Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mercer Valve 9500 Series Sizing Program

Caricato da

Jason ThomasDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mercer Valve 9500 Series Sizing Program

Caricato da

Jason ThomasCopyright:

Formati disponibili

www.mercervalve.

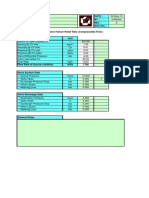

net 9500 Series Pilot Operated Safety Relief Valve Sizing Program

POINT MOUSE ON RED ARROW TO VIEW DISCLAIMER

To use the Mercer Valve sizing program, the information on "DATA ENTRY" sheet must be com "DATA ENTRY" sheet, notice the red arrows thoughout the sheet. Point on these arrows for m program. This information may help entering correct data into the program. Enter data into the pull down menu boxes to choice different options. When all information is entered and correct required area and choose a valve size to meet given conditions. The pull down menus at the bot you to select the appropriate accessories. After your selection process is complete the data en addition using the "Printout" a data sheet for the Pilot Operated Valve can be viewed and prin important for the proper selection, quoting, and ordering of the valve. Thank you for using Me

Pilot Sizing version 6.1CUST

12-Oct-10

SAK

et

e Sizing Program

RY" sheet must be completed. While changing the nt on these arrows for more infomation about the ram. Enter data into the shaded boxes and use the n is entered and correct, the program will solve for l down menus at the bottom of the screen will allow is complete the data entry sheet can be printed. In can be viewed and printed. . This information is Thank you for using Mercer Valve Company, Inc.

v6.1CUST as of 12-OCT-2010 SAK

2/2/2013 9500 SERIES PILOT OPERATED RELIEF VALVE SIZING

NAME: COMPANY: LOCATION: TAG NUMBER: PHONE: FAX: QUOTE #: REFERENCE #: QUANTITY:

1) Select information from boxes below. Sizing Method: Select 9500 Series Type: 2) Sizing Conditions Atmospheric Pressure: Allowable Over Pressure: 14.7 10 Compressiblity Factor: 4) Pressure Operating Pressure: Valve Set Pressure: 6) Back Pressure Superimposed Back Pressure Variable: Constant: 0 0 psig Orifice Size: Built-Up Back Pressure Variable: 0 psig Selected Orifice Area: Selected Orifice Flow: D Orifice 0.151 374.751 scfm Required Orifice Area: 100.00 psig 5) Temperature Operating Temperature: Relieving Temperature: 7) Capacity & Calculations 100.0 0.040 in 60.0 60.0 Fahrenheit System Type:

Relieving Temperature only used for Sizing Calculation

3) Media

Name:

Natural Gas 0.6 1.27 1

Main Valve

Main Body Material: Inlet Size: Inlet Flange Type: Flange Ratings: Main Valve Seat: Main Valve O-Rings: Backflow Preventer: Auxillary Filter: Pressure Snubber: Sour Gas Service:

Pilot Valve

Pilot Type: Pilot Body Material: Pilot Valve Seat: Pilot O-Rings: Field Test Connection: System Blowdown: Test Gag: Lift Lever:

Disclaimer

Disclaimer

As per ASME code, Section VIII, Division 1, para. UG-125(a), the customer accepts all responsibility in insuring that the correct pressure relief valve is installed for their application. The purchase order for the pressure relief valve confirms the sizing calculations and material compatibility choices made by Mercer Valve are correct for the application.

Note: This sizing program does not take material compatibility or pressure and temperature limitations into account for choosing materials. Please verify all material choices with Mercer Valve Company, Inc.

v6.1CUST as of 12-OCT-2010 SAK

2/2/2013

Pilot Operated Valve Specification Sheet

Customer Name: Company: Location: Phone: Fax: Quote #: Reference #: Valve Tag Number:

Fluid Data FLUID MOLECULAR WEIGHT GAS CONSTANT

SUPERIMPOSED CONST BP

FLUID STATE SPECIFIC GRAVITY

k-RATIO OF SPECIFIC HEATS

COMPRESSIBILITY FACTOR REQUIRED CAPACITY

SUPERIMPOSED VARIABLE BP

BUILT-UP BP

OPERATING TEMP OPERATING PRESSURE

TOTAL BACK PRESSURE

RELIEVING TEMPERATURE

ATMOSPHERIC PRESSURE

SET PRESSURE FLOWING PRESSURE CDTP OVER PRESSURE DISCHARGE COEFFICIENT AND AREAS VALVE CERTIFICATION / DESIGN CODE SYSTEM TYPE REQUIRED AREA FLOW COEFFICIENT SELECTED ORIFICE Sizing Results

MAXIMUM CAPACITY OF VALVE AT OVER PRESS. TAG CAPACITY

GAS/VAPOR 0.6 1.27 100.000 scfm 0.00 psig psig 0.00 psig psig 60.000 Fahrenheit Fahrenheit 14.70 psig psia 124.70 psig psia 10.00 psig psig ASME, Section VIII, Div. 1 ASME BOILER AND PRESSURE VESSEL CODE, SECTION VIII, DIVISION 1 0.040 0.151 in in 374.751 scfm 300.3 SCFM AIR 116 11.5 dB lbF ASME SA216 WCB CRBN STL Carbon Steel Teflon Viton Orings w/Buna Backups 316 Stainless Steel 316 Stainless Steel 316 Stainless Steel Semi Nozzle 316 Stainless Steel 316 Stainless Steel 3/8in. OD w/ .035in. Wall Thickness ASME SA 351 CF3M Stnls Stl Carbon Steel Viton / Viton Viton 90 Durometer 316 Stnls Stl 17-7 PH Stnls Stl No No No No None No None - Standard No Snap Pilot Operated Pressure Relief Valve 0.870 D Orifice

Natural Gas 17.4 344.1 1 0.000 0.000 60.000 0.00 100.00 100

Main Valve

DECIBEL LEVEL BODY SEAT PISTON NOZZLE FITTINGS TUBING BODY SEAT INTERNALS

REACTION FORCE BONNET O-RINGS DISK

Materials

BACKFLOW PREVENTER

Options

AUXILLARY FILTER

FIELD TEST CONNECTION

BONNET O-RINGS SPRING PRESSURE SNUBBER SOUR GAS SERVICE TEST GAG LIFT LEVER Pilot Valve P/N:

Pilot Valve Repair Kit P/N:

SYSTEM BLOWDOWN Valve Type Main Valve P/N:

Main Valve Repair Kit P/N:

Pilot

95-27D1307S

S-1100007

Valve Information

Inlet and Outlet Connections Center to Face Dimensions Quantity A=

95-2D70 95-S10 1 in. 150 lb RF x 2 in. 150 lb RF 4 in. B= 4

1

in.

Disclaimer

As per ASME code, Section VIII, Division 1, para. UG-125(a), the customer accepts all responsibility in insuring that the correct pressure relief valve is installed for their application. The purchase order for the pressure relief valve confirms the sizing calculations and material compatibility choices made by Mercer Valve are correct for the application.

Comments

Potrebbero piacerti anche

- Hazop StudyDocumento7 pagineHazop StudyAnderson JoeNessuna valutazione finora

- Piping Specification BreaksDocumento6 paginePiping Specification BreaksvijeyimusNessuna valutazione finora

- Data Sheet Pressure Relief ValveDocumento10 pagineData Sheet Pressure Relief ValveAnonymous UArnIExNessuna valutazione finora

- Unit OperationsDocumento4 pagineUnit OperationsCeazar Justine Fulugan100% (1)

- Burn Pit CriteriaDocumento28 pagineBurn Pit CriteriaVenkat Rangan100% (7)

- Wastewater Treatment Concepts and PracticesDocumento212 pagineWastewater Treatment Concepts and Practicesfajar waskito100% (5)

- Deluge System ManualDocumento64 pagineDeluge System ManualAsman Ahmad100% (3)

- Surge Control Dynamic Simulation Centrifugal CompDocumento3 pagineSurge Control Dynamic Simulation Centrifugal CompAnil B YadavNessuna valutazione finora

- PSV 0600B Well Test Separator - L03Documento6 paginePSV 0600B Well Test Separator - L03Ebby OnyekweNessuna valutazione finora

- Drygasdownchoke - XLS: This Spreadsheet Calculates Downstream Pressure at Choke For Dry GasesDocumento2 pagineDrygasdownchoke - XLS: This Spreadsheet Calculates Downstream Pressure at Choke For Dry Gasesmath62210Nessuna valutazione finora

- NORSOK P-001 Process Design PDFDocumento26 pagineNORSOK P-001 Process Design PDFMarcelNessuna valutazione finora

- NORSOK P-001 Process Design PDFDocumento26 pagineNORSOK P-001 Process Design PDFMarcelNessuna valutazione finora

- Shell K.O.drum SeparatorDocumento11 pagineShell K.O.drum SeparatorChitu Ionut LaurentiuNessuna valutazione finora

- Heat Exchanger Sizing AC-6050 #1Documento2 pagineHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleNessuna valutazione finora

- Drygasupchoke - XLS: This Spreadsheet Calculates Upstream Pressure at Choke For Dry GasesDocumento2 pagineDrygasupchoke - XLS: This Spreadsheet Calculates Upstream Pressure at Choke For Dry Gasesmath62210Nessuna valutazione finora

- Blowdown ReportDocumento26 pagineBlowdown ReportPaul OhiorNessuna valutazione finora

- Centrifugal Compressor Calculations: Suction Discharge Input ParametersDocumento1 paginaCentrifugal Compressor Calculations: Suction Discharge Input Parametersankur20610% (1)

- Compressor Control, Load Sharing and Anti-SurgeDocumento6 pagineCompressor Control, Load Sharing and Anti-SurgeJason Thomas100% (1)

- Welding Defects and PreventionDocumento2 pagineWelding Defects and PreventionVicky SinghNessuna valutazione finora

- PSV Sizing Calculations for LOX Cryogenic VesselDocumento3 paginePSV Sizing Calculations for LOX Cryogenic VesselpavanNessuna valutazione finora

- The HYSYS SpreadsheetDocumento10 pagineThe HYSYS SpreadsheetSyed Muzamil AhmedNessuna valutazione finora

- Weymouth Gas Flow CalculationsDocumento44 pagineWeymouth Gas Flow CalculationsPierre GermaineNessuna valutazione finora

- Process Design: Norsok StandardDocumento27 pagineProcess Design: Norsok StandardJason ThomasNessuna valutazione finora

- HMB Latest Stream ReporterDocumento20 pagineHMB Latest Stream ReporterConnor SailorNessuna valutazione finora

- Control Valve Failure Relief Rate - Gas ServiceDocumento3 pagineControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- Blowdown Orifice Sizing CalculationDocumento2 pagineBlowdown Orifice Sizing CalculationOmprakaash MokideNessuna valutazione finora

- PDFDocumento8 paginePDFvcharlesNessuna valutazione finora

- Guide For Vessel Sizing PDFDocumento24 pagineGuide For Vessel Sizing PDFManish542Nessuna valutazione finora

- Depressurization of CO2 PipelineDocumento10 pagineDepressurization of CO2 PipelineJason ThomasNessuna valutazione finora

- Functional Specifications FOR Separation Module: Onshore Engg. Services New Delhi Document No.: OESG/ARP/SP/M0002 REVDocumento17 pagineFunctional Specifications FOR Separation Module: Onshore Engg. Services New Delhi Document No.: OESG/ARP/SP/M0002 REVAnonymous O0lyGOShYGNessuna valutazione finora

- Depressuirng Calculation ResultsDocumento6 pagineDepressuirng Calculation ResultsIoana PopescuNessuna valutazione finora

- 02 PropaneRefrigerationLoopDocumento26 pagine02 PropaneRefrigerationLoopChristian ChineduNessuna valutazione finora

- Consequence AnalyserDocumento23 pagineConsequence AnalyserGlacier RamkissoonNessuna valutazione finora

- Table Convert MMSCFD To SI SKG BetungDocumento132 pagineTable Convert MMSCFD To SI SKG BetungGelorawan AditNessuna valutazione finora

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Da EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Valutazione: 3.5 su 5 stelle3.5/5 (3)

- Piping - Pipeline Design PressureDocumento3 paginePiping - Pipeline Design Pressureankur2061Nessuna valutazione finora

- Restriction Orifice Flow Control GuideDocumento3 pagineRestriction Orifice Flow Control Guidemsr22Nessuna valutazione finora

- Chemical CleaningDocumento32 pagineChemical Cleaningkae kae100% (2)

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Documento2 pagineMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNessuna valutazione finora

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDocumento20 pagineExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsagusnnnNessuna valutazione finora

- FGCP Line Sizing CalculationsDocumento86 pagineFGCP Line Sizing CalculationsToyinNessuna valutazione finora

- 3.2.G.2.3.D Two Phase Sep Sizing API 521 SI Units1Documento1 pagina3.2.G.2.3.D Two Phase Sep Sizing API 521 SI Units1Mike DukasNessuna valutazione finora

- Jisike Flowstation Debottlenecking and Gaslift Upgrade SizingDocumento2 pagineJisike Flowstation Debottlenecking and Gaslift Upgrade SizingmakamahamisuNessuna valutazione finora

- PSVDocumento1 paginaPSVsalman ahmedNessuna valutazione finora

- Rigorous Method For Fire Case (Process Engineer)Documento5 pagineRigorous Method For Fire Case (Process Engineer)ecovarrubias1Nessuna valutazione finora

- Transient - Chapter 11 - Advanced TopicsDocumento181 pagineTransient - Chapter 11 - Advanced TopicsPasquale CutriNessuna valutazione finora

- John M. Campbell & Company - Best Tips of The MonthDocumento152 pagineJohn M. Campbell & Company - Best Tips of The Monthcamanjarresv100% (3)

- Slug Catcher SizingDocumento6 pagineSlug Catcher SizingrezaNessuna valutazione finora

- API-12J - Horizontal Seperator Sizing OriginalDocumento2 pagineAPI-12J - Horizontal Seperator Sizing OriginalMichael HaiseNessuna valutazione finora

- Blocked OutletDocumento80 pagineBlocked OutletJagan Bose100% (1)

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Documento26 pagineSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801Nessuna valutazione finora

- Pipeline Software ComparisonDocumento2 paginePipeline Software Comparisonvivekag0% (1)

- Reboiler Selection ChartDocumento1 paginaReboiler Selection Chartankur2061Nessuna valutazione finora

- Toolbox Talk (Engineering)Documento4 pagineToolbox Talk (Engineering)GiftObionochieNessuna valutazione finora

- Fire Relief Dynamic StudyDocumento2 pagineFire Relief Dynamic StudyImtinan MohsinNessuna valutazione finora

- Estimate Settle-Out Pressure and Temperature in Compressor LoopDocumento3 pagineEstimate Settle-Out Pressure and Temperature in Compressor LoopFahad Maqsood100% (1)

- UOP PX-Plus ™ XPDocumento2 pagineUOP PX-Plus ™ XPana_dcz7154Nessuna valutazione finora

- PDM-P-CS-002 - HP Prod SeparatorDocumento6 paginePDM-P-CS-002 - HP Prod Separatorfirman adiyantoNessuna valutazione finora

- Process Calculation - Purge Gas CalculationDocumento1 paginaProcess Calculation - Purge Gas CalculationmakamahamisuNessuna valutazione finora

- 3 Phase Separator SpreadsheetDocumento4 pagine3 Phase Separator SpreadsheetToyinNessuna valutazione finora

- PSV Sizing Tool - API BasedDocumento11 paginePSV Sizing Tool - API BasedJoseph Paul Ilagan0% (1)

- Slug Catcher Sizing SpreadsheetDocumento14 pagineSlug Catcher Sizing Spreadsheettoño16Nessuna valutazione finora

- Basic Surge Control System: FCV CoolerDocumento2 pagineBasic Surge Control System: FCV Coolerankur2061Nessuna valutazione finora

- GRND LVL Conc of Unburned Flammable Gas Joe Wong CheckedDocumento1 paginaGRND LVL Conc of Unburned Flammable Gas Joe Wong Checkedankur2061Nessuna valutazione finora

- Pressure Reducing CalculatorDocumento12 paginePressure Reducing CalculatoralifbaharunNessuna valutazione finora

- Basicflowmeasurement 150428100633 Conversion Gate02 PDFDocumento50 pagineBasicflowmeasurement 150428100633 Conversion Gate02 PDFankur2061Nessuna valutazione finora

- Bulletin 71.4MR108 PDFDocumento20 pagineBulletin 71.4MR108 PDFBledarNessuna valutazione finora

- Bottomholenodaloil-Gg - Xls Description: This Spreadsheet Calculates Flowing Bottom Hole Pressure Based OnDocumento3 pagineBottomholenodaloil-Gg - Xls Description: This Spreadsheet Calculates Flowing Bottom Hole Pressure Based OnJhan GavilanNessuna valutazione finora

- Weymouth EquationDocumento7 pagineWeymouth EquationCHANADASNessuna valutazione finora

- Wall metal temperature during emergency depressurizationDocumento7 pagineWall metal temperature during emergency depressurizationmihaileditoiu2010Nessuna valutazione finora

- M=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dDocumento23 pagineM=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dHoa NguyenNessuna valutazione finora

- Liquid Line SizingDocumento8 pagineLiquid Line Sizingsamuad59Nessuna valutazione finora

- PSV Calcs PDFDocumento8 paginePSV Calcs PDFatulNessuna valutazione finora

- Equipo Mayor (Major Equipment List)Documento4 pagineEquipo Mayor (Major Equipment List)rondonjjNessuna valutazione finora

- Unlock Separator SizingDocumento42 pagineUnlock Separator SizingmortezasabetiNessuna valutazione finora

- Control Valve Sizing: How to Identify and Troubleshoot Problems On-LineDocumento42 pagineControl Valve Sizing: How to Identify and Troubleshoot Problems On-LineSalim AhamedNessuna valutazione finora

- Steam Control Valve Sizing for Tag PV123Documento2 pagineSteam Control Valve Sizing for Tag PV123dilip matalNessuna valutazione finora

- Spring Operated Safety Relief Valve Sizing Program: Point Mouse On Red Arrow To View DisclaimerDocumento20 pagineSpring Operated Safety Relief Valve Sizing Program: Point Mouse On Red Arrow To View Disclaimeranon_770350620Nessuna valutazione finora

- BE ProdBulletin AD1250AirMeasDocumento6 pagineBE ProdBulletin AD1250AirMeasMaria Gabriela BusteloNessuna valutazione finora

- Principle of Operation: Target Inline FlowmeterDocumento7 paginePrinciple of Operation: Target Inline Flowmeterابزار دقیقNessuna valutazione finora

- Compressor Recycle Service: Feed GasDocumento4 pagineCompressor Recycle Service: Feed Gasseth_yuiNessuna valutazione finora

- Air Cooler Design Sheiko PDFDocumento22 pagineAir Cooler Design Sheiko PDFJason ThomasNessuna valutazione finora

- Control ValvesDocumento139 pagineControl ValvesJason ThomasNessuna valutazione finora

- Compressor Recycle Service: Feed GasDocumento4 pagineCompressor Recycle Service: Feed Gasseth_yuiNessuna valutazione finora

- Anti-Surge Control ConceptsDocumento6 pagineAnti-Surge Control ConceptsJose Gustavo Robles MoralesNessuna valutazione finora

- Circle Seal CV Flow Coe Cients & Valve SizingDocumento2 pagineCircle Seal CV Flow Coe Cients & Valve SizingAlvaro NuñezNessuna valutazione finora

- Control Valve TheoryDocumento7 pagineControl Valve Theorysanvel123Nessuna valutazione finora

- ESD Avlve SelectionDocumento1 paginaESD Avlve SelectionJason ThomasNessuna valutazione finora

- LPPCombustion PowerGen 2007 FinalDocumento16 pagineLPPCombustion PowerGen 2007 FinalJason ThomasNessuna valutazione finora

- Fel en Oil and GasDocumento106 pagineFel en Oil and GasAlfonso NúñezNessuna valutazione finora

- 04 Flame TemperatureDocumento38 pagine04 Flame TemperatureGnanasambandan SwaminathanNessuna valutazione finora

- De-Pressurising Line DesignDocumento5 pagineDe-Pressurising Line DesignSiddharth GargNessuna valutazione finora

- PSV Calculation Factors Kd, Kc, KbDocumento2 paginePSV Calculation Factors Kd, Kc, KbJason ThomasNessuna valutazione finora

- BDVDocumento3 pagineBDVJason ThomasNessuna valutazione finora

- All Safe CatalogDocumento94 pagineAll Safe CatalogSimon Robinson100% (1)

- 1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionDocumento3 pagine1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionroxanaNessuna valutazione finora

- General Installation Practices: Section EDocumento26 pagineGeneral Installation Practices: Section EMohsen ArabifardNessuna valutazione finora

- Tubular Processing of The Glomerular FiltrateDocumento8 pagineTubular Processing of The Glomerular FiltrateOsama MohamedNessuna valutazione finora

- Syllabus 30A Fall 2014Documento4 pagineSyllabus 30A Fall 2014Gabby TanakaNessuna valutazione finora

- Taylor & Francis E-BooksDocumento6 pagineTaylor & Francis E-BooksVijaya Gosu0% (1)

- DP Level Measurement BasicsDocumento2 pagineDP Level Measurement Basicsjsrplc7952Nessuna valutazione finora

- Shell Momentum Balance 1Documento16 pagineShell Momentum Balance 1Kevwe Macaulay -GbogidiNessuna valutazione finora

- Ion Exchange PDFDocumento18 pagineIon Exchange PDFSarah LimaNessuna valutazione finora

- Water Pollution: By: Elya Noer Aini Justitia Cahyani Salma Auliya Fatimah Salma Cristy Syahidahalla Salma SakinatunnisaDocumento30 pagineWater Pollution: By: Elya Noer Aini Justitia Cahyani Salma Auliya Fatimah Salma Cristy Syahidahalla Salma SakinatunnisasalmaauliyaNessuna valutazione finora

- Erba URIC ACID DESDocumento2 pagineErba URIC ACID DEShexamed bme100% (1)

- PESSAT-Chemistry-Model-PaperDocumento12 paginePESSAT-Chemistry-Model-PaperpullagalkNessuna valutazione finora

- Boron FamilyDocumento20 pagineBoron FamilyP. PARIS KATHERINE REBECCAH BCMBC2019Nessuna valutazione finora

- Acid Cleaning For Nickel Alloys Pages From Handbook of Engineering Practice of Materials and Corrosion by Jung-Chul (Thomas) EunDocumento9 pagineAcid Cleaning For Nickel Alloys Pages From Handbook of Engineering Practice of Materials and Corrosion by Jung-Chul (Thomas) EunMohammad TaherNessuna valutazione finora

- Sloss Industries 1062235 M2234300 EX351 V 2Documento1 paginaSloss Industries 1062235 M2234300 EX351 V 2DanielDeFrancescoNessuna valutazione finora

- Combustion in SI & CI EnginesDocumento25 pagineCombustion in SI & CI EnginesVenkatesh KabraNessuna valutazione finora

- A Simplified Method For The Cultivation of Extreme Anaerobic Archaea Based SULFIDE 2000 !!!!Documento6 pagineA Simplified Method For The Cultivation of Extreme Anaerobic Archaea Based SULFIDE 2000 !!!!Vera Brok-VolchanskayaNessuna valutazione finora

- Chapter 7 PDFDocumento36 pagineChapter 7 PDFRbtl BañosNessuna valutazione finora

- Claycap Liquid Technical DataDocumento2 pagineClaycap Liquid Technical Datasaa6383Nessuna valutazione finora

- Safety Assessment of Methyl Glucose Polyethers and Esters As Used in CosmeticsDocumento29 pagineSafety Assessment of Methyl Glucose Polyethers and Esters As Used in CosmeticsCesar Miguel JuniorNessuna valutazione finora

- Tea Processing: How Leaves Become Black Tea in 4 StepsDocumento27 pagineTea Processing: How Leaves Become Black Tea in 4 StepsSaidur Rahman KhanNessuna valutazione finora

- Week No.2 - CLO-1 Size ReductionDocumento18 pagineWeek No.2 - CLO-1 Size ReductionkhalifaNessuna valutazione finora

- UOP Polybed PSA System For Gas Extraction PurificationDocumento2 pagineUOP Polybed PSA System For Gas Extraction PurificationchemiafNessuna valutazione finora

- Epogen Safety Data Sheet 20130213 Rev 4Documento8 pagineEpogen Safety Data Sheet 20130213 Rev 4Michael Marc Andico DeleonNessuna valutazione finora

- Paper 4 Jun 2001 PhysicsDocumento2 paginePaper 4 Jun 2001 Physicssolarixe100% (1)