Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hot Work Tool Steel: GMTC GMTC

Caricato da

pvdangDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hot Work Tool Steel: GMTC GMTC

Caricato da

pvdangCopyright:

Formati disponibili

Hot Work Tool Steel (H12)

Similar Steels

GMTC H12 AISI H12 B.S. BH12 DIN 1.2606 JIS SKD62

Chemical Composition

(wt%) Grade H12 C Si Mn 0.20 0.60 P max. 0.030 S max. 0.030 Cr 4.75 5.50 Mo 1.25 1.75 V 0.20 0.50 W 1.00 1.70 0.30 0.80 0.40 1.25 Remark : Ni + Cu0.75%

Characteristics

1. Excellent Resistance to Wear, High Strength at Elevated Temperature. 2. Good Homogenizing with High Toughness. 3. Extra- Fine- Structure without Grain-Boundary Carbide. 4. Inclusion Shape Controlled with High Cleanliness.

Application

For highly Stressed Hot Work Tools: 1.Extrusion Industry: Dies and Inner Liner for Extrusion 2.Forging Industry: Forming Dies, Press Dies 3.Die Casting Industry: Dies for Die-Carbide 4.Tool Industry: Punch, Hot Shear, Immediate Roller for Cold Rolling

Heat Treatment

1.AnnealingHeating slowly and uniformly to 845~900, furnace cooling to 540 at a rate 10~20/hr. Hardness HB 229 max 2.Stress Relieving Heat to 650~675, furnace cooling. 3.Hardening Preheating (1): Heat to approx. 540~650, holding 30 minutes per 25mm. Preheating (2): Heat to approx. 845~870, holding 30 minutes per 25mm. Austenitizing: Heat to approx. 1010~1050, holding 30 minutes per 25 mm. Quenchant: By oil or air. 4.Tempering 540~650, holding 60 inutes per 25mm. Air cooling. Double tempering.

GMTC

G R O U P

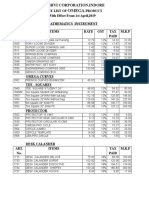

Hardness vs Tempering Temperature

65

60

55

Hardness (HRc)

50

45

H12

40 1020C Quench 35

30 0 100

Tempering Temperature C

200

300

400

500

600

700

Availability

1.Spheroidizing. 2.Available size range: 600mm.

References

(1) Harry Chandler, Heat Treaters Guide Practices and Procedures for Irons and Steels, p.602, ASM International(1995).

GMTC

G R O U P

Potrebbero piacerti anche

- Hot Work Tool Steel: Z Similar SteelsDocumento2 pagineHot Work Tool Steel: Z Similar SteelsMikeNessuna valutazione finora

- GMTC GMTC: Z Similar SteelsDocumento2 pagineGMTC GMTC: Z Similar SteelspvdangNessuna valutazione finora

- Hot Work Tool Steel: Z Similar SteelsDocumento2 pagineHot Work Tool Steel: Z Similar SteelsedelapolloNessuna valutazione finora

- Medium-Alloy, Air-Hardening Cold Work Tool Steel: GMTC GMTCDocumento2 pagineMedium-Alloy, Air-Hardening Cold Work Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- High Speed Tool Steel: GMTC GMTCDocumento2 pagineHigh Speed Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- High-Carbon, High Chromium Cold Work Tool Steel: Z Similar SteelsDocumento3 pagineHigh-Carbon, High Chromium Cold Work Tool Steel: Z Similar Steelsjaskaran singhNessuna valutazione finora

- High Speed Tool Steel: GMTC GMTCDocumento2 pagineHigh Speed Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- High Speed Steel: GMTC GMTCDocumento2 pagineHigh Speed Steel: GMTC GMTCpvdangNessuna valutazione finora

- Low-Alloy Special-Purpose Tool Steel: GMTC GMTCDocumento2 pagineLow-Alloy Special-Purpose Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- High-Carbon, High Chromium Cold Work Tool Steel: GMTC GMTCDocumento3 pagineHigh-Carbon, High Chromium Cold Work Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- Shock Resistant Tool Steel: GMTC GMTCDocumento2 pagineShock Resistant Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- 2312 DatasheetDocumento1 pagina2312 Datasheetfuransu777Nessuna valutazione finora

- Chemical Composition:: Material No.: CodeDocumento2 pagineChemical Composition:: Material No.: CodemustafabodurNessuna valutazione finora

- Plastic Mould Steel: GMTC GMTCDocumento2 paginePlastic Mould Steel: GMTC GMTCpvdangNessuna valutazione finora

- Cold Work Tool Steel-W1Documento3 pagineCold Work Tool Steel-W1irinuca12Nessuna valutazione finora

- Thyssenkrupp Steels For Enameling Product Information Steel enDocumento6 pagineThyssenkrupp Steels For Enameling Product Information Steel enle hoangNessuna valutazione finora

- eng-EN AB-46000Documento1 paginaeng-EN AB-46000Dragan PilipovićNessuna valutazione finora

- Material 11373Documento1 paginaMaterial 11373Deepak MadnaikNessuna valutazione finora

- Shock Resistant Tool Steel: GMTC GMTCDocumento2 pagineShock Resistant Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- Plastic Mould Steel: Z Similar SteelsDocumento2 paginePlastic Mould Steel: Z Similar SteelsMolnár SándorNessuna valutazione finora

- 1 2738 PDFDocumento2 pagine1 2738 PDFMiguelNessuna valutazione finora

- Mould SteelsDocumento32 pagineMould SteelsAnonymous B3I6zYNhqdNessuna valutazione finora

- Aisi D2: Cold Work Tool SteelDocumento7 pagineAisi D2: Cold Work Tool SteelEdilson Sarmiento AlonsoNessuna valutazione finora

- Tool Steel: Uni Euronorm WNR Din Afnor Aisi/Sae Bs - 1.2311 40crmnmo7 40Cmd8 (P20)Documento1 paginaTool Steel: Uni Euronorm WNR Din Afnor Aisi/Sae Bs - 1.2311 40crmnmo7 40Cmd8 (P20)Adrian FinichiuNessuna valutazione finora

- Yss Tool Steels BDocumento77 pagineYss Tool Steels BneramjanNessuna valutazione finora

- Hot-Work Tool Steel: GMTC GMTCDocumento3 pagineHot-Work Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- Standards R M Salem - UserguideDocumento49 pagineStandards R M Salem - Userguidearunas1081Nessuna valutazione finora

- Alloy Steels: GMTC GMTCDocumento2 pagineAlloy Steels: GMTC GMTCpvdangNessuna valutazione finora

- Plastic Mould Tool Steel: GMTC GMTCDocumento3 paginePlastic Mould Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- Heat TreatmentDocumento2 pagineHeat TreatmentAnonymous VRspXsmNessuna valutazione finora

- eng-EN AB-46100Documento1 paginaeng-EN AB-46100Akram Ben KhemisNessuna valutazione finora

- GB 20 & Astm 106Documento2 pagineGB 20 & Astm 106satheshNessuna valutazione finora

- Cold Work Tool Steel - Aisi D2: Typrical Chemical AnalysisDocumento2 pagineCold Work Tool Steel - Aisi D2: Typrical Chemical AnalysissansagithNessuna valutazione finora

- Vac Heat Treatment MonoTherm 2009 Engl (Kompatibilitätsmodus)Documento33 pagineVac Heat Treatment MonoTherm 2009 Engl (Kompatibilitätsmodus)AmitNessuna valutazione finora

- Cutting Tool Technology: Department of Mechanical Engineering University of Central PunjabDocumento22 pagineCutting Tool Technology: Department of Mechanical Engineering University of Central Punjabhashir siddiquiNessuna valutazione finora

- Hot-Dip Zinc-Coated Steel CoilsDocumento28 pagineHot-Dip Zinc-Coated Steel CoilsX800XLNessuna valutazione finora

- Aluminium-Alloy-6082-T6 or T651Documento2 pagineAluminium-Alloy-6082-T6 or T651Marcelo Noé CorsiNessuna valutazione finora

- Etchant Test On CastingsDocumento2 pagineEtchant Test On CastingsHarshaVeeragandhamNessuna valutazione finora

- Cryodur / 62SiMnCr4 SteelDocumento1 paginaCryodur / 62SiMnCr4 Steelacid.magicNessuna valutazione finora

- 1 2367Documento3 pagine1 2367korray1Nessuna valutazione finora

- Alloy Steels SNCM439Documento2 pagineAlloy Steels SNCM439gokul_raamNessuna valutazione finora

- PB Uddeholm Sverker 21 EnglishDocumento12 paginePB Uddeholm Sverker 21 EnglishulfwisenNessuna valutazione finora

- Aisi A2: Cold Work Tool SteelDocumento21 pagineAisi A2: Cold Work Tool SteelRahul NambiarNessuna valutazione finora

- No Two ContentDocumento2 pagineNo Two ContentBaiss AvyalimanaNessuna valutazione finora

- Place of Origin: Brand Name: Model Number: Application: Material: Dimensions: Surface: Inspection: AppearanceDocumento2 paginePlace of Origin: Brand Name: Model Number: Application: Material: Dimensions: Surface: Inspection: AppearanceAgustine SetiawanNessuna valutazione finora

- Tooling Materials&Heat TreatmentDocumento13 pagineTooling Materials&Heat TreatmentVinod MadireddyNessuna valutazione finora

- P20 Steel Plate Tool SteelDocumento4 pagineP20 Steel Plate Tool SteelSama UmateNessuna valutazione finora

- eng-EN AB-46000Documento1 paginaeng-EN AB-46000Akram Ben KhemisNessuna valutazione finora

- 20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelDocumento5 pagine20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelzhenyupanNessuna valutazione finora

- Property and Microstructure Evaluation As A Function of Processing Parameters: Large HY-80 Steel Casting For A US Navy SubmarineDocumento13 pagineProperty and Microstructure Evaluation As A Function of Processing Parameters: Large HY-80 Steel Casting For A US Navy SubmarineKay WhiteNessuna valutazione finora

- Plastic Mould Steel: GMTC GMTCDocumento3 paginePlastic Mould Steel: GMTC GMTCpvdangNessuna valutazione finora

- PB Uddeholm Sverker 21 EnglishDocumento12 paginePB Uddeholm Sverker 21 EnglishKOSTASPDFNessuna valutazione finora

- Hardness HSS - SKD11Documento5 pagineHardness HSS - SKD11Antonius PrakosaNessuna valutazione finora

- Aisi 306Documento3 pagineAisi 306Francisco SousalimaNessuna valutazione finora

- Uddeholm Heat Treatment of Tool Steel 06.2012 E8Documento20 pagineUddeholm Heat Treatment of Tool Steel 06.2012 E8tecnico0104Nessuna valutazione finora

- 10 129 139 PDF 13423Documento11 pagine10 129 139 PDF 13423Sinan YıldızNessuna valutazione finora

- 1.6523 20nicrmo2-2 - Aisi 8620Documento3 pagine1.6523 20nicrmo2-2 - Aisi 8620zhenyupanNessuna valutazione finora

- Gloria Material Technology Corp.: 2205 (UNS S31803) Duplex Stainless SteelDocumento1 paginaGloria Material Technology Corp.: 2205 (UNS S31803) Duplex Stainless SteelpvdangNessuna valutazione finora

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonValutazione: 4 su 5 stelle4/5 (1)

- Thermomechanical Processing of High-Strength Low-Alloy SteelsDa EverandThermomechanical Processing of High-Strength Low-Alloy SteelsNessuna valutazione finora

- Gloria Material Technology Corp.: XM-25 Precipitation Harding Stainless Steel SpecDocumento1 paginaGloria Material Technology Corp.: XM-25 Precipitation Harding Stainless Steel SpecpvdangNessuna valutazione finora

- Plastic Mould Steel: GMTC GMTCDocumento3 paginePlastic Mould Steel: GMTC GMTCpvdangNessuna valutazione finora

- D0 F04 D 01Documento1 paginaD0 F04 D 01pvdangNessuna valutazione finora

- GMTC GMTC: Gloria Material Technology CorpDocumento1 paginaGMTC GMTC: Gloria Material Technology CorppvdangNessuna valutazione finora

- High Speed Steel: GMTC GMTCDocumento3 pagineHigh Speed Steel: GMTC GMTCpvdangNessuna valutazione finora

- Shock Resistant Tool Steel: GMTC GMTCDocumento2 pagineShock Resistant Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- AISI 410 Martensitic Stainless Steel: Gloria Material Technology CorpDocumento1 paginaAISI 410 Martensitic Stainless Steel: Gloria Material Technology CorppvdangNessuna valutazione finora

- Gloria Material Technology Corp.: AISI 403 Martensitic Stainless SteelDocumento1 paginaGloria Material Technology Corp.: AISI 403 Martensitic Stainless SteelpvdangNessuna valutazione finora

- As 1554 Part 3 - Welding Reinforcing SteelDocumento29 pagineAs 1554 Part 3 - Welding Reinforcing Steelpvdang50% (2)

- B3 EECd 01Documento1 paginaB3 EECd 01pvdangNessuna valutazione finora

- Plastic Mould Steel: GMTC GMTCDocumento3 paginePlastic Mould Steel: GMTC GMTCpvdangNessuna valutazione finora

- Ni-Base Superalloy 718 (VIM+VAR) : Z Equivalent SpecificationDocumento2 pagineNi-Base Superalloy 718 (VIM+VAR) : Z Equivalent SpecificationpvdangNessuna valutazione finora

- High Speed Tool Steel: GMTC GMTCDocumento2 pagineHigh Speed Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- Hot-Work Tool Steel: GMTC GMTCDocumento3 pagineHot-Work Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- 440C Martensitic Stainless Steel: Gloria Material Technology CorpDocumento1 pagina440C Martensitic Stainless Steel: Gloria Material Technology CorppvdangNessuna valutazione finora

- Gloria Material Technology Corp.: AISI 416 Stainless SteelDocumento1 paginaGloria Material Technology Corp.: AISI 416 Stainless SteelpvdangNessuna valutazione finora

- High Speed Tool Steel: GMTC GMTCDocumento2 pagineHigh Speed Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- Shock Resistant Tool Steel: GMTC GMTCDocumento2 pagineShock Resistant Tool Steel: GMTC GMTCpvdangNessuna valutazione finora

- Gloria Material Technology Corp.: 1. Chemical CompositionDocumento1 paginaGloria Material Technology Corp.: 1. Chemical CompositionpvdangNessuna valutazione finora

- Evercut 303: Gloria Material Technology CorpDocumento1 paginaEvercut 303: Gloria Material Technology CorppvdangNessuna valutazione finora

- D 01Documento1 paginaD 01pvdangNessuna valutazione finora

- Gloria Material Technology Corp.: 1. Chemical CompositionDocumento1 paginaGloria Material Technology Corp.: 1. Chemical CompositionpvdangNessuna valutazione finora

- Fe-Base Superalloy A286 (EAF+ESR) A286 (EAF+VAR) : Z Equivalent SpecificationDocumento1 paginaFe-Base Superalloy A286 (EAF+ESR) A286 (EAF+VAR) : Z Equivalent SpecificationpvdangNessuna valutazione finora

- 420C Stainless Steel Spec.: Gloria Material Technology CorpDocumento1 pagina420C Stainless Steel Spec.: Gloria Material Technology CorppvdangNessuna valutazione finora

- Plastic Mould Steel: GMTC GMTCDocumento2 paginePlastic Mould Steel: GMTC GMTCpvdangNessuna valutazione finora

- Gloria Material Technology Corp.: AISI 420/SUS420J2 Stainless Steel SpecDocumento1 paginaGloria Material Technology Corp.: AISI 420/SUS420J2 Stainless Steel SpecpvdangNessuna valutazione finora

- Alloy Steels SCM440Documento2 pagineAlloy Steels SCM440Shamik Chowdhury100% (1)

- Alloy Steels: GMTC GMTCDocumento2 pagineAlloy Steels: GMTC GMTCpvdangNessuna valutazione finora

- High Speed Steel: GMTC GMTCDocumento2 pagineHigh Speed Steel: GMTC GMTCpvdangNessuna valutazione finora

- Ex No - 1 Crosshalving JointDocumento5 pagineEx No - 1 Crosshalving JointANISH PATIL (RA2111029010064)Nessuna valutazione finora

- UNIT-4-Manufacturing Technolgy IIDocumento32 pagineUNIT-4-Manufacturing Technolgy IIsirajudeen INessuna valutazione finora

- Bale LaydownDocumento15 pagineBale LaydownKhandakar NayemNessuna valutazione finora

- 4.O - Turning Chapter 4Documento5 pagine4.O - Turning Chapter 4John PeterNessuna valutazione finora

- HOW To Make A Sock DollDocumento15 pagineHOW To Make A Sock DollHelen Hodgson100% (1)

- (Metalworking) Model Engineer - Center Finding On The LatheDocumento1 pagina(Metalworking) Model Engineer - Center Finding On The LathekikoliverNessuna valutazione finora

- Instructions For Term PaperDocumento3 pagineInstructions For Term PaperTarundeep SinghNessuna valutazione finora

- Scraps The DogDocumento6 pagineScraps The Dogtatianateixeira325100% (2)

- WingspanDocumento3 pagineWingspanMark Burgett100% (2)

- Industrial Training ReportDocumento22 pagineIndustrial Training Report9896016960Nessuna valutazione finora

- Bosch 20182019 Catalog - Drillingfastening PDFDocumento52 pagineBosch 20182019 Catalog - Drillingfastening PDFPray OcampoNessuna valutazione finora

- Company Profile PBJ NewDocumento21 pagineCompany Profile PBJ NewDavidPrasojoNessuna valutazione finora

- Husqvarna/Viking Designer Ruby Deluxe Sewing Machine Instruction ManualDocumento30 pagineHusqvarna/Viking Designer Ruby Deluxe Sewing Machine Instruction ManualiliiexpugnansNessuna valutazione finora

- Kenmore 385.19000 Sewing Machine Instruction ManualDocumento134 pagineKenmore 385.19000 Sewing Machine Instruction ManualiliiexpugnansNessuna valutazione finora

- Robert Morse - The Detox Miracle Sourcebook EBOKDocumento5 pagineRobert Morse - The Detox Miracle Sourcebook EBOKhampish0% (1)

- Jacquard & ThreadDocumento38 pagineJacquard & ThreadIsha GargNessuna valutazione finora

- Module 2 in ForensicDocumento5 pagineModule 2 in ForensicShirven AncajasNessuna valutazione finora

- Scroll Saw Wood Working Craft-2013 Fall - Issue 52Documento100 pagineScroll Saw Wood Working Craft-2013 Fall - Issue 52TAANGTAWAN00795% (19)

- 1045 Steel Flat BarDocumento4 pagine1045 Steel Flat BarFebri SSNessuna valutazione finora

- A-6 SolutionDocumento2 pagineA-6 Solutionkishore nandyalaNessuna valutazione finora

- Drylin - Lead Screw Technology - Product RangeDocumento4 pagineDrylin - Lead Screw Technology - Product RangeLeandro SoaresNessuna valutazione finora

- The Lion King-Simba: MaterialsDocumento13 pagineThe Lion King-Simba: Materialsclau crvants100% (2)

- Bulk Deformation AssignmentDocumento9 pagineBulk Deformation AssignmentMuhammad FasihNessuna valutazione finora

- Crochet: Amigurumi UnicornDocumento4 pagineCrochet: Amigurumi UnicornLandy Delgadillo100% (1)

- Technical Data SheetDocumento1 paginaTechnical Data SheetMonali VarpeNessuna valutazione finora

- Fabric DefectsDocumento30 pagineFabric Defectsaparna_ftNessuna valutazione finora

- Importance of Tool and DieDocumento2 pagineImportance of Tool and DieCleng LaynesNessuna valutazione finora

- Manufacturing Process of A BearingDocumento4 pagineManufacturing Process of A Bearingalif hasyimNessuna valutazione finora

- SoxwebDocumento2 pagineSoxwebEliza DimNessuna valutazione finora

- OmegaDocumento6 pagineOmegaSUMIT JAINNessuna valutazione finora