Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Example Technical Note For Valves (Butterfly)

Caricato da

shakasspTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Example Technical Note For Valves (Butterfly)

Caricato da

shakasspCopyright:

Formati disponibili

TECHNICAL NOTES SUPPLIER SHALL COMPLY WITH THE FOLLOWING REQUIREMENTS: 1.

BIDDER TO NOTE THAT DEVIATIONS (IF ANY) SHALL BE STATED. IN CASE THERE I S NO DEVIATION, BIDDER SHALL STATE NO DEVIATION. 2. QUALITY MANAGEMENT REQUIREMENTS FROM SUPPLIERS AND SUB-CONTRACTORS SHALL BE INACCORDANCE WITH 84501-9200-9R-005 REV.4. 3. ALL INSPECTION, EXAMINATION & TEST OF INDIVIDUAL VALVE MATERIAL SHALL BE AS PER DOC.84508-9700-1L-024 AND 84501-9200-9P-006 REV.2. 4. ALL VALVES SHALL BE SUBJECT TO POSITIVE MATERIAL IDETIFICATION IN ACCODA NCE WITH 84501-9200-1L-025. 5. FULL CERTIFICATION OF RESULT OF INSPECTION AND TESTING SHALL BE PROVIDED BY VENDOR AND SHALL BEVALIDATED BY CONTRACTOR IN ACCORDANCE WITH BS EN 10204. 6. VALVE DESIGN SHALL BE FIRE TESTED IN ACCORDANCE WITH BS 6755 PART 2 OR A PI 6FA OR API 607AS SPECIFIED IN DATA SHEET. ALTERNATIVE TESTING IF PROPOSED SHA LL BE AGREED WITH THECONTRACTOR. THE MATERIALS OF CONSTRUCTION SHALL NOT VARY FR OM THOSE ON THECERTIFICATE. 7. ALL VALVES SHALL BE PROPERLY COVERED BY SUITABLE PROTECTIVE MEANS TO AVO ID ANY CORROSION, RUSTAND MECHANICAL DAMAGE DURING TRANSPORTATION AND STORAGE. 8. GASKET CONTACT SURFACE SHALL BE PROTECTED WITH WOOD, METAL OR PLASTIC CO VER AND RUST OF FLANGEFACE SHALL BE OF FIRM FILM. 9. RUST PROTECTION FOR INSIDE OF VALVE SHALL BE PERFORMED ACCORDING TO THE MANUFACTURERSSTANDARD. 10. VALVE SHALL BE DRY, CLEAN AND FREE FROM MOISTURE, DIRT AND ANY KIND OF F OREIGN MATERIALS. 11. END PROTECTOR TO BE USED ON FLANGE FACE SHALL BE ATTACHED AT LEAST THREE BOLT OR WIRING THROUGHAT LEAST FOUR BOLTS HOLES, AND SHALL NOT BE SMALLER THAN THE OUTSIDE DIAMETER OF THE FLANGE. 12. IN ADDITION TO THE MARKING REQUIRED BY STANDARD MSS SP-25.

13. CONTRACTOR MATERIAL IDENTIFICATION NUMBER (TAG NO.) SHALL BE MARKED ON E ACH PACKING CASE. 14. OCK. VALVES TO BE SUPPLIED WITH LOCKING DEVICES SUITABLE FOR HEAVY DUTY PAD L

15. ALL VALVES SHALL BE FITTED WITH AN ADJUSTABLE MECHANICAL STOP LIMITING D EVICE. 16. FLANGE SHALL CONFORM TO ANSI B16.5 FOR 24 AND SMALLER.

17. MATERIAL CERTIFICATE TO BE SUBMITTED SHALL INCLUDE THE RESULT AND RECORD OF HEAT TREATMENTTOGETHER WITH CALIBRATION RECORD OF EQUIPMENT USED, AS WELL AS RESULT OF CHEMICAL ANALYSIS ANDMECHANICAL PROPERTIES TESTS. 18. 19. ALL CERTIFICATES SHALL BE AVAILABLE PRIOR TO VALVES ARRIVAL. NO COPPER AND COPPER ALLOY SHALL BE PERMITTED IN ANY PRODUCT.

20.

GRAY IRON SHALL NOT BE PERMITTED EXCEPT FOR GEAR AND ACTUATOR.

21. MATERIAL CERTIFICATE SHALL INCLUDE THE RESULTS OF CHEMICAL ANALYSIS AND MECHANICAL PROPERTYTEST. 22. PAINT OR INK MARKING SHALL NOT CONTAIN ANY HARMFUL METAL OR METALS SALTS , SUCH AS ZINC, LEAD OR COOPER WHICH CAUSES CORROSIVE ATTACK ON HEATING. 23. WELDING FOR MINOR REPAIRS OF CASTING SHALL BE CARRIED OUT IN ACCORDANCE WITH AQUALIFIED WELD PROCEDURE SPECIFICATION, QUALIFIED IN ACCORDANCE WITH ASTM A488. ALLREPAIRS SHALL BE SUBJECT 100% NDE AS PER THE ORIGINAL CASTING. 24. FLANGE FACE SHALL BE SERRATED FINISH WITH A ROUGHNESS BETWEEN 250 AND 50 0 MICRO-INCHES. 25. THE FOLLOWING INFORMATION SHALL BE LEGIBLY AND CONSPICUOUSLY STAMPED ON RUST AND CORROSION RESISTANT IDENTIFICATION PLATE PERMANENTLY ATTACHED TO THE BO DY OR TOP OF THE HAND WHEEL : TAG NO. BODY AND TRIM MATERIAL MANUFACTURER NAME RATING MODEL NUMBER SIZE TYPE

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Essential Intrapartum and Newborn CareDocumento6 pagineEssential Intrapartum and Newborn CareDianne LabisNessuna valutazione finora

- Compounds and Chemical FormulasDocumento35 pagineCompounds and Chemical Formulasjolina OctaNessuna valutazione finora

- Pentacon Six-02Documento28 paginePentacon Six-02Melissa Moreira TYNessuna valutazione finora

- MPX-200 Service Manual PDFDocumento90 pagineMPX-200 Service Manual PDFvivijaNessuna valutazione finora

- 4 - Mixing Equipments Used in Flocculation and CoagulationDocumento27 pagine4 - Mixing Equipments Used in Flocculation and Coagulationhadeer osmanNessuna valutazione finora

- DM - BienAir - CHIROPRO 980 - EngDocumento8 pagineDM - BienAir - CHIROPRO 980 - Engfomed_twNessuna valutazione finora

- Radial Lead Varistors LA Varistor SeriesDocumento13 pagineRadial Lead Varistors LA Varistor SeriesLeman SihotangNessuna valutazione finora

- Summative Test SolutionsDocumento1 paginaSummative Test SolutionsMarian Anion-GauranoNessuna valutazione finora

- LapasiDocumento3 pagineLapasiWenny MellanoNessuna valutazione finora

- 2.3 & 2.5 Cell DivisionDocumento14 pagine2.3 & 2.5 Cell DivisionJhonnyNessuna valutazione finora

- Quotation: Kentex CargoDocumento2 pagineQuotation: Kentex CargoMalueth AnguiNessuna valutazione finora

- Practice Test: Ielts UsaDocumento11 paginePractice Test: Ielts UsajoseNessuna valutazione finora

- CNA Candidate HandbookDocumento57 pagineCNA Candidate HandbookSummerNessuna valutazione finora

- Agriculture and FisheryDocumento5 pagineAgriculture and FisheryJolliven JamiloNessuna valutazione finora

- Epidemiology of Injury in Powerlifting: Retrospective ResultsDocumento2 pagineEpidemiology of Injury in Powerlifting: Retrospective ResultsJavier Estelles MuñozNessuna valutazione finora

- The Allied Valve Spares Manufacturer Company Maharashtra IndiaDocumento10 pagineThe Allied Valve Spares Manufacturer Company Maharashtra IndiaThe Allied Valve Spares Manufacturer CompanyNessuna valutazione finora

- Nikki CV FormatedDocumento2 pagineNikki CV FormatedSaif AlamNessuna valutazione finora

- LTHE Comments On APG's Proposal No. 9090/3181-L&T-Detailed Engineering Services For EPCC-1-AVU Unit, Barauni RefineryDocumento9 pagineLTHE Comments On APG's Proposal No. 9090/3181-L&T-Detailed Engineering Services For EPCC-1-AVU Unit, Barauni RefineryajayNessuna valutazione finora

- Contoh Reflection PaperDocumento2 pagineContoh Reflection PaperClaudia KandowangkoNessuna valutazione finora

- BATES CH 6 The Thorax and LungsDocumento2 pagineBATES CH 6 The Thorax and LungsAngelica Mae Dela CruzNessuna valutazione finora

- 3M Window Film PR SeriesDocumento3 pagine3M Window Film PR SeriesPhan CrisNessuna valutazione finora

- Park Agreement LetterDocumento2 paginePark Agreement LetterKrishna LalNessuna valutazione finora

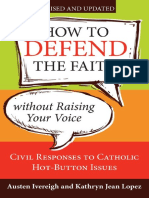

- How To Defend The Faith Without Raising Your VoiceDocumento139 pagineHow To Defend The Faith Without Raising Your VoiceCleber De Souza Cunha100% (2)

- Section-A: Terrace Ramp To Basement BalconiesDocumento4 pagineSection-A: Terrace Ramp To Basement BalconiesRitikaNessuna valutazione finora

- June 2019Documento64 pagineJune 2019Eric SantiagoNessuna valutazione finora

- Microporous WikiDocumento2 pagineMicroporous WikiIris BalcarceNessuna valutazione finora

- Anglo American - Belt Conveyor Design CriteriaDocumento19 pagineAnglo American - Belt Conveyor Design CriteriaIgor San Martín Peñaloza0% (1)

- Diplomate Course and Conferment RequirementsDocumento1 paginaDiplomate Course and Conferment Requirementsabigail lausNessuna valutazione finora

- Learnership AgreementDocumento10 pagineLearnership Agreementkarl0% (1)

- Bonding and Adhesives in DentistryDocumento39 pagineBonding and Adhesives in DentistryZahn ÄrztinNessuna valutazione finora