Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Welder Performance Qualification-Interactive Form QW-484A

Caricato da

Javed MohammedDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Welder Performance Qualification-Interactive Form QW-484A

Caricato da

Javed MohammedCopyright:

Formati disponibili

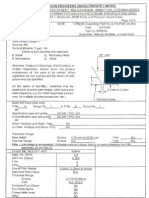

QW-484A SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONS (WPQ) (SEE QW-301, SECTION IX, ASME BOILER AND

D PRESSURE VESSEL CODE) Welders Name Identification No.

Identification of WPS followed Specification of base metal(s) Welding Variables (QW-350)

Test Description

Testing Conditions and Qualification Limits

Test Coupon Production weld Thickness: Actual values

GTAW Root SMAW Cover Manual GTAW with backing GTAW with backing to GTAW SMAW GTAW SMAW F1 F1 F1 F1 None GTAW Solid/Metal Max Max All Uphill * N/A GTAW N/A * N/A DC-EN

Welding process (es) Type (i.e., manual, semi-auto) used Backing (metal, weld metal, double-welded, etc.) Plate Pipe (enter diameter, if pipe or tube) Base metal P- or S-Number to P-or S-Number Filler metal or electrode specification(s) (SFA) (info only) Filler metal or electrode classification(s) (info only) Filler metal F-Number(s)

Range qualified

GTAW Root SMAW Cover Manual GTAW with backing GTAW with backing 2 7/8"OD and > .

GTAW F1 Root SMAW F1 Cover

Consumable insert (GTAW or PAW) Filler type (solid/metal or flux cored/powder (GTAW or PAW) Deposit thickness for each process Process 1: GTAW 3 layers minimum Yes No SMAW Process 2: 3 layers minimum Yes No Position qualified (2G, 6G, 3F, etc.) Vertical progression (uphill or downhill) Type of fuel gas (OFW) Inert gas backing (GTAW, PAW, GMAW) Transfer mode (spray/globular or pulse to short circuit GMAW) GTAW current type/polarity (AC, DCEP, DCEN)

+ * ** ***

(QW-302.4)

None GTAW Solid/Metal 1G Uphill N/A GTAW N/A * N/A DC-EN

****

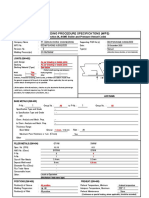

RESULTS

Visual Examination of Completed Weld

Bend test; Transverse root and face [QW-462.3 (a)]; Longitudinal root and face [QW-462.3 (b)]; Side (QW-462.2); Pipe bend specimen, corrosion-resistant overlay [QW-462.5(c)]; Plate bend specimen, corrosion-resistant overlay [QW-462.5 (d)]; Macro test for fusion [QW-462.5 (b)]; Macro test for fusion [QW-462.5 (e)]; Type Result

Type

Result

Type

Result

Alternative radiographic examination results (QW-191) Fillet weld -- Fracture test (QW-180) Length and percent of defects X Concavity/convexity (in.): Macro examination (QW-184) Fillet size (in.): Other tests Film or specimens evaluated by Company Mechanical testing by: Laboratory Test no. Welding supervised by We certify that the statements in this record are correct and that the test coupons were prepared, welded and tested in accordance with the requirements of Section IX of the ASME Code. Organization: Date: By:

Potrebbero piacerti anche

- Wps SawDocumento2 pagineWps Sawdevendrasingh2021100% (6)

- WPS PQR A36.20Documento5 pagineWPS PQR A36.20gchaves504100% (2)

- Iso 9606-3Documento30 pagineIso 9606-3Aleksandar StojanovicNessuna valutazione finora

- AWS D1.1 - Example PQR & WPS DocumentsDocumento4 pagineAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Gtaw WPQDocumento3 pagineGtaw WPQMuhammadShabbirNessuna valutazione finora

- WPS-PQR (Er309l Mo)Documento4 pagineWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocumento4 pagineWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNessuna valutazione finora

- LBW WOPQ REV. 2010a Interactive FormDocumento1 paginaLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- Super Duplex Stainless SteelDocumento1 paginaSuper Duplex Stainless SteelUma Shankar100% (1)

- ASME P Material NumbersDocumento1 paginaASME P Material Numbersmahi1437100% (1)

- Smaw Wps FinalDocumento3 pagineSmaw Wps FinalsheikmoinNessuna valutazione finora

- Proposed WPSDocumento2 pagineProposed WPSChisom Ikengwu100% (2)

- WPS PQR WPQ PeiplDocumento16 pagineWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Documento1 paginaQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Aries MarteNessuna valutazione finora

- WPQ Welder Performance QualificationsDocumento1 paginaWPQ Welder Performance Qualificationsjoshrathburn1980Nessuna valutazione finora

- Pin Brazing - DN80 Ph.1Documento14 paginePin Brazing - DN80 Ph.1Marcelo GuerraNessuna valutazione finora

- PQRDocumento2 paginePQRSreenivas Kamachi Chettiar100% (1)

- WPQ WELDER QUALIFICATION 16MM PLATE SMAWDocumento1 paginaWPQ WELDER QUALIFICATION 16MM PLATE SMAWniket0Nessuna valutazione finora

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocumento1 pagina193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Welding Procedure SpecificationDocumento3 pagineWelding Procedure SpecificationAhmed saber100% (2)

- WPS for 316L Pipe WeldingDocumento3 pagineWPS for 316L Pipe WeldingRichard Periyanayagam100% (3)

- According To ASME IX: Welding Procedure Specification (W.P.S)Documento4 pagineAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNessuna valutazione finora

- Wps Gmaw SawDocumento2 pagineWps Gmaw Sawupedro26Nessuna valutazione finora

- 19403955-WPS M.S. Is 2062Documento10 pagine19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDocumento2 pagineWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabNessuna valutazione finora

- P 91 - Welding WPSDocumento2 pagineP 91 - Welding WPSSuhailshah123475% (4)

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- WELDING PROCEDURE SPECIFICATION DETAILSDocumento2 pagineWELDING PROCEDURE SPECIFICATION DETAILStuatk60% (5)

- WPSDocumento3 pagineWPSKhurram Burjees100% (1)

- Wps - Asme Ix - Gtaw - PipaDocumento5 pagineWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- PQRDocumento2 paginePQRafqzfieNessuna valutazione finora

- Welder Qualification Test Certificate for Mohan ReddyDocumento2 pagineWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- Sample API 1104 WpsDocumento6 pagineSample API 1104 Wpsjacquesmayol100% (2)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Documento5 paginePage No: 01: SA 240 GR 304 SA 240 GR 304jobertNessuna valutazione finora

- WPS 2014-002 006 - 6G PipeDocumento3 pagineWPS 2014-002 006 - 6G PipejeswinNessuna valutazione finora

- WQTDocumento1 paginaWQTRamkunwar YadavNessuna valutazione finora

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocumento4 pagine163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- 03 WPS PQR For FCAWDocumento3 pagine03 WPS PQR For FCAWBrijesh Yadav100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocumento6 pagineWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNessuna valutazione finora

- WPS PQR PDFDocumento23 pagineWPS PQR PDFtomj9104Nessuna valutazione finora

- PQRDocumento2 paginePQRalokbdasNessuna valutazione finora

- Wps p91 - BhelDocumento2 pagineWps p91 - BhelAshish Gupta100% (4)

- WPQ Sample PrintoutDocumento1 paginaWPQ Sample PrintoutKannan VelNessuna valutazione finora

- PQR - 152Documento3 paginePQR - 152MAT-LIONNessuna valutazione finora

- Welding Procedure Specification For Storage Tank & Piping SystemDocumento3 pagineWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNessuna valutazione finora

- PQR & WPQ Standard Testing Parameter WorksheetDocumento4 paginePQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNessuna valutazione finora

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocumento2 pagineASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNessuna valutazione finora

- Val Caraig WPQTDocumento1 paginaVal Caraig WPQTMark Jason M. BrualNessuna valutazione finora

- For Fillet Weld Joint Project:Production ManifoldDocumento1 paginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Documento2 pagine(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNessuna valutazione finora

- WPS - Smaw - 2Documento6 pagineWPS - Smaw - 2Harkesh RajputNessuna valutazione finora

- PQR 01 PDFDocumento2 paginePQR 01 PDFVijay BhaleraoNessuna valutazione finora

- Wps For Carbon Steel THK 7.11 GtawDocumento1 paginaWps For Carbon Steel THK 7.11 GtawAli MoosaviNessuna valutazione finora

- WPQDocumento10 pagineWPQayoki100% (3)

- PQR TipsDocumento4 paginePQR TipsWaqas WaqasNessuna valutazione finora

- WPS 316 LDocumento4 pagineWPS 316 Llaz_k100% (2)

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- Saravanan Wpq-5g 50nbDocumento1 paginaSaravanan Wpq-5g 50nbDeepakNessuna valutazione finora

- mohanWPQ-1G 40NBDocumento1 paginamohanWPQ-1G 40NBDeepakNessuna valutazione finora

- WPQ PDFDocumento0 pagineWPQ PDFstanleyNessuna valutazione finora

- WPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSDocumento1 paginaWPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSMohamed Ahmed MaherNessuna valutazione finora

- WPQ Certificates Klis14Documento8 pagineWPQ Certificates Klis14AdhicharanNessuna valutazione finora

- FA - Pre Foundation Phase - Sample PaperDocumento5 pagineFA - Pre Foundation Phase - Sample PaperJaved MohammedNessuna valutazione finora

- BE - Pre Foundation Phase - Sample PaperDocumento3 pagineBE - Pre Foundation Phase - Sample PaperJaved MohammedNessuna valutazione finora

- Confined Space Entry (2005) PDFDocumento94 pagineConfined Space Entry (2005) PDFElsherif AlyNessuna valutazione finora

- 4 - A S SahneyDocumento32 pagine4 - A S SahneyJaved MohammedNessuna valutazione finora

- BE - B69c0.course Pack PDFDocumento87 pagineBE - B69c0.course Pack PDFJaved MohammedNessuna valutazione finora

- 4 - A S SahneyDocumento32 pagine4 - A S SahneyJaved MohammedNessuna valutazione finora

- BE - B69c0.course Pack PDFDocumento87 pagineBE - B69c0.course Pack PDFJaved MohammedNessuna valutazione finora

- QM - Pre Foundation Phase - Sample PaperDocumento12 pagineQM - Pre Foundation Phase - Sample PaperJaved MohammedNessuna valutazione finora

- BE - B69c0.course Pack PDFDocumento87 pagineBE - B69c0.course Pack PDFJaved MohammedNessuna valutazione finora

- (UOP) Corrosion and Fouling PDFDocumento352 pagine(UOP) Corrosion and Fouling PDFJaved MohammedNessuna valutazione finora

- Bohler ManualDocumento519 pagineBohler ManualCosmin OlteanuNessuna valutazione finora

- IndexDocumento3 pagineIndexJaved MohammedNessuna valutazione finora

- Comparison Dcument For ASTM0668 & ASTM0291 PDFDocumento2 pagineComparison Dcument For ASTM0668 & ASTM0291 PDFJaved MohammedNessuna valutazione finora

- Heat Exchange Reforming Technology - Indo Club - June 2008 SNL PDFDocumento17 pagineHeat Exchange Reforming Technology - Indo Club - June 2008 SNL PDFJaved MohammedNessuna valutazione finora

- Piping Mat. Specification PDFDocumento1 paginaPiping Mat. Specification PDFJaved MohammedNessuna valutazione finora

- TP 77 Pap PDFDocumento8 pagineTP 77 Pap PDFJaved MohammedNessuna valutazione finora

- A3a PDFDocumento7 pagineA3a PDFJaved MohammedNessuna valutazione finora

- TP 77 Pap PDFDocumento8 pagineTP 77 Pap PDFJaved MohammedNessuna valutazione finora

- Failure of Inlet Line in Gas Oil Desulphurisation Unit PDFDocumento11 pagineFailure of Inlet Line in Gas Oil Desulphurisation Unit PDFJaved MohammedNessuna valutazione finora

- Explosion in SW Tanks PDFDocumento9 pagineExplosion in SW Tanks PDFJaved MohammedNessuna valutazione finora

- Mountaineering Expedition Flag Off PDFDocumento3 pagineMountaineering Expedition Flag Off PDFJaved MohammedNessuna valutazione finora

- Coke Drum Life Improvement PDFDocumento16 pagineCoke Drum Life Improvement PDFJaved Mohammed100% (1)

- NRL Pipeline Hydrotest Format PDFDocumento1 paginaNRL Pipeline Hydrotest Format PDFJaved Mohammed100% (1)

- HTY Formaldehyde PDFDocumento2 pagineHTY Formaldehyde PDFJaved MohammedNessuna valutazione finora

- Steam Jacketed Piping Wps-Ndt-Fabrication Spec-Drawings PDFDocumento15 pagineSteam Jacketed Piping Wps-Ndt-Fabrication Spec-Drawings PDFJaved Mohammed100% (1)

- Field Inspection Record Format PDFDocumento1 paginaField Inspection Record Format PDFJaved MohammedNessuna valutazione finora

- Creep Testing in Steels PDFDocumento4 pagineCreep Testing in Steels PDFJaved MohammedNessuna valutazione finora

- Guide 4A-AA-22S Installation Guidelines PDFDocumento3 pagineGuide 4A-AA-22S Installation Guidelines PDFJaved MohammedNessuna valutazione finora

- Comparison Dcument For ASTM0668 & ASTM0291 PDFDocumento2 pagineComparison Dcument For ASTM0668 & ASTM0291 PDFJaved MohammedNessuna valutazione finora

- Traditional Lime TechiquesDocumento37 pagineTraditional Lime Techiquesfazeel100% (2)

- Wet Processing Technology LAb DocumentDocumento3 pagineWet Processing Technology LAb DocumentSanjana Islam Nilima0% (1)

- Qatar Building Engineering Company Site Work Procedure for Building PaintingDocumento5 pagineQatar Building Engineering Company Site Work Procedure for Building PaintingTATATAHERNessuna valutazione finora

- Civil4M Aluminium Sliding Works ChecklistDocumento1 paginaCivil4M Aluminium Sliding Works ChecklistKishoreNessuna valutazione finora

- Iron (Pig Iron, Cast Iron, Wrought Iron)Documento18 pagineIron (Pig Iron, Cast Iron, Wrought Iron)Bhanu Pratap SinghNessuna valutazione finora

- Enshu Vertical Machining Center GE15Ve PDFDocumento2 pagineEnshu Vertical Machining Center GE15Ve PDFManish GaurNessuna valutazione finora

- Manufacturing Final Exam GuideDocumento17 pagineManufacturing Final Exam GuideShah MalikNessuna valutazione finora

- Hempadur Primer 1530yDocumento4 pagineHempadur Primer 1530yRodrigo CondorettyNessuna valutazione finora

- Peplyn PDFDocumento2 paginePeplyn PDFArstNessuna valutazione finora

- Pressure & Leakage TestDocumento2 paginePressure & Leakage Testfizahwanhanif100% (2)

- Solidcam: Solidcam 2.5D Milling Package Using 3 Axis Machine: Cutter Conducts Milling Operations Mainly in Xy PlaneDocumento40 pagineSolidcam: Solidcam 2.5D Milling Package Using 3 Axis Machine: Cutter Conducts Milling Operations Mainly in Xy PlaneMathengeNderitu100% (1)

- Gas Welding SeminarDocumento17 pagineGas Welding SeminarMohd Sohail AliNessuna valutazione finora

- PM p2 d7 g6 Problemas LaminadoDocumento9 paginePM p2 d7 g6 Problemas LaminadoJorgeNessuna valutazione finora

- SIP Panel Butt Joint Welding GuideDocumento5 pagineSIP Panel Butt Joint Welding GuideQuality NabinagarNessuna valutazione finora

- Victorian (Sterling)Documento13 pagineVictorian (Sterling)NickiedeposieNessuna valutazione finora

- Korloy Turning InsertsDocumento76 pagineKorloy Turning InsertsR AksathNessuna valutazione finora

- 1 - Chapter 6 - 1 - 1 Material Removal Process - Introduction 21-1Documento34 pagine1 - Chapter 6 - 1 - 1 Material Removal Process - Introduction 21-1Fatin JoharNessuna valutazione finora

- Water Jetting BrochureDocumento4 pagineWater Jetting BrochureKenan mira Mohammed NasherNessuna valutazione finora

- Paint Data SheetDocumento2 paginePaint Data SheetdidiNessuna valutazione finora

- 14 Oktobar PrezentacijaDocumento56 pagine14 Oktobar PrezentacijaJovan VukovicNessuna valutazione finora

- Stainless Steel Cladding and Weld Overlays PDFDocumento13 pagineStainless Steel Cladding and Weld Overlays PDFm5416Nessuna valutazione finora

- Process For Preparing Laundry Powder DetergentsDocumento10 pagineProcess For Preparing Laundry Powder Detergentsqasimhafeez7274Nessuna valutazione finora

- Fully Enclosed: PP - PolypropyleneDocumento2 pagineFully Enclosed: PP - PolypropyleneNataliaNessuna valutazione finora

- Solution of Sheet No 2Documento7 pagineSolution of Sheet No 2RONIBAEL CORDOVANessuna valutazione finora

- Maulana Rosyid Hidayat: Curiculum Vitae 2022Documento2 pagineMaulana Rosyid Hidayat: Curiculum Vitae 2022Ridho ImmahdiNessuna valutazione finora

- Production Technology-Ii: Part-ADocumento3 pagineProduction Technology-Ii: Part-ARkrishna ANessuna valutazione finora

- Jotamastic 87: Cookie PolicyDocumento2 pagineJotamastic 87: Cookie Policyfaizal_7138Nessuna valutazione finora

- A. Stucki Company: Retroxt LP Bolt On Side Bearing 07563Documento1 paginaA. Stucki Company: Retroxt LP Bolt On Side Bearing 07563oliveira1305Nessuna valutazione finora