchaincoctalogo PDFFranco Matias TemporinNessuna valutazione finora

- Friction and Friction Coefficients For Various MaterialsDocumento14 pagineFriction and Friction Coefficients For Various MaterialsGia Minh Tieu TuNessuna valutazione finora

- Consolidated Contractors Welding Procedure SpecificationDocumento3 pagineConsolidated Contractors Welding Procedure Specificationsiva8000100% (1)

- FVD SeminarDocumento2 pagineFVD Seminaranand_316764947Nessuna valutazione finora

- 1190 1Documento88 pagine1190 1TONNessuna valutazione finora

- Relativity QuestionsDocumento4 pagineRelativity QuestionsChristoph KirchNessuna valutazione finora

- Coduto10 9Documento3 pagineCoduto10 9bagmassNessuna valutazione finora

- Section 8 Maintenance & SpecificationsDocumento30 pagineSection 8 Maintenance & SpecificationsTaha RdmanNessuna valutazione finora

- Fluid StaticsDocumento53 pagineFluid StaticsUsama AlameedyNessuna valutazione finora

- Overhauling Slipring Motors StandardDocumento19 pagineOverhauling Slipring Motors StandardAhmed AshourNessuna valutazione finora

- 320D & DL Parts ManualDocumento1.023 pagine320D & DL Parts ManualKeron Trotz95% (63)

- Hydraulic Accumulator (High Pressure) - Test and Charge: Pruebas y AjustesDocumento16 pagineHydraulic Accumulator (High Pressure) - Test and Charge: Pruebas y AjustesBrayan Sánchez ParedesNessuna valutazione finora

- Kershaw Scorpion RS64 DL RampDocumento3 pagineKershaw Scorpion RS64 DL Rampcamelia_pirjan5776Nessuna valutazione finora

- Design and Fabrication of Scotch Yoke Mechanism - Main PpiDocumento24 pagineDesign and Fabrication of Scotch Yoke Mechanism - Main PpiMusic LoverNessuna valutazione finora

- LS Circuit IntroductionDocumento18 pagineLS Circuit IntroductionMuhammad DaniNessuna valutazione finora

- Assignment QuestionDocumento15 pagineAssignment QuestionPratik WalimbeNessuna valutazione finora

- Cummins QSB6.7 168 KW (225 HP) at 2,200 RPM 160 KW (215 HP) at 2,200 RPM 17,800 KG 3.3 M 180 KN 2,948 MMDocumento2 pagineCummins QSB6.7 168 KW (225 HP) at 2,200 RPM 160 KW (215 HP) at 2,200 RPM 17,800 KG 3.3 M 180 KN 2,948 MMIwanNessuna valutazione finora

- 3784A KXX K4J K4M Clio Motor ManualDocumento32 pagine3784A KXX K4J K4M Clio Motor ManualDavid NebainNessuna valutazione finora

- Modelling, Identification and Control of A 2 DOF Helicopter PrototypeDocumento6 pagineModelling, Identification and Control of A 2 DOF Helicopter PrototypeosdacavNessuna valutazione finora

- DT60-DT70S (50 HZ)Documento3 pagineDT60-DT70S (50 HZ)Md ShNessuna valutazione finora

- Difference Between Spillback and Minimum Circulation Line - Google SearchDocumento1 paginaDifference Between Spillback and Minimum Circulation Line - Google SearchGourav KumarNessuna valutazione finora

- Assignment #3Documento2 pagineAssignment #3Choa Pei ShuangNessuna valutazione finora

- Grindex Lista de PartesDocumento28 pagineGrindex Lista de PartesMarco Antonio Cerna HaroNessuna valutazione finora

- Module-3: Kinematics: ExercisesDocumento1 paginaModule-3: Kinematics: ExercisesHamza SiddiquiNessuna valutazione finora

- API-653 Now Permits Lap-Welded Patch Plates For Shell Repairs - Carmagen EngineeringDocumento2 pagineAPI-653 Now Permits Lap-Welded Patch Plates For Shell Repairs - Carmagen Engineeringmohsen_267100% (1)

- Annual scissor lift inspection reportDocumento1 paginaAnnual scissor lift inspection reportWisnu WardhanaNessuna valutazione finora

- Small Bore Metric Seals CatalogDocumento64 pagineSmall Bore Metric Seals CatalogLeroy AraoNessuna valutazione finora

- Gas-Liquid Separators Sizing Parameter - Campbell Tip of The MonthDocumento18 pagineGas-Liquid Separators Sizing Parameter - Campbell Tip of The MonthsterlingNessuna valutazione finora